Author: Marshall Schott

Freshness of ingredients is viewed by brewers as being key to the production of delicious beer. Unfortunately, it’s not feasible for most to use all of their ingredients in their absolute freshest state, and thankfully there are methods that can be employed to extend their shelf-life.

A common recommendation when it comes to grain is to use it as soon after it’s milled as possible, as exposing the innards of malt purportedly expedites the staling process. A web search for “crushed malt shelf life” returns myriad hits suggesting once malt has been milled, the brewer has a window of about 2 to 4 weeks to use it before they’re assured poor results.

Despite my inability to find any real consensus on what exactly stale malt flavor is, I chose to accept this idea as truth and used it as motivation to buy a grain mill. The ability to crush malt immediately before mashing in was enticing, just another thing I could do to ensure I was making the best tasting beer possible. It wasn’t until I brewed a rather tasty beer using malt that had been milled years prior that I began to question this belief, to the point I figured it best to test it out in a more official capacity.

| PURPOSE |

To evaluate the differences between a beer where the malt was milled 6 months prior to being used and the same beer where the malt was milled immediately before use.

| METHODS |

For this xBmt, I wanted to make a beer that included more than just a pale base malt but wasn’t so characterful as to cover up any impact of the variable. Altbier seemed a perfect fit in both flavor profile and name.

Altschule

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 35.2 IBUs | 12.7 SRM | 1.051 | 1.014 | 4.9 % |

| Actuals | 1.051 | 1.012 | 5.1 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pelton Pilsner-style Malt (Mecca Grade) | 6.5 lbs | 60.82 |

| Metolius Munich-style Malt (Mecca Grade) | 1.75 lbs | 16.37 |

| Vanora Vienna-style Malt (Mecca Grade) | 1.75 lbs | 16.37 |

| Caramel/Crystal Malt - 15L | 8 oz | 4.68 |

| Gladfield Light Chocolate Malt | 3 oz | 1.75 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 20 g | 60 min | Boil | Pellet | 12.9 |

| Hallertauer Mittelfrueh | 30 g | 15 min | Boil | Pellet | 2.4 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Kaiser (G02) | Imperial | 75% | 56°F - 65°F |

Notes

| Water Profile: Ca 71 | Mg 1 | Na 10 | SO4 100 | Cl 50 |

Download

| Download this recipe's BeerXML file |

On April 9, 2018, after settling on a recipe, I weighed out two identical sets of grain and milled only one batch.

Both sets of grains were then placed in plastic bags.

After squeezing out as much air as possible, I sealed each bag with a double-knot then placed them in a dark and dry area of my garage until September 23, 2018, nearly 6 months later. I prepared for this dual batch full volume BIAB brew day by collecting identical amounts of filtered tap water in separate kettles.

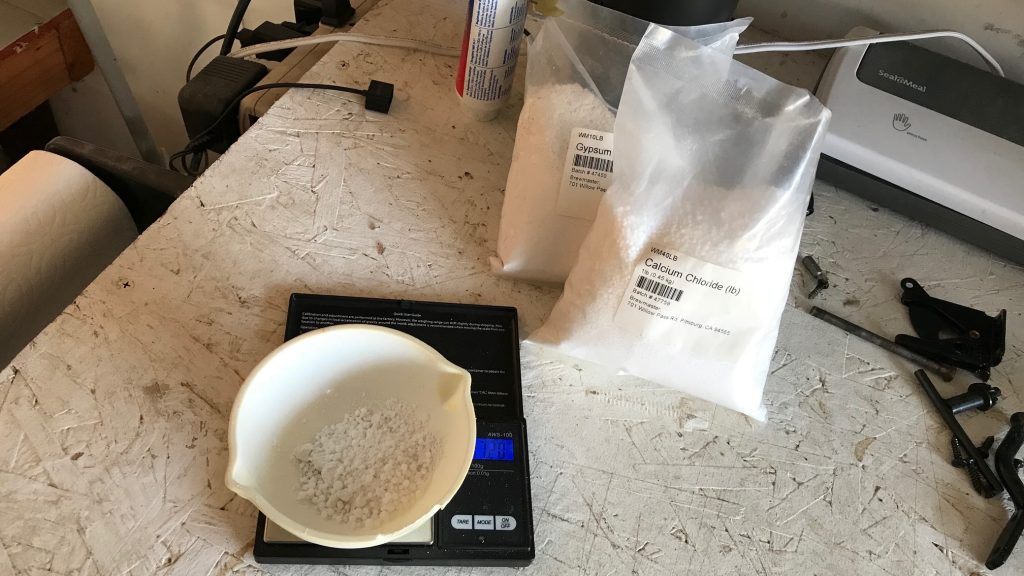

Each volume of water was adjusted to my target profile using identical amounts of minerals.

