Author: Matt Del Fiacco

There are a variety of sugars used in brewing that find a place in many different styles, one of the more common being candi syrup, which is a staple for styles such as Tripel and Belgian Dark Strong. In addition to contributing certain flavors to beer, adding this type of sugar is also a method for increasing the amount of alcohol without using more grain. However, such sugar additions can raise certain risks including increased osmotic pressure and enabling yeast to pursue the more simple sugar before maltose, both of which can lead to under-attenuated beer.

In an effort to combat these potential problems, some brewers have moved away from making sugar additions during the boil, opting instead to add the highly fermentable substance once active fermentation has started to wane, the goal being to decrease osmotic pressure on the yeast and thus create a more optimal environment. This methods is also said to preserve some of the more “delicate” flavors contributed by the sugar, which the boil and fermentation processes are believed to drive away. Moreover, adding sugar after high krausen ensures the yeast has ample opportunity to ferment the complex sugars extracted from the mash before moving on to the simpler sugars, resulting in a well attenuated and drier beer.

A seemingly novel method, at least based on the lack of information I could find on it, involves adding the sugar during high kräusen. In addition to preserving more flavor by not adding the sugar to the boil, advocates for this approach have some other ideas underlying its efficacy. It’s believed that by adding sugar when the yeast is most active yet fermentation is incomplete, it is better able to tackle the demands of metabolizing both the complex and simple sugars. Furthermore, the lower alcohol environment during high kräusen is thought to benefit the yeast as well, since higher concentrations of ethanol are known to negatively impact viability. Having tried the other common methods, I was interested to see how this approach would compare and designed an xBmt to test it out!

| PURPOSE |

To evaluate the differences between a Belgian Golden Strong Ale where candi syrup is added during the boil and one where candi syrup is added at high krausen.

| METHODS |

A local brewery makes an incredible Belgian Golden Strong, and so it has been on my list of beers to try making for quite some time. After some insistence from my wife that I make the style, I decided it would be a perfect opportunity to test out this variable.

Light Bringer

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 4.5 gal | 90 min | 26.4 IBUs | 5.2 SRM | 1.082 | 1.016 | 8.8 % |

| Actuals | 1.082 | 1.008 | 9.8 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Swaen©Pilsner | 12.625 lbs | 92.66 |

| Candi Syrup, Golden | 1 lbs | 7.34 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 14.4 g | 60 min | Boil | Pellet | 12 |

| Czech Saaz | 14 g | 30 min | Boil | Pellet | 3.5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Gnome (B45) | Imperial Yeast | 74% | 65°F - 75°F |

Notes

| Water Profile: Ca 51 | Mg 5 | Na 8 | SO4 72 | Cl 61 |

Download

| Download this recipe's BeerXML file |

Having collected RO water that I adjusted with minerals the night prior, I kicked things off by heating the brewing liquor brew day morning.

As the water was heating, I weighed out and milled the grains for each batch.

Once strike temperatures had been reached, I mashed in then check to make sure I hit my intended mash temperature.

