This xBmt was completed by a member of The Brü Club as a part of The Brü Club xBmt Series in collaboration with Brülosophy. While members who choose to participate in this series generally take inspiration from Brülosophy, the bulk of design, writing, and editing is handled by members. Articles featured on Brulosophy.com are selected by The Brü Club leadership prior to being submitted for publication. Visit The Brü Club website for more information on this series.

Author: Richard Westmoreland

When we begin our homebrewing journey, we are told to pay attention to a few details that will either make or break our batch of beer. After sanitation, one of the top details is yeast health. We’ve all seen it on score sheets for our less-than stellar lager attempts– “Pay attention to your yeast health” and “make sure you’re pitching enough healthy yeast.”

When it comes to yeast, the term viability refers to the amount of living cells present in a population of cells. Higher viability is said to have numerous positive benefits including reduced lag, quicker overall fermentation, and decreased yeast stress that can lead to the development of off-flavors. However, pitching too few cells or too many cells, referred to as underpitching and overpitching, respectively, is also believed to lead to problems.

Lagers are traditionally fermented in cooler environments that purportedly demand higher pitch rates, as with all living organisms, yeast perform slower in the cold. Surprised by the findings of Brülosophy contributor Ray Found’s previous xBmt on lager pitch rates, I put it to the test again to see if I could replicate his results.

| PURPOSE |

To evaluate the differences between underpitching and overpitching yeast in a lager beer of the same recipe.

| METHODS |

Since my current setup doesn’t allow for 10 gallon/38 liter batch sizes, I decided to split a 5.5 gallon/21 liter batch. I brewed a California Common inspired recipe for this exBEERiment, opting to ferment it cool with a traditional lager yeast.

Uncommonly Cali

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 46.4 IBUs | 12.7 SRM | 1.051 | 1.013 | 5.0 % |

| Actuals | 1.051 | 1.011 | 5.3 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Ale Malt 2-Row (Briess) | 11 lbs | 86.27 |

| Carafoam | 12 oz | 5.88 |

| Vienna Malt (Weyermann) | 12 oz | 5.88 |

| Chocolate (Briess) | 4 oz | 1.96 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Northern Brewer | 28 g | 60 min | Boil | Pellet | 9.9 |

| Northern Brewer | 28 g | 10 min | Boil | Pellet | 9.9 |

Download

| Download this recipe's BeerXML file |

I brewed this batch on my Robobrew electric system, mashing at 152°F/67°C for 60 minutes and boiling for another 60 minutes.

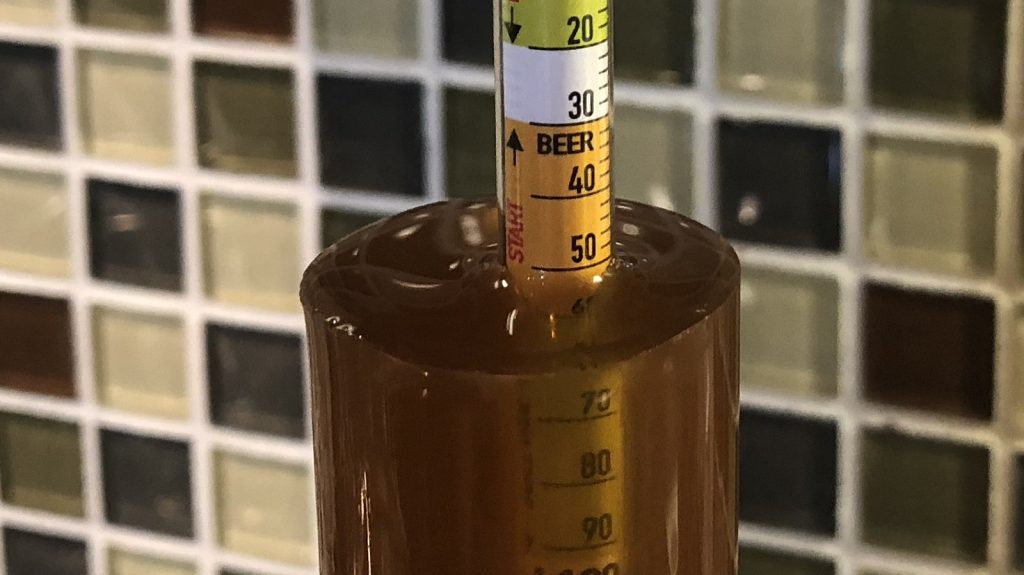

After chilling the wort with my immersion chiller, I took a hydrometer measurement showing the wort was at 1.051 OG.

