Author: Jake Huolihan

The German Beer Purity Law known as the Reinheitsgebot mandated that beers be produced with only 4 ingredients, none of which were carbon dioxide from an external source, often used by modern brewers for carbonation purposes. Despite these limitations, German brewers developed a few methods for carbonating that adhere to the purity law including kräusening, recapture of CO2 produced during fermentation, and spunding, which is perhaps the easiest of them all. (bunging) the fermentation to allow for the co2 produced during carbonation to naturally carbonate the beer.

Spund translates to bung, hence spunding involves bunging the fermentor before fermentation is complete, disallowing the escape of CO2, which ultimately carbonates the beer. Even with our ample access to packaged CO2 and no laws restricting its use, many modern brewers have adopted this method, as it allows them to save money by reusing what would otherwise be lost. Additionally, some contend it has a qualitatively positive impact on beer by producing a finer carbonation and preserving certain characteristics believed to be lost when force carbonating.

There are some things that require consideration when it comes to spunding. Brewers must know what their FG is going to be, which requires a good enough brewing process to be able to predict, and they need to be attentive to fermentation in order to spund at the appropriate time. The only piece of gear required is a spunding valve, which is basically a pressure relief valve that holds a set amount of pressure in the keg.

As a lover of German beers, I was interested to see if spunding, a method I’ve used a handful of times, results in a beer that’s noticeably different than a force carbonated beer.

| PURPOSE |

To evaluate the differences between a pale lager carbonated using force carbonation and one carbonated with the spunding method.

| METHODS |

I went with a simple German Helles Exportbier in hopes it would allow any differences to shine through.

Bubbles

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 6 gal | 60 min | 26.5 IBUs | 4.0 SRM | 1.053 | 1.016 | 4.9 % |

| Actuals | 1.053 | 1.015 | 5.0 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Malt (2 Row) US | 5.5 lbs | 45.36 |

| Weyermann Pilsner Malt | 4.5 lbs | 37.11 |

| Weyermann Vienna | 1.25 lbs | 10.31 |

| Carafoam (Weyermann) | 8 oz | 4.12 |

| Carahell | 6 oz | 3.09 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 19 g | 60 min | Boil | Pellet | 11.5 |

| Saaz | 15 g | 30 min | Boil | Pellet | 1.4 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Harvest (L17) | Imperial Yeast | 72% | 50°F - 60°F |

Notes

| Water Profile: Ca 81 | Mg 2 | Na 46 | SO4 74 | Cl 81 |

Download

| Download this recipe's BeerXML file |

I started off by reviewing Kai Troester’s BrauKaiser website where I learned wort produces 2 volumes of CO2 for every °P. Since the beer I planned to brew would be fermented at 50°F/10°C, it would retain 1.15 volumes of CO2, meaning natural carbonation would need to contribute 1.25 volumes to reach my desired serving carbonation of 2.4 volumes. Using the BrauKaiser calculator, I determined I would need to keg the beer when it was about 0.63 °P from FG. Since I’d be using a spunding valve, I figured kegging with 1 °P left to go would provide a little insurance.

I whipped up a large starter of Imperial Yeast L17 Harvest to split between the batches a couple days ahead of time.

Having prepared the night before, my brew day started with turning on my electric elements to heat the water, during which I milled the grain.

Since this variable would be introduced post-boil, I mashed in on the single 10 gallon batch and hit my target temperature.

A check of my mash pH about 15 minutes in showed it was right where I planned.

When the mash was complete, I raised the grain bag out of the kettle and let it drip into the wort that was being heated.

The wort was boiled for 60 minutes with hops added as noted in the recipe.

With the boil complete, I quickly chilled it with an immersion chiller to a few degrees warmer than my groundwater temperature.

