Author: Brian Hall

The most common homebrew batch size is 5 gallons/19 liters, a standard set decades ago that has become commonplace. Whether looking at recipe kits or engaging in a casual discussion with other brewers, this is the volume most will reference, and while the reasons for this aren’t terribly clear, it led to the development of gear intended specifically for this batch size, thus solidifying it as the gold standard. However, while the majority may live in a world of Lincolns, there those who do things a bit differently.

A growing number of homebrewers have taken to brewing both smaller and larger batches, which is easier these days thanks to the increased equipment options that accompanied the growth of the hobby. A popular approach for those who aren’t interested in making a full 5 gallons/19 liters of beer or enjoy experimenting with the brewing process is to make less, usually in the 1-3 gallon/4-12 liter range. When downsizing in this way, there are few things the brewer might consider, one of which is the impact fermentation volume has on beer.

On the surface, the amount of beer being fermented likely seems a banal topic, all else being equal, an unlikely contributor to beer character. My curiosity on this subject was piqued after a prior xBmt on fermentor headspace in which two different volumes of beer were fermented in identical vessels returned significant results, as it led to me question whether the culprit was actually the headspace or the volume fermented. Despite typically brewing larger batches, I decided to test this one out for myself.

| PURPOSE |

To evaluate the differences between beers made from the same wort that were fermented at different volumes.

| METHODS |

I went with a characterful big beer for this xBmt in hopes of accentuating any differences caused by the variable.

Big World Barleywine

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 51.8 IBUs | 10.8 SRM | 1.110 | 1.036 | 10.0 % |

| Actuals | 1.11 | 1.019 | 12.4 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Lamonta American Style Pale Malt (Mecca Grade) | 25 lbs | 98.04 |

| Crystal 55 Patagonia | 8 oz | 1.96 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Galaxy | 35 g | 60 min | Boil | Pellet | 14 |

| Galaxy | 28 g | 15 min | Boil | Pellet | 14 |

Notes

| Water Profile: Ca 117 | Mg 3 | Na 10 | SO4 84 | Cl 168 |

Download

| Download this recipe's BeerXML file |

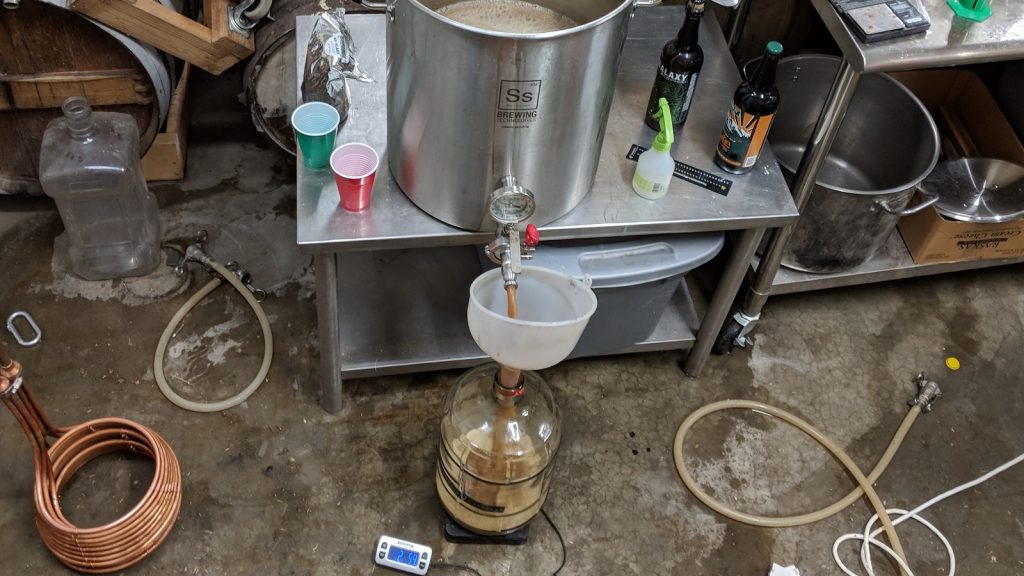

In order to isolate the variable as best as possible, I brewed a single 7.5 gallon/28 liter batch of wort that would later be split between different sized fermentation vessels. After collecting the water, adjusting it to my desired profile, and getting it heating up, I weighed out and milled the grain.