Staggering the start of each batch to keep things from getting too hectic, I mashed in the pre-milled grains before milling the other set of grains, which were mashed in 20 minutes later to achieve the same target mash temperature.

Each mash was covered and left to rest for 60 minutes.

During the wait, I measured out the hop additions for both batches.

At the completion of each mash, I removed the grain filled fabric filters, allowing them to drip until the same pre-boil volume was reached in each kettle. The worts were then brought to a boil with hops added as indicated in the recipe.

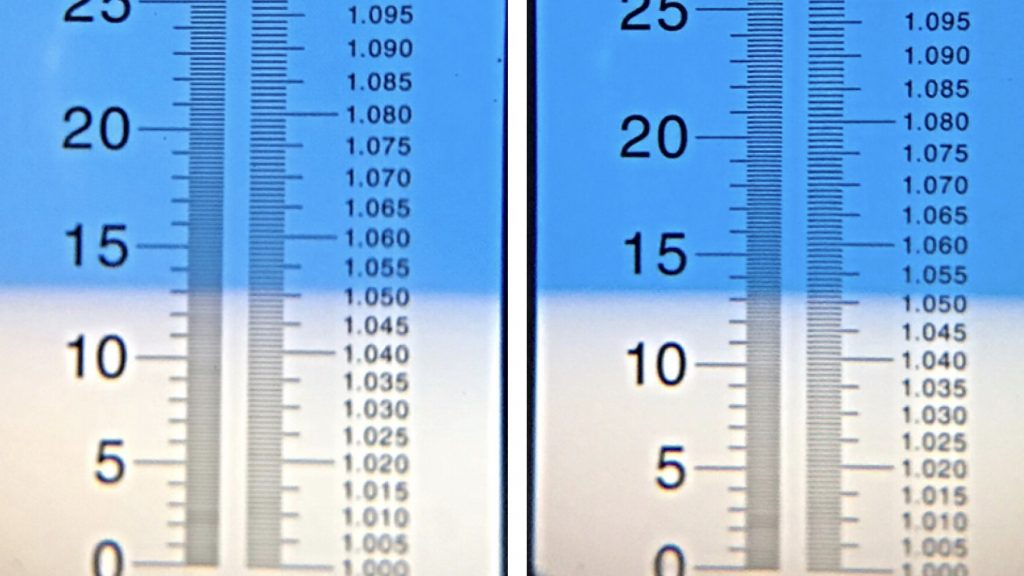

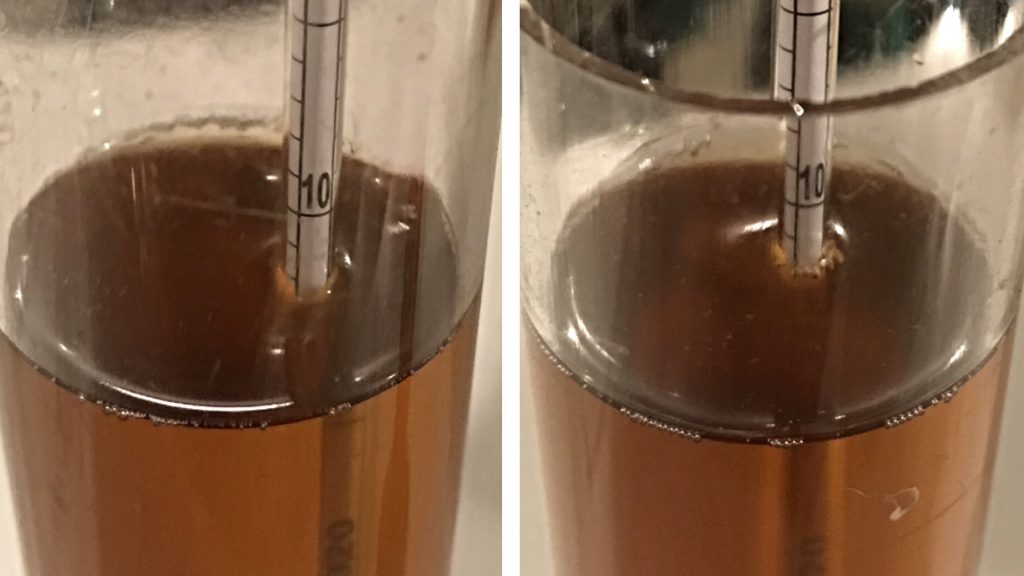

At the end of each 60 minute boil, the worts were quickly chilled before I took refractometer readings showing they’d achieved the same OG.

