Author: Phil Rusher

Quality in, quality out. A common trope that applies as much to beer production as anything else. Over the years, brewers have learned that the best beer is made with high quality ingredients, and when it comes to yeast, quality is largely a function of yeast viability, which is the amount of living cells present in a given population. A method used by many brewers to improve viability involves propagation of yeast in a starter to increase cell counts, allowing for specific pitch rates based on the beer being brewed.

To be sure, yeast starters are miniature batches of beer, and there’s plenty of anecdote and even some evidence to suggest that reusing yeast from an actual batch works well. However, whereas brewers typically use just a portion of the remnant yeast cake to ferment a subsequent batch, a fairly commonly discussed approach among homebrewers involves racking fresh wort directly onto the entire yeast cake from a prior batch.

Assuming the yeast is fresh and not contaminated, reusing the yeast cake all but guarantees high viability, to the point some might be concerned about overpitching, which some believe can lead to a watery mouthfeel with lacking flavor. Furthermore, it’s not just yeast at the bottom of a fermentor post-fermentation, but all the other stuff that makes up trub from the previously fermented batch, all of which might have an impact on flavor. Still, the benefits of high viability, reduced lag, and saving some coin by not using a new pack of yeast are enough to outweigh risks for some homebrewers, many of whom report positive results.

I’ve tried my hand at reusing yeast cakes with varying degrees of success, though I’ve never done an actual comparison. Curious to learn more about this frugal method, I decided to put it to the test!

| PURPOSE |

To evaluate the differences between a beer fermented with the entire yeast cake of a previous batch and one fermented with a properly sized yeast starter.

| METHODS |

With the hope of accentuating any potential differences caused by the variable, I designed a very simple pale lager for this xBmt.

Perilous

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 25.6 IBUs | 4.4 SRM | 1.050 | 1.010 | 5.3 % |

| Actuals | 1.05 | 1.007 | 5.7 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Franco-Belges Pilsen | 10.25 lbs | 99.79 |

| Midnight Wheat | 0.35 oz | 0.21 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

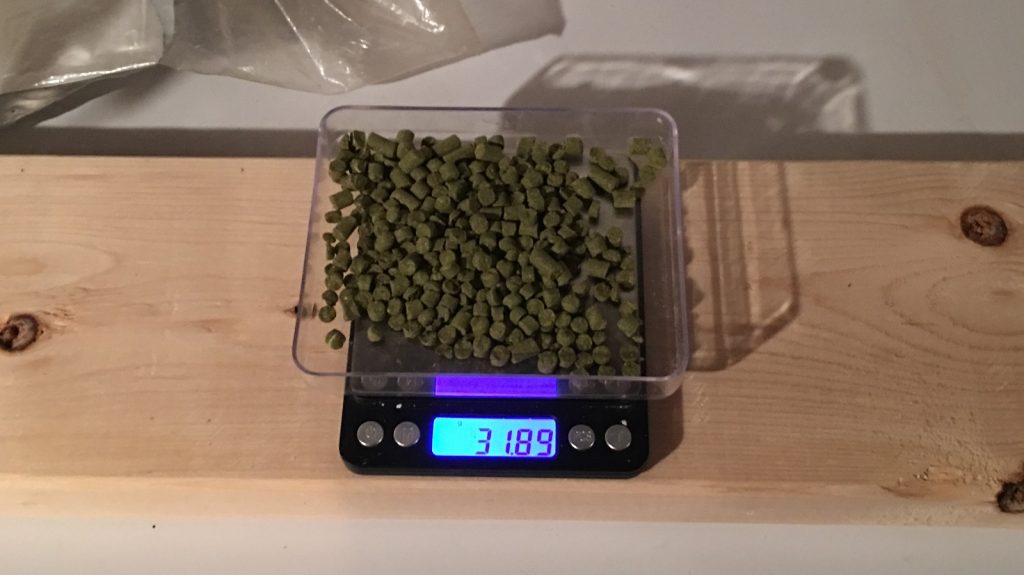

| Hallertau Magnum | 18 g | 60 min | Boil | Pellet | 10 |

| Hallertauer Mittelfrueh | 15 g | 10 min | Boil | Pellet | 3 |

| Saaz | 15 g | 10 min | Boil | Pellet | 3 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Urkel (L28) | Imperial Yeast | 73% | 52°F - 58°F |

