Author: Phil Rusher

Carbonation is a key factor in any beer, and the degree of carbonation in a given style often has a lot to do with the method traditionally used to produce it. For instance, English ales often have minimal carbonation as a result of cask conditioning, while many Belgian styles are downright effervescent thanks to aggressive refermentation in the bottle. In many cases, these carbonation methods have evolved over time to meet both brewers’ needs and regulatory restrictions.

Take Germany, for example. The infamous Reinheitsgebot, or German beer purity law, originally stipulated that beer produced in Germany may only be produced using barley, hops, and water (yeast had yet to be discovered), meaning brewers weren’t allowed to add sugar at packaging. As a result, they were forced to find alternative ways to carbonate their beer, with one such alternative being a method known as kräusening.

In a nutshell, kräusening is the process of carbonating a finished batch of beer with actively fermenting wort, usually of the same style, rather than with sugar or compressed CO2. While it’s a technique that may sound antiquated in light of our modern practices, many brewers rely on kräusening to pay homage to traditional German brewing methods, with some claiming it has a positive impact on beer quality. Curious to see for myself, I put it to the test!

| PURPOSE |

To evaluate the differences between beers carbonated using either force carbonation or kräusening methods.

| METHODS |

In the hopes of emphasizing any differences between the beers carbonated using different methods, I went with a clean Festbier for this xBmt.

Lumberjack

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 21.6 IBUs | 6.8 SRM | 1.056 | 1.014 | 5.6 % |

| Actuals | 1.056 | 1.01 | 6.1 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pelton Pilsner-style Malt (Mecca Grade) | 5.5 lbs | 47.83 |

| Vanora Vienna-style Malt (Mecca Grade) | 5.5 lbs | 47.83 |

| Metolius Munich-style Malt (Mecca Grade) | 8 oz | 4.35 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 14 g | 60 min | Boil | Pellet | 11 |

| Hallertauer Mittelfrueh | 15 g | 20 min | Boil | Pellet | 3.7 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Harvest (L17) | Imperial Yeast | 72% | 50°F - 60°F |

Notes

| Water Profile: Ca 51 | Mg 0 | Na 25 | SO4 75 | Cl 63 |

Download

| Download this recipe's BeerXML file |

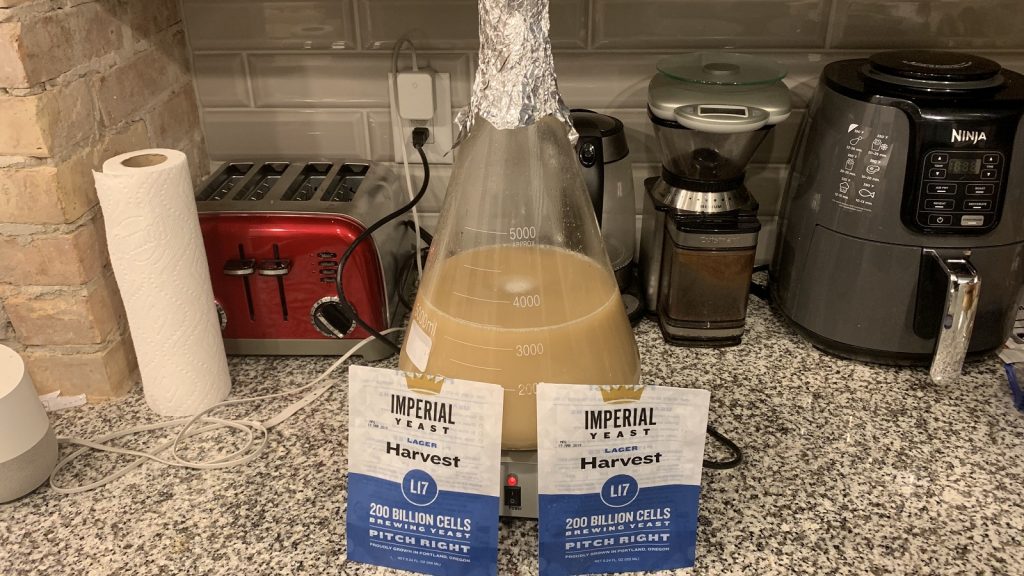

The day before brewing, I made a single large starter using two pouches of Imperial Yeast L17 Harvest.

In order to maintain as much consistency between the beers as possible, I brewed a single 10 gallon/38 liter batch and split the wort evenly between two identical fermentation vessels. Having previously collected and adjusted RO water, I started my brew day by lighting the flame on my burner to heat it up then proceeded to mill the grain.

With the water adequately heated, I added the crushed grain then checked to ensure it hit my target mash temperature.

During the mash, I prepared the kettle hop additions.

When the 60 minute mash rest was complete, I began the sparge and collected the sweet wort in my boil kettle.

The wort was then boiled for 60 minutes with hops added as listed in the recipe.

At the end of the boil, I chilled the wort then took a refractometer reading indicating my target OG was hit.

Next, equal volumes of wort were racked to identical fermentation vessels.

