Author: Jake Huolihan

Since the advent of transportation, food and beverage have been shipped from the point it’s created to the end user. While shipping has completely changed the world, allowing for mass production of consumables, it does pose some few issues, food spoilage being the most problematic.

With the creation of cold shipping, manufacturers were able to send perishable items all over the world and largely overcome the spoilage issue. As for beer, some large breweries even market the fact their product remains cold from the time it leaves their facility to when the consumer purchases it. Cold storage of beer is believed to be important because, like most food products, it undergoes staling reactions that are amplified as temperatures increase.

As someone who abhors shipping beer, my homebrew only ever sees warmer post-packaging temperatures when it’s poured for consumption. However, many homebrewers compete, and one constant about competition is that it requires one to package and ship their beer. Without the means of a large commercial brewery, homebrewers are resigned to ship beers in less than ideal conditions, usually resulting in bottles being jostled around in warm environments for a few days. This has always concerned me and is one of the main reasons I compete so rarely. Are my concerns overblown? I designed a simple xBmt to test it out!

| PURPOSE |

To evaluate the differences between a beer that underwent conditions similar to warm shipping and the same beer that was stored in a cool keezer.

| METHODS |

Since this variable would be introduced post-packaging, I brewed up a single 10 gallon/151 liter batch of Helles for this xBmt.

Schubsen

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 21.4 IBUs | 3.7 SRM | 1.045 | 1.008 | 4.9 % |

| Actuals | 1.045 | 1.01 | 4.6 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Odyssey Pilsner | 9.75 lbs | 89.66 |

| Weyermann Vienna | 1.125 lbs | 10.34 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Loral | 5 g | 60 min | Boil | Pellet | 10.3 |

| Loral | 13 g | 30 min | Boil | Pellet | 10.3 |

| Loral | 5 g | 5 min | Boil | Pellet | 10.3 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Global (L13) | Imperial Yeast | 75% | 46°F - 56°F |

Notes

| Water Profile: Ca 65 | Mg 0 | Na 8 | SO4 67 | Cl 68 |

Download

| Download this recipe's BeerXML file |

A few days prior to brewing, I whipped up a large starter of Imperial Yeast L13 Global, equal amounts of which would be added to either batch (and a couple others).

In preparation for brew day, I weighed out my grains before collecting the water and adjusting it to my desired profile the night before brewing.

When I woke up the next morning, I turned on the elements to heat my strike water then proceeded to mill the grains.

I then weighed out the kettle hop additions.