Each batch of wort was then racked to a sanitized Brew Bucket.

It took about 3 hours in my cool chamber for both worts to stabilize at my target fermentation temperature of 66°F/19°C, at which point I direct pitch a single pouch of Imperial Yeast G02 Kaiser into each batch.

Airlock activity was observed the following morning and both beers appeared to ferment similarly henceforth. At 2 weeks post-pitch, fermentation activity was absent and I took a hydrometer measurement confirming both beers had reached the same FG.

I reduced the temperature in the chamber to 34°F/1°C for a 2 day cold crash before kegging.

The beers were burst carbonated overnight and allowed to condition for an additional week before being served to unsuspecting participants.

| RESULTS |

A total of 26 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the beer made with malt milled 6 months prior to being used and 1 sample of the beer made with freshly milled malt then asked to identify the sample that was unique. While 14 tasters (p<0.05) would have had to correctly identify the unique sample in order to reach statistical significance, only 11 (p=0.22) made the correct selection, indicating participants in this xBmt were unable to reliably distinguish an Altbier made using malt milled 6 months prior to use from one made using malt milled immediately before use.

My Impressions: Given the time that went into preparing this xBmt, I wanted to make sure I gave it a fair shake and attempted 12 semi-blind triangle tests over a 2 hour period, the only alcohol consumed being the beer from the test samples. Despite engaging in various exercises to reset my palate, I selected the unique sample on 4 of my attempts, exactly 1/3 of time, which aligns rather nicely with random guessing. To my palate, the beers were identical in aroma, flavor, and mouthfeel, which was a good thing considering they were also quite tasty examples of Altbier.

| DISCUSSION |

It’s not uncommon to hear from a homebrewer who picked up the ingredients for a batch only to have plans suddenly change and their brew day postponed, typically leading to questions about what to do with their milled grain. A valid concern for the quality conscious that’s often met with a recommendation to brew with it within 4-6 weeks in order to avoid problems.

The idea that milling grain reduces its shelf-life is rampant in brewing circles, likely playing a role in many a brewer’s decision to purchase their own mill. It makes sense, on some level, that keeping the starch encased inside a rigid shell might have a preservative effect by limiting its exposure to oxygen. Indeed, one of the more commonly cited issues in regards to using pre-milled grain has to do with staling, which is a function of oxidation.

The fact tasters in this xBmt were generally unable to tell apart an Altbier made with grain milled 6 months prior to use from one made with freshly milled grain calls this idea into question. If milling expedites the staling process in the manner so often discussed by brewers, one would expect the beer made with freshly milled grain to be noticeably different in character than the one made with pre-milled grain. But that didn’t seem to be the case, the beers were arguably more alike than not, suggesting any impact of time influenced both sets of grain similarly.

During one data collection session, a participant who correctly identified the unique sample in his first triangle test, feeling confident in his ability, asked to be retested, to which I happily obliged. After studying the aroma, flavor, and mouthfeel of each sample in this second round, the taster indicated with sureness the odd-beer-out. Except this time he was wrong. The discussion hastily moved away from the variable in question…

This being the second time I’ve brewed with old milled grains to produce a beer I enjoyed drinking, I can’t help but wonder how the idea that milled grains demand immediate use came to be accepted as fact by so many. In searching for an answer online, all I could find were anecdotal reports from forum users and recommendations from homebrewing authorities, but no actual experiment findings. As an owner of a mill who keeps bulk grains on hand, this isn’t an issue that necessarily applies to me, but these findings will influence my response to questions regarding what to do with 3 week old milled grain.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

49 thoughts on “exBEERiment | Impact Using Old Crushed Malt Has On Altbier”

I’ve sort of commented in this vein before….you guys keep doing experiments where the results indicate that the variable causes no significant difference. You set up the experiments with a negative control but there is no positive control! Doesn’t it make sense that the tasters should trained to identify the thing you want them to be tasting for? Do a positive and a negative control and then ask the tasters to rate where in the middle the beer you are testing for falls. Yes this is going to require making three batches and one of them is probably going to be “godawful” but I could imagine running the horrible batch at small scale or bottling the control batches and then doing a series of experiments each with various degrees of your variable in question and using the same controls for each. In other words, if your goal is to find out what stale malt flavour is, then why not a) make a beer that is absolutely going to have stale malt and then b) dial it back and find out how much you can get away with until it isn’t noticeable. Right now, based on your experiment, we have a hunch that six months is ok but are concerned that maybe your tasters didn’t know what to look for (among other concerns that not doing a positive control will generate)

This is an important suggestion. The nature of these experiments are to produce a boolean, yes or no, answer. This is valuable, but has its limitations. Its been suggested that a lot of what we do in brewing is a belt and suspenders approach. Meaning a lot of rules that help produce good beer. Removing just one will not by its self kill the beer. Or in this case, one rule taken to a certain level instead of a more extreme level, is unlikely to produce a poor result.