The fermenters were placed next to each other in my chamber and allowed to finish chilling to my target fermentation temperature of 62°F/17°C, at which point I split the yeast starter evenly between the batches. A day later, both were showing similar signs of activity.

Six days after brewing the xBmt beers, I made a 5 gallon/19 liter batch of the same Festbier recipe that was identical in every way except volume and fermentation vessel; this beer would serve as the source of kräusen when it came time to package.

After a week of fermentation, I took hydrometer measurements of the xBmt beers showing both had reached the same FG, indicating it was time to introduce the variable.

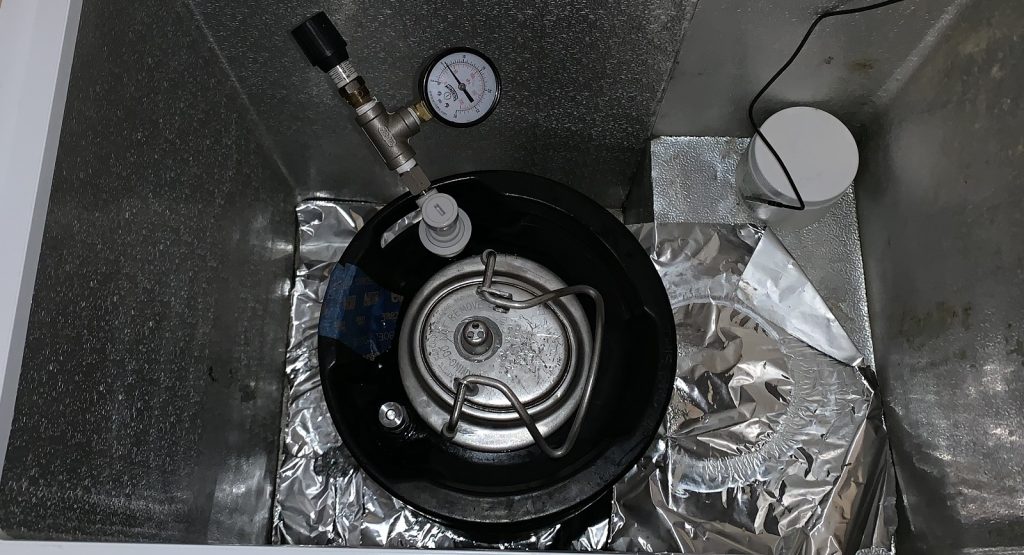

Using a scale, I racked approximately 2500 mL of the recently brewed and fermenting Festbier to a sanitized keg, which based on information found on the Braukaiser blog, was the amount needed to produce my desired level of carbonation; this volume was confirmed by the Brewer’s Friend Gyle and Krausen Priming Calculator.

I then proceeded to rack the xBmt beers to their respective kegs, one of which was completely empty.

The force carbonation beer was placed in my keezer and left to slowly carbonate at 13 PSI, which based on my particular setup, would produce a similar level of carbonation as the kräusened beer. Meanwhile, the keg with the kräusened beer was held in my 62°F/17°C chamber with a spunding valve attached so as to avoid overcarbonation.

After a week, the krausened beer keg was placed next to the force carbonation beer in my keezer with CO2 attached for serving. After one more week of conditioning, I began serving the beers to tasters for evaluation.

| RESULTS |

A total of 25 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the force carbonated beer and 2 samples of the kräusened beer in different colored opaque cups then asked to identify the unique sample. While 13 tasters (p<0.05) would have had to identify the unique sample in order to reach statistical significance, 14 (p=0.016) made the accurate selection, indicating participants in this xBmt were able to reliably distinguish a Festbier carbonated using the force carbonation method from one carbonated using the kräusening method.

The 14 participants who made the accurate selection on the triangle test were instructed to complete a brief preference survey comparing only the beers that were different. A total of 3 tasters reported preferring the force carbonated beer, 6 liked the kräusened beer more, 3 had no preference despite noticing a difference, and 2 reported perceiving no difference.

My Impressions: Out of the 7 semi-blind triangle tests I attempted, I correctly identified the odd-beer-out just 3 times. To my palate, these beers were essentially identical, both tasting clean and malt forward with a really nice supportive herbal hop character.

| DISCUSSION |

Carbonating beer by adding a dose of another actively fermenting beer in a method referred to as kräusening was once quite common, particularly among brewers forced to abide by certain strict brewing laws. As both brewing and technology progressed over time, other methods of carbonation became available, one of the most common today being force carbonation. While many view the various methods of carbonation as different means to the same end, there are those who believe kräusening has a perceptible impact, and the fact tasters in this xBmt were able to distinguish a force carbonated beer from one that was kräusened provides some support for this claim.

In considering other explanations for these results, one thing in particular came to mind– whereas both xBmt beers were fermented in PET carboys, the beer used for kräusening was fermented in a stainless Brew Bucket. It’s possible this is responsible for the differences tasters perceived, though given the short amount of time that beer spent in the stainless fermenter and the relatively small volume used for kräusening, I’m personally doubtful.