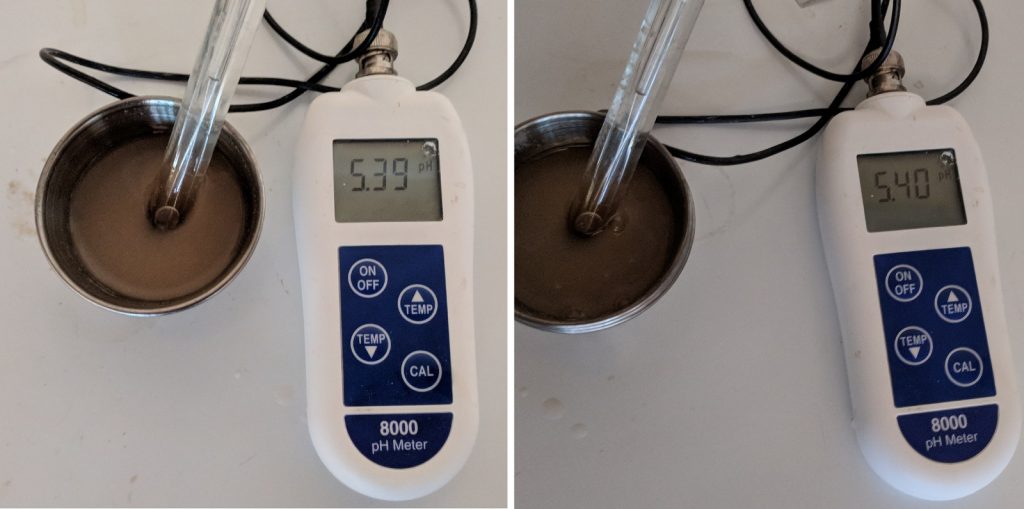

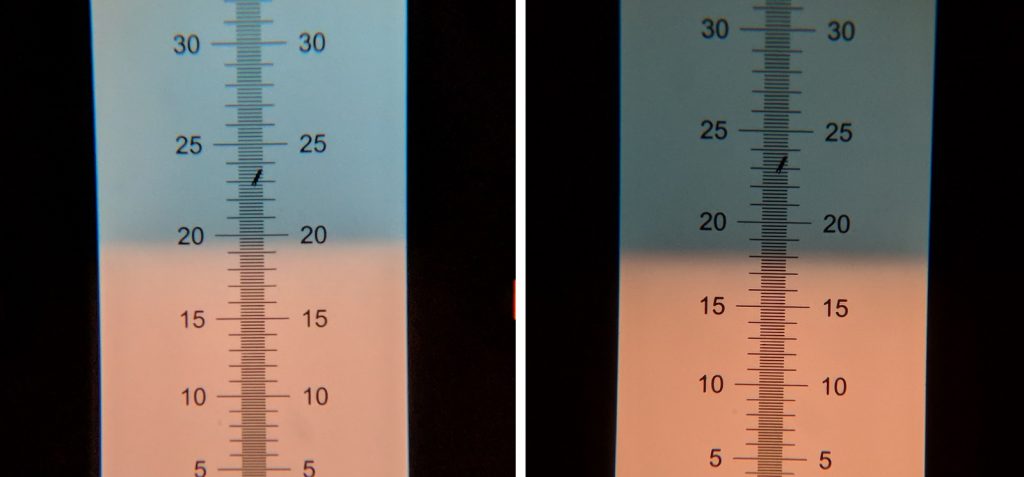

I took pH readings 15 minutes into each mash confirming they were similar.

Once the 60 minute mashes were finished, I removed the grains and began heating the wort. During the lull, I weighed out the same amount of kettle hops for both batches.

Each batch was boiled for 60 minutes with the candi syrup added to one batch with 10 minutes left to go while the other batch was left alone.

With the boils complete, I quickly chilled each batch using my CFC and running the wort directly into fermentation kegs.

Hydrometer measurements at this point showed the boil addition wort was at the expected 1.082 OG while the kräusen addition wort was at 1.075 OG, predictably.

I tucked the kegs away in my fermentation chamber and let them both settle to my pitching temp of 64°F/18°C before returning to pitch a single can of Imperial Yeast B45 Gnome into each batch.

Both beers were actively fermenting 2 days later, which is when I went ahead and added the candi syrup to the kräusen addition batch.

I gently increased the temperature of the fermentation chamber over the next 4 days until it was sitting at 80°F/27°C, where I let it sit for an additional 5 days before taking hyrdometer measurements confirming FG had been reached for both beers.

I then proceeded to pressure transfer the beers to sanitized serving kegs.

The beers were place in my cold chamber for an overnight crash before I fined with gelatin and hit them with high pressure CO2 for carbonation. Perhaps as a function of the Imperial B45 yeast, these beers refused to drop clear, even after a couple weeks of conditioning.

| RESULTS |

A total of 26 people of varying levels of experience participated in this xBmt during a monthly CHAOS Homebrew Club meeting. Each participant was served 1 sample of the beer with the candi syrup added during the boil and 2 samples of the beer with the beer added at high kräusen in different colored opaque cups then asked to identify the sample that was unique. While 14 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 12 (p=0.12) were capable of doing so, indicating participants in this xBmt were unable to reliably distinguish a Belgian Golden Strong Ale where the candi syrup was added during the boil from one where it was added at high kräusen.