Notes

| Water Profile: Ca 64 | Mg 0 | Na 8 | SO4 76 | Cl 60 |

Download

| Download this recipe's BeerXML file |

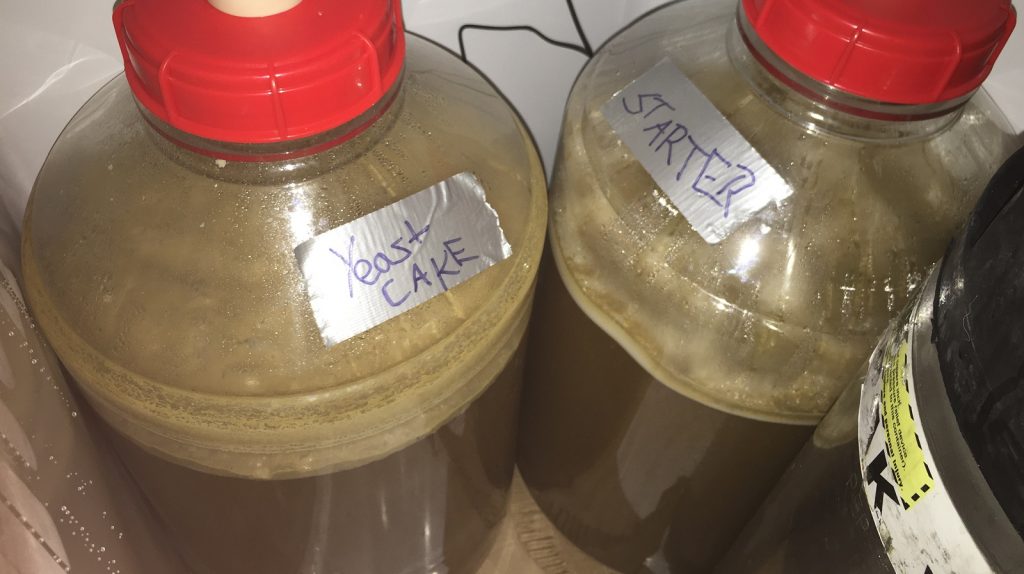

The actual start of this xBmt occurred 2 weeks beforehand when I brewed a German Leichtbier that I used to build up a yeast cake. Then, using a pouch of Imperial Yeast L28 Urkel from the same lot as the yeast used for the Leichtbier, I made a yeast starter a couple days beforehand.

On the morning of this xBmt brew day, I started the slow process of collecting RO water prior to leaving for work.

As soon as I got home, I hit the flame on my burner and adjusted the water to my desired profile. While the water was heating, I weighed out and milled the grain directly into a BIAB grain bag.

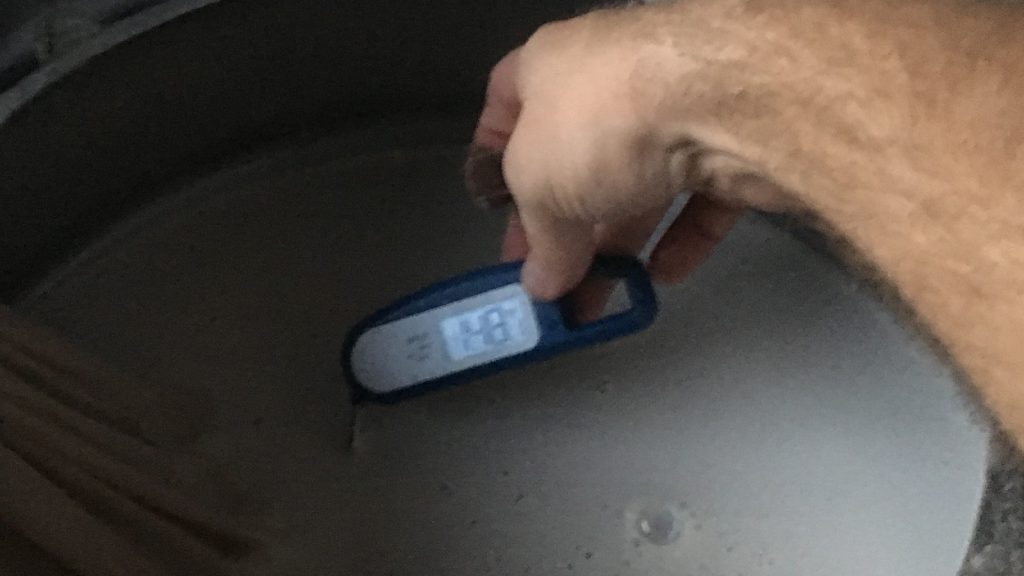

With strike temperature reached, I mashed in and gave the grains a gentle stir before checking the ensure I’d hit my target mash temperature.

At the end of the 60 minute mash rest, I removed the grain bag and allowed the sweet wort to drip into the kettle while I weighed out the kettle hop additions.

The wort was brought to a boil and hops were added per the recipe.