With the water properly heated, I incorporated the grains and checked to ensure it reached the expected mash temperature.

Following a 60 minute mash, I removed the grains and let them drip until my target pre-boil volume was reached.

The wort was then boiled for 60 minutes with hops added at the times listed in the recipe.

With the boil completed, I quickly chilled the wort, then it was time to fill the different sized fermentors. For this xBmt, I went with 3 gallon/12 liter and 6 gallon/23 liter glass carboys that, based on their dimensions, would result in nearly identical volume to surface area between the batches.

At this point, I collected remnant wort to make separate starters of Imperial Yeast A31 Tartan, each one calculated to propagate the yeast needed to achieve the same pitch rate given the volume.

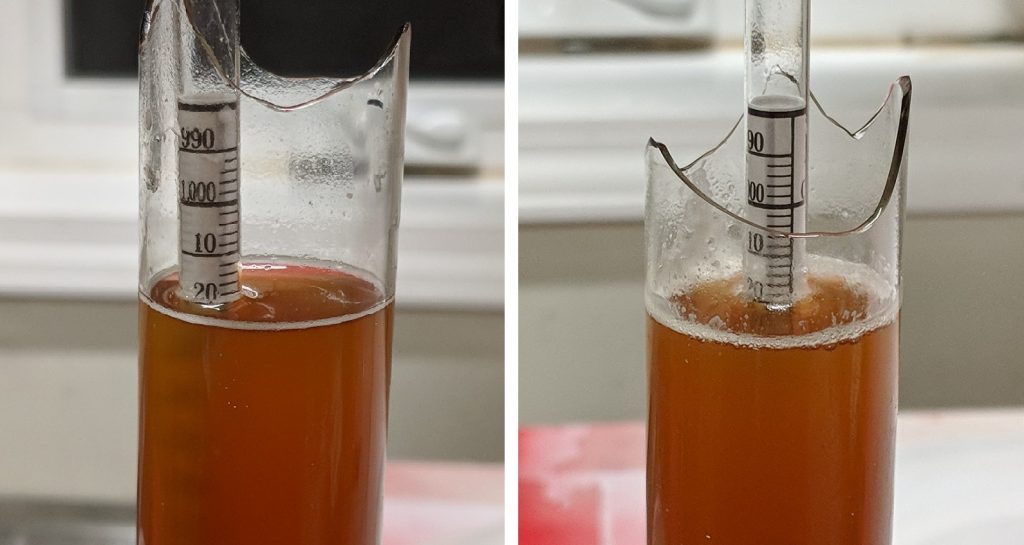

A hydrometer measurement at this point showed the wort was sitting at a hefty 1.110 OG.

The worts were placed next to each other in the same chamber that was controlled to 66°F/19°C and left alone until I returned to pitch the yeast later that day. Both were showing similar signs of activity the following morning.

After 10 days of fermentation, both batches appearing to be finished, I took hydrometer measurements revealing both had reached the same target FG.

In another attempt to reduce the impact of extraneous variables, I racked equal amounts of each beer into separate 2.5 gallon/9.5 liter kegs, using a scale to ensure both kegs received the same volume of beer (the other half of the 5 gallon/19 liter batch went into a different keg).

The kegs were placed in my cold keezer where they were carbonated and left to condition for a few weeks before they were ready to serve to tasters.

| RESULTS |

A total of 26 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the low fermentation volume beer and 1 sample of the higher fermentation volume beer in different colored opaque cups then asked to identify the unique sample. While 14 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 4 (p=0.99) did, indicating participants in this xBmt were unable to reliably distinguish a beers of the same recipe that were fermented in either a 3 gallon/12 liter or 6 gallon/23 liter glass carboy.

My Impressions: Out of the 5 triangle tests I attempted, I chose the odd-beer-out once. To my palate, there was nothing different about these beers, even in side-by-side samplings they tasted identical. While this beer was a nice tasting beer with some interesting fruity notes, its strength made it a difficult one to crush, so I threw some in the cellar to see how it changes over time.

| DISCUSSION |

The impact fermentation volume has on beer likely isn’t a factor many immediately consider when determining their batch size, as it would seem variables such as recipe and water chemistry would play a bigger role. However, there a few things that could be influenced by batch size, like volumetric pressure and temperature due to exothermic reaction during fermentation. With how relatively small the differences between 3 gallon/12 liter and 6 gallon/23 liter carboys its, perhaps it’s unsurprising that tasters were unable to reliably tell apart beers fermented in either.