My Impressions: Based on my sampling prior to collecting data, I wasn’t confident at all I would be able to tell these beers apart, the tasted like the same beer. Out of 5 triangle tests, I selected the odd-beer-out 3 times, which isn’t much better than random chance. I expected the beer with the syrup added during fermentation to be a bit more crisp and clean, which unsurprisingly is what I detected in biased side-by-side tastings, despite the fact they finished at the same FG. I perceived both beers as having the same spicy aroma with low alcohol notes and a grape-like flavor that reminded me of white wine characteristics. I’ll definitely be brewing this recipe again with some minor tweaks, the IOY Gnome yeast knocked it out of the park and I think it may become a staple around my home.

| DISCUSSION |

From the perspective of a speculative brewer who has a decent grasp of yeast and fermentation, the idea that making sugar additions when yeast are most active might reduce the risk of certain problems that can occur when sugar is added in the boil sort of makes practical sense. However, the fact participants in this xBmt could not reliably tell apart Belgian Golden Strong Ales made using either method calls this claim into question. Furthermore, when viewed in light of the non-significant results from a previous xBmt on staggered sugar additions, it seems the timing of sugar additions may not have all that big of an impact in terms of both objective and subjective measures.

Going into this xBmt, I wasn’t so much interested in the perceptible qualities of the beers as I was the differences that could be objectively measured. I’ve a particular fondness for big beers and have dealt with stuck fermentations in the past, so I can relate with the desire to use methods to reduce the risks of it happening. I thought it was interesting that both beers in this xBmt came back with the same exact FG, indicating equal attenuation regardless of when the sugar was added.

It seems plausible this lack of a difference is due in part to advancements in yeast production and overall quality, as each batch was hit with 200 billion yeast cells. Interestingly, nobody noted any flaws in either beer despite the fact I didn’t propagate the recommended pitch rate with starters, they were pitched directly into each high OG wort and fermented as expected.

This is an interesting variable to me, one I plan to continue exploring using different sugars, methods, and beer styles. Until then, I’ll stick with my standard process of adding it to the boil because it’s what’s easiest for me.

If you have thoughts about this xBmt, please feel free to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

12 thoughts on “exBEERiment | Sugar Additions: Boil vs. High Kräusen In A Belgian Golden Strong Ale”

Merry Christmas! I’ve been wondering about this for years. I’ve been making BGSA for several years now, as my wife and I both love it. I have been making a wort of around 1.050-55 with only Pils and then fermenting that out almost completely (3-5 days.) I then boil up enough cane sugar in a little water to boost the gravity up another 20 points. Let it chill down and dump it into the wort. It always blasts through that sugar very quickly. I also ramp up to around 80F by the time I’ve added the simple sugar, so all of that fermentation is effectively completed at 80-85F. The resulting beer has a ton of clove, which I really enjoy. Some people don’t like the clove as much, so it might be better to add sugar to the boil and ramp more slowly. Your recipe seems to deviate from most online advice in that it has a small percentage of simple sugars. Does the resulting beer have an overly intense malt character? I should try dropping the simple sugars some just for fun. Thanks!

Hey Aaron, merry Christmas!

I definitely wouldn’t call it an overly intense malt character, but it is definitely a bit sweeter than I would expect from the style. In the future, I’ll likely be using more cane sugar in this recipe, close to 15% of the grain bill. Definitely enjoyable still!

Interesting. Most of my Bgsa and Tripels use 3 lbs of sugar. I wonder if just using 1 ib would not make much of a difference. I just use cane sugar and add one lb. to the boil then one when the kraeusen starts to fall then one more a little later. I also start the fermentation at 65 for 2 to 3 days. Then warm to 70. I like the fruity phenolic in this range I get with the WLP530 yeast.

Also could the beer not clearing be a protein problem with the malt and not the yeast?

