Author: Matt Del Fiacco

Through the years, I’ve fermented beer in a wide variety of vessels, from 3 gallon PET carboys to stainless corny kegs. While I appreciated being able to watch fermentation happen, the PET carboys were somewhat difficult to clean without some scrubbing, which could create bacteria harboring scratches in the plastic. The larger opening of corny kegs, and the fact they’re made of stainless steel, lessened my cleaning concerns, though a fair degree of leg work was required to make sure they were immaculate.

As a big believer in the perils of cold-side oxidation, my main reason for moving to fermenting in kegs was the fact it would allow for completely closed transfers, a tricky task for other fermentors. In addition to the disassembly required to clean, there were some other downsides to making this switch, namely that I had to reduce my batch size to 4 gallons/15 liters since corny kegs only hold 5 gallons/19 liters of liquid. It also tied up a keg I could otherwise be using to serve beer.

As pleased as I’ve been with fermenting in kegs, they’re certainly not perfect, so I’d been keeping my eyes peeled for other options that were made of stainless, had a wide top opening, possess a bottom valve, and allow for pressurized transfers. Numerous new fermentors on the market hit some of these marks, but there was one I was most interested that hit them all—the Anvil Bucket Fermentor.

Anvil Brewing Equipment provides a line of high quality equipment designed by Blichmann Engineering and endorsed by How To Brew author, John Palmer. When the opportunity arose for me to put the Anvil Bucket Fermentor through it’s paces, I accepted, curious to see how it’d compare to other fermentors I’ve used.

Disclosure: The product reviewed for this article was provided by the manufacturer in exchange for an honest review; no other compensation was provided. The opinions expressed in the article are solely those of the author and a concerted effort was made to approach the review from an unbiased perspective.

Assembly & Use

Not long after agreeing to this review with Palmer and Blichmann, a couple well packaged Anvil Bucket Fermentors arrived at my house.

Assembly couldn’t have been easier, just tighten a few pieces and the units were ready to go. Prior to first use, I gave the fermentors a good cleaning with PBW to remove any residue that might have been leftover from the manufacturing process. Once clean, I soaked them in Star San solution then let them air dry to passivate the stainless.

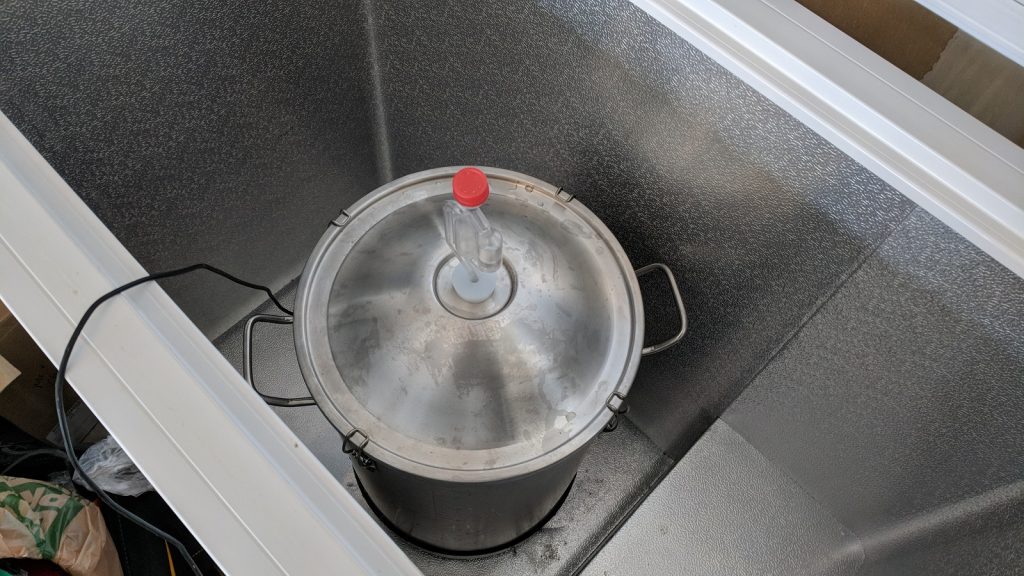

I’ve followed a similar protocol each time I’ve used the Anvil buckets, which starts with wiping out the inside with a cloth dipped in PBW solution then rinsing with hot water. Next, I add a good amount of StarSan solution to the fermentor and let it soak for a few minutes before swirling to ensure sanitizer covers all surfaces. After pouring out the StarSan, I cover the airlock hole and let it sit until my wort is ready to transfer. Once I fill the fermentor with chilled wort, I attach the lid, place a piece of foil over the airlock hole, then place it in my fermentation chamber to finish chilling to my desired pitching temperature.

