This xBmt was completed by a member of The Brü Club in collaboration with Brülosophy as a part of The Brü Club xBmt Series. While members who choose to participate in this series generally take inspiration from Brülosophy, the bulk of design, writing, and editing is handled by members unless otherwise specified. Articles featured on Brulosophy.com are selected by The Brü Club leadership prior to being submitted for publication. Visit The Brü Club Facebook Group for more information on this series.

Author: Matt Skillstad

Maintaining a mash pH in the commonly accepted optimal range of 5.2 to 5.6 is said to encourage efficient conversion of starch into fermentable sugar, prevent the extraction of excess tannins that lead to a harsh hop bitterness, and generally lead to a better tasting finished beer.

When I first started brewing, I made many hoppy beers using my highly alkaline tap water that ended up having a very harsh bitterness, an issue that went away after I began paying attention to water chemistry and adjusting my mash pH. It’s for this reason I was taken aback by a previous xBmt showing a beer made with a high mash pH was indistinguishable from one made with a proper mash pH. In How To Brew, John Palmer points to evidence suggesting the optimum pH can vary with the agent one uses to adjust mash pH, which got me thinking– Marshall had to use pickling lime to artificially raise his mash pH, whereas my tap water is naturally higher in pH. Perhaps acidifying the mash for pH reduction would result in a different outcome?

Curious to explore this variable for myself, I decided to brew two beers using my alkaline tap water, one of which had the mash pH adjusted to the standard range with phosphoric acid while the other was left alone. Setting aside the the effect of the acid on bicarbonate levels, both beers would have identical mineral profiles as well.

| PURPOSE |

To evaluate the differences between a beer made with a high mash pH and one made with a more standard mash pH.

| METHODS |

I decided to test this variable out with a simple Cream Ale, as I thought it would highlight any potential differences.

Basic Beer

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 6 gal | 60 min | 14.9 IBUs | 3.1 SRM | 1.051 | 1.012 | 5.2 % |

| Actuals | 1.051 | 1.012 | 5.1 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner (Weyermann) | 7.75 lbs | 70.45 |

| Corn - Yellow, Flaked (Briess) | 2.5 lbs | 22.73 |

| Pale Malt, 2-Row (Rahr) | 12 oz | 6.82 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Tettnang | 28 g | 60 min | Boil | Pellet | 3.2 |

| Tettnang | 28 g | 10 min | Boil | Pellet | 3.2 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Safale American (US-05) | DCL/Fermentis | 77% | 59°F - 75°F |

Download

| Download this recipe's BeerXML file |

The day before brewing, I measured out two identical sets of grain then milled them directly into Brew Bags.

After filling separate identical kettles with the same volume of filtered tap water, I added 12 mL of 85% phosphoric acid to one to bring it into the standard range, while the other was left alone. My electric immersion heater was placed in one kettle and set to come on a few hours before I planned to brew. The next morning, I mashed in on the high pH batch about 30 minutes before the standard mash pH batch, both hitting the same target temperature.