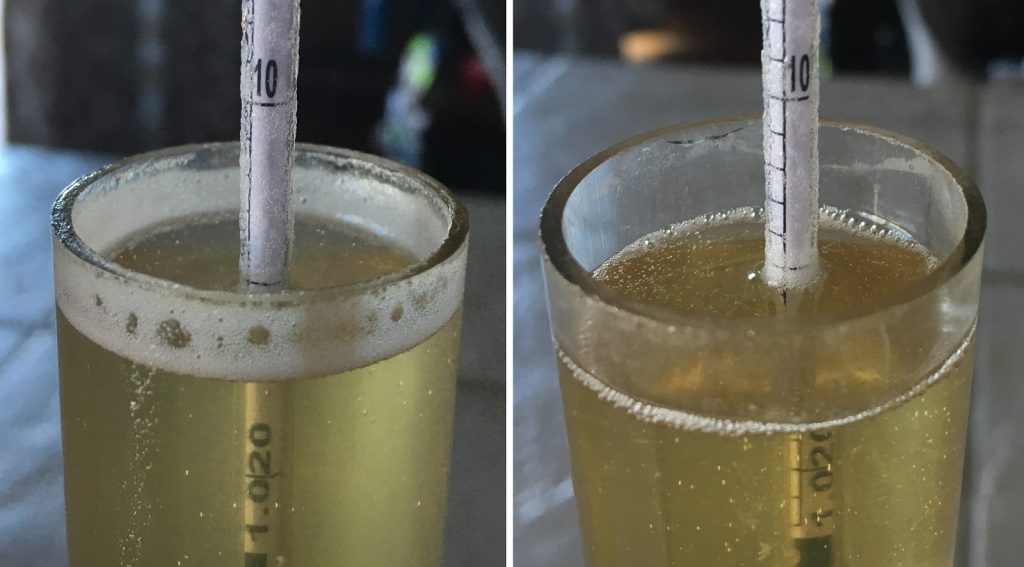

I took a hydrometer reading to confirm I’d hit my target OG.

I proceeded to rack equal amounts of wort to separate Brew Buckets that were placed in my chamber to finishing chilling. I then collected some of the remnant wort and threw in a bit of yeast for a forced fermentation test to determine my final gravity.

The following day, with both worts stabilized at 48°F/10°C, I evenly split the decanted starter between the batches before hitting each with 90 seconds of pure oxygen.

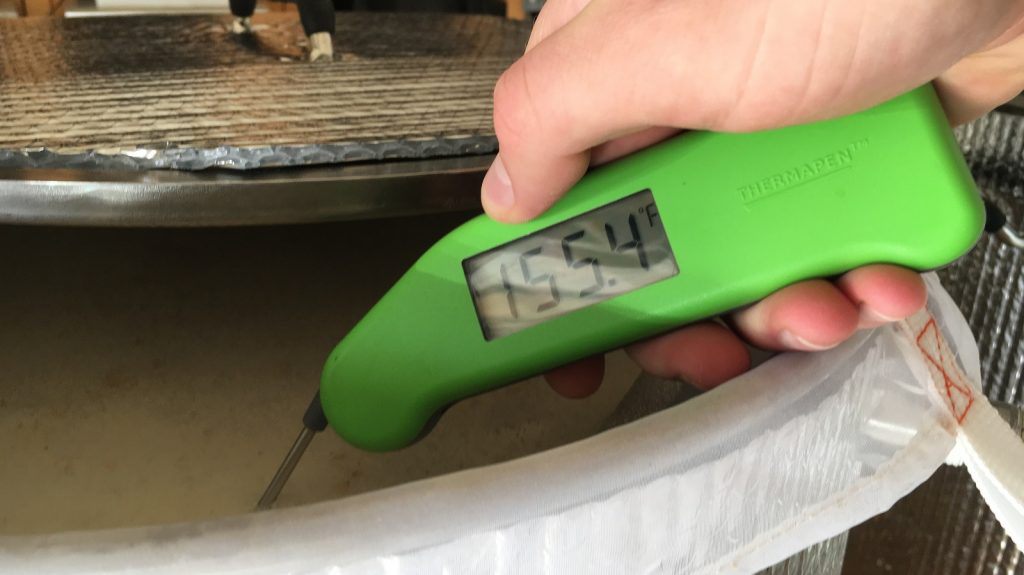

By the next morning, the beers were happily bubbling away. It was at this point I noticed the forced fermentation beer seemed done, so I took a hydrometer measurement and found it was at 1.015 FG. This meant I would need to spund around 1.019 SG.

