Author: Jake Huolihan

One of the more common approaches to brewing among beginners involves blending malt extract with water to create a base wort then steeping specialty malts to add character. Depending on the malts steeped, one can produce any number of styles from the same base wort. While I’ve long since left the world of extract brewing, this same basic technique is being used by some all-grain brewers to easily produce various styles.

The process is simple and involves first splitting the wort from a single large mash between two or more kettles. From there, each wort can be hit with various combinations of specialty malts, boiled with unique hop varieties, and fermented with different yeast strains to create drastically different beer styles. Starting with a basic pale wort, a brewer can produce anything from a hoppy American Pale Ale to a rich and malty American Porter, all from a single mash.

As is often the case, there are some who question this technique, namely those who feel the inclusion of specialty malts in the full mash imparts a quality unattainable by steeping alone. However reasonable it may seem that steeping specialty malts could accomplish a similar result as mashing given they’re largely non-diastatic and used primarily to impart color and flavor, I was curious to see for myself and decided to put it to the test!

| PURPOSE |

To evaluate the differences between a Stout where all the specialty grains were included in the mash and one where the specialty grains were steeped in the wort prior to boiling.

| METHODS |

I went with a Foreign Extra Stout for this xBmt and designed a recipe inspired a few others I found online.

Ascension

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 66.8 IBUs | 48.5 SRM | 1.069 | 1.017 | 6.9 % |

| Actuals | 1.069 | 1.017 | 6.9 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Exclusivo Pale Malt (Cargill) | 15 lbs | 89.55 |

| Roasted Barley | 1.75 lbs | 10.45 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 50 g | 60 min | Boil | Pellet | 11.5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Darkness (A10) | Imperial Yeast | 73% | 62°F - 72°F |

Notes

| Water Profile: Ca 58 | Mg 0 | Na 8 | SO4 60 | Cl 61 |

Download

| Download this recipe's BeerXML file |

The night before brewing, I collected the water and adjusted it to my desired profile before weighing out and milling the grains, making sure to keep the roasted grains separate for one of the batches.

I awoke the next morning and began heating the first volumes of water, separating the start of each batch by 20 minutes. Once strike temperature was reached, I mashed in and checked to ensure both reached the same target mash temperature.

An obvious and unsurprising difference in color was observed during the mash rest.

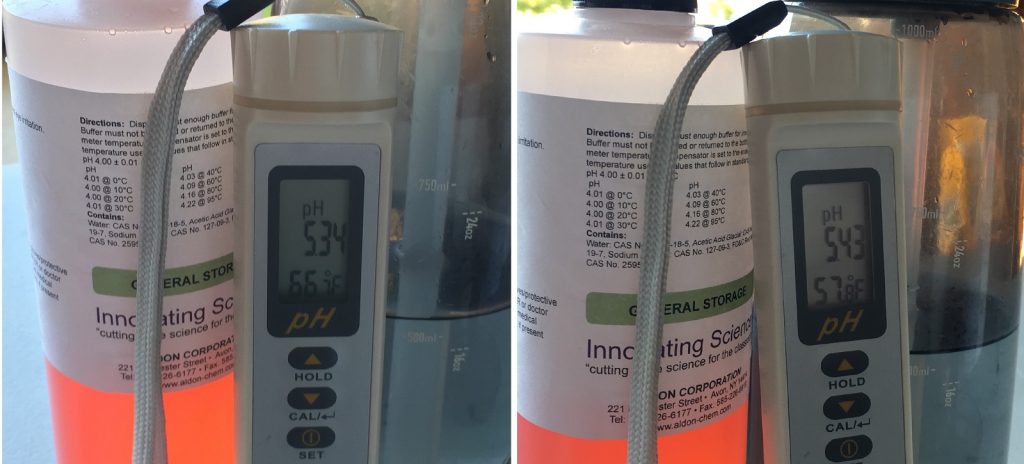

I took pH measurements 30 minutes into each mash, the one including roasted grains being predictably lower.

