Author: Brian Hall

Brewers give a decent amount of attention to the quickness that wort is chilled following the boil, an issue important enough to inspire the development of myriad mechanisms designed to hasten the process. Included among the various purported benefits of quick chilling is that it allows for immediate pitching of yeast into wort of a proper temperature. Unfortunately, homebrewers unable to invest in fancy glycol chilling units are only able to chill their wort to the temperature of their groundwater, which can be quite a bit warmer than ideal pitching temperatures.

While some employ the use of an ice bath to assist in the chilling process, many have taken to simply leaving the fermentor full of warmer-than-wanted wort in a temperature controlled chamber until it stabilizes at their desired pitching temperature. The time this takes is dependent on the temperature of the wort, though it’s not uncommon for brewers to leave their wort alone overnight, returning to pitch the morning after brew day.

One of the oft cited risks in leaving wort to sit un-pitched for an extended length of time is that it increases the chances of a contamination taking hold and ruining the beer. Another concern some have voiced has to do with oxidation of the wort, which is believed to lead to stale beer, whereas yeast pitched soon after chilling takes up oxygen during the lag phase.

Even living in Anchorage, I often have issues chilling wort to my desired pitching temperature, something I know brewers in warmer climates experience often. While the concerns expressed about delaying yeast pitch make some practical sense to me, I was interested to test it out for myself under more extreme conditions.

| PURPOSE |

To evaluate the differences between a beer where the yeast was pitched soon after chilling the wort and one where the yeast was pitched after a 40 hour delay.

| METHODS |

I went with a NEIPA for this xBmt, partially because of how sensitive the style seems to be to various things, but also because I was running low and wanted some on tap.

Delayed Gratification

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 33.4 IBUs | 5.5 SRM | 1.060 | 1.016 | 5.9 % |

| Actuals | 1.06 | 1.013 | 6.2 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

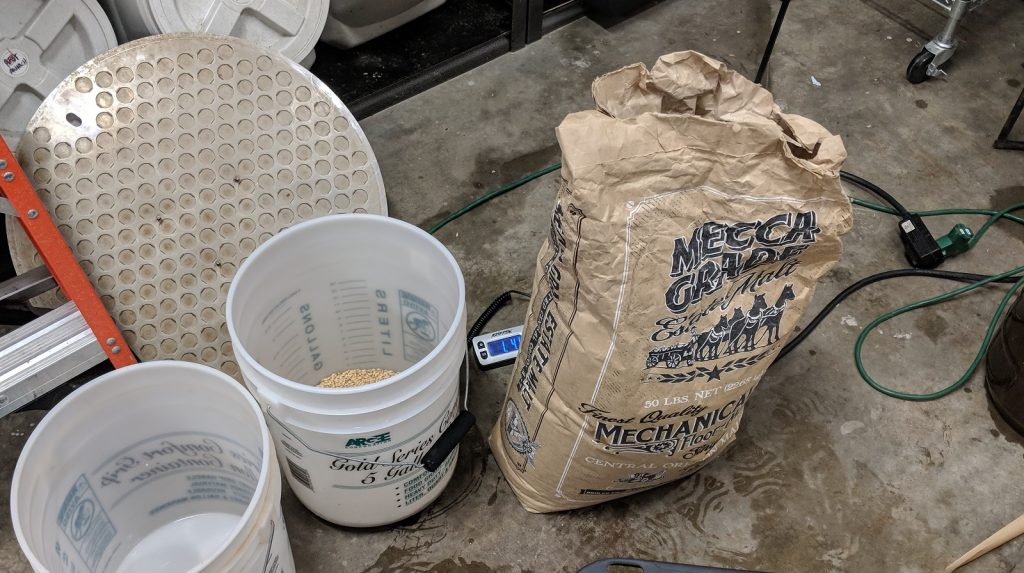

| Lamonta American Style Pale Malt (Mecca Grade) | 9.003 lbs | 67.93 |

| Oats, Flaked | 3 lbs | 22.64 |

| Vanora Vienna-style Malt (Mecca Grade) | 1.25 lbs | 9.43 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 7 g | 60 min | Boil | Pellet | 12 |