A hydrometer measurement take 3 days post-pitch showed the beer was at 1.020 SG, close enough for me, so I racked it to a keg.

Once the keg was full of the fermenting beer, I attached a spunding valve initially set to 15 psi then placed it next to the other beer before raising the temperature of the chamber to 60°F/16°C; when the beers reached this warmer temperature, I set the gauge to 22 psi (based on this chart).

Hydrometer measurements taken a few days later showed both beers had reached the same FG.

At this point, I kegged the force carbonation beer then moved both to my cool keezer. Since these were traditional lager beers, I went with Greg Noonan’s advice and allowed them to lager for 9 days per °Plato, which amounted to 60 days before serving them to tasters.

| RESULTS |

A total of 22 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the force carbonated beer and 1 sample of the spunded beer in different colored opaque cups then asked to identify the unique sample. At this sample size, 12 tasters (p<0.05) would have had to identify the unique sample in order to reach statistical significance, which is precisely the number who did (p=0.03), indicating participants in this xBmt were able to reliably distinguish a beer that was force carbonated from one carbonated via spunding.

The 12 participants who made the accurate selection on the triangle test were instructed to complete a brief preference survey comparing only the 2 beers that were different. A total of 5 reported preferring the force carbonated beer, 2 liked the spunded beer more, 3 reported having no preference despite noticing a difference, and 2 reported perceiving no difference.

My Impressions: I made my first few triangle test attempts right after kegging the beers, and they were mostly guesses. However, after the lagering period, I was more able to tell a difference and my triangle test performance drastically improved, I could consistently distinguish the odd-beer-out. I perceived the force carbonated beer as having a sort of honey-like aroma, quite similar to my perception of many commercially available German lagers found on US shelves, while this was less present in the spunded beer. There’s no way I could choose either of these as a favorite because I thought both were great, despite being a little different from each other.

| DISCUSSION |

Spunding is a method lauded for both its pragmatic benefits, such as using CO2 produced during fermentation for natural carbonation, as well as the impact it has on the ultimate character of beer. The results from this xBmt showing participants were able to reliably distinguish the force carbonated Helles Export from one that was spunded do support the notion that either approach has a unique impact.

Perhaps the simplest explanation for this difference is that natural carbonation imparts a different character than force carbonation, though it seems unlikely given both rely on the same CO2 gas and principle of dissolving under pressure. It could also be that spunded beer has a lower risk of oxidation since it’s kegged during active fermentation, giving the yeast time to scrub any oxygen introduced during the transfer. On the other hand, the more common approach uses these days involves packaging beer that is done fermenting, which is a major vector for oxygen ingress, then hitting it with gas to carbonate.

The preference data showing most people liked the force carbonated beer more than the spunded beer suggests either neither beer was oxidized or that people enjoy the flavors of oxidized beer. I’ve tasted many oxidized beers and while the honey character I perceived in the force carbonated beer is something some associate with oxidation, the fact is it was still very good, even 2 months after packaging.

Spunding does involve a bit more work than force carbonation, which may be unappealing to some, though I see it as a useful option in certain situations. I won’t be be adopting this method for every batch I make, but certainly for beers I plan to age for awhile, especially lagers, mostly because it’s easy insurance.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

61 thoughts on “exBEERiment | Carbonation Methods: Force Carbonation vs. Spunding In A German Helles Exportbier”

Spunding 🍻. I feel silly thinking I “invented” fermented interuptus – After repeated batches with same dark lager and S-23 yeast I’d bottle at 1.018 / 9 and am confident of 4 points of carbonation. Since you’ve introduced me to it, I’ll certainly reference as spunding in the future. Thanks for all you do! Tony L.

Hahahaha I love this, cheers

I did a large number of lagers of different styles this way last year. After doing forced ferments on the first few and determining that the fg was extremely consistent I did same as you. I allowed a couple weeks for beers to finish ferment in bottles and then stored. Never did lager. Great beers that tasted great when I drank the last of them nearly a year later. One of these won a gold in Ohio State Fair contest. Downside is a fair bit of yeast residue that is easily disturbed.