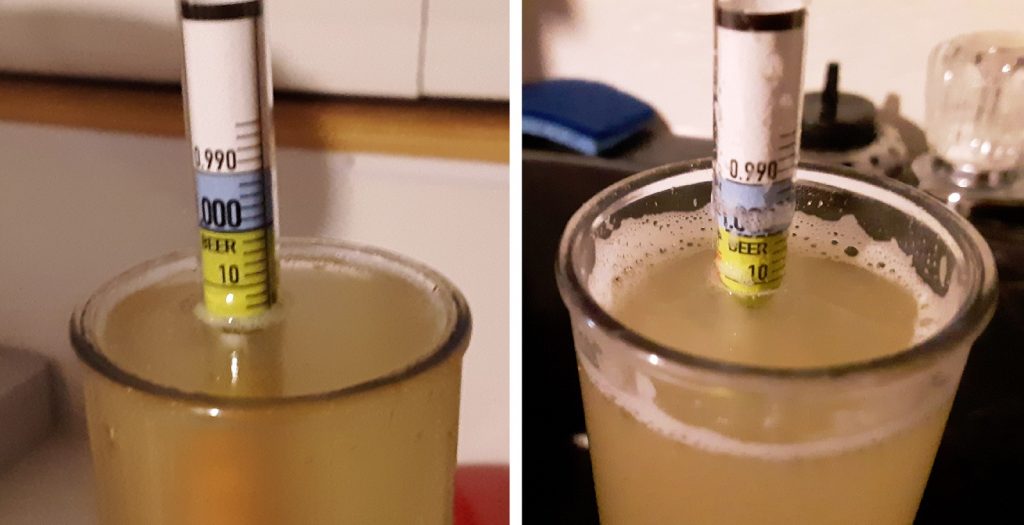

Measurements taken 15 minutes into each mash rest confirmed the expected differences in pH.

At the end of each 60 minute mash rest, I hoisted the grain bags out of the kettles and allowed them to drain as I began heating the sweet wort.

Another set of pH measurements taken at this point showed the difference remained.

Both worts were boiled for 60 minutes with hops added at the times listed in the recipe. With each boil complete, I quickly chilled the worts.

I took another set of pH measurements indicating the difference remained

Refractometer readings showed the OG of the high mash pH wort was a couple points lower than the standard mash pH batch.

Each wort was then racked to a sanitized stainless fermenter.

After pitching a pack of Safale US-05 into each batch and placing them next to each other in my 64°F/18°C chamber, I collected samples of both worts in glasses and let them sit out for a couple hours. The standard mash pH wort was noticeably clearer than the high mash pH wort.

After 4 days of fermentation, I raised the temperature in the chamber to 66°F/19°C. With no signs of activity 3 days later, I took hydrometer measurements showing the high mash pH beer finished with a slightly higher FG than the standard mash pH beer.

I also took a final pH reading at this point showing the beers were indeed different.

I then racked the beers sanitized CO2 purged kegs.

The filled kegs were dosed with equal amounts of priming solution then left to carbonate at 66°F/19°C for 2 weeks before being moved to my keezer for cold conditioning. Samples taken a week later showed the high mash pH beer was noticeably clearer than the standard mash pH beer.

While the standard mash pH beer got slightly more clear over the following 3 weeks, it never caught up to the high mash pH batch.

| RESULTS |

A total of 20 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the high mash pH beer and 1 sample of the standard mash pH beer in different colored opaque cups then asked to identify the unique sample. A total of 11 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, which is exactly how many did (p=0.038), indicating participants in this xBmt were able to reliably distinguish a Cream Ale made with a mash pH of 6.12 from with a mash pH of 5.28.

The 11 participants who made the accurate selection on the triangle test were instructed to complete a brief preference survey comparing only the beers that were different. A total of 3 tasters reported preferring the high mash pH beer, 6 liked the standard mash pH beer more, and 2 had no preference despite noticing a difference.

My Impressions: I attempted 5 triangle tests and was easily able to identify the odd-beer-out every time. To me, the high mash pH beer was fine and didn’t have any obvious off-flavors, but I did perceive a slight harshness and it generally tasted lifeless. It honestly reminded me of some of beers I brewed before I started managing my water chemistry, which was actually a little nostalgic in a way. I felt the standard mash pH beer was much cleaner and brighter with a more citrusy hop flavor, I definitely preferred it over the high mash pH version.

| DISCUSSION |

It’s commonly accepted that a high mash pH can result in less efficient conversion of starches into fermentable sugars while also leading to the extraction of astringent compounds from malt and hops. However, the non-significant results from the original Brülosophy xBmt on high mash pH called this idea into question, which made me wonder if perhaps the starting water might play a role. The fact tasters in this xBmt were able to tell apart a beer made with naturally high pH water, leading to a higher mash pH, from one where the mash pH was adjusted down with phosphoric acid suggests it may very well have an impact.

