Author: Jason Cipriani

Yeast pitch rate is viewed by most brewers as being one of the more important components to crafting good beer, with inadequate amounts contributing to under-attenuation and certain undesirable off-flavors. According to many, pitching the proper amount of yeast can lead to quicker starts to fermentation, faster finishes with complete attenuation, improved consistency and predictability, and generally higher quality beer.

Countering these claims are the results of numerous xBmts we’ve performed on pitch rate. Tasters have been largely unable to distinguish beers pitched with recommended cell counts from those pitched with either too little or too much yeast. Not unexpectedly, comments from readers following publication of these results have tended to offer possible explanations as to why the difference wasn’t greater, a common one of which had to do with the yeast strains being used.

Belgian Ales are known for possessing unique characteristics such as spicy phenols and fruity esters, which particular yeast strains are known to contribute. Compared to more notably cleaner yeasts, it’s believed that those used to make Belgian Ales are more sensitive to certain fermentation conditions including pitch rate– pitching too little yeast can result in over the top spiciness to the point of being unpleasant, while pitching too much can lead to an out-of-style ester bomb. I decided to test this claim out for myself with a Belgian Dark Strong Ale.

| PURPOSE |

To evaluate the differences between a high OG beer fermented with either a yeast starter or direct pitch of the same Belgian Ale yeast.

| METHODS |

For this xBmt, I went with a slightly modified version of Ray Found’s Belgian Quad recipe, a style I don’t brew often and was excited to have on tap.

Bain de Sang

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 90 min | 42.6 IBUs | 24.7 SRM | 1.084 | 1.014 | 9.4 % |

| Actuals | 1.084 | 1.008 | 10.2 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| EuroPils (Cargill) | 15.75 lbs | 82.89 |

| Special B Malt | 4 oz | 1.32 |

| Candi Syrup, D-180 | 1 lbs | 5.26 |

| Candi Syrup, D-90 | 1 lbs | 5.26 |

| Cane (Beet) Sugar | 1 lbs | 5.26 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Columbus/Tomahawk/Zeus (CTZ) | 28 g | 60 min | Boil | Pellet | 13 |

| Willamette | 28 g | 15 min | Boil | Pellet | 5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Monastic (B63) | Imperial Yeast | 76% | 68°F - 78°F |

Notes

| Water Profile: Ca 15 | Mg 2 | Na 0 | SO4 22 | Cl 16 |

Download

| Download this recipe's BeerXML file |

Relying on my favorite pitch rate calculator, I threw together a starter of Imperial Yeast B63 Monastic, the size of which was based on manufacture date. At the time of yeast pitch, the single pouch of yeast was estimated to have approximately 100 billion cells remaining, as it had been manufactured nearly 2 months prior, whereas the yeast starter was estimated to have closer to 400 billion cells.

On brew day, I started off by turning the flame on under my keggle of brewing liquor, which I’d treated to achieve my desired profile. While the water was heating, I weighed out and milled the grain for a 10 gallon batch.

With my water at strike temperature, I stirred the grains in before checking the mash temperature.

I began recirculating the wort and set a time for 60 minutes, stealing a small sample to check the mash pH about 15 minutes in.

