Author: Jake Huolihan

Back in the early days of homebrewing, it was customary for brewers to transfer their beer off of the trub resting at the bottom of the primary fermentation vessel into a secondary vessel for a period of conditioning before packaging. The main purpose of this step was to avoid picking up off-flavors caused by autolysis, or yeast cell death, which can lead to such undesirable characteristics as raw meat or burnt rubber.

At some point in the last decade, give or take, the practice of racking to a secondary came to be questioned by many, with brewers claiming the quality of available yeasts had improved so much that autolysis wasn’t as big of an issue, certainly lower than the increased risk of both oxidation and contamination that occurs when racking beer from one vessel to another. This thinking has permeated modern homebrewing. Nowadays, most brewers opt to ferment entirely in a single vessel, with many also choosing to add hops, fruit, wood, and other flavorings directly to primary.

My venture into homebrewing began after the paradigm shift, and while instructions still included recommendations to rack to a secondary, it never was a normal part of my process. The way I saw it, if commercial breweries were packaging from primary when the beer was finished fermenting, there was no homebrewers couldn’t either. And like many, it’s worked out rather well for me, I’ve never made a beer with noticeable autolysis off-flavors. However, most of my beers are packaged fairly soon after fermentation is complete, which left me wondering if the amount of time a beer is left to sit in primary has any impact.

| PURPOSE |

To evaluate the differences between beers packaged either immediately after fermentation is complete or after 3 weeks of aging in primary.

| METHODS |

The goal being to emphasize any differences caused by extended time in primary, I went with a clean Märzen for this xBmt.

Stuck In The Terminal

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 22.4 IBUs | 6.9 SRM | 1.055 | 1.014 | 5.4 % |

| Actuals | 1.055 | 1.018 | 4.9 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Weyermann Vienna | 7.5 lbs | 61.22 |

| Munich II (Weyermann) | 3.75 lbs | 30.61 |

| Odyssey Pilsner | 1 lbs | 8.16 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 8 g | 60 min | Boil | Pellet | 11.5 |

| Perle | 15 g | 30 min | Boil | Pellet | 8 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Harvest (L17) | Imperial Yeast | 72% | 50°F - 60°F |

Notes

| Water Profile: Ca 49 | Mg 0 | Na 8 | SO4 38 | Cl 61 |

Download

| Download this recipe's BeerXML file |

I started off by collecting the volume of RO water needed for this 11 gallon batch.

After adjusting the water to my desired profile, set my electric controller to heat it up then moved on to milling the grain.

With the water adequately heated, I added the grains and stirred to incorporate before checking the mash temperature.

The mash was left to rest for 60 minutes, during which I stirred every 15 minutes.

I weighed out the kettle hop addition during the mash rest.

When the mash was complete, I collected the sweet wort in my kettle and brought it to a boil.

The wort was boiled for 60 minutes, after which it was quickly chilled to slightly warmer than my groundwater temperature.

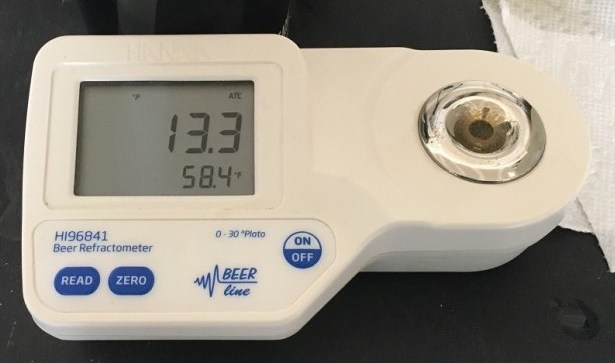

A refractometer reading revealed the wort was right at the OG I’d planned.

The wort was split evenly between identical Brew Buckets before being hooked up to my glycol chiller and left to finish cooling to my desired fermentation temperature of 50°F/10°C. Using remnant wort from the kettle, I made a couple vitality starters using Imperial Yeast L17 Harvest.

