Author: Jake Huolihan

Considered a spoilage organism by many, Brettanomyces (Brett) is a genus of yeast known for being highly attenuative and producing unique characteristics not found in beer fermented with Saccharomyces alone. While historically avoided by all but perhaps a few Belgian and English brewers, the growth in popularity of wild and sour ales has done wonders for stripping Brett of its bad reputation. Well regarded breweries such as Crooked Stave, Russian River, and The Rare Barrel rely on Brett, often in conjunction with other yeast and bacteria, to produce award winning beers.

Given the rich history of wild and sour ale, it should be no surprise that strong opinions exist regarding best practices when it comes to beers in which Brett is used. Perhaps as a function of its strong attenuation abilities, Brett beers are often served with a fairly high amount of carbonation, and the method used to create said carbonation is viewed by many as being a key contributor to the quality of the finished product. Those favoring natural carbonation speak about its numerous benefits including finer bubbles, creamier head, and even the development of desirable flavor characteristics due to pressures put on the yeast during the conditioning phase. Alternatively, these beers can be force carbonated just like any other beer, with many claiming it has no perceptible impact while simplifying the process.

One of my favorite commercial beers is Orval, a Trappist ale that’s hit with Brett following primary fermentation with a Belgian yeast strain. It’s also naturally carbonated in the bottle, a feature believed by many to positively influence the overall drinking experience. With a couple past xBmts suggesting no difference between natural and force carbonation, I was curious to see how things would play out with Brett in the mix and decided to put it to the test!

| PURPOSE |

To evaluate the differences between force carbonation and bottle conditioning in beers inoculated with Brettanomyces following primary fermentation with a Saccharomyces strain.

| METHODS |

Purportedly modeled after English pale ales, Orval is known for a fresh hop clean character when fresh which evolves in the bottle due to the presence of brett. I whipped up a simple English style ale and got to brewing.

Favre

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 53.6 IBUs | 6.5 SRM | 1.053 | 1.005 | 6.4 % |

| Actuals | 1.053 | 1.008 | 5.9 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsen (Dingemans) | 4.125 lbs | 40 |

| Special Pale (Cargill) | 1.5 lbs | 14.55 |

| Vienna Malt (Weyermann) | 1.25 lbs | 12.12 |

| Carahell (Weyermann) | 1.125 lbs | 10.91 |

| Crystal, Dark (Simpsons) | 3 oz | 1.82 |

| Sugar, Table (Sucrose) | 2.125 lbs | 20.61 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Perle | 30 g | 60 min | Boil | Pellet | 8 |

| Saaz | 30 g | 60 min | Boil | Pellet | 1 |

| Perle | 25 g | 30 min | Boil | Pellet | 8 |

| Saaz | 15 g | 30 min | Boil | Pellet | 1 |

| Perle | 30 g | 0 min | Boil | Pellet | 8 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Precious (B53) | Imperial Yeast | 76% | 65°F - 73°F |

| Suburban Brett (W15) | Imperial Yeast | 78% | 64°F - 74°F |

Notes

| Water Profile: Ca 44 | Mg 0 | Na 8 | SO4 65 | Cl 33 |

Download

| Download this recipe's BeerXML file |

After gathering my grains the night before brewing, I prepared the water by adjusting it to my desired profile then scheduled my heat stick to turn on a few hours before I planned to start the next day.

I started off my brew day by milling the grains.