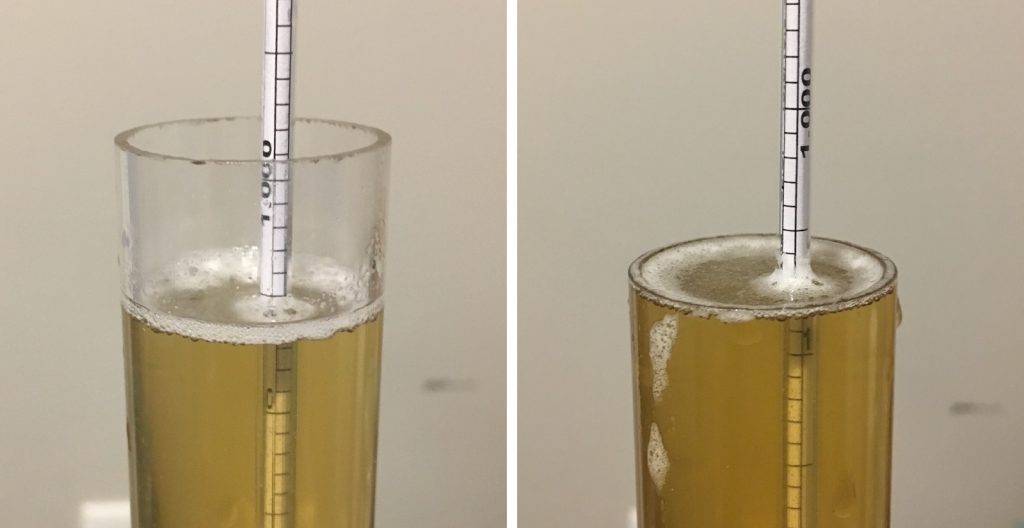

With the 60 minute boil complete, I chilled the wort with my homemade immersion chiller before taking a hydrometer measurment showing it was at the planned OG.

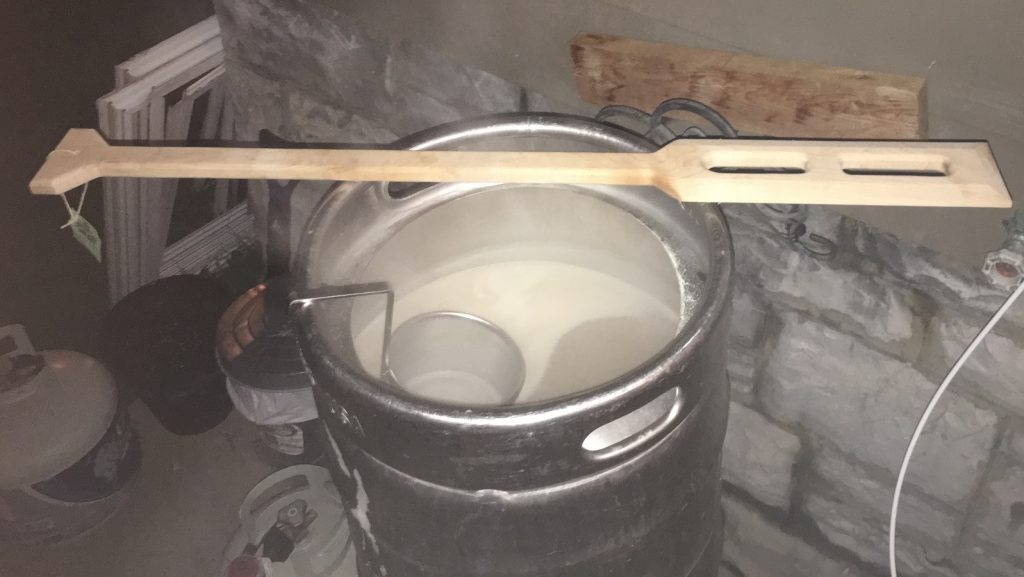

Due to my warm groundwater this time of year, the wort was still a bit warm, so I placed the entire kettle in my chamber to finish cooling to my target pitching temperature of 50°F/10°C. It was during this time I kegged the German Leichtbier, making sure to rid the fermentor of as much beer as possible while leaving behind a think layer of yeasty trub.

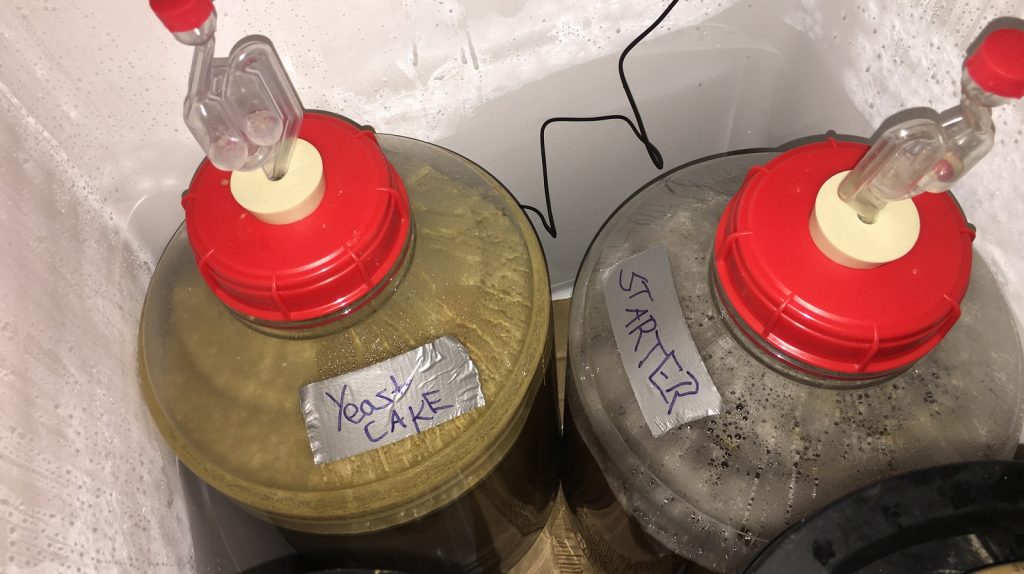

With the wort adequately chilled a couple hours later, I split it equally between the fermentor containing the yeast cake and an identical empty fermentor, that latter of which the yeast starter was pitched into. Things were looking quite different right off the bat.