Having never used the kräusening method before, I was generally pleased with the experience and found it far less complicated than I originally thought. One downside for the less patient is that it requires a longer wait before the beer is ready to serve, at least when compared to my standard burst carbonation approach. Despite my positive experience, I likely won’t rely on kräusening for carbonation too often, as I rarely have multiple batches of the same style in progress at the same time. I’m certainly not ruling it out, but if I do end up kräusening again, it’ll probably be down to serendipity rather than planning.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

22 thoughts on “exBEERiment | Carbonation Methods: Force Carbonation vs. Kräusening In A Festbier”

That’s a really cool Xbmt. U guys always come up with great introspective ideas for thinking outside the home brewing box. And btw my beer has never been easier to make, and never tasted better thanks to Brülosophy. Prost!

D’aaaaww shucks. Thanks man. And thank you for reading! I’m glad that you’ve been able to get so much out of what we do. And I’m in the exact same boat as you; back before I came on board here I learned a great deal about brewing while digesting what Marshall and the others were putting out.

Curious question, out of the tasters whom correctly identified the odd beer out, did any mention to you what they perceived as the differences?

This depends on when they consumed the beer. When the beer was still pretty green people noted the krausened beer having a yeasty character, and this was my experience as well. Any fermentation character that was present eventually dissipated, though and at that point the beers were essentially identical.

Great experiment, I wonder if the krausening method would be beneficial for a neipa to reduce oxygen exposure. With such a heavily hopped style like that you could probably Krausen with a different, lighter style as long as you used a similar hop profile and yeast?

I think that from a cold side oxidation standpoint any beer style might benefit from the O2 scavenging, though I’m not certain that it’s really necessary if your packaging technique is good.

And I think that if you were to use, say, a light colored and generously hopped Blonde Ale to krausen a batch of NEIPA, you would probably do just fine. If you need to use different yeast strains I’d suggest using something super clean to krausen with. Why don’t you give it a shot and let me know how you do!

I don’t know when I’ll do another hazy beer since I have a handful or more of beers on my to do list. I didn’t have any oxygen issues with that one that I could tell. My thought about a lighter style is just that if you wanted something different vs doing the same beer repeatedly. I rarely make the same beer back to back this early in my brewing experience.

I see. I think ideally the beers would be the same or at least really similar. But who knows, we’ve been surprised by results before!

Just curious, and a bit off topic, but what made you choose that particular water profile?

Definitely not off topic. But it’s just a balanced water profile I arrived at using the Bru’n Water spreadsheet.

Schneider Weissebier is carbonated by taking finished beer and adding “Speise” (green, freshly brewed, but not yet fermented wort). This fresh beer has all the sugars, the finished beer still has plenty of yeast in suspension. When I brew a Schneider clone, I use a 1qt ball canning jar. Sanitize the jar, using stainless steel sanitized tongs, dip it into the rocket hot wort (just after flame out), and fill it (with a little head space). Put a sanitized Ball jar lid and ring on it and put it in the fridge. When it’s time to bottle, I take the wort from the fridge, add it to the bottling bucket, first, then add the fermented Weissebier on top, swirling enough to ensure distribution of the wort. Cap, and let the secondary, bottle fermentation take place to carbonate. Works like a charm 1 qt out of a 6 gallon batch, then back into it at bottling.

The spiese method of carbonation uses wort withheld from the fermentor. Not needing wort from an active fermentation is one advantage over krausening.

Another advantage for small batch brewers: extra beer — the volume added to the bottling bucket — when packaging.

Spiese calculator here;

https://www.brewersfriend.com/gyle-and-krausen-priming-calculator/

For a batch size of 2.5G (~9.5L) … my speise comes from chilling the trub. 2 QT trub = ~1 QT speise.

I am from Germany but until now I did not know this term. I would call it add “Speise” to the young beer to carbonate it. Thanks for the information!

Right, that’s a really common misunderstanding. Speise refers to wort you add to a finished beer that was saved from when you brewed the beer.

Great and interesting experience again. Would you give it a try if we are speaking about bottle priming? So adding a certain amount of actively fermenting beer instead of priming sugar. Thank you in advance!

Yeah sure, I think this would work for bottle conditioning. I might be a little more conservative with the volume of actively fermenting wort, though.

Great job, enjoyed the read. Can I ask are you using the grainfather in the picture as a heater and recirculation system back to the keggle mash Tun?

Thanks! The Grainfather was used for heating sparge water and running sparge water through the mash tun. It’s basically just my new newest version of a ragtag fly sparge setup.

Have you heard of adding actively fermenting wort to a finished or almost finished batch in order to help “clean up” the final batch? I do this with most of my lagers and I would love an experiment to test if it makes a difference!

Yeah I think I’ve heard people doing that. I think any potential issues that solves are the result of poor yeast health and/or low cell counts.

I have a friend who worked as a brewer for Deschutes in Bend, Oregon for many years, and he said that they krausen all their bottled beers due to increased shelf stability. The longer shelf life is due to lower dissolved oxygen levels after the active yeast has consumed the O2. I would assume this would also help keep hoppy beers fresher longer for the same reason.