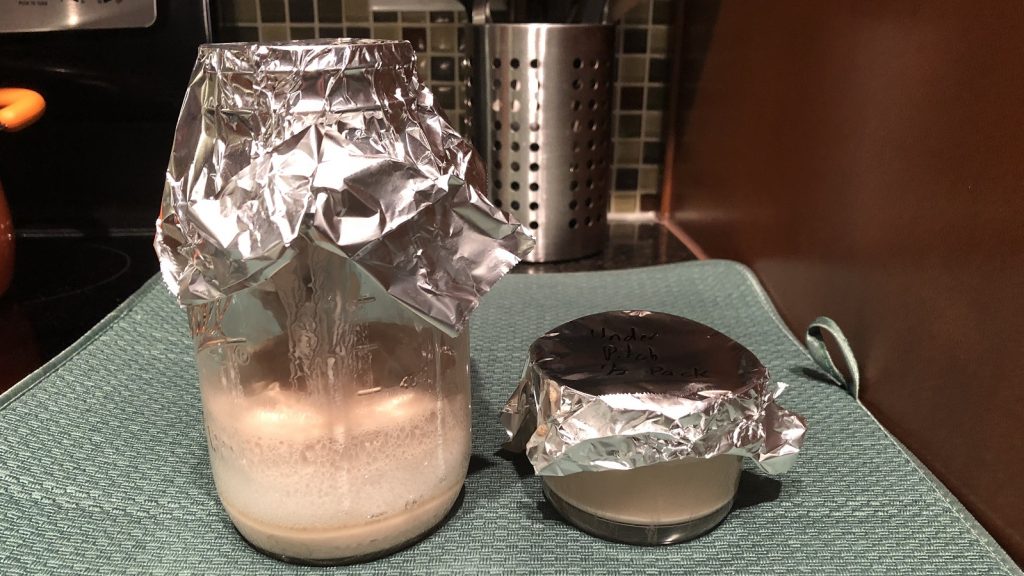

I then prepared the yeast by rehydrating ½ packet (~5.75 grams) of Saflager W-34/70 for the underpitch batch and and 2 ½ packets (~28.75 grams) for the overpitch batch in 95°F/35°C water.

Next, I transferred 2.25 gallons/8.5 liters of wort into two 3 gallon carboys that were placed in my fermentation chamber controlled to 50°F/10°C before the yeast was pitched. While the overpitch beer was showing signs of activity including a solid kräusen 10 hours after pitching, it took nearly 36 hours for signs to appear in the underpitch batch.

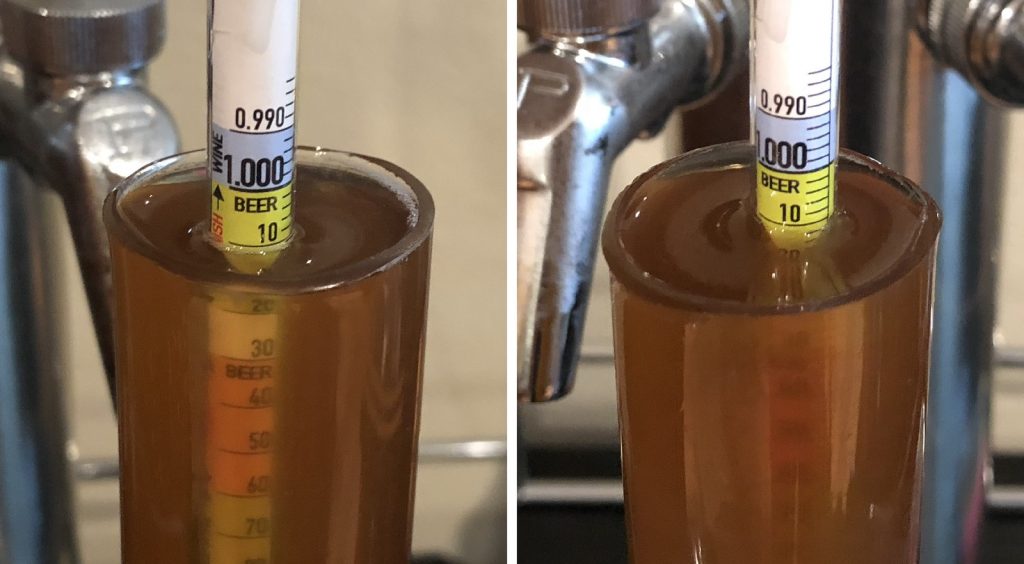

I gently raised the temperature to 62°F/17°C over the course of the next week. Once activity had halted, I took hydrometer measurements over 4 consecutive days that were all the same, indicating fermentation was complete.