When the wort has stabilize at my desired temperature, I remove the lid, pitch the yeast, then swap out the foil for an airlock. Packaging consists of moving the fermentor to a raised spot, connecting my racking tubing to the barb, and opening the valve to start the flow of beer into my keg.

Using a rudimentary pressure transfer rig that anyone with a kegging system can easily piece together, keeping beer under a blanket of CO2 during packaging to reduce the risk of oxidation is super easy.

The large opening and lack of a bunch of parts to disassemble make cleaning the Anvil Bucket Fermentor a cinch. After removing and rinsing the lid, I’ll spray the inside down with water to remove any large debris then give it a good PBW scrub with a soft cloth until clean. I’ll soak the removable spigot in leftover PBW solution for a few minutes then rinse it off with hot water. Finally, I place the unit upside down to air dry. The entire cleaning process, which requires no CO2 like with kegs and very little elbow grease, takes maybe 5 minutes per fermentor. I seriously love how stupid simple these things are to clean.

Detailed Feature Overview

There are many features of the Anvil Bucket Fermentors, some unique and others common among similar fermentation vessels. I picked out a few of the bigger features to discuss what I believe to be some pros and cons.

Stainless Steel

There’s little argument that stainless steel is one of the best materials for fermentation, as it’s impermeable to oxygen, relatively easy to keep clean and sanitize, and incredibly durable. Plus, it looks really pretty!

Overall, the fact the Anvil Bucket Fermentor is made of stainless is a huge plus, though it does add to the cost of the unit, as stainless is simply more expensive than plastic or glass. However, it’s been argued that over the long term, stainless is the better deal, as it won’t require replacement the way plastic carboys do. Outside of this, the only other downside to the Anvil Bucket being made of stainless is that it’s opaque, so no more mindless gazing at my fermenting beer, which really isn’t a big deal.

Volume Markings

When using plastic, glass, or corny keg fermentors, I had to rely on a bit of guessing when it came to filling them with wort, which is a thing of the past with the Anvil Buckets. They’re also embossed into the stainless, so no worries whatsoever about them ever going away.

The volume markings, which I tested to ensure precision, allow me to see how much wort I am collecting from the kettle so that I get exactly the amount I want. While arguably unnecessary, they are really convenient and add some value.

Dimensions

I was hesitant to comment on this aspect of the Anvil Bucket Fermentor only because issues with dimension are hugely dependent on each individual user’s brewery setup. However, I figured it worthwhile since I use a chest freezer as chamber, which is fairly common among homebrewers. The Buckets have a total width of 16.5 in./42 cm, which is quite a bit larger than other fermentors I’ve used, especially corny kegs. Unfortunately, I’m unable to fit 2 Anvil’s next to each other in my 7 cubic foot chamber, which poses an issue only because the majority of my brewing is for dual batch xBmts.

Additionally, due to having a domed lid, the Anvil fermentors can’t easily be stacked, a small inconvenience for those with limited storage space.

The height is about 26 in./66 cm with the airlock in place, so it ought to fit in most chest freezer fermentation chambers just fine.

Concave Bottom

Looking at the Anvil Bucket Fermentor from the outside, it appears to be flat bottomed, though it is actually slightly concave.

While not technically conical, I’ve found this feature is still very helpful. When fermentation is complete, the trub settles out into the cone, which when combined with the adjustable diptube, allows for very easy transferring of clear beer to the package.

Racking Spigot

Every fermentor I’ve used in the past has required the use of either a clunky siphon rig or CO2 pressure, while the Anvil Bucket Fermentor has a spigot that makes for quick and easy racking. of the fermentor features a threaded male connection that allows for quickly removing the barb while keeping the spigot itself intact.

In addition to being supremely convenient, the open end of the spigot is threaded, meaning the barbed attachment can be removed while keeping the spigot in place.

I really appreciate having the option to customize my gear to fit my system and process, so this is an easy mark in the pro column for me. One of the first modifications I made after receiving my Anvil fermentors was to attach a liquid line and disconnect to the barb, which allows me to keep the entire racking assembly together and clean without being attached during fermentation.