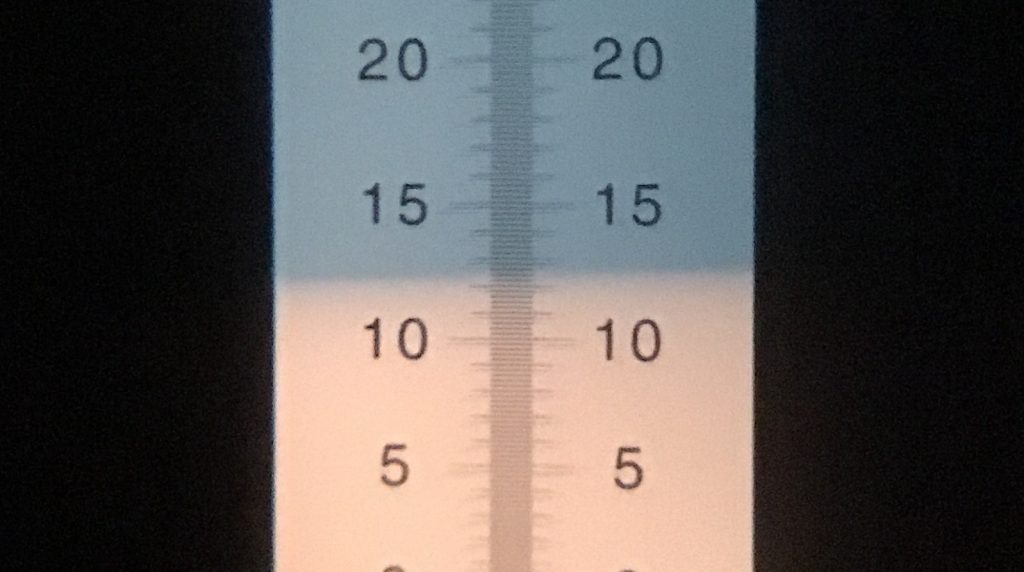

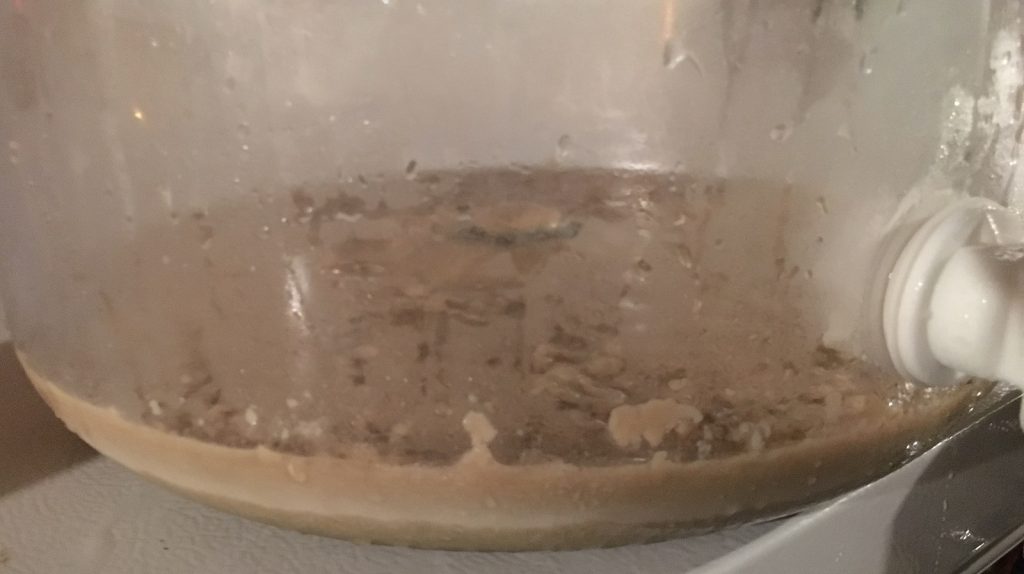

The beers were then left to ferment at 53°F/12°C and, predictably, the yeast cake beer began showing signs of activity before the one pitched with a yeast starter.

At just 12 hours post-pitch, the yeast starter beer had developed a healthy kräusen.