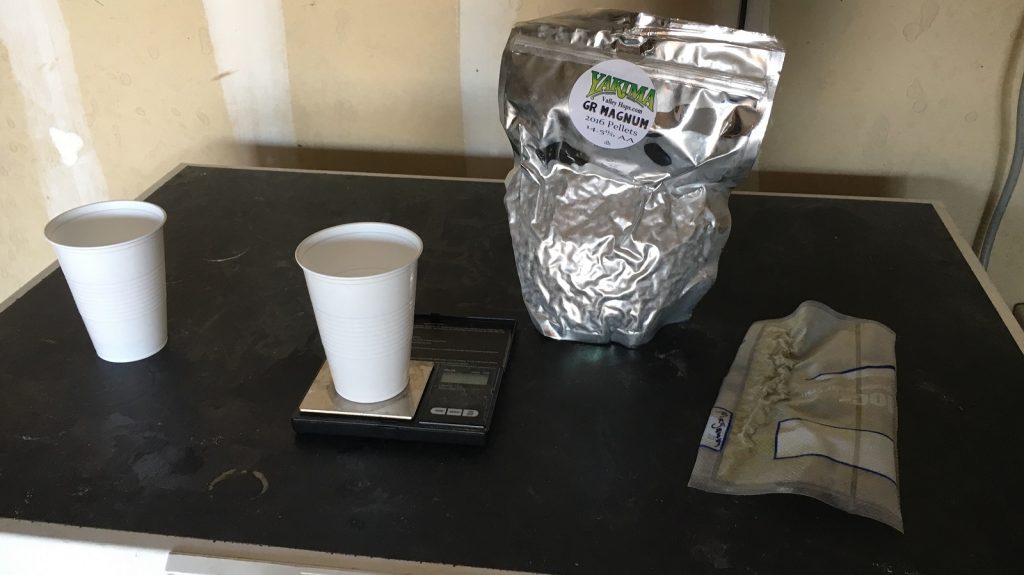

During the saccharification rests, I weighed out the kettle hop additions.

Following each 60 minute mash rest, the sweet wort was transferred to separate kettles.

While I immediately began heating the full mash wort to a boil, I set my temperature controller to hold the other batch of wort at 150°F/66°C then added the bagged roasted grains.

After a 20 minute steep, the grains were removed and I began heating the wort like normal. The worts were boiled for 60 minutes with hops added per the recipe.

Once each boil was finished, I quickly chilled the wort to a few degrees warmer than my groundwater temperature.

Refractometer readings at this point showed the worts had achieved the same OG.

I proceeded to rack identical volumes of wort from each kettle to separate sanitized Brew Buckets.

The filled fermentors were connected to my glycol system, which dropped the temperature of each wort from 80°F/27°C to 62°F/17°C in just 10 minutes. I pitched a single pack of Imperial Yeast A10 Darkness into each batch then hit both with a 60 second dose of oxygen.

Both beers were showing signs of activity the following morning and I left them alone to continue fermenting. With diminished activity 5 days post-pitch, I raised the temperature of the beers to 68°F/20°C to ensure complete attenuation. Hydrometer measurements taken a couple days later revealed the FG of the beers was ever so slightly different.

The warm beers were transferred to kegs that were then placed in my keezer. After a couple weeks cold conditioning on gas, the beers were carbonated and ready to serve.

| RESULTS |

A total of 20 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer made with the roasted grains included in the mash and 2 samples of the beer made with steeped roasted grains then asked to identify the one that was unique. While 11 tasters (p<0.05) would have had to correctly identify the unique sample in order to reach statistical significance, only 7 (p=0.50) made the correct selection, indicating participants in this xBmt were unable to reliably distinguish a Stout made with roasted grains included in the mash from one where the roasted grains were steeped in the wort prior to boiling.

My Impressions: While my initial tastes of these beers made me fairly convinced I would be able to tell them apart, that just wasn’t the case. Out of 5 semi-blind triangle test attempts, I guessed the odd-beer-out just 2 times.

| DISCUSSION |

Steeping specialty grains in wort to add color and character is a common practice among extract brewers, though a seemingly rare method used by those who brew all-grain. On the surface, steeping grains is unnecessary when brewing all-grain, as it’s easy enough to simply include it all in the mash. However, for the brewer looking to easily produce more than one style of beer from one batch of wort, this is a handy approach, and the fact tasters couldn’t reliably tell apart a beer made in such a manner from one where the roasted grains were included in the mash suggests it’s viable as well.

Considering the non-enzymatic nature of the specialty grains used in these xBmt beers, it’s not terribly surprising tasters were unable to distinguish them. In both cases, which involved equal amounts of roasted grains being held at a similar temperature, the primary goal was extracting color and flavor rather than converting starch to sugar. These results seem to indicate this can occur equally as well in the mash as it can in hot wort.

I never doubted that steeping specialty grains worked well, but I was curious to see if it might have a noticeable impact on beer character as compared to mashing with grains. The fact it doesn’t appear to makes me all the more interested in playing around with this very simple method using various combinations of specialty grains. While having a kettle to boil each “batch” makes things easier, the Short & Shoddy BIAB brewer who’s comfortable letting wort sit around for a bit could probably get away with storing the remnant wort in an insulated cooler while the first batch boils. For the brewer looking for a little more variety in their beer life, this may be just the ticket!

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

31 thoughts on “exBEERiment | Roasted Grains: Full Mash vs. Steeped In Wort In A Foreign Extra Stout”

Was the steeped grains beer head consistently thicker than the other one?

No they were pretty much the same

Great experiment! Was literally thinking of doing this the other day during the summer when I have limited time to brew but want all my kegs full. Thanks.

So being the complete opposite results of Roasted Grains Part 4 (where you could tell a difference), could it be that darker malts would have given you a different result?

The methods used in pt. 4 were definitely different from this xbmt.

Quick question: Was there a mashout step after the saccharification? If not, there might have been just enough enzymes around to skew the results a bit.