Using my WiFerm Controller, I cold crashed the beers to 34°F/1°C before fining both with gelatin.

After 5 days cold, I transferred the beers to separate kegs that were placed in my keezer and burst carbonated at 30 psi for 8 hours, which turned out to be perfect! After some cold conditioning time, the beers were ready to serve.

| RESULTS |

A total of 17 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the underpitch beer and 2 samples of the overpitch beer then asked to identify the unique sample. At this sample size, 10 tasters (p<0.05) would have had to make the accurate selection in order to reach statistical significance, though only 7 (p=0.33) did, indicating participants in this xBmt were unable to reliably distinguish an underpitched lager from one that was overpitched with the same yeast.

My Impressions: In my initial samplings, the overpitched beer seemed drier, more watery, and had a little more of a “harsh” hop bite to it while the underpitched beer seemed sweeter, maltier, and more balanced overall. However, over 4 blind triangle test attempts, I picked out the unique sample only twice, indicating any differences may not have been as strong as I thought.

| DISCUSSION |

We’ve all heard that a single pack of liquid yeast does not contain the cell count necessary for a healthy fermentation of 5 gallons/19 liters of beer, especially if it’s a few months old. While a single packet of dry yeast is said to contain more than enough cells for ale, it’s often recommended to pitch 2 or more packs into a lager to compensate for the cooler fermentation temperature. Once again, the fact tasters in this xBmt were unable to reliably tell apart a lager pitched with 50% of the recommended amount of yeast from one pitched with 250% the recommended amount calls the common advice on pitch rate into question.

Before this experiment, I’d never pitched more than a single pack of yeast into a batch, whether dry or liquid. Based on these results and my personal experience with these beers, I don’t plan to start spending more money on yeast just to match “recommended” pitch rates, as I’ve found my beers attenuate just fine and taste great to my palate doing what I’ve been doing. That said, I would like to experiment more with pitch rate on beers of higher gravity.

| About The Author |

Richard Westmoreland is a homebrewer from Houston, TX who got his start in 2015 with a 1 gallon extract kit. After his first batch, he was hooked and decided to dive headfirst into all grain brewing. Richard currently brews multiple batches per month on a Robobrew 3-in-1 electric system, and he is also the inventor of the WiFerm Temperature Controller.

Richard Westmoreland is a homebrewer from Houston, TX who got his start in 2015 with a 1 gallon extract kit. After his first batch, he was hooked and decided to dive headfirst into all grain brewing. Richard currently brews multiple batches per month on a Robobrew 3-in-1 electric system, and he is also the inventor of the WiFerm Temperature Controller.

Would you like to have your experiment featured on Brulosophy.com? Join The Brü Club today! The Brü Club is a growing community of curious homebrewers who regularly engage each other on topics important to us all. Membership is free and comes with all sorts of cool opportunities. Learn more at TheBruClub.com!

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

25 thoughts on “The Brü Club xBmt Series | Yeast Pitch Rate: Underpitch vs. Overpitch In A Lager”

Nice job. You used a 1/2 packet of yeast in a half batch (2.5 gal) of wort. From a cell count perspective that doesn’t seem underpitched to me. I’d like to see your results if you used half that amount.

^this

In a cool fermented lager, according to pitch rate calculators and assuming fresh yeast, Rich underpitched by about 9bil cells. But I agree, he did a nice job, certainly better than not exploring anything at all 🍻

I agree with Marshall. Nice job Rich! Also, cool invention. I especially like the compatibility with the Tilt (even though I don’t have one). Good luck!

Very interesting result. I think this is the 9th pitch rate exbeeriment and all have failed to find statistically significant evidence that pitch rate matters. I suspect pitch rate (& starters) are both irrelevant provided santitation is good.

There’s some truth to this assertion, but we homebrewers don’t have access to the hardcore cleaning and sanitizing chemicals used in commercial breweries. PBW and sani-clean, for example, are no match for piping-hot sodium hydroxide and peracetic acid. If you use glass or plastic fermenters, I can almost guarantee that there’s a permanent biofilm of bacteria on the inner wall, no matter how diligent you are about cleaning and sanitizing. At best you’ll keep those bacteria at bay with rigorous cleaning/sanitizing procedures. Using starters and a typical pitch rate are good insurance that the yeast will outcompete the biofilm. Also, it’s likely that your assertion is (very) contingent on yeast strain. Try pitching Wyeast 3068 at 0.33 mil/mL/P vs 1 mil/mL/P into a hefeweizen and you will end up with radically different beers, guaranteed.