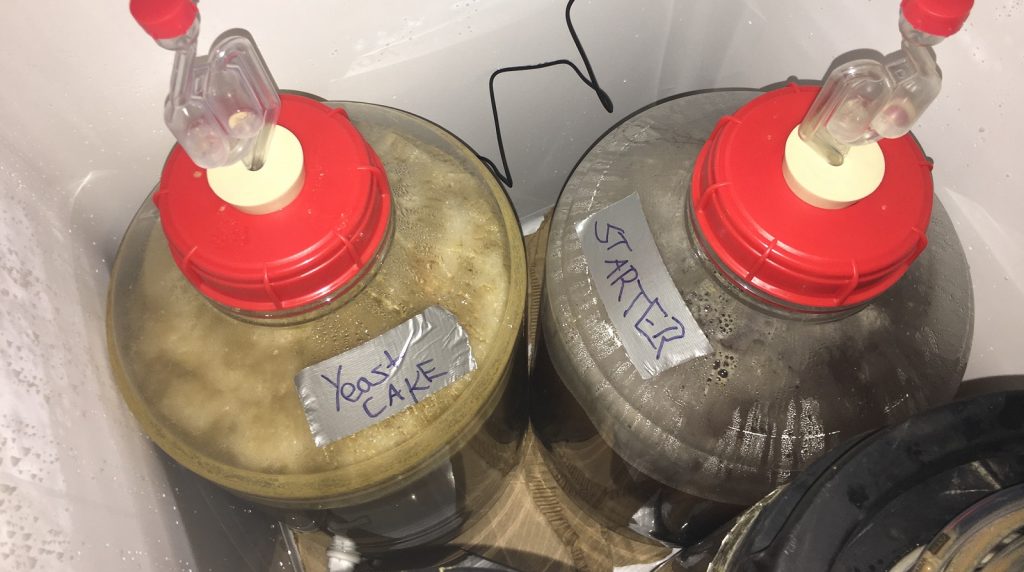

After 2 full days, the beers were beginning to look more similar than different.

Both beers were showing signs of reduced activity on day 6 of fermentation.

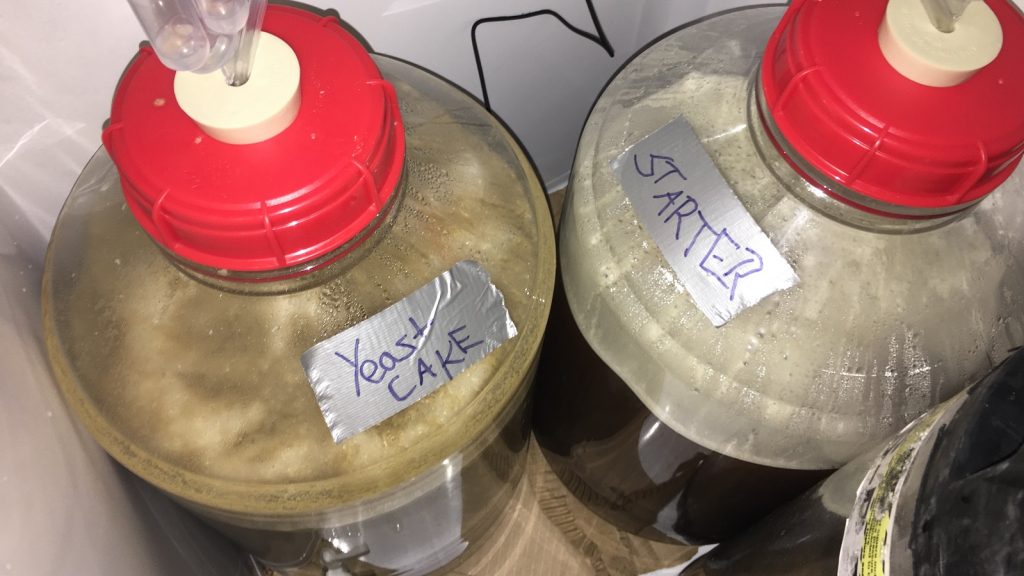

I left the beers alone for 5 days before ramping the temperature up to 63˚F/17˚C for a diacetyl rest. After a few more days, I took hydrometer measurements showing the yeast cake beer had a slightly lower FG than the beer pitched with a yeast starter.

I dropped the temperature for cold crashing and fined both beers with gelatin, returning 2 days later to package.

The beers were placed in my cool keezer and burst carbonated over 48 hours before I reduced the gas to serving pressure. After a 4 week lager period, the beers were ready to serve.

| RESULTS |

A total of 25 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the beer fermented with the yeast cake from a prior batch and 1 sample of the beer fermented with an adequately sized yeast starter in different colored opaque cups then asked to identify the unique sample. While 13 tasters (p<0.05) would have had to identify the unique sample in order to reach statistical significance, 16 (p=0.002) made the accurate selection, indicating participants in this xBmt could reliably distinguish a pale lager fermented with a full yeast cake from one fermented with a yeast starter.

The 16 participants who made the accurate selection on the triangle test were instructed to complete a brief preference survey comparing only the beers that were different. A total of 5 tasters reported preferring the yeast cake beer, 7 liked the yeast starter beer more, 1 person had no preference despite noticing a difference, and 3 reported perceiving no difference.

My Impressions: During early samplings, I wasn’t sure I was going to be able to tell these beers apart, but out of the 5 triangle tests I attempted, I chose the odd-beer-out every single time. To me, the yeast cake beer was dominated by a green apple character reminiscent of acetaldehyde, pushing any malt and hop flavor to the background. I perceived the yeast starter beer as having a bready malt flavor with low spicy and herbal hop character, and an appropriate touch of sulfur in the nose.

| DISCUSSION |

Pitching an adequate amount of yeast is thought by many to be one of the most important components to producing good beer, hence the popular use of yeast starters. While underpitching yeast is ardently believed to be the cause of many faults, the potential perils of pitching too much yeast is a bit understated, with some claiming it’s nearly impossible to achieve on the homebrew scale. Arguably, reusing the entire yeast cake from a previous batch of beer is one way to do it.