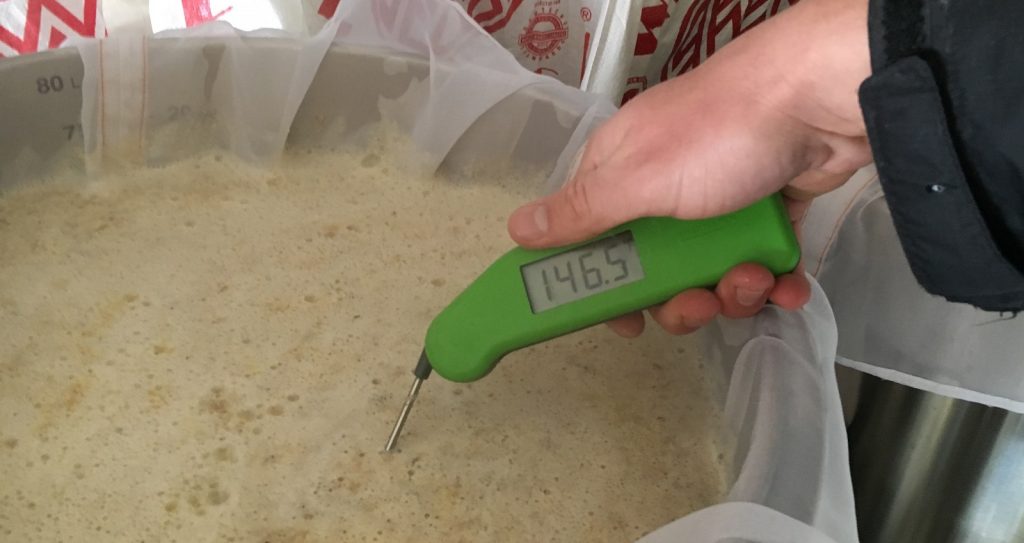

When the water was slightly warmer than strike temperature, I transferred it to my mash tun for a brief preheating before mashing in to hit just a hair lower than my target mash temperature.

I briefly stirred the mash every 15 minutes over the 60 minute rest.

Once the mash was finished, I collected the sweet wort in my kettle and turned the heating elements on.

The wort was boiled for 60 minutes with hops added as stated in the recipe.

At the end of the boil, I quickly chilled the wort.

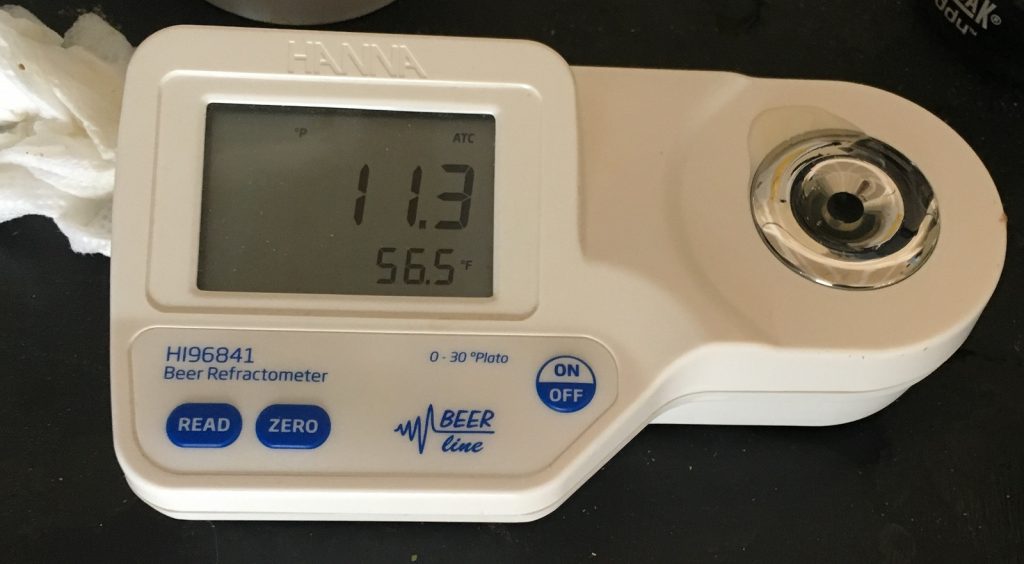

A refractometer reading showed the wort had reached a respectable 11.3 °P, or 1.045 OG.

I collected equal volumes of wort in separate sanitized Brew Buckets.

The filled fermentors were controlled to my desired fermentation temperature of 64°F/18°C and, after the yeast was pitched, each was hit with a 90 second dose of pure oxygen. I noticed airlock activity just a couple hours later. After 7 days, signs of fermentation were absent and I took hydrometer measurements confirming the same FG had been reached in both beers, so I proceeded with kegging.

The filled kegs were placed in my keezer and burst carbonated. Once carbonation was stable in both beers, I removed one keg from my keezer and placed it in my car to emulate a warm shipping environment. The things we do for science…

After 10 days of carpooling with me, during which the late spring Denver weather got quite warm, my beer had a new worldview and decided it was time to return to its home in my cool keezer. I allowed the beers to lager for another 2 weeks before serving them to blind participants.

| RESULTS |

A total of 21 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the beer that was stored only in a cool keezer and 1 sample of the beer that spent 10 days in the backseat of a warm car in different colored opaque cups then asked to identify the unique sample. At this sample size, 12 tasters (p<0.05) would have had to identify the unique sample in order to reach statistical significance, though only 5 (p=0.88) made the correct selection, indicating participants in this xBmt could not reliably distinguish a beer stored consistently cool from one stored in an environment that emulates warm shipping.