Similarly I’ve won many medals with both spunded and force carbed beers. I’m wont to think it doesn’t make the difference ppl seem to think does, in a vacuum

Did you get the beers carbonated to exactly the same level. I know you that you were careful in your process. I’m just wondering if there was a slight difference between them that was skew the test results.

Yeah, spunding valve makes that pretty simple honestly.

I’d be worried about not enough yeast to scrub out diacetyl by racking off main fermentation to early for lager. I guess if you lager for 6 months that won’t be a problem?

To me, when I think about stuff like this I consider that even the brightest beers still have small amounts of yeast that are in suspension, so when racking off the yeast cake from the fermentation vessel to the keg there will still be plenty of yeast for spunding; the turbid green beer (metaphorically green) that’s pictured in the cylinder for the gravity sample is obviously full of yeast! Concurrent to this natural carbonation yeast will also be cleaning up byproducts like diacetyl, and it stands to reason that is why he increased the temperature to D-rest levels at this point. And yes, extended lagering will usually help clean up these fermentation compounds as well, so the 2 months that were spent in the cold box probably facilitated this.

So, the tl;dr (at least as far as I’m concerned) is that in cases like this you probably don’t need worry about not having enough yeast for a D-rest!

Time is the key then. I usually need more yeast for just 2 days of d-rest. Also depending on pitching temps, I’ll have to pitch low in the 40s to eliminate the need for d-rest

Am I right in thinking you lagered the spunded batch on the yeast but separated the forced batch from the yeast? If so, it’s possible the spunded batch attenuated a small amount more during lagering, which could account for some of the difference in perceived taste/flavour. A gravity reading at serving point would show if there was a difference in FG.

Honey flavour does suggest oxidation. As you point out, a small amount of oxidation isn’t a big deal. If you stored for longer than 60 days the preference might shift as the force carbed beer might go downhill faster.

Looks like he’s saying he racked the spunded batch to a separate keg to finish fermentation and left the force carb’d batch on the cake to complete fermentation

“Spunding does involve a bit more work than force carbonation, which may be unappealing to some, though I see it as a useful option in certain situations.”

Well, the effort varies. In the UK I can’t get CO2 delivered and I’d have to drive to a seller (like a paintball specialist). Spunding and casking involve less gear to pick up and replenish on.

FYI, I get mine delivered from http://www.adamsgas.co.uk ; they seem to be quite widely available, although the delivery fee is a good portion of the price of the bottle…

Thanks, Michael! I think I’ve identified a local stockist through them! A lot more expensive than priming, though.

I am finding lately that many homebrewers actually prefer sweeter (slightly oxidized) beers over fresh, crisp, non oxidized beers. Personally I don’t get it, sweet, heavy honey flavors are not refreshing.

Hi. You are one of my favorite things on the internet. I currently use those little red oxygen cans from home depot and a diffusion stone (with sanitary filter) but they get used up frustratingly fast. Any recommendations? So you use those or do you keep a larger O2 tank?

I use those as well, they last me quite a few batches though I don’t think I’ve ever figured out how many. If you keep the flow low so it’s only breaking the surface versus vigorous bubbling they may last longer.

Thanks. Please keep up the great work.I read every Exbeeriment and frequently use your results to modify my own brew days.

The regulators for those small tanks seem to leak a bit, so I’d recommend removing it from the tank between oxygenations. I seemed to make better use of the tanks after I started doing this.

Any difference in head retention and foam stability? It is often said that naturally-carbonated beers have smaller and finer bubbles than force-carbonated beers, but I have not conducted comparisons of my own.

I had read that spunding is key for neipa to prevent aroma carryoff by the co2. Any chance we see a similar experiment with a more aroma forward style?