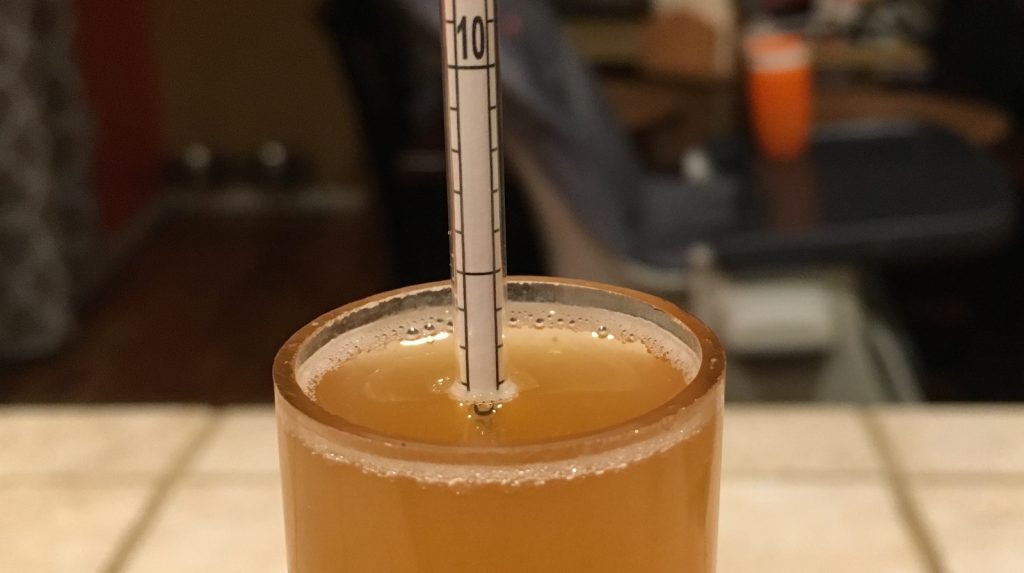

The starters were pitched 4 hours later and activity was noted just a few hours later. With diminished signs of fermentation activity observed 10 days after pitching, I gently raised the temperature to 58°F/14°C for a diacetyl rest. Hydrometer measurements taken from each batch at 13 days post-pitch showed both were sitting at the same FG.

Both beers were then chilled back down to 50°F/10°C and left for a day before being cooled further to 45°F/7°C. After another 2 days, I racked one of the beers to a CO2 purged keg while leaving the other in primary for extended aging.

The filled keg was placed in my keezer, which I keep at 38°F/3°C, slightly cooler than where the beer in primary was being held. After 3 weeks, I racked the primary-aged beer to a CO2 purged keg and placed it on gas next to the other beer in my keezer. I allowed both of these beers to lager for 4 weeks before serving them to tasters.

| RESULTS |

A total of 22 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer kegged when FG was reached and 2 samples of the extended primary beer in different colored opaque cups then asked to identify the unique sample. While 12 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, 13 (p=0.012) did, indicating participants in this xBmt were able to reliably distinguish a Märzen that was aged in the primary fermentor for 3 weeks from the same beer that was packaged when FG was reached.

The 13 participants who made the accurate selection on the triangle test were instructed to complete a brief preference survey comparing only the beers that were different. A total of 4 tasters reported preferring the beer packaged immediately after fermentation was complete, 2 said they liked the beer aged in primary for 3 weeks more, 5 had no preference despite noticing a difference, and 2 tasters reported perceiving no difference.

My Impressions: Of the 5 triangle tests I attempted, I picked the odd-beer-out just 3 times, which really isn’t much better than chance. The beers were very similar to my palate, but if I noticed any differences, they were related mostly to the apparent flavors of older, oxidized beer.

| DISCUSSION |

The idea of leaving beer in the vessel it was fermented in for any amount of time after the completion of fermentation used to be universally condemned by brewers, though these days is considered standard practice for many. As anyone who has experienced the off-flavors associated with autolysis is well aware, it’s not pleasant at all, definitely something to be avoided. For this reason, the practice of racking to a secondary makes practical sense, and the fact tasters in this xBmt were able to tell apart a beer aged in primary for 3 weeks from one packaged when fermentation was complete suggests the extended contact time had a perceptible flavor impact.

While differences were seemingly present between these xBmt beers, there’s no way of knowing what the cause was, particularly whether or not autolysis was the culprit. Some brewers actually view a brief period of aging in primary as a good way to ensure undesirable fermentation byproducts are taken care of, in fact it’s not too uncommonly recommended to proceed with packaging 3 to 4 weeks after pitching yeast. It’s possible this or some other unknown factor is responsible for these results.

My standard approach since I began brewing a few years ago has been to package soon after fermentation is complete, my main impetus admittedly being impatience– the sooner the beer is kegged, the sooner I get to drink it. Going into this xBmt, I didn’t actually expect the beer aged in primary to be any different from the one kegged sooner and was surprised with the findings. Seeing as I’ve been happy with the beers I make, I won’t be making any changes to my process, though in the event I end up leaving a beer in primary longer than planned, I won’t fret over it too much.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

28 thoughts on “exBEERiment | Impact Extended Time In Primary Fermentation Vessel Has On A Festbier”

I was excited to read this one but I wouldn’t consider 3 weeks “extended time in the primary”. Everything I’ve read on autolysis indicates there are no issues under 1 month. Given this reading, I would have liked to have seen closer to 8 weeks to see if participants picked up any undesirable flavors.