My Impressions: Out 5 self-administered blind triangle tests, I correctly guessed the unique sample just one time. They were identical in every respect, completely indistinguishable, which was a good thing considering I rather enjoyed the beer.

| DISCUSSION |

It’s scientific fact that heat hastens certain chemical reactions, the most concerning for brewers being oxidation, hence the effort (and money) invested in making sure beer stays as cool as possible once it leaves the brewery. Anyone who has been drinking beer for any length of time has had a pint that was obviously out of its prime, despite the date code being somewhat recent, an issue some attribute to the product being shipped in a non-refrigerated environment. This has always made sense to me, which made the results from this xBmt showing tasters couldn’t distinguish a beer that spent 10 days as a passenger in my warm car from one that sat still in my cool keezer all the more surprising.

While these results may be used by some as evidence that warm shipping environments have little negative impact on beer, there are a few caveats to this xBmt. First off, the beers were kegged, and I’ve developed kegging procedures over the years that keep oxygen ingress to a minimum, so it’s possible there simply wasn’t enough oxygen present for oxidation to occur. Bottling may very well produce different results, and seeing as most competitions only accept bottles, this is something one should keep in mind. Also, these homebrewed xBmt beers were consumed 10 days after packaging, far sooner than commercial breweries can ensure, as their product may end up sitting on a warm shelf for weeks before somebody gets to it.

I won’t pretend I perceived any differences between these beers, my own triangle test results speak for themselves, but I have no plans to start storing beers warm prior to serving. That said, given my tight packaging processes, I certainly feel a little less worried about shipping beers off to be judged.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

38 thoughts on “exBEERiment | Impact Warm Shipping Has On A Munich Helles”

Thank you for the article.

A small note though, 10 gallons is almost 38 liters, not 151.

I just recently entered the Ohio Brew Week competition. I entered an American Lager that I bottled directly off my faucet and overnight shipped from NJ to Ohio in the middle of a 90+ heat wave. The beer won best of show so I think these beers are a bit more resilient than we give them credit for. Maybe doing a similar test with a heavily hopped IPA would yield significantly different results?

My thoughts exactly. Need to do it with an IPA

We can ALSO do it with an IPA, or similarly hoppy beer, but we didn’t NEED to. It’s a different experiment, one that is also very interesting and will look forward to those results as well.

Another thought – what exactly is a “warm” car? A 90*F heat wave is very different from the 118*F we had out in the Corona, California area last week.

In my day job, I work with electric cars and trucks. If I had to do this experiment myself, I would install a data logger on the outside of the keg that tracks the temperature and humidity. This will tell us how warm the car is. I would also like to see the keg get some more miles outside of Denver – perhaps even actually be shipped across country to another contributor.

You should totally do that xbmt!

Elliott, as an apartment home brewer, I have been trying to find some kind of inexpensive data logger to see which closet in my apartment stays the most stable temperature. as I know nothing about them, the ones I do find seem to be too expensive for the simple test I want to do. Can you recommend any?

Good experiment. Another factor present in commercial situations is light ingress. Perhaps a future version of the experiment could a split batch where half (or some) of the batch is bottled, then left on a warm “store shelf” for a few weeks. The other half would be kegged and thus protected from light. Perhaps heat and light together (or light alone) has a more profound staling effect.

Either way, nice job, Jake.

You should have tried this xbmt with a more heavily hopped beer. guarantee the results would be different.

Should have? Or perhaps could have?

The xbmt is what it is, a pale lager is a great style choice for this xbmt imo because it’s such a delicate beer.