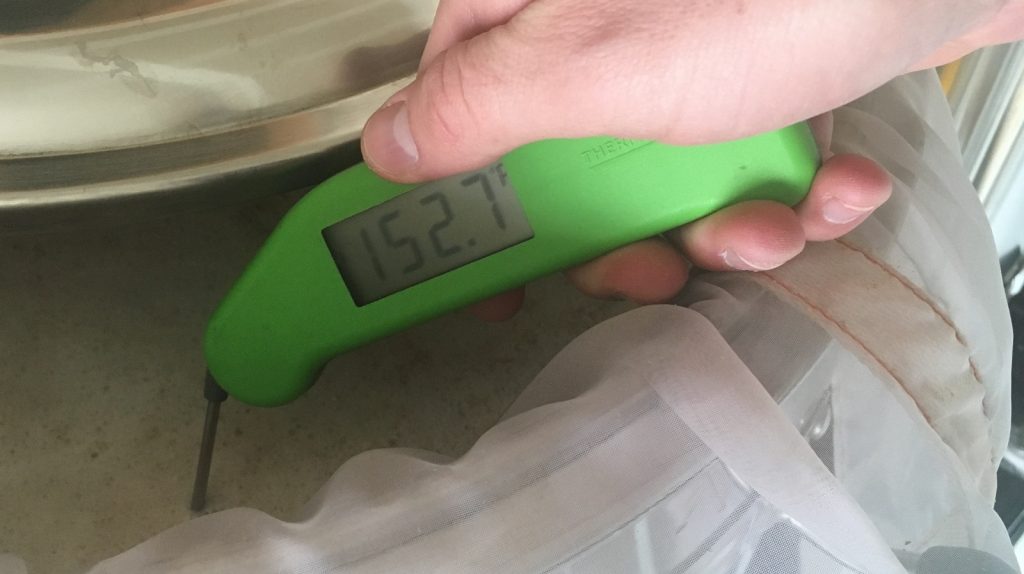

With the water properly heated, I incorporated the grist then checked the mash temperature.

The mash was left to rest for 60 minutes during which I stirred every 15 minutes with my large whisk.

With the mash step complete, I collected the sweet wort in a kettle.

The wort was then boiled for 60 minutes, during which the hops and sugar were added at the times stated in the recipe.

Once the boil was complete, I quickly chilled the wort.

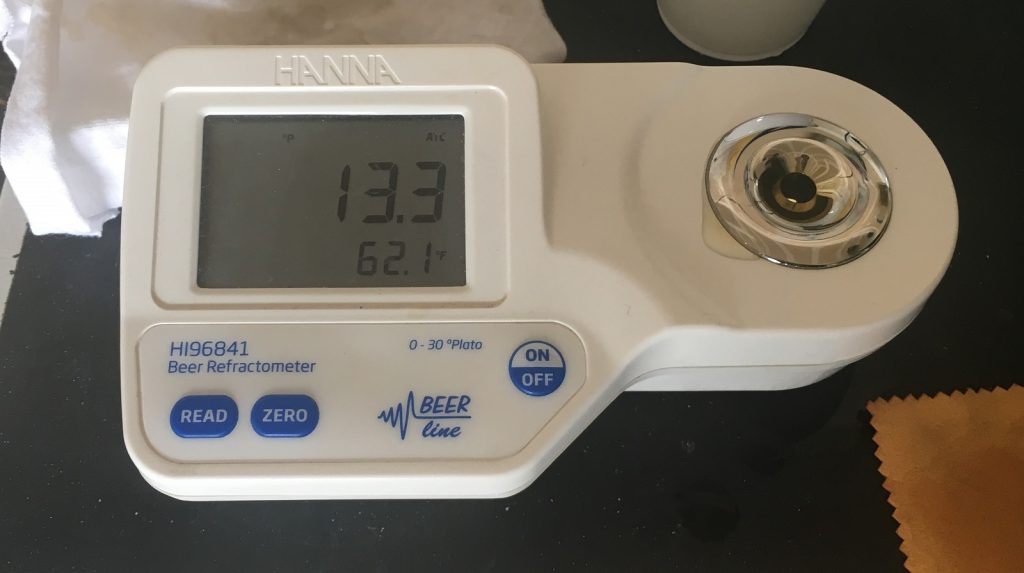

A refractometer reading showed the wort had achieved my target OG.

Equal amounts of wort were then transferred to a pair of identical fermentation vessels.