Could for sure be a protein problem, every now and then I have this experience with gelatin which is odd.

How is your experience with 530?

I definitely plan to try this recipe again with sugar comprising more of the grain bill.

I brewed a Belgian Strong a month or so ago. The first bottle I cracked had an unforgettable “roasted chocolate ice cream” aroma which was in stark contrast to the marginally dry beer. That wonderful aroma faded just a few bottles later. I can only surmise that aroma came from the candy sugar (added at flameout). You mentioned aroma, of course, but no notes if it faded quickly.

So, I wonder if the beer would hold on to that wonderful smell longer if I added it at high krausen? I guess it certainly won’t hurt for me to find out for myself next time!

Merry Christmas Matt and all!!

I work as a winemaker at Fenn Valley, and recently took up home beer brewing. Now with that said, I have been making wine commercially where I work since 1999, and do the labs on all the wines, just to give you my background.

We chapitalize (add sugar – regular cane or beet sugar, both are same chemically) our grape juices from what ever they may be up to 22.5 Brix for white wines, and 24 Brix for red wines, along with additions of Super Food yeast nutrient as needed. Ciders take a lot more nutrient, around 3.5 lbs/M as well as an additional 1.5 lb/M of DAP.

At most wine brix there is really no issues with excessive amounts of osmotic pressure, IE high Brix. We make our Vignoles when the acid drops to acceptable levels, and that usually ends up having Brix in the 26-28 degree range. Our Vidal Ice wine often comes in at 42 Brix and we use Uvaferm 43 yeast for that as it is the strongest yeast we have and will ferment it ….slowly, over a few weeks, to an EtOH of around 10%.

That said, I would not worry about adding sugar at the time of boil, or more specifically at the very end of boil to get it well dissolved into solution.

If you have a protien haze and can happen if you have left over nitrogen compounds, one of the way to eliminate them is not with Gelatin, but with bentonite. Say 1 tsp/ 5 gallon, mixed with at bit of hot water to thoroughly dissolve in the bentonite. Add to the finished beer using a vigorous stir…. I would suggest a paint mixer on a cordless drill. SLOWLY add the bentonite and keep up the agitaiton for several seconds, gas the headspace and leave alone for several days 4-6 would be good. Then rack off the lees, or in beer that would be “trub”.

Interesting article.

the tasted like the same beer.

*they*

Sorry to get back so late but I had Christmas dinner to do. I have tried many Belgian Yeasts but always go back to WLP530 or Wyeast 3787 (Westmalle) yeast. Like most Belgian yeast it can be different flavors depending on which temperature it is fermented at. With the lower temperature and a healthy yeast cell count I am trying to slow down the yeast growth to eliminate any off flavors and higher alcohols.

Merry Christmas and Cheers. .

Hi there, I have often if I undershort my OG added around 200-300 gram of cain sugar to my beers, and it is done during the fermentation, and I never had the “feeling” it have ruined the beer……..wheeof these bers would have been way better if no addition was made is hard to say, but I can for sure say those beers turned out in a good way.

So nice to see this xBmt also show the impact of during a sugar addition is low! But one thing to add before people start make hughe additions, is that low alchol beers sometimes shows to be great….so a misfortune of a lowOG might be a nice summer beer!

Klaus

These results disappoint me. I’ve made two attempts at a 10% IIPA using honey 1lb of honey with 10 minutes left in the boil. The finished product had a harshness in the finish that I was hoping could be eliminated by adding the honey after high krausen or scrapping the honey altogether.

never boil honey. add it after the msin fermentation is winding down or done. buy good honey, like orange blossom or some other delicious variety

I am interested in your timing of gelatin – it reads like you transfer your beer to the secondary. then cold crash, then reopen and add gelatin. Any concern with Oxygen, or is there a step I am not understanding.

Love my belgian golden strongs, great to read others’ recipes. Thanks. I use inverted sugar, used citric Acid to invert, then crack the toffee and add at 10 min to go, in a hop spider to minimise stick on elements. Keen to know others’ way of adding inverted sugar.

Finally, is the FG more of a guess when adding fermentables at high krausen?