Would results be different with a hoppy beer? Possibly, only one way to find out though.

Thanks for running this experiment. There’s nothing wrong with running this xbmt first on a Helles, but Helles, Pilsners and other similar beers are meant to be stored for long periods in warm storage (check out any beer store in Germany where they store Helles and Pilsners warm and give them 12 months of shelf life). LIke others have noted, something like an IPA, session IPA, NE IPA, etc. would likely be more susceptible to aging from warm storage and would be neat to see on the next one. Even from very big breweries, if you have their IPAs/Session IPAs after even 3-6 months of cold storage it tastes completely stale and lifeless.

I agree with you 100% about Helles being a delicate beer and agree with your rationale in choosing it. Yes, could have is a better response.

Hop character is one of those things that can really get destroyed by warm temps, especially a hot car! I’ve experienced this myself by intentionally storing two of the same freshly bottled competition pale ale’s in the fridge vs a kitchen cabinet. I did a side-by-side blind taste test to see what the NHC judges would taste had the beer been stored improperly before evaluation. It was a completely different beer. All the delicate, fruity hop aroma was gone. All that was left was a bland, generic citrusy flavor. It was very easy for myself and my friends to tell them apart.

I’d love to see you guys try this on an IPA!

Nice to see I am not the only one who spills all over my garage.!

Haha that’s star San from spraying out the ball valve prior to racking

Interesting exbeeriment. The one thing with heat though, is any infections or off flavors that are hidden when the beer is cold, could blow up when held at high heat for week or more. Had a Belgian Dubble that was fine at my house held in fermenter at 66F, tasted great, Brought the carboy to my LHBS for transfer to a club barrel. But three days in a 90 degree room at the shop and an infection bloomed in no time. Luckily it was before going into the barrel!

Nice Jake!

Posted on accident, please feel free to delete!

Nice Jake! Small clarification – in the discussion it says you were able to serve to people 10 days after packaging but wasn’t it quite a bit longer since you carbed, had a 10 day joyride, then cooled off for another 2 weeks?

I agree with Mark Buster that the introduction of transfer, bottling, and light would’ve tested the the “warm shipping” scenario more accurately (in my opinion). I only bring that up because you raised the point about how beers are affected when they’re sent for competition. Without bottling the beer, you didn’t really replicate that. Perhaps an additional experiment for you?

My only concern is a week might not be long enough. We emulate hot storage for a few weeks and notice big swing’s, most. Commercial breweries can’t get product out within a week or two, then add the shipping and stocking time on top of that. P.s. love these write ups you do.

Yeah it’s tough to say really given the insane variability o shipping just given the weather. Much of the ten days the beer spent in my car were at an airport parking lot where the weather was 90 during the day and like 50-60 at night so the swings were definitely large. Either way we have some more ideas for this type of variable planned as we’ve all become pretty fascinated with the post fermentation portion of brewing

This was a helpful article! My friends and I have been kicking around the idea of making batches of homebrew to take on vacation (11-12 hours in the back of a truck, in corny kegs) to put in the kegerator we bring instead of buying commercial when we get there. This nudges us farther in that direction!

@ Jared – We do this every summer with a Kolsch. The first time I really babied the beer and kept it on ice. This summer, I just put the cold keg back there and let it ride for 8 hours. The only negative impact I noticed was that once the beer warmed it took a little longer for it to cool back down and allow the CO2 to return to solution before I could get a good pour. (So take your commercial beer for day 1 and by day 2 your homebrew will be good to go if you have plenty of head pressure).

As for the XBMT, thanks Jake, really enjoyed seeing this. As you pointed out, I’d be interested to see the same thing in bottle form someday. I did a mini version of that experiment by leaving some bottles in my car during the Texas summer for a week of my commute (to simulate UPS ground shipping). I did this while I was sending bottles from TX to CA for review on a podcast (so that I could taste the beer treated the same way the judges would). I tasted that beer side-by-side with a bottle I’d kept in the fridge for a week, and I couldn’t tell a difference side by side (though I didn’t actually do a triangle test).