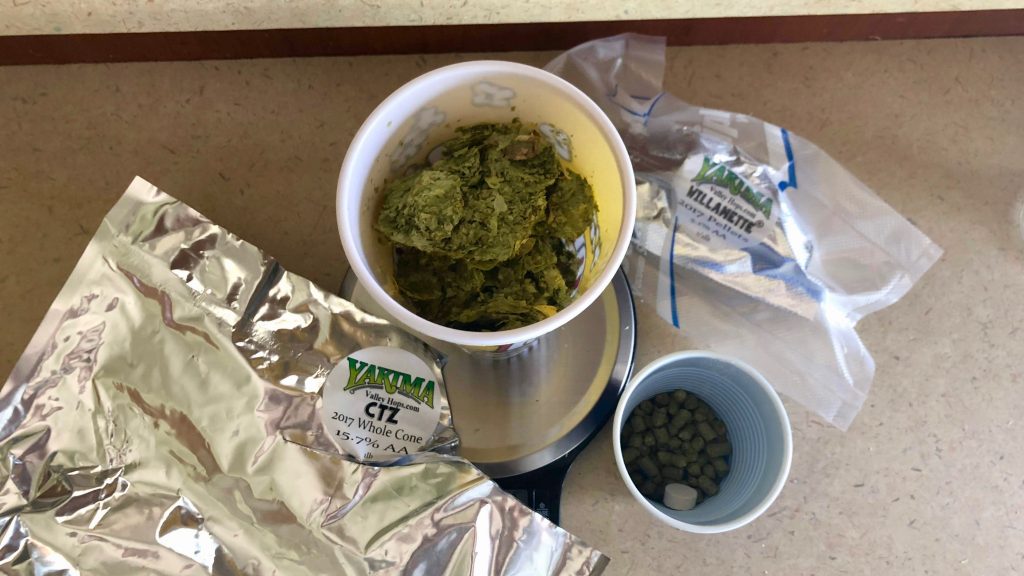

At the end of the mash rest, I batch sparged with water I’d preheated with my HotRod heat stick. Once the pre-boil volume of wort was in my kettle, I hit the flame and moved on to measuring out the kettle hop addtions.

In addition to hops, various sugars were added during the boil at the times stated in the recipe.

At the completion of the boil, I ran the wort through my plate chiller directly into separate sanitized fermentation vessels, each receiving an identical volume.

At this point, I took a hydrometer measurement that revealed the wort was at a respectable 1.084 OG.

The filled fermentors were placed next to each other in my chamber to finish chilling to my desired fermentation of 72°F/22°C, which the crew settled on given the particular yeast strain and beer style. After a couple hours, I returned and pitched the starter into one batch while the other was direct pitched with a pouch of the same yeast.

The batch pitched with the yeast starter was active the following day and going crazy at the 48 hour mark, a point at which the direct pitch beer had yet to show any sings of fermentation. My nerves settled the next, approximately 60 hours after pitching the yeast, when I noticed airlock activity on the direct pitch batch. After 11 days, I noticed signs of fermentation were absent, so I took hydrometer measurements that showed a very slight difference in attenuation between the beers.

I proceeded with kegging the beers.

The filled kegs were cold crashed in my keezer, fined with gelatin, and burst carbonated. I let the beers condition for 2 weeks while I was on a business trip before serving them to blind participants.

| RESULTS |

A total of 20 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the standard pitch rate beer and 1 sample of the direct pitch beer in different colored opaque cups then asked to identify the unique sample. At this sample size, 11 tasters (p<0.05) would have had to identify the unique sample in order to reach statistical significance, though only 8 (p=0.34) made the accurate selection, indicating participants in this xBmt were unable to reliably distinguish a Belgian Dark Strong pitched with the recommended amount of yeast from one that was pitched directly with a single pouch of yeast.

My Impressions: When tasting these beers side by side, I was confident there was a difference. I perceived the direct pitch beer as having a slightly thinner mouthfeel than the standard pitch rate beer. Then I completed a total of 7 semi-blind triangle tests and picked the odd-beer-out only once. Despite my beliefs, these beers were the same when I wasn’t aware of which one I was drinking. The beer was actually very good! My wife best described it as having a “spicy banana” flavor, though it’s not all spice, I think it is nicely balanced with a nice malt character and a hint of raisin in the finish.

| DISCUSSION |

“Adequate” is relative when it comes to pitch rate, as certain styles demand varying amounts of viable yeast to produce the intended outcome. Most modern brewers agree that under-pitching yeast is rarely ever ideal, as it increases yeast stress such that certain undesirable off-flavors can be produced. However, a slight under-pitch is used by some as a technique to add character to certain styles of beer that would otherwise be absent given a higher pitch rate.

It’s commonly claimed that the stress put on Belgian yeast from being under-pitched can lead to increased levels of phenol and ester production, which can be highly desired for these types of beers. For this reason, some brewers ignore typical pitch rate recommendations when making these styles, choosing instead to pitch a bit less than purportedly optimal rates. However, tasters in this xBmt were unable to reliably distinguish a Belgian Dark Strong Ale pitched with an adequately sized starter from one that was direct pitched with a single pouch of yeast.