Practically speaking, racking wort onto a yeast cake has numerous benefits– the yeast has high viability, the brewer isn’t spending money on a new pack of yeast, and less cleaning since the (hopefully uncontaminated) fermentation vessel gets reused. The numerous positive reports from brewers using this approach clearly suggests it’s a valid option, even if tasters in this xBmt could tell apart a beer made in such a manner from one pitched with a standard yeast starter.

Considering these results, I can think of a couple possible contributors to the difference noticed by tasters, the first being overpitching. Some tasters noted a distinct tart apple-like character in the finish of the yeast cake beer, which matches my experience, leaving me wondering if perceptible levels of acetaldehyde were present. Meanwhile, this character was absent in yeast starter beer, which I experienced as cleaner overall. Based on the results of the latest kettle trub xBmt, it also seems plausible all of the residual trub in the fermentor was the culprit. The fact the yeast cake beer ended up noticeably more clear provides some support for this hypothesis.

Adding this to my past experiences with reusing yeast cakes, I’m not convinced it’s the method for me. That said, I am curious to see how things would play out with different yeast strains or higher OG beer styles. Until then, I’ll be sticking to more normal pitch rates.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

37 thoughts on “exBEERiment | Yeast Pitch Rate: Yeast Cake vs. Yeast Starter In A Czech Pale Lager”

I do not doubt the results of this xBMT. But I question using a sponsor’s product in a comparative analysis as being scientifically unbiased. Just a thought. Love the Podcast and this website.

I’m not sure how that matters at all, as we kept everything else constant. TETO.

I’ll echo the original commenter about this xBMT in that it is clearly a significant xBMT and a useful finding. I’ll also add that as most experiments have greatly been done with a small subset of products, e.g. Mecha Grade malts and Imperial Yeast, it limits some of the value of the findings as values over brewing as a whole. That all being said, please take what I say with a grain of salt as the opinions of one person. I appreciate the work you all do.

Well they have to use some product, and each experiment would only be using one, so whether they use one companyi or a mix of them doesn’t really effect the validity of the experiments. If anything the standardization of products could yield more reliability to the results themselves.

-another grain of salt

I practice reusing the yeast cake quite often but have never done a side by side comparison. That being said, the conditions where I repitch are very different. When I do it, I repitch into a progressively darker and/or hoppier beer. Also, I don’t just rack the beer on top to avoid cleaning a vessel and potentially introducing unwanted flavors from fermenter gook. I leave a little bit of beer in the bottom to swirl up the yeast cake and pitch that into the next batch which had the wort collected in a freshly cleaned, freshly sanitized vessel.

For example, I just did a 3-beer series with WLP001 starting with a Blonde Ale, repitched to an American Brown, repitched to an Imperial stout. Last year I also did a Blonde to a pale ale, to an DIPA. No overt off flavors were detected by my brew club which consists of about 50% BJCP judges.

Reading this makes me a bit curious to try a triangle test of my own but using the “darker/hoppier” approach I’ve used since starting this. Great read though! Makes me wonder if I just sort of stumbled into an effective way of doing the repitch without realizing it.

Yeah when we were thinking about what we wanted to do and potential beer styles to test the whole lighter –> darker and less bitter –> more bitter thing came up too. To be clear, this can work, and it can even work out really well sometimes. But this is one of the many commonly believed anecdotes that no one really has any data to support, but rather, it’s a thing everyone says because they hear somebody else say it.

I’ve never tried yeast washing or doing anything resembling the swirl method you mention. That sounds kind of like what I think is a more common approach: rack as much beer out of the FV as you can, add sterile water to trub/yeast cake, swirl, allow the trub to settle until you see stratification then pour out the less flocculent and supposedly healthier yeast that remain in suspension into another vessel.

My feeling on this too is repitching has its place. When you’re planning a really big beer like a Barley Wine, Russian Imperial, etc. the starter volume has to be so massive you’re pretty much doing a 5-gallon-ish beer anyway. For these kinds of big beers repitching is planned and not just a convenience.

I do try to avoid overly hopped beers in the middle of a repitch run to limit the trub using my method. I supposed if I was really concerned about it, I could do the washing method. What I do is pretty much the RDWHAB version.

*RDWHAHB

I have many times pitched wort onto a freshly racked fermenter, right on the full yeast cake. But I never did a side-by side like this. I always see rapid take-off as shown in this experimented. The LAST time I did this howere, I think I must have either introduced something when racking in the fresh wort, or they may have been a contaminant lurking in the cake after the previous beer. The second beer, (a stout) finished out, and I left it for another week or two to clean up. Then I noticed some signs of a pellicle forming on top.

Fearing a ruined stout, I went ahead and tasted, and kegged it. No sour notes at all, but it was a coffee stout and I wonder if the roastiness from the malts and the acidity of the coffee may have masked it.