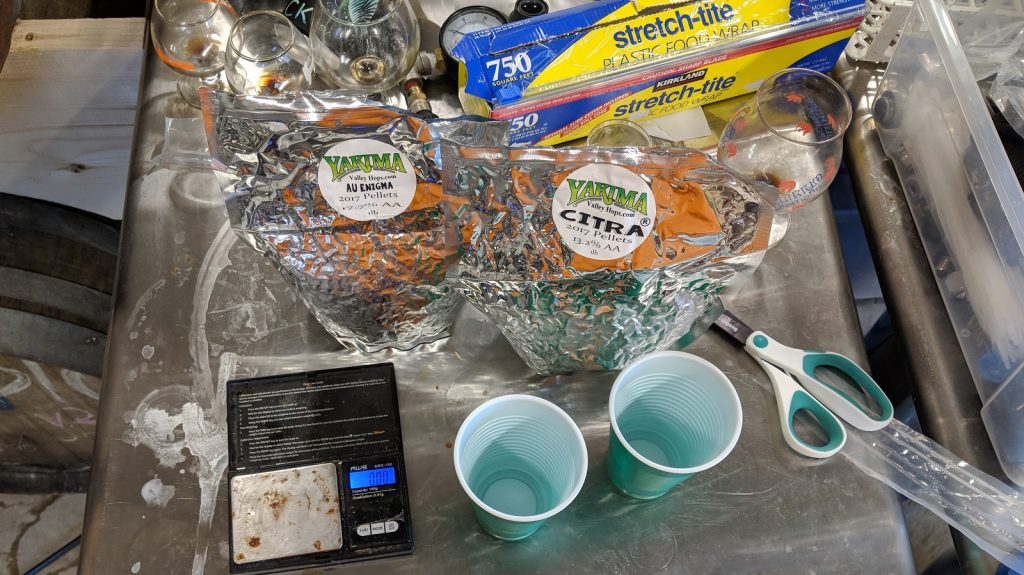

| Citra | 28 g | 5 min | Boil | Pellet | 12 |

| Enigma | 28 g | 5 min | Boil | Pellet | 16.5 |

| Citra | 43 g | 1 min | Boil | Pellet | 12 |

| Enigma | 43 g | 1 min | Boil | Pellet | 16.5 |

| Citra | 57 g | 6 days | Dry Hop | Pellet | 12 |

| Enigma | 57 g | 6 days | Dry Hop | Pellet | 16.5 |

Notes

Water Profile: Ca 117 | Mg 3 | Na 10 | SO4 84 | Cl 168 |

Download

| Download this recipe's BeerXML file |

After collecting the RO water for two batches and adjusting them to same profile, I weighed out identical sets of grain.

As the water was heating, I proceeded to mill the grains.

With strike temperature reached, I mashed in on both batches to checked to make sure they settled in at a similar temperature.

The full volume BIAB mashes were left alone for a 60 minute saccharification rest, after which I removed the bags and allowed them to drip until my expected pre-boil volume was reached.

I then combined the worts in a single kettle and lit the burner to get it heating up before weighing out the kettle hop additions.

The wort was boiled for 60 minutes with hops added per the recipe.

At the end of the boil, I chilled the wort to 72°F/22°C, the temperature at which cooling slowed significantly.

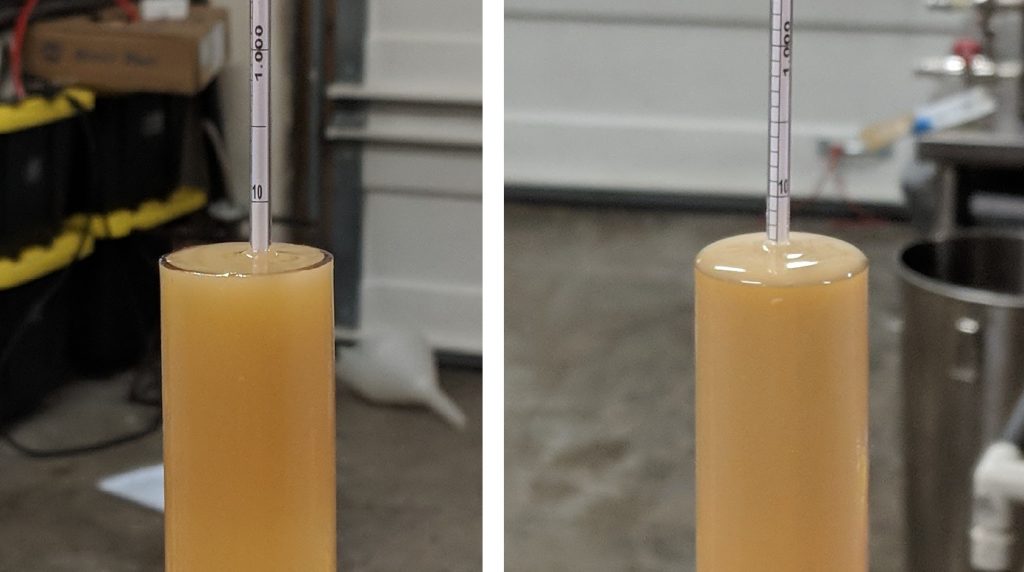

The wort was split between identical Brew Buckets and placed next to each other in my fermentation chamber controlled to 66°F/19°C. Hydrometer measurements confirmed my target OG was hit.