With a number of past xBmts on pitch rate returning similarly non-significant results, it would seems the evidence is pointing to propagation of yeast in starters as being less necessary than many believe. I’ll admit, as a proper pitch rate proponent, I fully expected the beers in this xBmt to be different, and the fact they weren’t has left me somewhat conflicted.

It seems plausible that yeast quality is playing a role here, as labs like Imperial Yeast are producing a high quality product that may simply maintain viability longer than the yeast of 10+ years ago. Or maybe our understanding of pitch rate, and the beliefs we hold about its importance, is incomplete, even when it comes to more characterful strains like like those used to ferment Belgian ales. Either way, while I’ll likely continue building starters for most of the beers I brew, I won’t fret about direct pitching if I have a free afternoon and decide to brew.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

30 thoughts on “exBEERiment | Yeast Pitch Rate: Yeast Starter vs. Direct Pitch In A Belgian Dark Strong Ale”

I think that this one would have been better had someone actually made counts for the yeast cells in both the starter and the pouch. As it is, you have some estimations, but you do not even have an error range on these limits. It could effectually be that the lower range cell count for the starter and the upper range cell count for the pouch lie much closer than you think.

I think doing cell counts would be a good idea, except that it goes well beyond the means, and will of the average homebrewer. The average homebrewer is not trained in microscopy, or spectroscopy.

I don’t disagree that yeast cell counts would have been interesting, but we are still talking about home brewers and our setups, techniques, etc. A starter aiming for 400 billion cells is still double that of a fresh yeast pack from Imperial the day it comes out.

The main point being that most brewers who are advocates of yeast starters (which isn’t surprising when we’re talking about a 1.084 OG beer), that an approximately 400 billion yeast cell starter would NOT turn out anything like an underpitched 100 billion yeast cell pitch. Margin of error between the two cell counts wouldn’t minimize what most brewers would say would make a completely different beer.

If there’s one area of homebrewing that is based on dubious science, it’s pitch rate. I would argue that both beers in this experiment started with the same yeast count: 100 million cells. I’m assuming the whole starter was pitched, not just slurry after decanting. If so, the only meaningful difference is that one beer starts in a small container (the starter flask) and the other starts in a large container (the fermentation vessel). Why should that make any difference? Both beers have exactly the same growth curve in terms of cell numbers. Both will have any esters associated with lag, exponential growth & stationary phases. There’s no scientific reason to expect any kind of difference.

I’m not sure I agree, Ben. The growth curve for the yeast starter begins however many hours before pitching the starter was prepared, and potentially has the benefit of additional oxygenation required for cell multiplication. But I do see your point. The one piece of information we don’t know is the maximum number of cells that existed in the fermenting wort, and it’s quite possible that this number was the same for both beers. It’s clear we do not know what the limiting factor for yeast growth is. It was long assumed to be oxygen but evidence suggests this may not be the case.

“The growth curve for the yeast starter begins however many hours before pitching the starter was prepared”

Agreed, but that simply amounts to fermentation beginning at a different time. Making a starter means fermentation begins a bit earlier and ends a bit earlier. The idea that fermentation begins at pitching, which is what I often read, isn’t quite right.

There are some other variables introduced by making a starter: oxygenation of yeast during growth phase might be higher; temperature of wort during growth phase might be higher; starter wort might be of different composition than main wort and affect flavour. But these are not the usual justification for making a starter, which is the usual cell-count narrative (irrelevant if the whole starter is pitched).

Your conclusion is based on the false assumption that yeast starters should be allowed to ferment. Fermentation is NOT something that you want in a starter. The whole point of a starter is to grow additional well oxygenated yeast cells and then make them go dormant, so a starter should be refrigerated at high Krausen when cell density is near its maximum.

If what you say is true then there’s no point in pitching more than 1 yeast cell into a beer. The packs of 100 billion cells you buy from the store were propagated from a single cell culture using food media (wort). So what’s the point in them?

Since that’s clearly not true, then there is a hole in your argument.

Yeast starters are not dubious science, but most homebrewers aren’t doing them properly.

Could you please add some important details? How long did your starter go for? How long before pitching the pouch did you warm it up? Did you oxygenate either wort?