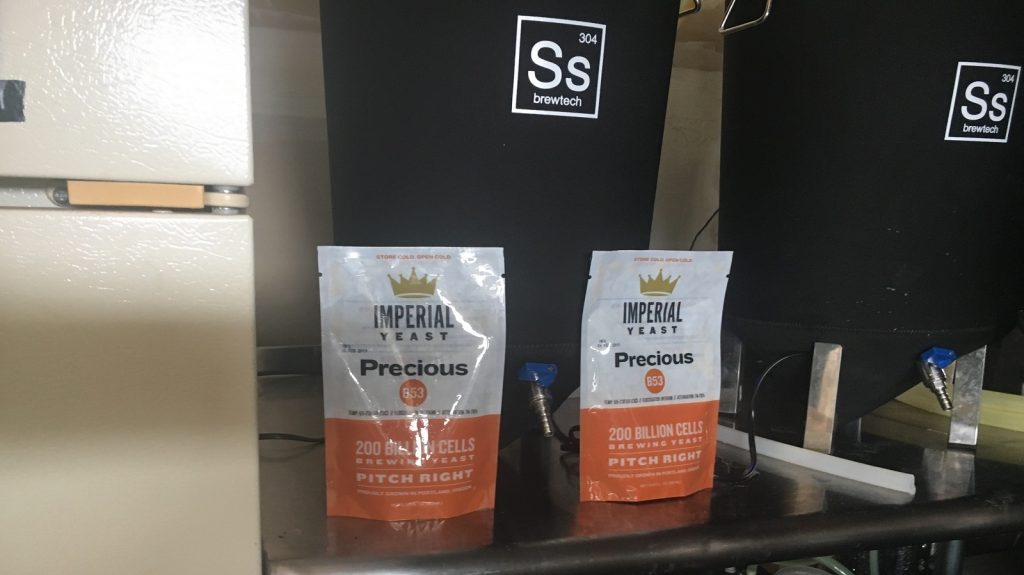

After connecting the filled fermentors to my glycol chiller set to maintain both at 66°F/19°C, I pitched a pouch of Imperial Yeast B53 Precious into each one.

Both beers were vigorously fermenting 6 hours later and were left alone for 7 days before I took hydrometer measurements confirming they had reached the same SG.

The beers were then racked to separate kegs.

At this point, I pitched a pouch of Imperial Yeast W15 Suburban Brett into each beer.

While the beer that would be force carbonated had a standard blowoff tube connected to the gas post, I attached a spunding valve to the natural carbonation batch and set it to a PSI that would produce the desired volume of CO2 based on ambient temperature. After a month of conditioning at approximately 65°F/18°C, I took a second set of hydrometer measurements that showed the beers finished at the same SG.

After a couple weeks in my cool keezer, both beers shared the same level of carbonation and clarity, making them ready to serve to unsuspecting participants.

| RESULTS |

A total of 21 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the force carbonated beer and 1 sample of the naturally carbonated beer in different colored opaque cups then asked to identify the unique sample. While 12 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 10 (p=0.12) did, indicating participants in this xBmt were unable to reliably distinguish beers secondarily fermented with Brettanomyces that were either force carbonated or naturally carbonated.

My Impressions: Out of the 5 triangle tests I attempted, I guessed correctly exactly one time. To me, both beers were more similar than different, which was great seeing as this was one of the best beers I think I’ve ever made, truly a joy to drink!

| DISCUSSION |

Viewed by many as being one of the biggest inconveniences in brewing, others hold bottle conditioning in high regard, particularly when it comes to funkier styles fermented with wild yeast. While there’s no arguing the fact that CO2 is CO2, the idea that certain conditions under which carbonation occurs can have some sort of qualitative impact seems, at the very least, plausible. However, corroborating past results, tasters in this xBmt were unable to tell apart Brett beers that were either force carbonated or naturally carbonating, suggesting carbonation method may not have the impact some believe.

From one perspective, these results may feel a bit dismal, a knock to the romanticism that accompanies engaging in the tediously traditional task of bottle conditioning. However, there is a bright side– natural carbonation is an easy way to save a few bucks on CO2! Sure, certain approaches may require a bit more time, for example those who skip spunding and rely on dosing the beer with priming sugar, but the benefit is using significantly less CO2. Spunding valves are great because they allow for carbonation via the gas produced by fermentation, so not as much waiting, plus they look pretty cool too.