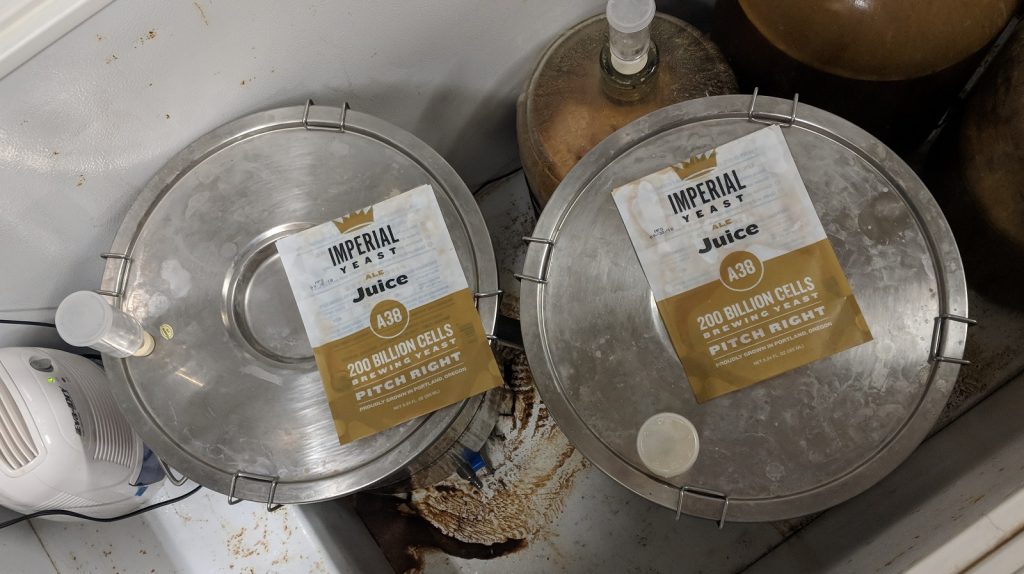

I left the worts in my chamber while I cleaned up my brewing mess and took care of family matters. I returned a couple hours later to direct pitch a single pouch of Imperial Yeast A38 Juice into one of the batches, then did the same to the second batch 40 hours later.

Fermentation activity was observed just a few hours after pitching the yeast into either batch and proceeded similarly. At 4 days post-brew, I returned to add the dry hop addition.

I left the beers alone for another week before taking hydrometer measurements showing they both reached the same FG.

The beers were then racked to separate sanitized and CO2 purged kegs.

The kegs were placed in my cool keezer and burst carbonated overnight before the gas was reduced to serving pressure. After a few days of conditioning, they were ready to serve to participants!

| RESULTS |

A total of 21 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the early pitch beer and 2 samples of the delayed pitch beer in different colored opaque cups then asked to identify the unique sample. While 12 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 5 (p=0.88) did, indicating participants in this xBmt were unable to reliably distinguish a NEIPA where the yeast was pitched soon after the wort was chilled from one the yeast was pitched 40 hours after the wort was chilled.

My Impressions: Over a series of blind triangle test attempts, I was unable to consistently tell these beers apart from one another, they tasted exactly the same to me. For those who have asked for my favorite NEIPA recipe, this is it! I really the combination of Enigma and Citra, which the simple grist allowed to shine through.

| DISCUSSION |

Contamination is a serious concern when it comes to brewing good beer, and sugary sweet wort is a very attractive environment for spoilage microbes. For this reason, brewers are often wont to pitch yeast as soon after the boil as possible such that their pure culture can out-compete any critters that may have made their way in. The fact tasters in this xBmt were unable to tell apart beers where the yeast was pitched either soon after the wort was chilled or following a 40 hour delay seems to suggest waiting isn’t a guarantee for disaster.

While it’s possible my neurotic sanitation practices contributed to these findings, another concern occasionally expressed about delaying yeast pitch has to do with oxidation of the wort. With how sensitive NEIPA appears to be to oxygen, I would have expected to observe at least some difference appearance and flavor between these xBmt beers, which wasn’t the case at all. Both the early and delayed pitch beers tasted and looked the same throughout the few weeks they were on tap.