I think these tests have been amazingly valuable in ridding poor ideas and shinning light on more mystical aspects of brewing. I think there is room now to take the tests to the next level.

and how do you propose these tests get “taken to the next level?”

Can’t agree more with you on this one. All these experiments do is indicate how sensitive the tasting panel is to the variable in question. Not surprisingly the answer is usually ‘not very’.

The fact that the tasters “didnt know what to look for” is a good thing. It means their tasting experience is genuine and isnt influenced by what they are “looking for”. Also, if they enjoyed the beer even at 6 months after milling, it means that you can make good beer with grains milled at least 6 months prior to brewing. Which is a good finding since a lot of home brewers tend to be paranoid about things that maybe arent a big deal.

I don’t think it’s the pre-milling that would be the problem, but exposure to air–specifically, moist air. And from what I know, it would be a reduction in enzyme activity, not necessarily taste. So all-malt beers wouldn’t be a problem, typically.

As a beginning brewer, I’d order 2-3 kits worth of pre-crushed grains at a time… then life would happen and it would be months before the last all-grain beer kit would get brewed. The bag of grains would sit in the box under the bench in the kitchen, until brew day. I always felt this underlying tension that I wasn’t getting to brew the beer these crushed grains represented. In the end, the beers came out great (my goal is making tasty beer at the $20/case price point). I’m glad to see, while I was violating convention, my experience is similar to this exbeeriment. 🙂

This post came right in time. This weekend I brewed an English Brown Ale with over 6 months old milled grains. The wort tasted excellent; gonna wait and see how the finished beer will taste.

Well I brewed a Saison last weekend where the best before date on the bag was last April and I have 2 bags of crushed pale malt which are best before 2020 and who knows when it was crushed. These crushed grains could therefore have a best before life span of 2 to 3 years! These are not even vacuum packed bags so there would still be oxygen in the bag for any affect to take place. As it happens I don’t plan on leaving it around that long.

A key part of your experiment was that you stored the milled grain in a well sealed container and removed excess air from the bag. Some LHBS I have used provide the milled grain in brown paper bags vs plastic bags which I would feel are less than desirable for long term storage. One LHBS near me (which unfortunately closed) used plastic bags and I picked up multiple brew sessions of milled grain at their closeout sale and even after a couple months that grain/beer was fine. My recommendation to others, confirmed by this experiment, is to store the milled grains well and they are good for a couple months at least. Thanks for further confirmation.

I’ve never had problems with crushed grain staling. I guess it could absorb moisture if stored somewhere humid & then get mouldy, but I think paranoia about oxygen is unwarranted. If it was a significant problem, people would crush their own “fresh” flour for making bread/cakes etc.

I think there’s an element of post-purchase rationalization involved in advice on techniques involving brewing equipment. Anyone who’s invested significant money or labour in brewing kit is likely to be biased in favour of its merits, whether or not it actually makes a difference, and then spread the word on forums etc. Hence brewing fridges for temp control, grain crushers for the “freshest” beer, wort chillers for the clearer beer, thermapen thermometers because mash temp is critical, kegging becaused kegged beer is superior to bottled beer, etc. etc. As the short and shoddy series shows it’s not hard to make good beer with simple gear and techniques.

This post is a great example of the statistical methodology issues I brought up on Thursday.

The non-significant result of this xBmt does not indicate that tasters are “unable to reliably distinguish an Altbier made using malt milled 6 months prior to use from one made using malt milled immediately before use”. It just indicates that we can’t say with certainty that tasters can distinguish the beers.

The following statement is also incorrect: “The fact tasters in this xBmt were generally unable to tell apart an Altbier made with grain milled 6 months prior to use from one made with freshly milled grain calls this idea [that milling grain reduces its shelf-life] into question.” The non-significant result actually does nothing of the sort.

This xBmt probably should have been designed to test whether milled and un-milled grain are equivalent, but it was instead designed to test whether they are different. When trying to test for equivalency in the future, it might be worth looking into the two one-sided tests procedure: http://journals.sagepub.com/doi/10.1177/1948550617697177

Anyhow, I’m looking forward to hearing more about the discussions with statisticians that Marshall mentioned to last week!