Either way, both beers turned out fine, but I am definitely going to put my direct yeast-cake pitches on hold for awhile…

Thanks for doing the side by side. There is so much going on here. First I can say that I have repitched yeast for years, but I never once pitched into a dirty carboy. It seems frought with problems. Also for ales if the carboy is filled enough much of the trub sticks to the neck. (A good exp. to try is high fill versus lower fill in a carboy and test the difference)For years I would just collect the cake in a mason jar and reuse within 7 days. Since I carried over trub I became concerned after two or three reuses that the next beer would pick up off flavors. Now I will repitch the 2nd and 3rd gen then discard. Sometimes I wash with preboiled water but then do a starter if the yield is low. While trub removal results in small changes in flavor profile, IMO, for the fermented brew, it does help keep yeast clean for repitching. Another aspect I try to do for big beers is take the yeast slurry and do a small starter the night before, just to get it going. Lastly I would love to know from the yeast companies what nutrients are missing or low after first pitch. Do we double up on nutrient? Do nothing ? Or something else

When you use nutrients sold by the yeast manufacturers, it’s often just dead and dehydrated yeast, so you’re primarily looking at cell wall components. But yeast are a hearty bunch and they can usually scavenge what they need to survive from what the grain/water/fermentor headspace provide.

Question regarding your carboy to keg transfer method. My setup is nearly identical (I have a 1/2” spigot and tube.) However I can’t seem to avoid tiny bubbles forming in tubing at the spigot and near the keg post. I’ve tried with clamps/without. I’ve tried with airlock in/out. I even fitted airlock so I could slowly feed CO2 and create a positive pressure. Nothing prevent bubbles. Any help is greatly appreciated.

Yeah, those areas are the worst with this because of the turbulence generated by transferring from one vessel to another. A few things come to mind for this:

1. Unless you purge the line before hooking it up to the keg/carboy, you’re going to have a small amount of air in the line that feeds the keg. This amount of air is, in my experience, small enough to ignore.

2. You’ll want to make sure that there is adequate air entry in the top of the carboy to facilitate transfer of beer to the keg. I didn’t do it with this one, but I often do this by removing the airlock and covering with a paper towel sprayed with Star San.

3. You can fiddle around with the tube while you’ve got the spigot open. Just bend it up a little bit until the bubbles disappear.

Oh, also, check out the diameters of your tubing vs your spigot and whatever you’re using to attach to you disconnect on the keg. I use swivel nuts with barbs and I like to make sure that the barb only enters as much of the tubing as it needs to – having the barb stick too far in will generate turbulence. Same with the spigot on the carboy.

I too pitch onto yeast cakes but like many I reduce the amount of slurry I am pitching onto by the swirl method. But I usually pour the excess yeast into a jar to save and then pitch into the used fermentor on whats left. I make a conscience effort to pour off the hop matter and proteins of the trub and focus on saving the denser yeast cake itself. Could never bring myself to pitch onto an entire cake. That just looks like too much!

I have reused yeast cakes for years.Along with Jameson’s comment about always darker and/or hoppier, fermentation chamber has to be kept cooler on ale yeast cakes. I typically start ales at 65 degrees F and ramp up after a couple days to 70. With a yeast cake, first two days are at 60, then ramping up.

Like many others, I’ve re-pitched onto a full yeast cake many times and I’ve never noticed a problem except one time when the original beer turned out to have some kind of weird off-flavor and the second beer had the same. I think that one had a contamination of some kind in the first batch.

What I will often do, and just recently did with 10 gallon batch of Mexican Pale Lager, followed by a 10 gallon batch of Vienna Lager is this:

First, I make the 10 gallon batch of the lighter lager. When I’m kegging that, I put 5 gallons of fresh wort from the second been into one of the old fermenters and stir it well to mix up the yeast, trub, and new worth. I then rack half of that into a second fermenter and fill both fermenters back up with 2.5 gallons or so of fresh wort. Basically, I’m splitting the entire yeast cake of a 5 gallon batch in half for two more 5 gallon fermenters.

My recent 10 gallons of Mexican Pale Lager (a Pacifico clone) followed by Vienna Lager are two of the best batches of beer that I’ve made in hundreds of batches over 7 years.

Ya makes sense this would work out well. It’s the same concept as what I do – dumping half the yeast cake before racking on the second beer. Should help avoid over pitching.

Chris M: hello, this is an old post but I wonder if you read this, if you wouldn’t mind sharing the details of your Pacifico Clone recipe. I have been trying to brew something similar for a while. I am thinking pils malt with 5% wheat and adding a bit of Cascade, because to my palate there seems to be a bit of american hops in Pacifico. Also, I use a similar approach to yeastcake reusing-3 generations. I also had contaminated batches but I traced it to carboys that were not properly sanitized and beer from yeast cakes always tastes fine. Anyway…Thanks for reading.

Sure. For a 5.5 gallon no chill batch: 3 lbs pale malt, 3 lbs Pilsner malt, 3 lbs flaked corn, 1/2 lb wheat malt. 3 grams calcium chloride and 3 grams gypsum. 1/4 oz Magnum for bittering. 1 oz Hallertau as it goes into the no chill cube (which is often equated to a 20 minute addition). Used Imperial Organic Que Bueno Mexican Lager yeast for that batch. Mashed at 148 for this batch and I do BIAB. I think I fermented for two weeks at 154 and then rose to 162 for 3 days before kegging.