As validating as these findings may be for those who are unable to effectively chill their wort all the way to ideal pitching temperatures, it’d be foolish to suggest that pitching as soon as possible isn’t the better practice. Not only does it unarguably reduce the risk of potential contamination, but it means less time for the beer to be finish, even if by a little. I’ll continue pitching yeast as soon as the wort reaches my desired pitching temperature, but in those times it takes a bit longer, I won’t fret about leaving it in the chamber for some time.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

36 thoughts on “exBEERiment | Impact Of Delaying Yeast Pitch On Hazy IPA”

I live in Albuquerque. We cherish our water. I never use it to cool beer. I use the Aussie no chill system. It can be a month before I pitch yeast. I have one batch in the fermentor, and two in the Aussies right now. (I am always 2 to 3 batches behind)…

If you are waiting a month before pitching yeast you may be putting yourself at risk for botulism. Their spores can survive boiling and the pH of wort isn’t low enough to inhibit their growth (and obviously there’s no alcohol to kill them). Hops may inhibit them to some degree but I’m not sure I’d count on that.

Just pitch the yeast and turn your wort into beer and wait a month to drink it, it’ll be much safer.

Not really. Odd thing every body forgets when they give this advice is the anti bacterial impact of the hops. Alpha acids, in both their isomerized and non-isomerized forms, are particularly effective against gram positive bacteria. C. Botulinum is gram-positive. It is effective enough that there are patents in the US for using hop oils at 1ppm or higher (https://patents.google.com/patent/US6251461) to prevent botulism in commercial food processing. I wish I could find the original research for that patent.

Anyway. As long as you are brewing with some hops, this is not really a serious concern.

One way to chill wort to below ground water temps that I have used for years is just *reverse* the use of your immersion chiller. Stick the chiller in a bucket of ice water & run the wort *through* the chiller.

Granted, you don’t have a ton of temperature control that way, but it will take boiling hot wort down to lager pitchable temps (55-60F) with one pass.

I tend to wait 12 hrs or so before i pitch yeast. By that time the trub settles and the desired stable temp is reached. Then i infuse with pure oxygen and pitch yeast. Feedback has been positive from friends since i started this practice.

I now do the same, after frustratingly trying to chill the wort down by immersion chillers in the past.

Last two brews I’ve strained the hot wort into a sanitised keg. Sealed it and placed it in my larder fridge in my garage to help the chilling.

Pitch in the morning by pouring it through sanitised strainer & sprinkling the yeast on the top foamed up wort

My last batch it was a noChill NEIPA and I kept wort about three weeks at +- 2 Celsius in my keezer until pitch yeast. No off-flavors, delicious beer. I am almost neurotic about sanitation as well and also I try get less headspace that I can.

So when you added the wort to your fermentor, and then waited for 40hrs. How did you seal that off? When I do this it always sucks in sanitizer from the blowoff tube.

I just had an airlock on it. I’m sure some air got in.

NEIPAs are sensitive to oxygen is oxidation of the residual hop material, not the wort.

There is hop material from hot side/whirlpool hops in the wort.

I’ll also mash Friday night, boil Saturday morning, then pitch Sunday… crazy talk!

I tend to brew, then cool my wort as low as I can get it with ground water, then move to my fermentation chamber and let it equalize for a several hours (4-12) then aerate (with pure O2) and pitch. It’s worked well for me so far.

This isn’t really replicating the scenario though. In both cases, the wort was chilled immediately after boiling. To be a representative test, one half should be put into the fermentor bucket before cooling, and left to cool slowly on its own. The other half should be chilled quickly and then put into the fermentor.

I’m not sure that the results will be different, but one batch will at a higher temperature for a while, and that may promote unwanted infection, oxidation or other effects.

The exbeeriment was comparing a delayed pitch, not chill vs. no chill. Unless the brewer lives in an area with tight water use restrictions, at least some effort should be taken to cool the wort.

It wasn’t really the experiment I expected to see when I read the title. ..

I thought this would be an experiment when on one batch you chill the wort like normal with a counterflow or immersion chiller and pitch the yeast and the other batch you just let the temperature freefall to pitching temp after boiling. That would have been much more revelant as that’s the way people go if they don’t chill. They don’t chill and WAIT 2 days to pitch, they have no way of cooling(or just don’t want to waste any water) so they let the temp freefall after boling and after a couple days, when pitching themp is reached, they pitch. That would’ve been a much more revelant and interesting experiment as it’s a lot closer to reality and not just a sort of hypothetical thing. You also could’ve ended up with a more signifiacant difference(not sure) and then not to mention how the appearance would have changed where 1 batch had 2 days to settle…

I sold my wort chiller 5 years ago and have not looked back. it was not convenient to hook up a 50 ft. hose from the spigot to the garage, especially on the winter. after the boil I store the wort in a sanitized corny keg until I am ready to transfer to a carboy to ferment. I push the beer from the keg to the fermenter with CO2. I have not had a bad experience to date with this method. Is every beer a medal worthy beer? probably not, but it still tastes good

Off topic slightly, but I see you have the Monster Mill MM-3Pro. What do have the gap set at?