This is exactly my issue with all conclusions of “Myth busted: XY does not actually have any impact on beer” that are often read into the results. The simple null-hypothesis approach could easily be adapted to the situations where we actually want to conclude that two beers are the (essentially) the same, rather than different. And we could use the same results from the triangle tests to investigate in both directions.

If we decided to call two beers “distinguishable” (this word is just a placeholder, call it whatever you want) if, say, at least a fifth of all (that is, from some unspecified population from which we assume to draw participants at random) people (meaning person at a given time and place) had the ability to actually and correctly identify the odd-one-out in a mixed set of three, then a random (see above) person would be correct in a triangle test with a chance of at least 1/5+(4/5)*(1/3) (at least a fifth chance that they are among those that clearly pick it out and succeed and a third for the remaining part of our population). That number is roughly 46.7%.

If we then had two batches of beer and our aim was to prove they were “practically equivalent”, then our null-hypothesis would be that at least 46.7% of triangle tests would be positive. Now, I did not actually do the maths, but in this xbmt 42.3% of all tests were successful, so the null hypothesis can certainly not be rejected at a 5%-level based on this set of data.

Long story short: we should not be saying that these findings indicate that the beers were not distinguishable. We should be saying that the findings are inconclusive in both directions, they neither show that the beers were distinguishable nor that they were indistinguishable. I know, it does not sound quite as sexy.

Exactly! Based on a non-significant result, all we can say is that we cannot say that the beers were distinguishable.

A lot of the non-significant xBmts are probably due to their small sample sizes. For example, if the sample size in this xBmt had been 1000 and the same result was obtained (i.e., 42.3% of the triangle tests were accurate), the result would almost certainly be significant, and we would be able to say that the beers are distinguishable.

This misreporting of non-significant results has clearly biased Brulosophy toward concluding that common brewing techniques have no effect.

With respect to your suggested approach, you are basically describing an equivalence test that could be done to determine whether the data indicate with a sufficient degree of certainty that the variable has no effect.

An equivalence test would define a range within which we would say that the beers are indistinguishable or equivalent (in your example, your range would be accurate triangle test results of between 0% and 46.7%). However, since we are dealing with sampling, a statistical method would need to be used to determine what the likelihood is that a result showing equivalency was actually due to chance, taking into account the sample size. That would be where a statistical method like the “two one-sided tests procedure|” would come into play — it would tell you what the likelihood is that the result showing equivalence was due to chance.

I typically vacuum seal grain leftovers. in theory, all the air has been removed, then stored in a dry dark place in my basement. but how long can grains sit before going stale? Guess a sample taste could answer that.

Great experiment!

Neat experiment, and timely too. I’ve had some unmilled grain sitting around for quite a while and wondered about the potential impact. Helps put me at ease. For those nay-saying the triangle tests, considering that some of the largest producers of beverages (Coke, Pepsi) use triangle tests to evaluate new variables, I would think it would be adequate for these experiments.

Your reference to beverage corporations utilizing triangle testing reminds me of the Pepsi challenge. While I agree that the, sometimes, sweeping generalizations that are made or implied from these experiments are incorrect at worst and misleading at best, there is value in that they are building evidence towards best practices developed in a git-r-dun manner that most homebrewers find themselves; who among us is brewing in a lab anyway?

Getting back to my Pepsi challenge comment then, perhaps incorporating a preference test where the variable and control samples are blindly given to tasters and they can choose either sample or no preference. So, while the work of this blog is overstepping itself by making or implying definitive statements on how certain variables affect beer in general, I would appreciate knowing how the average beer drinker enjoyed either sample compared to the other or that he/she just didn’t care as they seemed to taste the same. I can use that as an input to my brewing, knowing that the average beer drinker does or does not prefer this variable (mash temp, pH, grain age, milling date, etc.), in order to decide whether I should waste time or other resources on it.

Interesting stuff. I guess I always interpreted the “stale” malt anecdotes as being more about the overall freshness of malt that LHBS’ get versus the big brewers. So in some ways the more relevant experiment might be to brew one more beer using the exact same recipe but with all fresh malted grains. IOW, this test was about whether a beer brewed with 6 month old non-crushed grain is appreciably different than a beer brewed with 6 month old crushed grain. Both grains are six months old. I think many of us would be interested in whether you can make BETTER beer with fresh grain vs. old grain.

