Author: Phil Rusher

Beer comes in varying degrees of color, flavor, and haziness, but one thing they all have in common is at least some level of bitterness. Responsible for the good majority of bitterness in beer, hops contain alpha acids that, in the presence of boiling wort, get converted into iso-alpha acids, which are perceptibly bitter.

The most common forms of hops are whole cone and pellets, the latter of which comes in two main types that are delineated by their weight relative to the whole hop cone. Type 45 (T-45) pellets are processed in a manner that results in less leafy material and a higher concentration of alpha acids as compared to Type 90 (T-90) hops, which are essentially the broken down and pelletized version of whole cone hops. While T-90 pellets are used far more often, there’s some who feel all the leafy material being in contact with wort can contribute less than desirable characteristics, and one way to avoid this involves the use of an interesting modern hop product.

Purported to retain all of the good stuff from hops including alpha and beta acids as well as the various aromatic oils while getting rid of the unnecessary bits, hop extracts are produced using CO2 to concentrate the hop resins into a viscous liquid that can be added directly to wort. The production of hop extract occurs at cool temperatures so that the alpha acids remain non-isomerized, allowing it to be used in a similar way standard hops are used, albeit with much less material and, some might contend, a higher degree of precision.

I’ve been interested in learning more about this relatively novel product since first hearing about it a couple years ago, particularly its impact on bitterness quality compared to standard T-90 pellets, which I use almost exclusively. Despite having no real issues with the character of my pellet hop beers, I picked up some extract to test it out for myself!

| PURPOSE |

To evaluate the differences between beers bittered with either T90 hop pellets or hop extract.

| METHODS |

After some discussion with the crew, I settled on a Best Bitter for this xBmt with a single bittering addition with the hope of emphasizing any differences caused by the variable.

Soggy Bottom Bitter

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 47.6 IBUs | 12.7 SRM | 1.048 | 1.012 | 4.8 % |

| Actuals | 1.048 | 1.011 | 4.9 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Malt, Maris Otter (Thomas Fawcett) | 5.5 lbs | 55 |

| Canada Malting Munich 10L | 3 lbs | 30 |

| Crystal Malt - 60L (Thomas Fawcett) | 1.5 lbs | 15 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| CTZ OR Hop Extract | 25 g | 60 min | Boil | Pellet | 16 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| House (A01) | Imperial Yeast | 74% | 62°F - 70°F |

Notes

| Water Profile: Ca 111 | Mg 2 | Na 10 | SO4 143 | Cl 80 |

Download

| Download this recipe's BeerXML file |

I started my brew day collecting two equal volumes of RO water.

After adjusting both sets of water to my desire profile, I began heating it up then moved on to weighing out and milling the grain.

Once each batch of water was appropriately heated, I mashed in and set the controller to maintain my target mash temperature of 152°F/67°C.

Seeing as the HopShot hop extract I purchased was made from CTZ hops, so I used pellets of the same variety for this xBmt. During the mash rest, I measured out the amount of hop pellets BeerSmith predicted would contribute the same 48.5 IBU expected in the hop extract batch.

At the completion of each mash rest, the grains were removed and sparge before I started heating the wort. As soon as a boil was reached, the single addition of either pellet hops or hop extract was added.

With each boil complete, the wort was chilled during transfer to identical fermentation vessels.