Given how low the spigot is, collecting samples is difficult because a glass doesn’t fit under the nozzle. I could connect some tubing to make this easier, but I’ve found that briefly lifting it onto the hump before sample collections isn’t that big of a deal and reduces the chances of making a mess. One could also pull samples from the top of the Anvil Bucket using the standard turkey baster method, but I prefer the spigot to avoid oxygen exposure.

The Bung

I’m struggling to understand why Anvil/Blichmann went with a silicone airlock bung for this fermentor, as just a little too much pressure when putting it in place can lead to silicone bits sloughing off.

This isn’t really a big issue and can be mitigated fairly easily by adding the airlock to the bung before gently placing it on the fermentor, or simply swapping out the silicone bung for an old rubber stopper.

Another concern I have about the use of silicone for this purpose is that it’s much more oxygen permeable than other types of rubber, so I wouldn’t feel comfortable storing most beers in the silicone bunged fermentor long term. In the end, this is a small and very easily fixed complaint.

| THE VERDICT |

Over the last decade, fermentation vessel options for homebrewers has grown exponentially, with offerings varying in material, size, and features. There’s no arguing that good beer can be produced using any of these options, so deciding on which on to go with really boils down to the conveniences it offers, and for me, the Anvil Bucket Fermentor hits most marks.

With the capacity to hold 7.5 gallons/28.4 liters of liquid, the Anvil can comfortably ferment a 5 gallon/19 liter batch of even high OG beer without much risk of a messy blowoff. The trade-off is that the unit is slightly larger than other fermentors, but not such that it’ll be problematic for most brewers, just those of us who ferment 2 batches side-by-side in a smaller chamber.

I love how easy packaging beer with the Anvil Bucket Fermentor is. The spigot with adjustable diptube means no more siphons, the conical bottom keeps all the trub out of the way, and it can withstand about 3 psi of pressure without leaking, meaning no oxygen ingress. Once empty, I spend about 5 minutes cleaning up and readying the fermentor for its next use.

Overall, any cons of the Anvil Bucket Fermentor are easily overshadowed by the pros. For the brewer looking for a durable fermentation vessel that will likely last them a lifetime, I highly recommend they consider this Anvil unit for the many conveniences it offers at a relatively affordable price.

Anvil Bucket Fermentors are currently available for purchase at Love2Brew, Adventures In Homebrewing, and Great Fermentations.

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

37 thoughts on “Product Review | Anvil Bucket Fermentor”

Thanks for the great review — I’ve been looking at these for a little while now and this answered most of my questions. The one question I still have is about monitoring fermentation temperature. I’ve noticed it doesn’t have a thermowell, but from one of the pictures it looked like there was a wire for a temperature probe. How did you handle this?

Get a number #7 stopper drilled for an airlock and an thermowell probe.

How large is the opening on the lid for the air lock?

Just measured it, it is about 1 1/4″

You should try fermenting in a Sanke. Brewers Hardware has cheap hardware to facilitate. 14 gallon batches. Add PBW and cap and roll around occasionally to clean. You can also naturally carbonate if you want or do no chill brewing easily. I love it.

I’ve definitely seen people do that with success! Glad that is working well for you man.

I was just thinking about buying one of these – your review couldn’t come at a better time!

I’ve had one of these for a bit and have replaced the stopper with a stopper that accomodates both an airlock and a long thermowell. That way the probe for my temperature sensor is actually in the fermenting beer.

I agree with Matt’s review. My major :criticism is the width of the fermenter, along with the handles that don’t fold down, make it difficult to position in my fermentation chamber. Small price to pay for the ease of cleaning and the other positive aspects described in the reviuew.

Does anyone else notice a difference between the smell of rubber stoppers vs silicone? Does this smell/flavor ever make it into the beer?

Purely anecdotally, I’ve used both rubber and silicone stoppers on a number of different fermenters and haven’t noticed a difference in the final product. But I also haven’t compared silicone vs rubber and long term aging.

Thanks. I was advised by my LHBS to use silicone instead of rubber, and I could definitely smell a difference between the two, but not sure if it would make it through to beer, especially since there is very little contact between the stopper and beer. Actually, I think the choice was between 2 different rubber stoppers, size #10, a solid one and the “universal” one that is shaped like a cup. The solid one had a weird smell.

Does the valve easily rotate so the bend dip tube can be positioned to get the clearest beer? Thanks for the review, I own one of the competitors and have been deciding whether to buy another of those or one of these. Cheers!

Hey there! It does, just rotating the spigot rotates the dip tube easily and you can avoid any trub. Cheers man!

