the_ad id=”22700″]

Author: Phil Rusher

The ingredients used in brewing have changed in many ways since people first began making beer. Due in large part to careful record keeping and tons of experience, brewers eventually landed on barley as the chief source of fermentable sugar, though some realized certain non-barley adjuncts can increase alcohol content while also contributing distinct flavor characteristics. One such example is the practice of using simple sugar, particularly when it comes to the production of Belgian-style beers.

Sucrose is found in myriad agricultural products and is typically processed into the white granulated table sugar known to most people. While table sugar can and has been used to make beer, some brewers began relying more heavily on invert sugars, which is sucrose that’s been broken down into the monosaccharides fructose and glucose via the use of both acid and heat, purportedly making it easier for yeast to digest. Such sugars come in two main forms– crystalline candi sugar, which is similar in appearance to rock candy, and a viscous liquid referred to as candi syrup, both of which are known to be quintessential in the production of Belgian beers including Dubble, Tripel, and Quad.

Despite coming from the same source, there are some out there who claim candi sugar affects beer character in ways that differ from candi syrup, perhaps as a result of the form in which they are presented. I’ve used both in my own brewing and can’t say I felt there was a huge difference, but I’ve never compared them side-by-side. Curious to see how they stacked up against each other, I designed an xBmt to test it out.

| PURPOSE |

To evaluate the differences between beers made with either crystalline Belgian candi sugar or Belgian candi syrup.

| METHODS |

Wanting to keep things simple to showcase any potential differences, I went with a Belgian Golden Strong Ale dosed with equal amounts of either candi sugar or candi syrup for this xBmt.

Spinning Free

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 25.0 IBUs | 3.9 SRM | 1.087 | 1.012 | 10.0 % |

| Actuals | 1.087 | 1.003 | 11.3 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Mecca Grade Pelton: Pilsner-style Barley Malt | 13 lbs | 81.25 |

| Candi Sugar OR Candi Syrup | 3 lbs | 18.75 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 15 g | 60 min | Boil | Pellet | 11 |

| Saaz | 30 g | 20 min | Boil | Pellet | 2.4 |

| Equinox (HBC 366) | 15 g | 10 min | Boil | Pellet | 15 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Gnome (B45) | Imperial Yeast | 74% | 65°F - 75°F |

Notes

| Water Profile: Ca 62 | Mg 0 | Na 8 | SO4 75 | Cl 60 |

Download

| Download this recipe's BeerXML file |

I began by collecting the full volume of RO water a couple days ahead of time.

On brew day, I adjusted the water to my desired profile and began heating it up before milling identical sets of grain for each batch.

With the water adequately heated, I stirred in the grains and set each Grainfather to maintain the same 151°F/66°C mash temperature.

While waiting on the mash, I weighed out the kettle hop additions for each batch.

Following the 60 minute mash rest, I removed the grains and sparged.

Both batches were then brought to a boil and, after 40 minutes, either type of sugar was added to each wort.

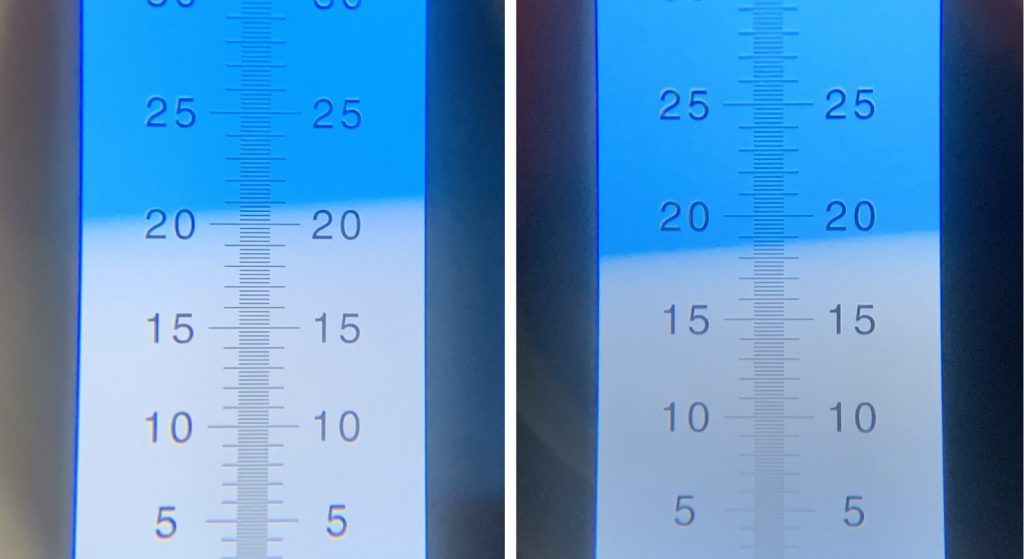

After another 20 minutes boiling, the worts were quickly chilled, at which point I took hydrometer measurements showing a fairly notable difference in OG.

Equal volumes of wort were racked to identical fermenters that I placed in the same 65°F/18°C chamber before pitching a pouch of Imperial Yeast B45 Gnome into each.

Both beers were showing signs activity the following day.

After 7 days of fermentation, I increased the temperature in the chamber to 75°F/24°C and let it sit another 5 days before taking hydrometer measurements confirming FG had been reached.

At this point, I proceeded with transferring the beers to CO2 purged kegs.