The starter spun for roughly 36 hours. The pouch sat out long enough to get to room temperature, 4 or 5 hours. No oxygen for either wort.

Since oxygen is well known to be necessary for yeast growth is it possible that by not oxygenating it you didn’t get the cell count you thought you were getting? I’ve never done it to starters either never having figured out a good way to do it.

I’ve been working as a Winemaker in Michigan since 1999. You do realize that yeast live….grow, and multiply? A yeast produces about 26 daughter cells before finally not being able to re-bud any longer. However, each daughter cell and their daughter cells grow to maturity and begin budding as well. In fact, the longer they are re-budding in a solution, the better adaptive they become to that environment. If there is sufficient oxygen, they grow and when that runs out the CO2/Etoh produciton takes over (anaerobic) before it’s CO2 / water. Even after they have run out of O2 and rely on the carbon in the sugar for their metabolism, they still manage to reproduce by budding, although at a much slower pace, and generally able to keep up with those that are old and dying out.

When you receive a packet of yeast, they are not all “new” young yeast, but rather a mixture, whether direct start or other. Original brewers that knew about what caused fermentation used old saved back yeast, often found on spoons left to hang and dry. Once population built, active fermentation started.

If you have the yeast, pitch what you want, but don’t sweat it if you are short just a bit. They will grow on their own. Don’t Worry. Have A Home Brew.

I agree. Open grassland for the yeast to populate then take off.

yeast is expensive, unless you are a sponsored blog ;-). I build starters so that I can save a pint for the next starter. Many things I do in brewing, rice hulls, high cell count, and yeast nutrients, are cheap insurance to make sure the brew turns out well. It will be interesting to see if you get comments from folks with stuck fermentations.

I am late to this thread so please excuse if this has already been covered.

It would seem simple recipes & clean finishing yeast would show differences more than Belgian.

There is a lot more going on in a Belgian beer.

I’m pretty sure that a previous complaint was “you should use a more expressive yeast”. Damned if you do, etc etc.

I think a real under pitch is the next experiment. Liquid or dry yeast. Pitch one batch at calculated rate, the other 1/4 of the rate. This will be a true test. This experiment with out cells count are probably too close in real numbers to see a significant difference.

They’ve done that one, and I believe the results weren’t significant. It was a lager with a 50% underpitch vs 250% overpitch with dry saflager 34/70.

I do small batches (1.5 to 2.5 Imperial gallons) of predominantly English beer, usually in the 3.2 to 4.5 ABV range. My worry is therefore over-pitching. If I use a whole pack of dried yeast in a 1.5 gallon batch, surely that is over-kill? I wonder if I’m damaging the finished beer with a super-abundance of yeast cells competing for limited resources?

Intresting results! What type of fermenting vessels are those?

The Genesis fermenter. https://www.homebrewing.org/Genesis-65-Gallon-Plastic-Fermenter_p_7662.html

The handles on those things are awesome!

It seems that many of the commenters are overcomplicating what is a simple experiment. The whole purpose of the experiment was to test the overwhelmingly believed necessity to create a starter prior to pitching your homebrew. Jason’s results simply show that under typical “homebrewing” circumstances, there was little, if any, discernible difference between a HOMEBREW being direct pitched from one where he pitched a starter (again, we are homebrewing). There is obviously more science behind all of this but for those wondering whether a starter is absolutely necessary to make great beer at home, these results provide valuable insight. Take it for what it is! Cheers.

Jason, can I ask whether you pitched the whole starter or decanted the wort off it and just pitched the slurry? Pitching the whole starter is what most brewers seem to do (and therefore valid for the xBmt) but in my opinion makes the effective pitch rate just 100 million cells as start of fermentation is when the starter begins fermenting, not when the starter is pitched.

I’d say the difference is that you are pitching 100M cells in a 1.038 starter, which grows to 400M cells. Then the comparison is the difference between 100M and 400M in a 1.084 wort

“I think a real under pitch is the next experiment. Liquid or dry yeast. Pitch one batch at calculated rate, the other 1/4 of the rate. This will be a true test. This experiment with out cells count are probably too close in real numbers to see a significant difference.”

They’ve already done that one. 50% vs 200% pitch of saflager 34/70.