In addition to the apparent perceptual differences, mash pH was observed to have other effects as well, mostly notably in regards to appearance– the high mash pH beer made with non-adjusted water was noticeably clearer than the standard mash pH beer. I can’t be certain what the cause of this is, but in Water: A Comprehensive Guide for Brewer’s, Palmer and Kaminski note that phosphoric acid has the potential to cause calcium to drop out of solution under certain conditions, which may have been the case here. Furthermore, the high mash pH beer started with a slightly lower OG and ended with a slightly higher FG, leading to a 0.6% difference in ABV and providing some support for the conventional wisdom regarding conversion efficiency.

To this day, I use my relatively high alkalinity tap water for brewing and adjust it down using phosphoric acid such that my mashes are around 5.5 pH. Based on the results of this xBmt and my own personal experience, I will definitely continue this practice in my own brewing, as it seems to have enough of an impact to affect the character of the beer I brew.

Special thanks goes out to Adam Hervert from the Elkhorn Valley Society of Brewers for letting me borrow his kettle, burner, and pH meter so I could do this side-by-side brew.

Matt Skillstad is a happy husband to a wonderful wife (who likes his beer!) and proud father of 5 children under 7 years old from Pierce, Nebraska. He has been brewing since 2011 and, in addition to The Brü Club, is a member of the Elkhorn Valley Society of Brewers. He enjoys experimenting with his brewing in an effort to make better beer in less time with less effort. When not brewing or hanging with his family, Matt enjoys bike riding and golfing (poorly).

Matt Skillstad is a happy husband to a wonderful wife (who likes his beer!) and proud father of 5 children under 7 years old from Pierce, Nebraska. He has been brewing since 2011 and, in addition to The Brü Club, is a member of the Elkhorn Valley Society of Brewers. He enjoys experimenting with his brewing in an effort to make better beer in less time with less effort. When not brewing or hanging with his family, Matt enjoys bike riding and golfing (poorly).

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

16 thoughts on “The Brü Club xBmt Series | Impact High Mash pH Has On Cream Ale”

You partially made this point: in I’m reading the solubility isotherm correctly the maximum soluble of calcium phosphate concentration differs by around two log values for these two pH values. I don’t know your water chemistry but perhaps the mineral content of the two batches is also different

Crazy how different your results are from Marshall’s! Every so slight difference in mash efficiency. Difference in attenuation. Difference in clarity. More of a difference in post-fermentation pH. And, of course, significant number of tasters able to pick the odd beer out.

Couple questions:

1) For the post-fermentation pH measurement, did you degas the samples? I’m just surprised how much lower your readings are than Marshall’s, and I wonder if perhaps the residual dissolved CO2 from fermentation might be throwing off the measurement.

2) Did you gelatin fine? If not, I wonder if that might have had something to do with you seeing a pronounced difference in clarity when Marshall did not (in addition to any precipitory effects of the phosphate). I suppose gelatin fining could also have masked a difference in perception in Marshall’s version of the experiment.

The samples were de-gassed. I actually took 2 sets. Pre-carb & post-carb de-gassed that matched. No finings used other than whirlflock.

Here is my base water.

Water Profile: Ca 77 | Mg 11 | Na312 | SO4 26 | Cl 5 | HCO3 248

Nice work Matt! I really like how many pH readings you took throughout the process. I think the difference in clarity may just be from the high pH beer carrying over more haze into the fermentor (likely proteins). The heavier proteins would have helped the yeast flocculate and drop out of suspensions faster. Just a thought. Nice work again!

Hi Matt – This is a well done exbeeriment! THanks for running it. I noticed on your low pH batch the final pH is under 4. Most texts would consider this too low. I have had this experience with a hefewiezen and a cream ale with rye wheat and oats. My feeling is I adjusted the strike water too low. Unlike you my Seattle city water is very soft. An unadjusted mash would run in the 5.8 range. I also wonder if the results would be different if using lactic acid would change the clarity or just use acid malt. Some folks complain about lactic leaving a tartness. I never have been told that on a score sheet or otherwise even the two low pH batches. Last I wish for the triangle test participants where asked to do it three times and compare the results.