I recently did a Dortmunder that sat in primary for 4-5 weeks because I didn’t have a free keg. It was one of the cleanest lagers I’ve tasted.

Indeed, autolysis is probably very rare for homebrewers and would require much longer time on the yeast cake. There are other potential problems with leaving the beer to long on the yeast cake; yeasty aromas and poor head retention. Again, I would think that three weeks is not problematic.

I would guess that the practice of getting the beer off of yeast in the primary is one that comes out of the professional brewing practice. At that larger scale, getting the yeast off soon after primary accomplishes two goals: 1) allow for reharvest at maximum vitality, and 2) autolysis driven by the large hydrostatic pressure exerted on flocculated yeast in a large conical. That’s just my take, but at the homebrew scale I would agree that it has little impact and could even help to remetabolize some unwanted compounds in a beer during maturation on the yeast cake.

Love the experiments, keep of the great work!

Interesting, I have to bottle my beer and transferring to secondary helps with the clarity and reduces the sediment at the bottom of the bottle. In your picture, does the ‘aged’ beer glass have condensation on it or is the beer cloudier?

And for me that is also the main reason that I do transfer to secondary after about a week (depending on the beer), faster and better clarification. However, I have more patience than the Brü guys, I regularly let beers condition in secondary for up to six or eight weeks before bottling (esp. bock and Duvel clones, also RIS).

Same process for me, I don’t use fining to clear any further and bottle around 3 weeks from brew day. I have at times racked a third time, never had any issues. Bottle conditioning a week or 2 improves results.

As a new brewer, I primarily brew ales so I don’t have to worry too much about temperature control of the fermentation. Many of these ales IPA’s that are dry-hopped. I’m interested to know about any difference between dry hopping in a primary vs. transferring secondary for the dry hop process.

I have a coffee stout that’s been in primary for 2 months now, all kegs are full, so I just drink it straight from the fermenter. It still tastes great and fresh and the fermenter must be at 50% full of oxygen.

Not my preferred way of doing it, but my spare 5lbs CO2 tank is empty and my LHBS didn’t have any full in stock when I sent, so I gotta let air in if I want the beer out.

You could call your local weld supply store or any of the gas companies like PRAXAIR or Air-Gas and get bottles. Generally that’s where the LHBS gets them from.

I hit whichever is more convenient or available as in your case.

And often the welding supply will be cheaper. The guy that runs the place I go was saying how homebrewing and marijuana growers have been a big boost in gas sales. Apparently grow houses use a lot of CO2 for some reason.

Very possible the difference in flavor was more due to the temperature difference than the time spent on the yeast cake.

I’ve done both in my past. I’ve left beers in the primary for a month just because I forgot or got busy. I never had the autolysis problem. Nor have I had oxidation problems from racking when I did use a secondary more regularly. This is one I’ve always chalked up to personal preference. Currently, I’m sort of in the same boat as the author. I transfer as soon as I can and use the secondary only for brightening, usually employing some type of fining agent. Then right to carbonating. It’s more about speed for me than anything.

I think a good companion experiment would be to leave both beers in a fermentation vessel for over a month, but rack one after the beer hits terminal into a new vessel. Leaving it in a non-pressurized container for a month + will probably cause some oxidation. This way you’d just be testing whether racking or leaving in the yeast cake has a perceptible difference.

Or maybe using one of those newfangled conicals that let you pull off the yeast could be used and then you’re just testing yeast vs no yeast

In regard to this passage:

“While differences were seemingly present between these xBmt beers, there’s no way of knowing what the cause was, particularly whether or not autolysis was the culprit. Some brewers actually view a brief period of aging in primary as a good way to ensure undesirable fermentation byproducts are taken care, in fact it’s not too uncommonly recommended to proceed with packaging 3 to 4 weeks after pitching yeast. It’s possible this or some other unknown is responsible for these results.”

…It’s interesting to me that the opposite wasn’t considered or mentioned here. Autolysis is responsible for very noticeable and highly undesirable off-flavors in beer. I’ve tasted those off-flavors once, and I’ll *never* forget it… Given that, if autolysis was responsible for the perceived flavor difference in the beer, it would be obvious autolysis was the culprit, to my mind.