These results only serve to further strengthen my belief that the way I carbonate my beers likely isn’t having much of an impact. Perhaps there are certain conditions we’ve yet to test that will suggest otherwise, but as for now, I’m comfortable accepting the either approach works just fine. As someone who regularly uses both force and natural carbonation methods, this is a good thing.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

20 thoughts on “exBEERiment | Carbonation Methods: Force Carbonation vs. Natural Carbonation In A Brett Beer”

One month is extremely young for Orval. When I visited Belgium a bar offered fresh and aged Orval, the fresh was 6 months post bottling the aged was two years… Both were good and surprisingly different experiences. The 2 year old bottle was delicious and while maybe a bit more brett character and lower hops it did not taste at all oxidized or stale to my pallet. I’m curious to know if force carbing will introduce enough dissolved oxygen to stale this beer over longer periods of time.

That shouldn’t be a problem since Brett consumes oxygen, if you don’t put it in a wood barrel with micro oxygenation it will probably consume all the oxygen.

I agree that one month is young for Orval. My initial plan was to leave these for quite a while however upon tasting after only a month it was clear the brett had done its duty and I decided to enjoy now

Interesting experiment and as a Packers fan, I love the beer name. The one question I have is the conflict between your states purpose and method. Your stated purpose is

“To evaluate the differences between force carbonation and bottle conditioning…”

But you compared forces vs spunding (natural conditioning but not bottle conditioning). I’m not sure if there would have been a difference but there is substantial differences in the physics/process between spunding and bottle conditioning (volume, pressure relief valve, sugar dosing, etc.). Also you stated the beer you were using as the basis for the experiment, Orval, was bottle conditioned. While a valuable experiment, it seems to miss the mark on the stated purpose this time.

I could probably change up the language there, really the goal was to compare natural carbonation v force carb. Bottle conditioning is natural carbonation, keg conditioning is bottle conditioning in a different type of bottle 🙂

Having never ventured into the world of making beers with Brett or any other bugs intentionally. I get the impression the argument over natural vs forced carbonation has more to do with potential oxygen exposure resulting in potential off flavors in the finished beer. Natural carbonated beer “should” have any oxygen scrubbed by the remaining yeast/bugs resulting in a “more” shelf stable beer. I’m I wrong in this idea? Is it different when Brett is involved?

You’re not really wrong no, that’s the theory. With Brett there are other factors related to oxygen and how brett uses it to create different expressions than stale necessarily. The main ones I’m aware of being THP and acetic

Thanks Jake! I thought I’d heard acetic mentioned but couldn’t remember the specific off flavors mentioned with Brett. Still need to to give one a shot soon but I think I will spund it to be safe.

As far as testing strictly naturally produced CO2 versus force carbonation, I think you succeeded in testing for this. The problem that I think some people have with this experimental design is that it doesn’t reflect typical process when it comes to mixed fermentation Sacch/Brett beers. So, there is a sort of disconnect that some readers are having with this article, I think.

Let me clarify what I mean. Typically, Sacch/Brett beer is packaged after the Brett fermentation. The packaging process potentially (and often) introduces oxygen into the bottle. The biggest potential difference between force carbonating and natural carbonation at this point is THP production, but also acetic acid production *if* the package is kept at room temperature (THP might be produced even if the beer is immediately chilled for forced carbonation due to oxygen reactions, although we don’t know for sure). If the package is chilled immediately, as could be the case for forced carbonation, but not for natural carbonation due to obvious reasons, a lot of byproducts of the oxygen exposure could be skipped, but THP is apparently a bigger concern in this case, and vice versa for the natural carbonation package.