Great comments. I agree that starters are about the speed at which active fermentation begins and the length of time before fermentation is completed. I’ve been inspired by this website to change some of my 25 year brewing processes, including now regularly doing “vitality” starters (though I do it a bit different and just take some cooled wort from my batch and spin on a stir-plate for 5 hours while the rest of the batch sits in the fermenter). The result is that I can generally go from fermentation to serving in one week…four days to ferment, one day to cold-crash, one day to carbonate, then drink.

That said, I remain firmly a believer that yeast is yeast is yeast. The strains across the 3-4 major brands are genetically similar (being kind) or identical (being pragmatic). How healthy the average yeast pack is leaving the manufacturer is up for debate, but I’ll trust the Brulosophy team that the Imperial Yeast products give more consistent results. I’ve never really noticed any variability in fermentation *quality* amongst WhiteLabs/Wy’east/Imperial product lines in the end product. How quickly fermentation takes off and lasts…sure. But then again, doing a starter helps even the playing field too.

Caveat: I’ve used almost exclusively White Labs products over the past 10 years and have given them a couple of strains that they sell. My beer is still drinkable. 🙂

In all of my decades of brewing I have never used a starter, and I have never used liquid yeast. I do however “start” my yeast in about half a litre of fresh wort from the beginning of the boil.

In my experience and opinion this not only re-hydrates the dried yeast but also wakes it up, acclimatises it to the wort, and therefore gives it a head start. I currently have a saison started with this method, using Lallemand Belle Saison dry yeast, just 15 hours ago. The brew is well under way with the blow-off tube pouring foam into the collector bottle.

I also used to direct pitch dried yeast in to my wort (as per the instruction on some brands), and although it may take an hour or two longer to get going it still produced good results.

The claim that direct pitching increases yeast stress does not make any sense to me. When you make a starter of liquid yeast in say two litres of wort made from DME, the yeast is in a constricted environment, with the cells competing for a limited supply of sugar.

Put that yeast directly into a fermenter pull of well aerated wort it has an unlimited supply of food and nutrient. How can that cause stress? All I see is a very happy yeast partying in a wonderful open environment, in the biggest ever “starter”.

I am continually amused by those adherents to “cloning” well known commercial beers, who are so anal about yeast starters and cell counts, when those same commercial breweries have been brewing the same beer for in some cases hundreds of years. When they started producing those fine ales little was known about yeast and how it worked, let alone cell counts!

“Put that yeast directly into a fermenter pull of well aerated wort it has an unlimited supply of food and nutrient. How can that cause stress? All I see is a very happy yeast partying in a wonderful open environment, in the biggest ever “starter”. ”

Exactly right. Stress means adverse conditions (insufficient food or nutrients, low temperature, toxic environment). There are all sorts of bogus theories about yeast stress in brewing. One of the most common is that yeast are stressed by undercowding and so “throw esters”. In fact the generalisation that yeast throw esters when stressed clearly isn’t true as the optimum temperature for yeast grown (around 80 F) is avoided like the plague by most brewers, and lager brewers ferment at the lowest and most stressful temps that yeast can tolerate.

” Stress means adverse conditions (insufficient food or nutrients, low temperature, toxic environment). There are all sorts of bogus theories about yeast stress in brewing. One of the most common is that yeast are stressed by undercowding and so “throw esters”. In fact the generalisation that yeast throw esters when stressed clearly isn’t true as the optimum temperature for yeast grown (around 80 F) is avoided like the plague by most brewers, and lager brewers ferment at the lowest and most stressful temps that yeast can tolerate.”

Nice to read that I’m not the only one that thinks this way (honestly, if you want to talk about stress, throwing 100b cells into media that can only support 200b… that’s gotta be “stressful”). Though I would argue the optimal temperature for yeast growth is higher still… when I used S. cerevisiae in the lab I would culture it at 30C (86F).

Even in an ideal wort, yeast still have to contend with osmotic stress. The higher the OG, the more the stress. Making a low-OG starter (vs. a wort’s higher OG) is a way to “ease” the yeast into the osmotically stressful environment, which (in principle) means better fermentation. Also, a starter greatly shortens the lag phase, minimizing other microbes’ ability to take hold. IMHO, this alone is reason enough to use starters to increase cell count.