The filled kegs were placed in my cool keezer and burst carbonated over the course of a couple weeks, at which point they were ready to serve to tasters.

| RESULTS |

A total of 21 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the beer made with candi sugar and 1 sample of the beer made with candi syrup in different colored opaque cups then asked to identify the unique sample. In all, 12 tasters (p<0.05) would have had to identify the unique sample in order to reach statistical significance, though only 4 did (p=0.95), indicating participants in this xBmt were unable to reliably distinguish a beer made with crystalline Belgian candi sugar from one made with Belgian candi syrup.

My Impressions: While I felt both of these beers tasted crisp and had the characteristics I associate with Belgian styles, I perceived the one made candi syrup as being more slightly more smooth and less sharp than the one made with candi sugar. In my own biased triangle test attempts, I identified the odd-beer-out more often than not, but they were definitely more similar tasting than I expected based on the ABV difference.

| DISCUSSION |

From a molecular perspective, candi sugar is the same as candi syrup, the only real meaningful difference being that the latter possesses a higher water content. However, some brewers maintain each type of sugar imparts its own unique characteristics to beer, leading to preferences for one or the other. The fact tasters in this xBmt were unable to distinguish beers made with the same proportion of either candi sugar or candi syrup suggests it may not have a noticeable impact.

What makes these results so surprising is that the beers had one glaringly obvious difference– the one made with candi sugar was 11.3% ABV while the candi syrup version was at 9.8%. Both being relatively potent, it’s possible any differences due to the alcohol levels was covered up by some other component such as Belgian yeast character. While I’d learned both types of sugar could be used interchangeably, hence the use of equal amounts of either in each beer, the 0.009 OG difference can likely be explained by the fact candi sugar has a higher PPG (1.046) than syrup does (1.032).

Belgian candi sugars and syrups are preferred by many brewers because they’re invert, which purportedly makes them easier for yeast to digest. However, it’s well known that yeast produce invertase, the glycoprotein responsible for breaking sucrose down into fructose and glucose, leading one to question the necessity of using processed sugars in brewing. Regardless, Belgian candi sugars and syrups come in various darknesses that are know to impart beer with desirable flavor characteristics that can’t be achieved with table sugar. For this reason, I’ll continue using Belgian candi sugars in my brewing, the form of which will be decided based on convenience and price.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

18 thoughts on “exBEERiment | Belgian Candi Sugar vs. Syrup In A Belgian Golden Strong Ale”

If we know the PPG for each, why did we decide to use the identical mass? Usually it is good practice to reduce the number of variables. Instead, we knowingly maximised them. Why? This is a similar experimental design error that was made in a previous posting comparing DME to malt extract in syrup form.

I had considered controlling for PPG/gravity but decided not to based on my prior experience with these products. I also had a hunch that despite this difference it would be really difficult for tasters to discern one from the other, also based on past experience.

“I also had a hunch that despite this difference it would be really difficult for tasters to discern one from the other, also based on past experience.”

Wasn’t this what you were trying to assess with the experiment in the first place?

Among other things. But yes.

I recently tried to transfer into a keg like you are doing. It went painfully slow. I use ball lock kegs and had the purge open. How long does it take you to gravity transfer into your cornie? What size hose are you using?

3/8″ tubing. The time isn’t terrible, between 5-10 minutes. I find that using a gas disconnect instead of just opening the PRV helps with the gas exchange and time, but I’ll gladly spend the extra couple minutes to minimum introducing oxygen.

Ferment in a keg, transfer with co2, problem solved! 🙂

Did you attempt to compensate for the sugar syrup being roughly 20% water and 80% sugar, whereas the rock candi form is 100% sugar?

What brand and SRM of candi-syrup did you use.

I don’t think the crystallized candi is actually 100% sugar, but either way, I wanted to use equivalent masses of each type of sugar instead of accounting for differences in PPG. Candi sugar is rated 0 SRM and syrup is rated 1 SRM.

Exactly. Someone is clearly “doing a science” here. I’d suggest that readers place very little stake in the results or conclusions of this posting.

So you’re saying rhat every time hypotheses are confirmed science is called into question?

@PhilRusher: no, I’m saying that every time an experiment is performed with multiple variables or without controls, the results are called into question. Seems obvious.

Nice exbeeriment … another data point demonstrating actual instrument measurable differences are not easily detected by blind tasters.

Any theory on why the syrup beer came out clearer? In this style clarity is important and I would still strongly prefer to make the clearer beer given understanding tasters using opaque cups might not appreciate the extra effort.

Finally any plans to try Dextrose or Sucrose vs Candi Sugar? That is the exbeerient that would make it possible to skip at least one specialty ingredient and make these beers with confidence from ingredients typically on hand and saving significant money – I guess about $20/batch using table sugar vs candi sugar/syrup based on price at Morebeer.

Not sure at all why there was a slight difference in haze! I was going to fine with gelatin but by the time I remembered to I had already begun serving to people so I didn’t want to change anything to keep it consistent. In the end though,they both ended up being bright.

I don’t think we’ve done those sugar xbmts yet but it would be fun to try! Matt’s been wanting to make a BGSA again, maybe this can scratch that itch.

I would love to see this replicated on a BDSA with dark Candi syrup side by side with brown sugar or table sugar. There’s probably some consideration for color differences but the added maillard reaction in dark Candi sugar should probably distinguish itself from table sugar, even though some still claim the difference is indistinguishable in this specific case.

Exactly, the results of this xbmt were expected. Dark candi sugar vs. (not too) dark candi syrup would be more interesting.

2nd Standard table sugar VS invert sugar/candi Sugar exbeeriment. Would be great to know if yeast can break down them sugars. If the attenuation would be the same and taste the same.

How fermentable are candi sugars? There is a dearth of information online, and what information I have found cannot be correct (100% has been suggested, which defies common sense). Thanks so much for all your hard work!