Would love to see this too, though the continual dry hop additions could present issues with the timing of sounding a neipa.

any plans to try this with a more aroma forward beer? I had read that spunding is key to the biotransformation step to prevent aroma carryoff with the C02. That said the source suggesting keeping the spund low to 5psi or so

THanks for running this test I am very interested in trying this I have built a spunding valve as you show but find either the keg or it leaks very slightly over time. More advice on the spunding valve would be appreciated. Next time I will just keg and check pressure with the valve. My next questions relates to the “honey” notes. Industrial CO2 may have more O2 in it than would be acceptable in packaged beer. Hence why beer in kegs gets stale if not consumed in a reasonable time. I have direct experience with comparing a glass of pils from the bottom of the keg and a bottle taken after carbonated. Lastly your initial SG is not 1053 and looks more like 1056. This seems to occur on many of these expbeeriments that I read. The bottom of the meniscus should be read not the top. Cheers

Spunding valves- I use a <$5 harbor freight regulator and have been pleased (item#68223). I've ran carbonation up to 100 psi to pressurize an empty keg and avoid reliance on purchased gas. I have a plug in the "inlet" side of the regulator. A barbed fitting goes on the "outlet" side and runs to a gas fitting via a short length of tubing. I often tilt the keg momentarily so some liquid gets in the tubing so I can monitor bubbling.

Colin, curious about how you pressurize the empty keg to 100 psi with captured CO2. Do you let the fermentation pressure build to that level?

Can you provide more details on your use of that regulator? I’m thinking of trying something similar.

Gas Reservoir keg-

To avoid contamination with oxygen, start by filling it with water. Attach picnic spigot to liquid tap and place in bucket to receive the water.

Connect gas posts from fermenting keg to gas reservoir keg. There will need to be a T in this line that has the regulator I mentioned. It needs to be connected backward of the arrow on the reg. Other port needs to be plugged. This regulator serves to vent pressure at whatever limit you set.

Allow fermentation pressure to drive water from gas reservoir keg. Eventually you will see bubbling in the bucket, at which point you can disconnect the picnic spigot and allow pressure to build. At times I allow fermentation pressure to get that high.

Realistically you will have a second T which will branch gas off to another regulator to feed serving kegs. This regulator will need to be plumbed in normal orientation with respect to the arrow. Set to serving pressure. I used the same regulator and replaced the gauge with 0-30 psi range unit. I haven’t been as happy with the regulator in this application, but I get by.

Your beer keg will be over pressured for what you want to drink and you’ll need to vent off some gas. I prefer to do this with keg cold in hopes it retains more hop aroma. Your second regulator will vent off the excess pressure but it’s possible the keg will foam up and get your gas lines icky if venting is done at a fast rate. So I have a needle valve that serves to slow the rate at which gas is vented. After pressure is vented down to serving levels, I open the valve up. From this point forward gas will flow from pressure reservoir keg to drive out the beer you drink (and keep constant pressure on it).

Thanks for the clarification, Colin. I can understand most of what you described, but pictures would help a bunch. Do you have pictures of any of your setup available?

I’ve also been thinking about this lately. I’ve started doing my hoppy or yeast-driven-spicy beers in kegs with spunding to try to drop the O2 to zero. I was bothered by the fact that after all of my hard work I had to attach it to a CO2 cylinder, which probably contains some O2. I was thinking of doing some kind of fermentation using water, yeast nutrient and sucrose in a keg, let it purge out a second keg for a day or so and then let it grow in pressure to like 50 PSI so I can use it to serve another keg of IPA.

Mike G-

Let me clarify- the spunding regulator only has a hose attached to its “output” port. It’s “input” port is plugged. “Relieving” regulators vent excess pressure from their outlet port.

The serving regulator is used conventionally where the inlet side is connected to high-pressure side and serving kegs connected to outlet.

I don’t think I have means to attach a pic.

Aaron-

Using keg for both fermentation vessel and serving should reduce oxygen. I made something so that the dip tube draws from the top to avoid all the sediment. Morebeer . com product FE101A seems like it would do the same thing.

I doubt purchased CO2 has much O2 in it, though.

You could have a water/sugar fermentation for the purpose to CO2 generation but a batch of beer will make a big excess of what is needed to carbonate, purge gas reservoir keg of water, and enough pressure to serve the whole keg.

All I can say is that my NEIPA’s don’t darken noticeably by the time the keg kicks (~2 months tops). Darkening is known to occur as a result of oxygen.