I’m one of those people that visit Portland, Burlington, Monson, etc, in search of good beer and while I don’t leave it in a hot car, it’s tough to refrigerate cases and cases of beer in a hotel room. Impossible, really. So this was really nice to read both as a home brewer and a craft beer enthusiast. I never perceived any change in a beer that been sitting in hotel AC temps for a few days but I always wondered if it didn’t hurt it in some way. Now I know! Thanks!

Great write up! I’m curious if you could comment on the hop profile you got from the beer? I’ve used Loral twice in beers. once a saison I did not care for and once a bitter I quite enjoyed. The bitter also had some EKG in it. I perceived what I would call a very nice tea like quality to the hop profile. I’m not sure if I was picking up the Loral or the EKG. Any thoughts? Or anyone else?

I definitely get a tea like flavor from most English hops so I’d guess that was EKG.

To me loral gives a nice spicy citrus type flavor which I love in lagers. I’ve used it in one Belgian beer which I currently have on tap and have to say I don’t care for it too much in that. To me it doesn’t really compliment the earthy phenolic tones of Belgian yeast very well.

Thank you sir!

I appreciate the experiment as run. However I think no homebrewer competes by shipping a purged keg. If you ever decide to rerun this, I think unpurged bottles would more accurately reflect real-world conditions.

The experiment design, while producing an interesting finding, isnt germane to homebrew competitions. I’ve only shipped bottles, and never heard of one requiring a corny. Repeat with bottles of a hoppy IPA and I suspect the results will be different.

As an aside, I tried two cans of a local IPA – one kept at room temperature, one put in a 120°F water bath for two hours to stimulate several days of hot storage. Both were then chilled before tasting. Room temp tasted pretty good, while the heated one had almost no hop character at all. Tasted like a completely different beer. Heat can really trash an IPA and it won’t take long.

So one simply had a 10 day extended diacetyl rest over the other? No bad thing

I’d like to see a experiment of bottles, shipped across the country by air and by truck. My Air shipped NHC IPA got killed for oxygenated, same beer that finished 2nd in the IN state fair.

Could the pressure changes pull more air in through the crown caps?

Nice experiment. But why didn’t you lager before you transported warm? Wouldn’t this be more realistic to a consumer environment? Assuming that most beer will be drunk shortly after the purchase?

I honestly don’t think that really matters in this xbmt, though I’m open to being wrong. Lagering is literally just aging.

This is an experiment I’ve been waiting for. Long story short, for the past year and a half I’ve been trying to clone Sculpin IPA, even conversing with their head brewer to get it dialed in. I was always left with a great IPA, but one that didn’t laste like Sculpin. It was not until three months ago when I went to LA for work and stopped at Ballast point in Long Beach that I realized I’ve been making it right all along. Fresh Sculpin at the brewery is the same in my basement. It made me think that the aging and the heat in transport to the east coast changed the beer. I’ve tried the keg in a car thing for a week. Good to know I’m not alone! Yet, it didn’t change it at all.

However, I had a friend clone this and he gave me a bottle, but I forgot about it and was left in a heated environment for three weeks (in front of a sunny window at work). His clone was exactly like I get in the bottle.

So, I just made another batch and I have one of the kegs in my attic and the other in my 64 degree basement. I’m letting it stay up there for four weeks. My curiosity remains so it’s worth it to me. I was thrilled to see someone else is curious about this too. I’ll keep you posted

Do Loral hops remind you of Fruit Loops?

Only if used in the dry hop or heavy late hop stage. Otherwise they remind me of a citrusy noble

Here in Brazil, foreigh beer tooks sometimes 3 months in hot weather.

Great experiment, but I’d love see this carried out over a longer period say six months or more with one keg at room temp and one kept in the cooler.