.031!

I wonder if there would have been a more noticeable difference if you would have done a “no chill” on the delayed pitch portion. That wort would have been in temperature ranges that might foster the growth of different organisms. Although if there are simply no organisms in there anyway maybe it doesn’t matter. Thanks for the experiment.

Only one way to find out! I just often delay pitching for whatever reason, wanted to test. Thanks!

I’d be more worried about the state of your fermentation chamber!

Yeah, the compressor is having issues right now, I’m working on it.

Hi Brian, thanks for this. In Scotland so don’t often have a problem with groundwater temp! That said, I used to build vitality starters from wort before I started using a venturi to oxygenate. Since then I’ve pitched straight away for great fear of the dreaded microbes. Out of curiosity, how and when did you oxygenate the batches? Did you do them both immediately on chilling or just before pitch?

That was going to be my question: when and how did you oxygenate? If you did it just prior to pitching the yeast in both cases, then I would expect the no-difference results. But if you let an oxygenated wort sit for 40 hours before pitching, I would expect oxidizing to occur — enough so that it might be detected in the taste.

I didn’t oxygenate. I just did a vitality starter and added the yeast. I don’t oxygenate many of my beers.

This article made me nervous.

Last summer when I was away from home I tried one of these kits

https://www.themaltmiller.co.uk/product/fresh-wort-beer-kits/

which in essence are wort packaged by a micro brewery in 25 litre plastic containers until the home brewer wants to use it. I used it in September though the wort had been packaged in January! It was fine, fermentation all went as per normal and a pretty decent beer at the end of it. Wort is much more forgiving than I could ever have imagined

I also EasyChill overnight and let nature do it toll outside due to the cold Danish climate. I mostly use yeast slurry from former brews and hence whiele boiling set up a vitality starter and hence pitch a very nice amount of happy yeast-cells 24 hours later!

By EasyChill, I simly wrap the pot+lid in a palstic bag and attach a work-out rubber band to keep narsties + oxygen out!

I done this for my 150 brews, and has never ownen a chiller and likely will never! I guess I have had 3-4 infected batches, and 2-3 of them was likely from Fermentatours not been clean more than connected till EasyChill/Overnight Chillling!

After reading so many of these expirements and listening to the podcast along with my one experiences, I am convinced that sanitation is the single most important part of brewing. If you have good sanitation practices, the remainder of the brewing process seems to be forgiving in many ways. We could all do with a little neuroses when it comes to sanitation.

You may be right about that. But I have never seen any exBeeriments regarding sanitation, so we don’t really know how neurotic is “good enough”. I suspect that pitching billions of healthy yeast cells drives down any residual microbes down to undetectable (though not zero) levels in the finished beer.

My last batch it was a noChill NEIPA and I kept wort about three weeks at +- 2 Celsius in my keezer until pitch yeast. No off-flavors, delicious beer. I am almost neurotic about sanitation as well and also I try get less headspace that I can.

Great Article. I do have a question on the recipe though. How did you figure the 33.4 IBU in this recipe? I put into Beersmith and got around 105, even if I remove the dry hop and the original Magnum hops I am still at 95. I am just wondering if there are some different calculations.

I’m just using beersmith at the default setting. It does say 33.1 for me.

So… I live in Canada, temperature is -12 C in nov here on the prairies -30 sometimes in Jan. They say its a dry cold. We make up for it hot dry summers. I also have sleep apnea, so buy lots of 4 litre opaque plastic jugs of distilled water for my cpap machine. What I do is boil my wort. And then after the 1 hr to 90 minute boil pour my 6- 8 litres of wort evenly into two empty distilled water jugs. Since all ever had in them is distilled water, I don’t even sanitize them. I then put them out on my patio with the lids off (to let the heat funnel out) and throw a clean black or green plastic garbage bag over them to protect them from the elements and sun (since hops dont like the sun). The garbage bags provide zero insulaton to keep the heat in. This typically chills them down to room temperature pretty quickly without the need for a wort chiller. I look forward to cold, somewhat breezy days in the winter to brew my summer ales.

I finally brewed this beer knowing my wife is a Citra lover. It was the hit of Thanksgiving. Kicking myself for only making a 3 g trial batch. Highly recommend!