I say this because I’m fortunate to be close to a craft maltster, Valley Malt (Hadley, MA) and I was able to secure some truly fresh craft malt (<1 week from malt/kiln). I cracked the sack of pale malt this weekend and can say after 25+ years of homebrewing that I've never smelled anything so wonderfully malty in my life. Had a similar experience when I wanted to try out the new shipment of Viking Malt that MoreBeer received over the summer. I think the grains that make it down to the LHBS level are just older and, given recent trends showing homebrewing is slowing down across the country, doesn't get the turnover needed.

I tasted the wort from this weekend's batch and it's just as bready and cracker-y tasting as I'd hoped, and this was with a SMaSH beer (pale + Denali).

That said, it's always great to know that (as always) beer is far more forgiving than you'd be led to believe. "Relax. Don't Worry. Have a Homebrew." is as relevant a sentiment today as it was 40 years ago.

This was my thought, both grains were 6 months old, so the factor was crushed freshness, not grain freshness.

I agree, a fresh malt beer vs old malt beer will be interesting, and to add another factor, do first beer fresh malt beer, second beer old malt uncrushed stored 6 months, and 3rd beer old malt crushed stored 6 months.

That would be nice 😀

Problem with fresh and old malt as you suggest is that either your “fresh” malt is from the same production batch from the maltster and therefore not any fresher than the old malt sample; or it is from a different batch and may have differences due to factors in the malting process and not age.

Now you have the potential for multiple variables, malting process, harvest age, barley terrior and all that. Becomes difficult to pin down the cause of any difference detected.

Informative as always. I often find myself wondering just how fresh my stored, pre-milled grains really are, and what impact that might have. Good to know it may not be a huge factor for the time frame I usually keep grains around.

Also, bonus points on the article because I’m a sucker for a good altbier recipe:

https://brucrafter.com/award-winning-altbier-recipe/

Marshall,

Thanks for running this experiment. I’m one of your readers/listeners who has requested this experiment (a few times). I sometimes purchase multiple kits via mail order and wonder about lost freshness with the last kit sitting around waiting to be brewed. I’ve also been to one of the retail locations of a major mail-order homebrew store and seen the pre-milled kits on the shelves waiting to be purchased and shipped; I’ve wondered how long ago the grains were milled and how that might affect the ultimate experience of the homebrewer. Mostly, I like to buy my grains (fresh-milled) from one of our LHBSs. They typically mill the grains into a brown paper bag. As I drive home, my car fills with the wonderful smell of fresh-milled grains; however, I always wonder if those aromas filling my vehicles represent flavors and aromas that would otherwise go into my beer if they weren’t escaping from the brown paper bag into my car. So, I typically put the full paper bag into a plastic bag immediately, even if I’m planning to brew the next morning. If the grains won’t be used for several days, then I’ll vacuum seal the grains to maintain freshness.

After reading the results of this experiment, I won’t change my process much. It takes minimal effort to bag and/or vacuum seal some grains.

The biggest take-away (for me) from this experiment is informing the decision I’ve been contemplating of whether to purchase a grain mill. I’ve contemplated the benefits of purchasing a good mill: (1) cost savings from purchasing grains in bulk, (2) freshness from milling immediately prior to brewing, and (3) convenience of brewing without planning a trip to the LHBS.

However, these benefits are offset by: (1) the cost savings (per batch) would take a long time to cost-justify the purchase of a good 3-roller miller. I don’t mind spending the extra $ at the LHBS to support their business, (2) the freshness benefit are called into question by your experiment results, (3) even if I were to purchase base malts in bulk, I probably wouldn’t bother with the hassle of maintaining an inventory of different specialty malts; hence, I would still need to trek to the LHBS in preparation for a brew day. Besides, I kinda enjoy going to the LHBS, chatting with the guys there, and supporting their business.

Thanks, again, for running this experiment. My next equipment purchase will be a RO water system rather than a grain mill.

Cheers, BG

Even though the thought never occurred to me for some reason, the idea of being like flour, as Ben mentioned above, seems to be quite relevant to this issue.

Having said that, I would have thought a longer time frame would have been your choice, given that you mentioned using grain that was milled ‘years prior’. Also, would it not have been more effective, along with greater age difference, to use a more ‘real life’ scenario of grain that you just purchased? Either unmilled, then milled at home, or like those of us that don’t have a grain mill (i just do it all at the LHBS). Mill it there, take it home, store it, then a year later, go get exactly the same grain bill, mill it there (checking to make sure mill is consistent), then go brew both? Just some thoughts, but I still liked the exbeeriment, keeps us in check, keeps us relaxed about it.