I never mash out. There were certainly enzymes active in the steeped beer when the malts were added

Did you happen to take a pH reading of the worts after steeping the roasted grains? Just wondering if the pH ‘caught up’ to the full mash beer.

Very interesting. I’ve steeped grains overnight in ambient temperature water then removed the grains in the morning before heating up the mash water. The results are dramatically different then mashing the grains. Very little acrid flavor and reduced roastiness. Would be a fun future experiment.

Great experiment as always. How about cold-steeping overnight (in the fridge) and placing spent grain on top when flysparging (or discarding spent grain entirely) ?

Im going to try this with partigyle. I also wonder if this works best with the strong flavors of roasted grains. Either way the idea that we can take the 2nd runnings of our tripel and turn it into some kind of amber beer, or even a dry stout is appealing. Great experiment.

That is how I have done this. Mashing the big beer, after filling the first boil kettle I would toss the dark grains in the mash tun and put in fresh strike water and let them steep for 15-30 min.

Worked really well.

It is great to be reminded of things like steeping grains. Although the xbrmt was not significant, it sounds like a great technique to make multiple beers out of one wort for someone that struggles to find time for brew days. Even a great way to make smaller test batches by just splitting off a small portion of wort. Great job!

Btw, I was curious what you thought of the finished beer, taste wise? It seemed like a very simple stout recipe. I am guessing the xbrmt had some influence on the make up of the grist. Cheers.

I mean I thought the beer was pretty solid. I submitted it to a comp as a foreign extra stout and it didn’t score as well as I hoped, so I tried it next to Guinness extra, I think had I submitted it as an American stout it would have done better.

Overall stouts just aren’t my jam but it was good enough I’d drink a couple pints on a cold day.

Based on brewing many stouts and porters, I have found increasing your chloride to sulfate ratio to 3-1 or higher really makes the malt character pop.

Thanks for the feedback. I have only brewed one stout myself and wasn’t pleased with the result. I’m looking at brewing a porter/stout next and every bit of feedback I can get is helpful.

I’ve never heard of steeping grains in wort, always in just water. Why steep in wort, when steeping grains are done in water? I don’t think it’s an “apples to apples” comparison. Or I’m missing something? (more likely that).

As an extract brewer originally I steeped in wort sometimes (mixed LME with water prior to steeping) and in water sometimes.

This xbmt was really trying to see if you could get two different beers from one mash

Interesting exbeeriment!

Though it’s a bit impractical for the average brewer to use that method in order to create 2 beers from the same wort.

I think a follow up exbeeriment should be done in order to find out whether you can utilize steeped specialty malt in a bit of water that will be boiled separately or cold steeping and then making a triangle tasting.

Yes, that’s what I was trying to say. Steeping in the wort probably isn’t really all that different than mashing them, but cold steeping in water vs a warm water steep and then added to the boil may bring out some differences. I’ve really never heard of an extract brewing steeping in LME, since LME/DME are non diastatic anyway.

Really? I used to do it all the time before I switched to all grain. It was a Charlie Papazian endorsed technique back in the 90s. However, there were no BIAB baggies back then – can you say “staining your wort through the kitchen collander” boys & girls?

Twas a tad messy!

However, I tend to cold steep now when planning a partigyle brew as I can set it up a day or so before and save time on Brew Day.

Interesting! I love to split my batches for easy variety, this opens up some possibilities!

Has there been an exberiment yet on the difference between cold-steeping and hot-steeping? Or cold-steeping vs in the mash? That would be interesting… Thanks for another cool data point!

For all those asking, they did a cold steep vs mash in Pt 4 here: https://brulosophy.com/2017/12/04/roasted-grains-pt-4-cold-steeping-vs-full-mash-exbeeriment-results/

Awesome, thanks!

I’ll add my $0.02 in regards to Cold Steeping. At least 24 hours in the fridge. Add it to the cooling wort; preferably around 180 F. I’ve found through trial and error, if I really want a sharp, roasted flavor, I add the roasted malts to the mash for the final 30 minutes. Something a bit more tame, cold steeping is the way to go. FWIW, it takes me about 10 minutes to get the wort to 180 but then another hour or so to get to pitching/oxygenation temps.

This sounds like a good workable approach. I’ve had good results just steeping the grains overnight in the mash water at the ambient temperature of the water. I recommend double-bagging your crushed, roasted malts because they get pretty powdery and can slip through the mesh. In the morning, simply dunk the bag of grains a few times and remove the grains and proceed with the mash as normal. The harshness and astringency comes when the husk is exposed to the heat of the mash water. Removing the grains before heating the water solves this problem…assuming that’s what you are striving for.

Anytime I can save a step or two, I’m all for it. I will have to give that a try on my next porter. Have you ever steeped overnight in the sparge water?

I would be curious to see how the results would be on a RIS, since the roasted grain bill is larger.

Please, do an XBmt with Hop Mashing, this is such a controverse subject, totally deserves one!.