I have 2 of these also… I silver soldier a 1/2” spud from brew hardware over the air locker port.. I use a blow off tube start to finish… I also have a 1/4” male flare fitting to adapt to that spud and I am able to push out the brew with gas.

I also cut off the dip tube so it leaves 1/2 gallon behind…

Very cool! I’d love to see that, messing with the airlock is something I want to look into more.

Out of curiosity, why cut the dip tube and not just rotate it?

Because when it’s straight down, I know for a fact I’m not sucking up any more yeast than necessary …

And now I’m tinkering with spunding valves too!

Nice review. Does anyone have thoughts on this fermentor vs. SS brew bucket?

I’ve got one of the original SS Brewtech fermenters that I love but have been looking for a second one. Maybe this is the one?

I use a 40l crab cooker

Have it, love it. As for cons, I think they tend to be more of an inconvenience depending on your particular setup.

I’ve never taken the gasket off the underside of the lid when cleaning. I just puddle some StarSan around it and let it sit for 5 or 10 minutes.

How does that racking arm handle trub heavy beers like a NEIPA? It seems a bit short….

I have the SS and the Anvil. Both are equal to task. One thing I noticed with the Anvil is that when I wash it, a black “residue” remains on my towel when I dry it. I did wash with pbw and soak in Star San when I got it. And it has soaked in Star san a number of times since then. Haven’t experienced any off flavors thankfully. My SS does not do that. Probably the quality of the stainless steel.

Interesting observation. Thank you for that. Have you contacted Blichmann/ Anvil about your experience? I’d be curious as to their response.

I have not heard back from them

How easy is the valve to clean? Does anyone know if it would it be possible to retrofit it with something like this?

https://brulosophy.com/2015/05/28/brewers-hardware-quick-clean-take-apart-ball-valve-product-review/

How’s the valve to clean? Could it be easily replaced with something like the brewer’s hardware quick clean take apart ball valve?

https://brulosophy.com/2015/05/28/brewers-hardware-quick-clean-take-apart-ball-valve-product-review/

Question about your liquid line disconnect — Are you running 1/2″ tubing? I’d like to do the same, but I thought corny quick connects typically use 1/4″ barbs? Any advise on how you built your nice little transfer line?

I’m here with the same question. I know the barb on the bucket is 1/2″ but as you said most disconnect barbs are 1/4″ You can get 5/16″ barbs for your disconnects but that’s still a 3/16″ difference between the two barbs so I’d love a little more detail from Matt on this as well. Maybe a 1/2″ hose with a TIGHT hose clamp around the 5/16″ barb is good enough?

Another question I had was which size hose is used for the CO2 line going to the bung?

What I’d really like to do is attach a liquid ball post directly to the threaded ball valve so I can just hook a jumper up to the bucket and my keg. I emailed Anvil earlier today asking for the thread size / pattern so see if I can find an adapter to make that work.

Check this out.

https://www.brewhardware.com/product_p/fflbarb12.htm

Thank you JT, that’s exactly what I was looking for!

i’ve been checking brewhardware for months for this, its always out of stock. Does anyone else make this flare? I’ve searched and haven’t caught a scent. .

I need one of these too. Brew Hardware has been out of a lot of things I want lately. I also want some of their slim-line weldless hole plugs, but they’ve been out for a while.

Did you notice any scratches on the inside of yours when you got it? I just got mine, and there’s a handful of vertical scratches in it. There’s also a ring of scratches/rough surface finish about an inch below the valve. I’m a little concerned about being able to clean it with such poor surface finish, my SS Brewtech Mini’s seemed to be much better quality/finish.

What is the diameter of the bucket, NOT including the valve? I’m trying to determine if this will fit into my beverage refrigerator fermentation chamber if it’s turned 45 degrees to position the handle and valve flush against the door. Thanks!

Thanks for the great review. I just got one of these and had a couple questions after seeing how you’re using it. First, do you take any steps to reduce contamination risks when taking gravity samples using the valve? I’ve only used mine for one batch and I decided to use a thief for a sample mid fermentation instead of the valve because I was worried about the residue in the valve becoming contaminated as the beer was finishing up and then transferring that into my keg. Maybe I shouldn’t be concerned about this? Secondly, what sized tubing adapter did you replace the stock one with? I had a lot of air seeping into my 1/2 inch line using the one provided with the fermentor today, not good. Thanks again for the review, keep up the good work!

What setup (i.e. connectors, etc.) do you use for your fermenter to keg transfer setup?

Any feedback on your barb to keg transfer materials?