***

I’m not sure if I mentioned this, but another perk of fermenting under pressure is that very little headspace is needed. I also often tilt the kegs so the gas port is higher.

“I also often tilt the kegs so the gas port is higher.”

Interesting idea. I’m going to try this next time.

Thanks Colin. Did you disassemble the regulators and clean them before use? Someone mentioned them having air tool oil inside, which they cleaned before using.

colin k, are you on homebrewtalk? we should start a thread on this topic. it would be fun. i can start a thread if you want to start contributing to it.

I would like to see this done again. I am an American brewer living in Slovakia. Almost nobody force carbonates beer here. I have always had a theory that this is one reasons why the taste profiles never seem to compare. Many brewers are adopting “American” style craft recipes but using traditional european methods for making them.

Hey Matt,

Why do you wish to see it done again, may I ask? Just for further study and more proof? Curiosity?

Per the results they are perceivably different on this experiment. What was is your initial assumption? That they would not be different?

FWIW, I always want to see more studies done, just because i don’t like to hang my hat on one result.

You’ve caused me to have a thought!

What if you transferred your fermenting wort to a corny when it was around FG+8* and then connected your gas outlet to that of a cleaned and sanitised second keg which is fitted with a spund valve. It would mean you end up with 2 kegs, one with carbonated beer and a second that has been purged with CO2 and pressurised to your spunding pressure.

You could then allow the beer to settle and, when it is running clear, you can do a pressure transfer to the second keg and you haven’t used any external CO2 at all.

*-I’m assuming that if 4 points are needed to carbonate the beer then you’d need double that to pressurise the second keg, but I’m sure that the act on increasing the headspace in this way and Boyle’s Law means that it isn’t as simple as this.

I really like this idea. I have transported kegs for a couple of events and both times struggled with the layer of yeast at the bottom of the keg getting disturbed in transport. I decided next time I either need to transfer to secondary to leave the final yeast sediment behind or filter before kegging. Given that we always want to minimise exposure to air I was thinking of how to do a C02 powered transfer. This technique might do the trick. I really like the idea of capturing and re-using C02 too.

You could also try building/buying a floating dip tube, to draw beer from the top, which clears much faster from yeast and debris compared to the bottom.

I’m also intrigued by this idea.

How would you do a pressure transfer to the second keg when the second keg is already pressurized? It seems that if you depressurized the second keg first, there wouldn’t be enough pressure left in the headspace of the first keg to transfer the full volume of beer (assuming the first keg is nearly full). Or would there?

An alternate option would be to use the gas from the second keg (and the headspace of the first keg) to push the beer from the first keg into an empty and depressurized third keg; a small amount of gas from the second keg could be used to purge the third keg prior to the transfer.

yeah, i’ve done this. it’s a nice trick especially if you like to ferment in kegs..but it ties up a another keg…

I typically do what you’re talking about regarding charging an empty keg(s). Just start by filling it full of water and pushing the water into a bucket using a picnic tap. Keep tap submerged. When you see bubbling it’s time to let the keg start building up pressure. It doesn’t have to be a keg.

If you ferment to several multiples of intended volumes of CO2 dissolved in the beer, you won’t need additional pressure to transfer. Just move your spunding valve to an empty and set it for 1X intended volume pressure (temperature dependent). The beer will boil off CO2.

That said, if you allow pressure to vent from beer, it will likely stir up sediment. The solid particles act as nucleation points, bubbles cling to them, and they rise. Consider how a straw may float in a soda.

Is there a good reason to wait until the very last minute to put on the spunding valve? Why not just put it on when you know there is still extract remaining, whether it be half or a few gravity points? Is it annoyingly loud maybe or is there a worry of it clogging if fermentation is too vigorous? Worry that the yeast won’t perform well under pressure?

I usually wait until after dry hop. Adding hops to carbonated beer can cause a geyser (mentos effect). It can, of course, be a fun game to play with fire and try to get the lid shut before disaster strikes. Fire in the hole!