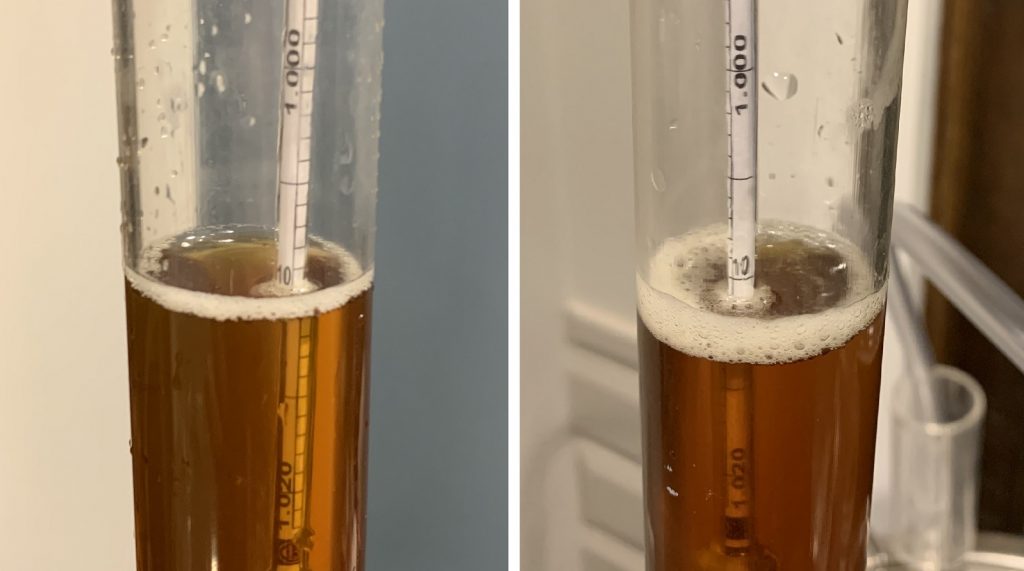

Hydrometer measurements confirmed both worts achieved the same 1.048 OG.

The filled fermentors were placed next to each other and I direct pitched a pouch of Imperial Yeast A01 House into both batches.

The beers were left to ferment at 66°F/19°C for 11 days, at which point signs of activity were absent and hydrometer measurements were taken that revealed a very slight difference in FG.

The beers were then transferred to sanitized and CO2 purged kegs.

After a brief period of burst carbonation, the beers were left to condition for a couple weeks before they were ready to be served to tasters.

| RESULTS |

A total of 21 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer made with T-90 pellets and 2 samples of the beer made with hop extract in different colored opaque cups then asked to identify the unique sample. While 12 tasters (p<0.05) would have had to identify the unique sample in order to reach statistical significance, only 8 (p=0.40) made the accurate selection, indicating participants in this xBmt could not reliably distinguish a Best Bitter made with a single bittering addition of T-90 pellet hops from one made with hop extract.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I chose the odd-beer-out only 3 times, and it wasn’t easy, the beers tasted incredibly similar. The only difference between the beers I think I might have detected was that the pellet hop version had a slightly sharper bitterness than the one made with hop extract. Regardless, I enjoyed both of these beers equally and had no preference.

| DISCUSSION |

Hop extract is marketed as a relatively cost effective way to impart bitterness to beer without adding all the leafy material known to contain compounds that some believe can lead to undesirable flavors. Moreover, the use of hop extract can increase overall yield, which while arguably more important on the commercial scale, is an added bonus for homebrewers as well, particularly if the resultant beer tastes better. Interestingly, tasters in this xBmt were unable to reliably distinguish beers bittered with either hop pellets or hop extract, suggesting they had a similar impact.

These findings contradict claims that hop material being in contact with wort for the duration of the boil can be detrimental to flavor, which is validating for those who have been brewing delicious beer for a long time without extract. However, it also seems possible the lack of a perceptible difference in these beers was a function of the amount of hops used, with larger charges leading to a larger delta. It also makes sense that the point in the boil at which they were added might have an impact, which is something I look forward to exploring in the future.

With the understanding that predicted IBU is an imperfect measurement for perceived bitterness, we sent samples of both beers to our friends at Oregon Brew Lab for evaluation. My aim was for both beers to be as close to identical in terms of bitterness as possible, using the amount of pellets and extract to achieve approximately 50 IBU. Given past lab results, I expected the measured numbers to be somewhat lower than what BeerSmith predicted, and I concurred with tasters who described the perceived bitterness as being rather low. But I was shocked when lab measurements indicated the pellet hop beer was at a paltry 9 IBU while the hop extract beer hit 10.5 IBU.

With the understanding that predicted IBU is an imperfect measurement for perceived bitterness, we sent samples of both beers to our friends at Oregon Brew Lab for evaluation. My aim was for both beers to be as close to identical in terms of bitterness as possible, using the amount of pellets and extract to achieve approximately 50 IBU. Given past lab results, I expected the measured numbers to be somewhat lower than what BeerSmith predicted, and I concurred with tasters who described the perceived bitterness as being rather low. But I was shocked when lab measurements indicated the pellet hop beer was at a paltry 9 IBU while the hop extract beer hit 10.5 IBU.