This xBmt avoids these oxygen issues completely, and for good reason if the goal is simply to look at the difference between naturally produced CO2 and forced CO2. That’s all this xBmt set out to do. To me, this xBmt is fairly tame and the results are unsurprising (sorry, that’s just me, I don’t mean to sound discouraging of this endeavor if it interests people). For people who are looking for some sort of relevance of the Brettanomyces to potentially show a difference in this xBmt, such a difference isn’t going to be likely due to the experimental design.

On a side note, I initially thought that maybe Jake unintentionally also tested a much more interesting hypothesis regarding Brettanomyces: whether or not head pressure during fermentation really produces a “funkier” tasting beer. Unfortunately though (or fortunately for the sake of this xBmt’s experimental design), I think that a blow off tube probably has around the same PSI as the spunding valve as per this calculator (https://www.omnicalculator.com/physics/hydrostatic-pressure).

I have always believed that the claim that bottle conditioning leads to “finer bubbles, creamier head” to be dubious. dissolved CO2 is dissolved CO2 (and the small fraction that exists as carbonic acid shouldn’t vary with method either). I suspect any observed difference in bubbles/head might be due to the presence of yeast providing more nucleation sites not an innate difference in the carbonation.

So you got good brett character after only one month?

Very good brett character yeah

I just racked a kettle (boo) sour that was brewed with passionfruit and pineapple-fermented with wyeast1007@64. OG 11p FG 2.75p. Racked to a keg with wlp644 with a blood for 2 weeks. Plato dropped to 2.25, activity was pretty strong and the brett character was mild so I now have it sealed in same keg. My idea/ hopes are to allow the brett to carb it underpressure while also creating the nuances that brett does. While one month may not be enough for orval to show characters, it’s probably pursposely done via pitch rate obv. I have a saison that showed zero brett character after conditioning in carboy for a few months. It was until I bottle conditioned with a very prolific culture that it showed character-almost immediately after the beer had been carbonated.

I also bottle condition 95% of the beers i make and can confirm longer stability, though i have pretty much always been all grain and try to limit my TDO as best i can.

Grrrr i meant with a blowoff tube not blood 😭

Wlp644 is not Brett, it is believed to express STA1 a glucoamylase, which will help slowly drop the gravity over time.

Isomerization- I apologize, I have been doing a lot of homebrewing lately following the loss of my pro brewing job. I used 644 sac trois for a different beer. I do take great notes, I just, Again, moved too fast as to proofread; I actually did use WLP 645(brett clausenii) in the secondary of this beer i mentioned above. And sorry to thread jack this post with my long comments just nerding out.

This is a great exbeeriment. In general, you guys have made me more relaxed when things go wrong. That bitter fermented at ambient temperature during a sudden November heat wave? Delicious.

I often carbonate naturally to save CO2 or if my keezer is temporarily full. Do you have dedicated Brett kegs and/or draft lines? I am comfortable putting a sour in a keg, but the soft vinyl liquid lines with brett or lacto coursing through them makes me queasy. What are your thoughts?

p = 0.12 (or in this case “two tasters below the significance cutoff”) seems to suggest at least some significance. There’s a growing movement in the scientific world to kill the “p < 0.05 = significance = important finding" equation, and the importance of the p value in general.

Worth a read:

https://www.nature.com/articles/d41586-019-00857-9

https://www.tandfonline.com/doi/full/10.1080/00031305.2019.1583913

Cool article and tasty-sounding recipe Jake. This is off-topic, but I’m curious as to whether you do anything different with Brett beers when serving them out of your keezer. Different lines? Certain kegs? More rigorous cleaning/sanitation regimen?I like brewing with Orval dregs but have always hesitated to run those beers through my draft system for fear of brett-ifying other beers.

Maybe there’s an exbeeriment idea there?

Anyway, nice work as usual and thanks for the article.

You whipped up an English Pale with Pilsen, Vienna, Carahell, Perle and Saaz, and a Belgian primary strain?! Interesting exbmt though, I’m drinking a bottle conditioned Orval style beer that I brewed at the moment, it’s really nice. Bottle conditioned, add Orval dregs in secondary.