Awesome, thanks Chris!!! I am giving this a shot next…Cheers!

One thing I didn’t see mentioned (and please let me know if I missed it) is the oxygen level or aeration of the worts at pitch time. I see the yeast starter sitting on a stir plate. This implies to me that these yeast are well aerated, fully roused, and reproducing. Could there be an issue where the starter yeasts are young and vigorous (these teenagers are ready and willing) whereas the yeast cake cells are in a different phase of life, like middle aged (not interested much in reproducing but very willing to take part in an all you can eat buffet)? I have read that yeast cells have many life phases and react differently to different environments.

Love your work. Keep on testing and have a homebrew.

I re-use yeast all the time…….I fill a smaller steril Jam Jar with slurry (300ml), put it in a plastic bag with some ethanol. The later is to make a vapor-like ethanol atmosphare there secure that any un-tight lid do not give issues! This yeast-slurry I add till a 24hours vitalitty starter (small amount of boiled wort) and let this starter have fun for 24 hours wiele the wort cools down overnight! I re-use the yeast mostly, and sometimes if I think it wnet bad, I have re-waken yeast from 2-3 bottles and used them even 6-12 motnhs old in bottled!

Just did the later on 1316 London ale from this Janauary and added yeasterday evning, and it was in full vigor this morning at 22´C!

I guess I have been on 5-6th generation for some now, incl. the bottle trick!

……forgot, if re-starting from old bottles, I have an additional step in between, eg.. regrows it once over 4-5 days, before adding it to the vitaility starter!

” 3 reported perceiving no difference.”

If these 3 of the 16 who perceived no difference doesn’t it make sense that these 3 didn’t perceive a difference the first time and just guessed correctly which means that perhaps only 13 people could tell a difference?

I know 13 still gives a p of >.05 but there is a notable difference between .002 and .05. I don’t know anything about how to do statistics but I do know that .002 is 25 times smaller than .05 and that seems like a big difference.

Statistics accounts for people who were guessing.

There’s an entire podcast with the Master Brewer’s Association where they interview a woman who talks at length about an acetaldehyde issue that was plaguing their brewery (but inconsistency). It would go away, and come back. It took them a while to determine exactly what was happening, but they determined it was actually the result of over-pitching. This is an important one, I think.

What was the original and final gravity of each?

Nevermind. U gave that info. I’m slow.

Very interesting, thank you.

I made a lager last year, overpitching by 100%, ie, 4 packs of dry yeast 34/70. These were expired packs, and I thought the overpitch would do no harm. The beer finished with green apple flavor, which required krausening to fix.

Right on. I’ve never used expired yeast but I’ve heard folks say that the dry expired yeast works just as well as the packs that are not expired. And you saw an improvement after krausening? How was the beer after that?

Hi Phil

The beer improved, but not as much as I would like. I cannot say for sure if the kausening or time cleared the green apple, but it went away. The beer still was not as crisp as I wanted. I’ve only made two lagers lagers, both were acceptable but need improvement.

This Xbmt has come at a great time for me as I have just done a similar experiment. My daughter was visiting for a few days from London and really wanted to make a beer with me. My problem was that both fermenters were full so I had no where to put the wort. I decided to dump the hot wart into a spare keg and use the “no chill” method. This I did which resulted in storing only 19 litres of wort. I use SS brew tech conical fermenters which I normally fill to 23 litres or so to net down to 19. I decided to rack the new wort (a porter) onto the trub/yeast cake and a small amount of the pale ale that I had just kegged. This I surmised would result in a full 19 litres after fermentation. I poured the now cold (20 deg C) wort into the fermenter with as much gusto as I could without splashing it all over the place and then set it back in the fermenting fridge. After 7 days I took a sample that was completely cloudy with yeast and trub. After settling for an hour it revealed a drop from 1.055 to 1.020. I waited another few days and crash chilled to 4 deg C to settle out as much as possible. It was clear at next inspection. I have subsequently kegged and carbonated this porter and it is tasting better than I expected so I have to conclude that using an old yeast cake is a good way to save money and time.

I have often used low gravity-low hop yeast cakes as a base for very high gravity beers (>= 1.100). In this scenario. This experiment is very different from the one reported here. It would be interesting to see a side-by-side comparison in this setting.

This is a great site. Keep up the excellent work people.

Hi,

I guess one important aspect here is how much trub you have left in the fermentor from the previous brew?

How did you filter the vort going into the fermentor

I have crystal clear vort into my fermentor when brewing lager, and I have good results from pitching on the yeast cake.

Right, I think that there is some room to think about how wort clarity might affect any beer really, but perhaps more so in the case of pale lager. I have never filtered wort for any of the beers I’ve made, rather I usually rely on whirlpooling if I want clear wort. That said, this particular yeast cake came from a Short & Shoddy pale lager I made and it contained a moderate amount of trub from the boil kettle.

For what it’s worth I’ve been doing some serial repitching with my unitanks after dumping some of the yeast/trub. It’s a great way to make beer.