I’ve been racking my brain for a way to explain these strikingly low numbers, and at this point, I’m really not sure what to make of them. What is nice is that they’re not that different, meaning both beers possessed similar levels of bitterness, as the xBmt results would imply. Either way, I plan to continue experimenting with hop extract and am particularly interested in its impact when used later in the boil.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

28 thoughts on “exBEERiment | Bittering Hops: T-90 Pellets vs. Hop Extract”

What is it with North American brewers and their obsession with crystal? I’m not surprised you can’t taste the hops with 15% crystal. Look at this actual brewbook entry for the Fuller’s ESB and London Pride partigyle : twitter.com/FullersHenry/status/1022805660868784130

Just UK pale malt, a touch of chocolate – and <7% light crystal. And Fuller's would be considered rather crystal-heavy by British standards, up north they would be using rather less crystal and at least as much sugar as crystal to dry out the beer.

And if I was being picky then I'd say anything over 4.5% is getting high for a best bitter, 4.2-4.3% is the norm, and aiming for a BU:GU of 1 is on the high side even for northern bitters, and definitely too high for a southern bitter which is what this seems to be aiming for. But it's the crystal that stands out.

I’m sorry my choice of ingredients makes you so upset. Can we still be friends?

All that aside, please keep in mind that sometimes for the aim of these xBmts is not necessarily to make one particular style of beer, traditional or otherwise. Rather, the idea is to focus on a particular variable.

Cheers.

The low IBU is pretty interesting. At first I was suspicious of the reported AA% content of the hops, maybe ask if they were aged and lost some AA. Most of my CTZs are running about 12-14 new and I assume lower if they are a year old.

But the oil gave same result so I think that rules out the quality of the pellets and the calculation.

So what was your boil like? Vigorous or a simmer? Did the hop oil go into solution or did it all stick to the side of the kettle? Might want to retry this exbeeriment with same recipe but 2x the hops and a more vigorous or longer boil.

Yes, the objectively measured low IBU is very interesting! My first thought was lower than reported AA from the hop supplier but if that can’t be the case because the hop extract was almost exactly in line with the pellets. To that end, I’m less inclined to think that any oils (from pellets or extract) being in any one area of the wort had anything to do the IBU level.

It’s difficult to say with any certainty what the culprit here is. I’m leery to point fingers at any one thing, but I suspect that the 110V North American Grainfathers do not produce as vigorous or a boil as higher voltage devices.

Time to revisit the boil vigor experiment with this recipe?

I’m 100% convinced boil vigor is responsible for the low IBU. Once I added a brew hardware heat stick to my grainfather setup I perceived a significant difference in bitterness an flavornin my beers.

I’m not sure how boil vigor would change the bitterness. The temp is constant as long as it’s boiling and unless there is some pressure change will not exceed 100C at sea level. I doubt the temp difference of the bottom of the pot between a vigorous boil and a regular boil will have much impact on the alpha acid conversion or other aspects of bittering with hops. Does anyone have a physical rationale for this?

I read each and every one of these exbeeriment articles and always find them interesting. This one though, really gives us something to think about, regarding calculated vs measured IBU! I’ve learned to take predictions with a grain of salt, especially since they don’t really take into account perceived bitterness (based on OG, style, ingredients, etc). But to have the objective, measured IBUs come out so much lower than the calculated expectation was really surprising to me. I hope we get to see more experiments where the samples are sent for lab testing, to see how common this is, and how different styles/recipes may (or may not) provide different results.

Thanks!

Definitely a lot to think about here. I think one of the more important things we should remind ourselves of is that the IBU is an altogether bad metric for perceived bitterness. I’m not certain that we’ll be committing ourselves to sending out all of our beers for lab analysis any time soon, but we will for sure be investigating hop utilization and all the rest moving forward!