Thanks Jim! I had done some research on finished beer pH & I read that Increasing FAN (free amino nitrogen) content is known to buffer against pH drop during fermentation & the use of unmalted adjuncts in the grist will decrease the amount of this compound. This is what I personally concluded. It may even align with your experience depending if your wheat, rye & oats were malted or not…… I typically target about 5.5 mash pH (at room temp) because I like how that tastes, but I targeted a little lower for this because I thought that most people would think 5.5 is a little high. I used to use lactic acid without issue (that I can taste) but I went with phos. here just because it’s said to be more flavor neutral. Whatever floats your hydrometer….

The final beer pH isn’t that far out of range. According to this BYO article http://bit.ly/34nfDat 4.2-4.6 is a standard final beer pH range for lagers, with some as low as 3.8, which is right where the adjusted beer is at.

Have let PH readings on brew day slide but after seeing this significant exbeeriment has got me ordering a new PH probe. Onya Matt love ya work Man!

Great work matt ! My experience with high mash mirrored your results not marshall’s. I am in the market for a new ph meter who makes the one you use for this experiment…thanks jim

Most peer reviewed dissertations seem to imply that 5.8 pH as measured at room temperature (5.5 pH if measured at mash temperature) is considered high end acceptable in the mash, and per ‘Brew Like A Monk’ at least one well respected Trappist Monastery intentionally mashes at 5.8-5.9 pH (and then adjusts to 5.2 pH pre the boil step) so perhaps you should have brought the 6.12 mash pH batch down to the most accepted high limit of 5.8 pH, and then subsequently adjusted it to 5.2 pH just prior to the boil. The practice of adjusting Wort to pH 5.1-5.2 pre-boil itself appears to be a typical industry practice. This (when compared to the fully mash pH adjusted batch with no subsequent pre-boil adjustment) would have revealed if pH adjustment to pH 5.1-5.2 pre-boil can effectively replace mash pH adjustment for most home brewers who will not likely be faced with mashing at what was a clearly out of anyone’s acceptable range pH of 6.12.

Seems like there are two variables that are being tested that may be affecting the beer. Mashing pH and final beer pH. The beer pH should have an effect on taste and perception. Actually that would be a relatively easy experiment. Split a batch post fermentation and adjust one down to the low pH and do a triangle test. I would bet people could spot a 2 point pH difference. Your description of the differences sounds an awful lot (to me) like what I would expect from a more acidic beer VS a less so one. The cloudiness and lower efficiency would seem to me to be more tied to mash pH. Like all good experiments the results bring up new questions! Nice job.

Liked the xBmt. It took me about 2 years of brewing before I started to take the pH seriously. Lots of blah and bad beer. I have stopped using acidulated malt in favor of using the 85% phosphoric solution. My beers seem to have a cleaner and crisper finish to them.

Great xbmt! Been brewing 5 years and just recently started adjusting my mash pH I notice a significant increase in efficiency from this. Would be interesting to delve into that further.

What pH meter are you using? I like that! Any amazon link?

If you click the pic of any of the pH meters, it should take you to the Amazon page.

Wow you’ve got some hard water to start with! What’s the pH out of your tap?

I’m trying to relate your findings to what I normally see, though my tap water is about 9.6pH but very very soft, so not much acid needed to hit 5.2-5.4.

I’m curious did you notice a difference between the 2 batches as the boil was starting? Did the high mash pH produce a hot break that took a long while to dissipate and lots of foam?

Before I adjusted pH I had harsh beers that came out much darker than expected,and I would get crazy boilovers. 10-15 drops of anti-foamer (I think I use the 5 star brand defoamer). Now when I adjust for 5.2pH I need maybe 1 drop?

The pH was 7.2 on the most recent ward labs test. I just noticed I had a typo in the water profile above. Na is actually 12ppm. The rest was accurate. I didn’t notice any difference in foam or hot break etc….until I let the post boil samples sit out a while. I used an equal amount of fermcap-s in each batch.