What’s interesting is viewing these findings in light of a couple past xBmt results. When looking at the impact headspace during fermentation has on beers fermented at different volumes in identical vessels, tasters were generally able to tell a difference. However, when beer volume was controlled, thus further isolating the variable of headspace, tasters couldn’t reliably perceive a difference. The fact tasters in this xBmt couldn’t tell apart beers fermented at different volumes in vessels that better controlled headspace further supports the notion that large amounts of headspace may very well impact beer character. That said, this is in no way a definitive remark on the way fermentation volume, vessel size, or headspace affects beer.

When viewed independently, these results suggest that beers made in smaller batches, or at the very least, fermented in smaller volumes, can be of equal quality as more standard batch sizes. I don’t brew many batches smaller than 5 gallons/19 liters, but when I have, I never noticed anything particular off about the resultant beers. When added to my experience being completely unable to tell the beers in this xBmt, I’m compelled to accept that fermentation volume on its own likely has little impact on beer quality.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

12 thoughts on “exBEERiment | Impact Fermentation Volume Has On Barleywine”

I went from brewing 5-gallon batches to 10- to 13-gallon batches using the same recipe but with the requisite increase in ingredients and never saw any changes in flavor. I didn’t have them side-to-side, so it’s good to see this experiment confirming my non-scientific observations.

I think I might have seen a bit of a change when I went from 1-gallon test brew to 10- to 13-gallon brews, but I think that was due to inexact ingredient measurements. I should probably start using grams to weigh hops. The amount of yeast used was also a wildcard.

It’s great that this was at batch sizes that are pretty typical for home brewers, but my expectation would be that the bigger difference would be in variance with measurements and such with small sizes. Where volume and pressure would come into play would be with fermentor geometry and/or much larger batch size. The pressure is a factor of how high the liquid goes not how much there is. 100 gallons in a fermentor big enough to keep the height of the wort about the same as a 5 gallon carboy will have the same pressure on the yeast. Take that same 100 gal and put it in a tube the same diameter as the 5gal carboy and you will have some serious pressure at the bottom. With a bottom fermenting yeast that might well produce noticeable results.

I’ve felt that my beer’s gotten better as I’ve gone up in batch size, but I think that has more to do with keeping everything kinda self-contained now with a SST fermentor with bottling valve. I can’t imagine the mess of carboys / buckets, tubing, and siphons that I was using could’ve done much for quality.

If the experiment was to see the effects of different headspace volumes, why wouldn’t you ferment both in 6 gallon fermenters? I think the back pressure differences might have made a difference, similar to fermenting in a closed fermenter vs. an open fermenter.

That wasn’t the experiment though – it was volume of beer, not headspace.

The point of the experiment was to evaluate the differences in volume of beer fermented, not headspace volume – that was done in a different experiment.

However, maybe i missed the discussion on how the headspace volume variable was held constant – was it just straight volume (hard to tell from the pics with no mention), or was the headspace:beer volume ratio taken into account?

Those final gravity measurement photos scare me.

Not surprising. It would be hard to imagine why volume would matter IF headspace was the same between the two conditions.

It would be more interesting and informative to make two separate batches, specifically to see if factors like hop utilization, rate/percentage of boil off, etc. affect the results. This is the same beer in two different vessels, not different sized batches.

A really cool website for those who want to get into small batch brewing https://www.gallonbrewing.com

The obvious take away here is that Brian needs a new hydrometer jar.

Mike

In NZ a 23 L batch is common as 30 L fermenter buckets are easy to come by. The extra volume gives space for krausen etc. That’s why the Grainfather is the size it is – 28L pre boil in a Grainfather usually translates to 23L in the fermenter with a bit extra for drawing off specific gravity samples. We don’t kave a 23 L version of the Corny keg though…

Those who build their own kit often scale it up to 50 L.