Wow 20% of predicted hop utilization!?! I’ve been noticing a lack of bitterness in some of my own beers and have been slowly ramping up the hop charges to try and compensate. It’s tough to follow through with a Helles recipe and your bittering charge is at 65 IBU! I have seen a grainfather in action and I must say, the boil is not very vigorous. With the previous exp showing now significance with boiling with a lid on I might suggest trying that. The hole in the top of the GF lid is enough to let some steam out.

Next experiment: hop utilization in a vigorous boil vs a typical grainfather boil!

Good suggestion, but I actually do leave the lid on while boiling for this reason. Stay tuned for more to come on hop utilization etc. 😉

I use CO2 extract for my Imperial Stout. For a 15.5 gallon batch (60-70 ibu dose), it’s 8oz of CTZ or 1.38 oz of extract.

8 oz of hops can retain a lot of wort… That’s primarily the only reason why I use it… That and I had it on hand so figured “why not”

I’ll pile on with the others (and you) that the IBU discrepancy is amazing. Fact that pellet and extract roughly same suggests that something else in recipe or process. #1’s comment says that crystal will cover “taste” of hops (dunno, i’ll take his word on it) – but the lab assay not necessarily match taste, quantitative analysis, right?

Keep up great reports, always enjoy reading and learning!

Phil wrote that he concurred with tasters who noted the beers tasted underbittered.

So the lab findings are in line with the human perception. Seems most likely the hop utilization was low for some reason. Or the AA% for both hops was inaccurate.

I’m less inclined to think it was AA because 1. the was accounted for and 2. the measured IBU was, for all intents and purposes, the same between the beers. Utilization seems to be the main thing at play here.

Have you guys done an experiment regarding boil veracity? 110v electric systems do a very mild boil, only boiling off about a gallon in an hour. I easily boil off 2 gallons in an hour using a natural gas burner and a very vigorous boil. Could matter in regard to hop utilization and ibu counts.

This seems to suggest there isn’t much of a difference, though it’s between burner strengths and it may not map to the lower temperature ‘boils’ of electric brewing systems: https://brulosophy.com/2017/05/29/boil-vigor-weak-vs-strong-exbeeriment-results/

Sure have! Put “boil” in the search bar here.

https://brulosophy.com/projects/exbeeriments/

I switched from propane to electric several months ago. The main difference in taste with my beers made on the electric system is that I perceive them to be less hoppy then Beersmith predicts. I’ve never done the same recipe twice until a few weeks ago so I couldn’t say what the cause was but I suspected boil vigor.

After making the same exact recipe but this time on electric, I’m fairly convinced it’s boil vigor. It could also be I switched to a smaller hop spider but who knows for sure. If my beer happens to make it to the second round of NHC, I will definitely be upping the calc IBUs. Great xbmt!

I wonder if it only matters if your doing a big IIPA or NEIPA where hop material is a concern? Then I can see the hopshot being more useful

Maybe there is a mess in the IBU calculation formula? Maybe there are coefficients set for litre and input is in gallon – they are roughly in similar relation as your predicted and measured values.

Good thinking, but no. The calculations are made through BeerSmith so all of that is handled in such a way to minimize human error. That and the hop extract manufacturer does their own internal testing to determine expected IBU level, so again, minimized room for human/mathematical error.

Should boil vigour impact the hop extract?

It’s already extracted and just getting mixed through isn’t it?

From the article:

“The production of hop extract occurs at cool temperatures so that the alpha acids remain non-isomerized, allowing it to be used in a similar way standard hops are used[…]”

What AA extract yield did you assume?

The default extract potential when using the Beersmith Grainfather profile is 100% hop utilization. Being that I have used that figure in the past with the GF and my propane setup without noticing a discrepancies between calculated and perceives bitterness that’s what I went with. I do plan on investigating the utilization rate for these units as well as others in the future.

I have been using Pacifica hop extract for years with batches, though sadly have no idea what amount of IBU is going in – I add 2ml of hop extract. Do you have charts you might forward to me for IBU vs volume or is it all weight.

The amount of IBU generated from extracts will vary depending on the manufacturer and hop variety. If I were you I’d stat with where I’m buying the extract from, they should be able to get some kind of conversion chart or means to provide theoretical IBU.