I ferment start to finish in kegs, but the author used something else for early stages. This might allow him to fill the kegs a little higher without krausen reaching the valve. I suspect pressure would significantly reduce the height of the foam though. I guess it helps if he has an abundance of fermentation vessels and no extra kegs. One thing I like about fermenting in kegs is using no-chill method. Heat is the only sanitizing agent I use.

Fermenting under pressure is shown to reduce esters and fusel alcohols for a given temperature. Esters are sometimes desired so perhaps that’s a reason to hold-off. All the authors here seem to have temperature controlled fermentation chambers, which are another means to manipulate esters/fusels. I do not, so pressure is my friend.

I guess another thing is keeping yeast/sediment to a min in the serving keg. I rigged my kegs to have a floating dip-tube function to draw from near the surface and highly recommend it. Fermentasaurus (available on MoreBeer) looks a lot like what I made (looks nicer than what I made, ahem).

Pardon my ignorance on this one, but couldn’t you have gotten similar results by simply priming in the keg?

One could certainly do that, but then it wouldn’t be deutscheland sound due to some outdated beer laws 🙂 as to whether the results would have been the same, I honestly don’t know, potentially.

Yeah, they do use priming called krausening!

Was there any measuring of dissolved co2? Without actually measuring this you quite possible have different carbonation levels. So in fact, you may just be measuring the preference of different volumes of co2. We use a Zahm in our brewery to measure this.

if pressure and temperature was the same, then carbonation level is the same.

Priming would requiring adding more sugar, which would then make the beers not identical. By spunding there’s no difference in the composition of the beer itself.

BTW, one question. And sorry if this has been covered before. But what is going on with the last two testers, when you say “The 12 participants who made the accurate selection on the triangle test were instructed to complete a brief preference survey comparing only the 2 beers that were different…. A total of 5 reported preferring the force carbonated beer, 2 liked the spunded beer more, 3 reported having no preference despite noticing a difference, and 2 reported perceiving no difference”? So, 2 perceived a difference on the triangle test, and then perceived no difference when they actually had two different beers in front of them? Isn’t that proof that their answer on the triangle test was random guessing, and so they shouldn’t be counted?

To your question, no the statistic factors in random guesses. Ten thousand foot view it assumes 1/3 right by guess and a certain number over 1/3 to establish a p-value we aim for dependent on sample size.

I ferment and serve in a single vessel (corny keg). I haven’t heard of the tables and calculations you speak of. I guess I just wing it lol.

I leave about 4″ of head space in the keg, set the spunding valve to 20psi and let er go. On one keg I have a floating beer line that supplies beer from the top and the other two I just cut an inch off the dip tube

In a week I have fully carbed beer. I suck out a pint or so I trub/beer (which I drink). And a week after that my beer is clear enough for me. And a week after that, it’s crystal clear.

I even sometimes throw wort right on the cake. Significantly less cleaning involved.

Love it

Has there been discussion of doing an exbeeriment with this method for IPAs/Pale Ales?

Holy beer nerds batman! This is good stuff. Scientific process to to 9’s……..well done.

Once you have racked a wort that is not quite finished fermenting to a keg with a spunding valve, how do you know when fermentation is complete? It seems hard to follow SG once the beer is kegged, without opening the lid. I don’t want to cold crash, or just place in my kegerator, prematurely. Or, am I just missing something simple since it is late at night now?

I mean depending on when you rack it, couple days and it’s fine. Slight guessing game but it is just beer

you can take a quick sample with a short serving line!!!!

I get that Reinheitsgebot doesn’t allow them to use CO2 when making the beer, but what about when it’s finished? Can German breweries use CO2 to serve the beer from a draft system?

what about secondary in keykeg/ecofass/other bag in keg system? how to deal with sounding valve there?

Totally off topic here, but in the pic of the grain bag being lifted, the mash tun has no reflectix; yet the next pic has abundant reflectix. Am I missing something? I am thinking of moving from the old picnic cooler to a one-kettle setup and that caught me eye…

I noticed the same thing, Mike. It might make sense to remove the reflectix before emptying the mash tun to avoid getting wort on it and make cleanup easier.

For you make the spunding valve or buy it from more beer. Also, what about all the krausen? It doesn’t ever clog up the gas post?

Thanks!