Very interesting. When I first started doing all grain I was told by a brewer that had several years under his belt that I was risking getting “stale malt flavors” because I was milling my malt the day before brewing. Less than 24 hours. So for years I was paranoid about this even though I usually still would mill it the day before. I would agree that a fresh batch (purchased recently) of milled malt v.s. old milled malt would be interesting.

Would have loved to know the temperature and humidity surrounding the grains.

Marshall lives in central California, crushed in April, stored in his garage, and brewed in September so you are looking at relatively low humidity with temperatures ranging from 50F to 95F.

Have you all ever pulled together a list of variables that don’t seem to make much of a difference, and those which have done so? My reading of these results over a couple of years seems to suggest that hardly anything really matters–it is seldom the case that your experiment actually shows that some practice makes a difference to tasters. In some cases, where traditional advice is ignored, people seem to like the non-traditional method (e.g. the experiment about changing the water chemistry).

Makes it seem like one can ignore 90% of the advice given by experienced brewers. Frankly, it makes them looks like fools for giving so much unsound advice, some for centuries no less.

And often, it makes you look cowardly–I can’t count the number of times your test showed tasters could not tell a difference, and yet you said you were not going to change your practice. I get that one experiment does not a significant result make.

What’s the point of all these tests if it’s not going to make a difference in how you or we brew?

I concur – not much seems to matter in homebrewing. I’m still patiently waiting for Brulosophy to compare an all-grain vs all-extract batch. Surely, again, no difference will be detected and then… what? Whoops?!

You so funny!

https://brulosophy.com/2016/01/04/extract-vs-all-grain-pt-2-comparing-recipe-kits-exbeeriment-results/

By the skin of one tasters teeth… Keep ’em comin’ though – shoot down every piece of “dogma” you can so eventually we can all mash in our kitchen sinks, drain the wort through the garbage disposal and not tell a difference from any other method, because Brulosophy did a science. As the previous poster mentioned, that you often don’t follow what your experiments suggest is, strange? You’re right, homebrewing truly is dead.

You do know that grain can be stored for years before being shipped and sold? Just because someone bought a sack of grain doesn’t mean the grain in it is brand new.

But, but, but….. I LIKE crushing the grain right before I brew. It’s a very important part of the rubric and ceremony!

I think people seem to keep making the error of assuming that having an educated palate means that it makes you a better taster. This is untrue. It only means that you are better at communicating what you detect. Witness the test where BJCP judge answers were parsed out.

The beauty of the blind tests is that it pairs away so much self deceit and BS.

There is of course still possiblity for statistical error (p values, people!), but the science of the triangle tests is generally good.

Triangle tests are fine so long as the apparatus you are using to detect differences is sensitive enough to detect said difference. Who is to say that every person on a tasting panel who could not detect any difference in the samples, lacks the palate sensitivity to detect differences in the first place? It is always assumed that if a difference is not detected it is because there is no difference to detect. Without validating the sensitivity of your tasting panel to a particular flavour profile the results really are meaningless. There could be a many significant results hiding in a sea of type II errors.

What you did at the end, letting the guy who got it right redo, would be very interesting to try again with all folks who got it right (or anybody who doesn’t admit to guessing)

Love these posts, always so informative. I’ve been tempted to have all my grains milled at my LHBS then cryovac them at home to save time on brew days, I think that’s exactly what I’ll be doing from now on!

Funny Marshall chose to complete this experiment now. I’ve been homebrewing for years and about two years earlier our family moved into a new home. I drifted from brewing for a while to work on remodeling an older home we moved into and began brewing frequently again about a year ago. Just last week and without knowing until now that he had completed this xBmt I came across a bucket of milled grains in the garage.

The bucket was labeled from late 2016 and contained a porter recipe (yes, milled two full years earlier). I figured I was brewing another beer anyway, why not make it a double brew day. I had just finished a kegged porter following the same recipe as the 2016 batch recently and knowing that one was delicious, I thought I’d give the old milled grains a shot and see how they turn out. I happened to have some spare yeast on hand that even happened to be the same yeast used in the recently brewed porter (Safale-04 English Ale). Even though I was temped to pitch an Imperial yeast into this batch to see how it changes or ferments compared to the last one, I stuck with the same recipe and the same yeast I had used previously.

I brewed the beer and have been monitoring the fermentation closely. So far, the fermentation appears similar to the same porter I had brewed fresh recently. I haven’t taken enough samples and am not brewing these beers side by side so I know I am unable to come to any scientific conclusion here. I brewed this beer simply for my own knowledge to answer my own question: Can I brew a decent beer with grains milled two years earlier and stored in a sealed bucket in my garage? What’s the worst that can happen, I have to dump the batch?