Instead, it may be likely the perceptible difference in flavor is derived from low levels of intermediary compounds produced during fermentation (i.e. acetaldehyde and diacetyl) that are still present in the beer that was packaged upon reaching FG. If the yeast didn’t have time to “scrub” all of these compounds out of solution prior to packaging, there would likely be a flavor impact. To my mind, this explanation makes much more sense when considering the metabolic processes and pathways of yeast during fermentation, the relatively “normal” three week duration of the primary fermentation, and the unforgettably obvious and atrocious nature of autolysis derived off-flavors.

Fair enough, but why would the yeast in one of the two containers be any less able to metabolize these compounds?

Nice xbmt Jake! I have a question about your attenuation. Judging by your yeast selection and mash temp, one would assume a lower FG. Any idea why it may have finished at 1.018? I also wondered your thoughts on one of the previous comments about any perceptible difference may have been due to the time spent at different temps and not actual contact time with the yeast. Any thoughts on the temp difference for the 3 weeks or was the temp difference marginal in your opinion?

Many moons ago I always racked beers to secondary. Another yeast cake would form at the bottom of the secondary as the yeast settled. It was a smaller cake than in primary, but still a cake. Which means that the rationale to rack to secondary for the purpose of getting the beer off the yeast has always been fatally flawed, because the beer would still be sitting a yeast cake in the secondary (albeit a lesser one). In any event, the pros package from primary but only after removing the yeast first, which they try to do as soon as possible. Yeast in large conicals don’t like the huge hydrostatic pressure on top of them, plus they’re still metabolizing in the cone in dormancy, which generates a lot of heat. These two things combined are why autolysis occurs at the pro level. Neither is an issue at the homebrew level. If a homebrewer is getting autolysis, they’re doing something dreadfully wrong. As for the flavor difference, I doubt it was oxidation, unless you opened the fermenter for a while or did something with the “aged” beer that’s not being reported. To my palate, the strong breadiness of munich II combined with the gentle fruitiness of a noble hop can yield a subtle vinous, sherry-like flavor. Perhaps this is what you were tasting?

I expected this one to have some relevance since I’ve encountered this in some of my own beers that have sat in the fermenter over a month. In all those cases, I get significant amounts of acetaldehyde in my beer. I learned that this is caused by natural alcohol oxidation reactions, not the typical green beer problems we often encounter. Stone Brewing has an article on this as well. https://www.stonebrewing.com/blog/stochasticity-lab/2014/guide-flavors-acetaldehyde

Another great Exbeeriment Jake! My friend is the Brewmaster at a local brewery, and he told me that the issue is the beer being left on the yeast after cold crashing. They often have extended diacetyl rests, but once they cold crash, they get it off the yeast cake within 48 hours. He would read this exbeeriment and say that it proves his point, however subtly. I would be curious if the temperature made the difference. I suppose that has been done with the negative results from the earlier exbeeriments related to the lack of significance of racking to a secondary fermenter.

This expeeimexp didn’t address the main impetus of your question. Why didn’t you package a beer that was aged in secondary for three weeks and one that sat on primary for three weeks (or more than a month as some suggested).

I still do secondary if I’m bottling .I find the clarity improves significantly in a secondary for a week before bottling .if I’m kegging, then the keg acts as the secondary as sediment will drop to the bottom and brighten with time.

I have had bottle conditioned ales that have sat on yeast for years and they taste fine. So I’m not convinced yeast is the cause.

Perhaps bits of malt grist or the trub is breaking down over time which changes the flavour.

Results section, paragraph 2. The numbers don’t add up. 4 + 2 + 6 + 2 = 14, not 13.

Fixed.

So if 2 of the 13 tasters who originally reported perceiving a difference then report that they did not perceive a difference, does that actually make the findings non-significant at 11 tasters perceiving a difference? I vaguely remember a similar situation being discussed in a previous podcast but I can’t recall which direction you went and why.

I assume packaged immediately means bottled. But I’m curious if the results would change if it were aged in a secondary for 3 weeks since the argument doesn’t seem (to me at least) whether or not bottling quicker makes a difference, but whether sitting on the cake makes a difference. We know from this one that bottling quickly can create a fresher taste, but not really if there’s a difference between aging in a primary and a secondary.

I don’t bottle unless it’s for an xbmt. Packaging means kegging for this xbmt. I haven’t done a secondary in probably five years

Shoot I have a beer that’s been in primary for almost two years now. I’ve just been too lazy to bottle it!

Curious to know if FG dropped further after 3 weeks. I’ve left some beers in primary for 4 weeks when i was busy and found they attenuate some more compared to my usual 10 day fermentation. Weird thing was in my usual fermentation schedule, gravity was stable from 7th to 10th day