I’m just not convinced it matters if wort is oxygenated and clean. Yeast will multiply until the sugar is consumed whatever their starting population. High pitch rates achieved by making a large starter don’t bypass the growth phase – it just happens in the starter vessel rather than the FV, and the beer ends up the same. If you ferment under airlock, don’t aerate the wort, and pitch a small number of yeast starved of ergosterol, then yes you might get a different beer.

Could heat kill the living “stuff” in the biofilm or I need to remove the film completely? For example sometimes I put boiling water into my kegs but I never scrub the insides. My theory would be that this leaves the biofilm on the walls of the keg but kills the yeasts and bacteria.

No, there is not a permanent biofilm on the inside of a clean and dry fermentor. Just consider, where would that biofilm would from?

Basic sanitation chemicals are sufficient to remove almost all contaminating microorganisms. Do not believe me? Try to sanitize a glas jar with sani -clean or similar and add boil some wort, let cool and transfer to jug. Set in room and monitor how long it takes until you see signs of spoilage.

With due respect, it’s naive to think that you are maintaining operating-room sterility in your garage, basement, or outdoor homebrewery. @Dan, yes pasteurization will do the trick. Pasteurization is as or more effective than chemical sanitation provided the equipment can withstand it (obviously). For hard-to-reach surfaces, pasteurization is ideal. Scrubbing is still useful though because a residue of dead microbes is simply food for living microbes.

and oxygenation, and quality of yeast.

I don’t think that this would have skewed the results, however, I couldn’t help but noticing that you pitched .5 a packet to 2.25 gallons of beer. If I’m not mistaken, wouldn’t that be the same as pitching the correct amount of yeast proportionately (1 packet to 5 gallons of beer). Just didn’t really seem to be underpitched but that does amplify your observation about lag time. Even if you say the difference between normal pitch and over pitch was the experiment, it’s quite a significant difference in lag time.

That would be fine for an ale but lagers require double that (apparently)

As has been discussed many times before when dissecting the results of these trials, we in the home brewing world have been subjected to and influenced by methods used in the professional world. The thing we typically are not burdened with are the production schedules of commercial brewers who must turn out the same beer, in the same timeframe, time and time again. Lag time before fermentation starts, stuck fermentations, and off-flavors, whether attributed to pitch rates or yeast viability/vitality, are things with which they simply cannot afford to monkey. As much as it pains me to dump a batch because of some flaw, I cannot imagine opening a valve and watching 20, 30, or 100 barrels of beer go down the drain.

Well said. I was thinking the exact same thing – is this issue truly applicable to the home brewer? I’m thinking no.

Nice work and thanks for posting. I imagine the participants were served the beer in opaque cups? Asking because it looks from the photo that the underpitched beer dropped brighter than the overpitched beer. Could be condensation/lighting/my eyes, but did you happen to see a notable difference in clarity between the two? Thanks again.

Yep! They were served in opaque cups

i’m still trying to figure out how you kept that 2nd fermenter from falling out! and they both look like glass too? cheers to that!

It’s easy to speculate in all the other variables that WOULD have resulted in a significant result. Higher OG, more traditional style like Pilsner, liquid yeast, etc. I’ll focus on two things. The first is that dry yeast viability is about as high as it gets. For liquid yeast you really do need to watch the age. At one month old, a liquid pack is similar to half a pack of dry yeast. The other thing is that not all styles can accommodate the bump in ester production that an underpitch will create.

Good job on the Xbeeriment man! Your three-legged brewing assistant is awesome as well!

Would be interesting to see underpitch boundaries pushed even more: say, 1g of dry lager yeast to ferment a standard 5 gallon batch. There should be significant difference somewhere finally!

What do you think of the Robobrew system?

As a home bread baker I have always understood that halving the yeast inoculation typically adds just one hour to the fermentation time. This is a complete contrast to the the brewers received wisdom.

Interestingly the recommended pitch rate for wine is much lower at 4g per 20L. It takes plenty of time and tastes harsh at the beginning but once lagered for 6month it tastes wonderful.

Keep in mind that there is a lot of natural yeast growing on the grape skin and a lot of wineries do effectively a “wild” fermentation and do not actually introduce any extra yeast.