I’ll let you know the results in a few weeks.

Thanks for the great content on this site and your Podcast’s Marshall. Your hard work and xBmt’s are appreciated.

How did your porter turn out?? I also have some kits that I didn’t brew immediately after buying, but I plan to use them. I read somewhere that extracts will develop a ‘maltier’ taste, and that grains lose some of the flavor with time so you have to compensate by adding a little more to each recipe. Seems logical, but when I add a bit more grain to a recipe they come out maltier/sweeter than expected, so perhaps there are greater aroma losses than flavor?

Additional exbeeriment could be freshly bought milled grains vs. slightly open stored millled grains for a couple months (Maybe a bag not tied well). I have made great beers with fairly old milled malt. Thanks for the exbeeriment!

You can do this by tasting the grains, or making a simple grain tea. I know that with Simpsons dark crystal malt you can taste the difference. Try newly milled malt vs malt from a month ago. The month old loses some of its sweetness compared with the newly milled.

With your recipe for an Alt, your water profile gives sulfate of 100, chloride of 50 – a 2:1 ratio which provides a bitter profile. But here you are trying to see what the malt differences may be. I think you should have chosen a malt forward recipe instead of an Alt. Next time, try a brown ale with a light hand of hops and a balanced, or malty sulfate/chloride ratio.

Interesting.

I recently brewed using milled grain from a sack I’d bought about 18 months previously, hops that had been in the freezer for a similar length of time, and dried yeast almost exactly on the bbe date (circumstances prevented me brewing for over a year).

Drinkable, but not great, and for some reason rather flat although usual quantity of priming sugar used.

Pre-milled malt bags I use in the UK come with a 6 month best before date. I have used pre-milled specialty malts and torrified wheat in the past that were more than 3 years old. Base malt bags are always factory sealed bags and the specialty malts were closed properly, after taking something out of them and stored dry and cool. Didn’t notice any off-flavors. The only problem once was when somebody left a newly delivered pallet of malt bags outside in the rain, some got wet inside and were used the next day.

I have some experience with stale tasting pre-milled malts though. For a malt tasting I obtained something like Low-color Maris Otter, Halcyon, Golden Promise from an UK home brew store. They sold only milled, I am pretty sure the didn’t have their own mill and I assume the bags in the back of the shop were old/stored open. That malt lost most of its aroma and tasted stale.

I am amazed at the anal attitude to milled grain in the US. Here in the UK almost everyone buys their grain ready crushed in 25 kg bags. I and most of the guys in my homebrew club regularly buy bulk crushed grain. Indead most small to medium breweries buy crushed malt buy the pallet. I have the crushed malt sitting for up to nine months with no detectable effect.

Denny Conn and Drew Beachum did a similar experiment and found no detrimental effect

Regards

Graeme Brown

East kilbride ( Scotland)

Potato chips stay fresh in a thin plastic bag for years. Would love to see this experiment with an open bag.

Thank you for this test. Interesting and makes me feel better about always buying in bulk.

I work in the beer packing industry and started home-brewing around a year ago but could not call myself knowledgeable by any means. One thing I would say is that I do see changes throughout the season on finished beer quality parameters as a result of using old malt, namely the pH of the beer increases i.e. where it would be pH4.2 on fresh malt it could drift to pH4.7 on the last of the malt reserves.

As such I do not question your results but may ponder whether the age of the malt is as/more important than actual grinding and the retailer’s pushing malt mills and sitting on grain stocks are happy to keep up these myths?

One thing I would also ask is does the alpha/beta amylase content in malt drop over time as I am still using malt over a year old but finding it more and more difficult to get complete conversion.

Last night I mashed a brew of pre crushed maris otter which was over ten years old (stored in a brewing bucket in the loft and forgotten about) all the signs are that it was perfectly fine. I achieved 85% efficiency, which is about my usual with fresh grain, and the unfermented wort doesn’t appear to have any off flavours which I can detect.

I wonder how much perfectly good grain gets wasted because of the myth that grain needs using immediately after crushing?

i know it’s been 2 years, but do you remember the beer tasting normal? i’m considering milling all my 50 pound sacks of grain to save time on brew day

Personally, I wouldn’t grind more than a few brew’s worth and most importantly seal it in an airtight container. The grain will pick up moisture from the air and go stale otherwise. I doubt the beer would taste bad but it will taste better when fresh ground. This would affect light beers moreso than ales, porters and stouts. I have an old bulk tub of ground pale malt which is still making good beer this highlighting I need to make more beer.