Author: Jake Huolihan

In addition to good flavor and aroma, a truly great beer will also possess quality foam when poured and a good body, both of which contribute to the overall character of beer in their own ways. In addition to making a beer look gorgeous, a good head serves as a sort of olfactory delivery system, each burst of a tiny bubble carrying with it desirable aromatics. A beer’s body, which is generally determined by the style, not only influences the way a drinker experiences the beer in their mouth, but also impacts the extent to which the flavor lingers on the palate. The discerning brewer looking to craft world class beer has various options available including certain process variables, such as mash temperature adjustment, as well as ingredients marketed specifically for this purpose.

Weyermann describes CaraFoam as a 2-row Caramel malt roasted to about 2 °L that improves a beer’s foam quality, head retention, and body. While it’s recommended CaraFoam make up 5-10% of the grist to achieve the intended effect, it can apparently be used at up to 40% without causing detriment to the beer. As a proprietary product of Weyermann, little else is known about what goes into producing CaraFoam. While many believe it to be interchangeable with Briess’ Carapils malt, others have claimed that in addition to its benefits on foam and body, CaraFoam also imparts a desirable flavor to beer. My curiosity piqued by the results of our recent Carapils xBmt, I designed a new xBmt to learn more about the impact CaraFoam has on beer.

| PURPOSE |

To evaluate the differences between a beer made with CaraFoam and an otherwise similar beer made without CaraFoam.

| METHODS |

I went with a delicate German lager for this xBmt in order to allow any differences in flavor or aroma caused by the CaraFoam to shine through.

Spume

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 36.7 IBUs | 3.6 SRM | 1.052 | 1.015 | 4.9 % |

| Actuals | 1.052 | 1.014 | 5.0 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Weyermann Pilsner Malt | 9.75 lbs | 81.25 |

| Carafoam | 1.25 lbs | 10.42 |

| Acid Malt | 1 lbs | 8.33 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Saaz | 45 g | 60 min | Boil | Pellet | 1.4 |

| Hallertau Magnum | 15 g | 60 min | Boil | Pellet | 14 |

| Saaz | 35 g | 20 min | Boil | Pellet | 1.4 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

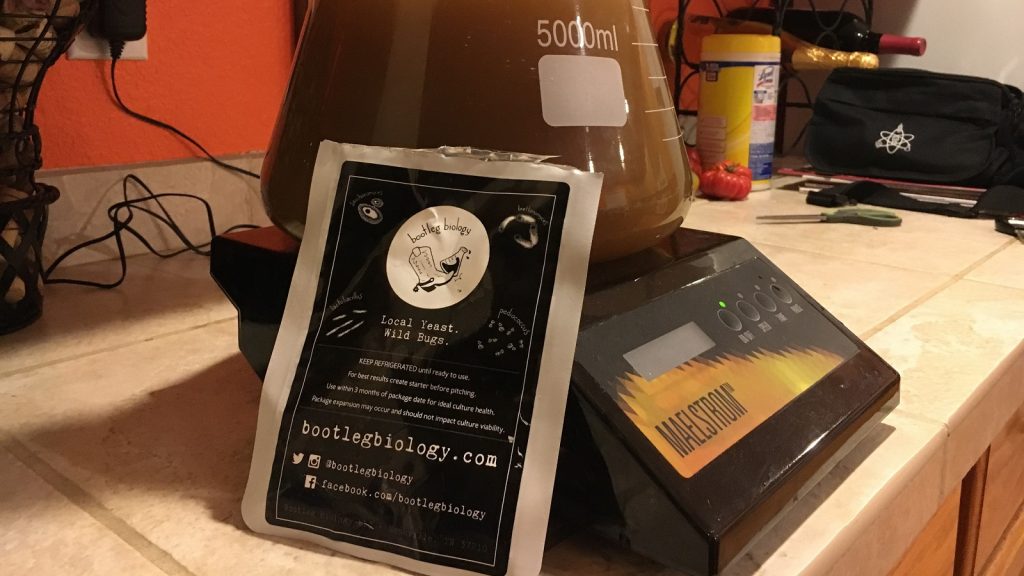

| Super Special (Ü) | Bootleg Biology | 72% | 46°F - 70°F |

Notes

| Water Profile: Ca 54 | Mg 2 | Na 46 | SO4 45 | Cl 55 |

Download

| Download this recipe's BeerXML file |

A day before brewing, I made large starter of a super secret mystery yeast from Bootleg Biology that would be split between the batches.

With the starter on a stir plate, I collected my grains for a morning brew the following day and paid closer attention than usual to the way the un-milled CaraFoam looked. Not much different than Pilsner malt, to my eyes.

I woke up early the next day and filtered the entire volume of water for both batches, adjusting each to the same profile. While the water was heating, I weighed out and milled the grains.

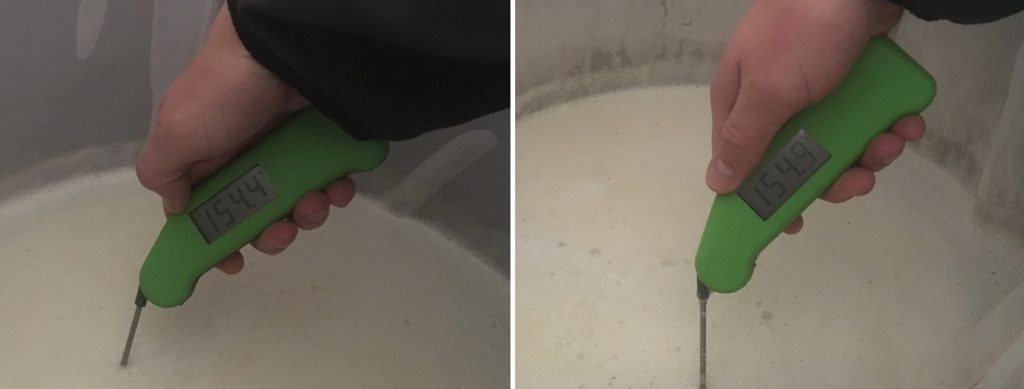

I mashed in on the CaraFoam batch 20 minutes after starting the batch without CaraFoam and was pleased to see both hit the same target temperature.

I let the mashes rest for 60 minutes, giving each a stir every 15 minutes before removing the grains.

The worts were then boiled for 60 minutes with hops added at the times stated in the recipe.

At the completion of each boil, I quickly chilled the wort to 64°F/18°C, a little warmer than my groundwater at the time.

Hydrometer measurements confirmed both batches were at the same target OG.

Each wort was racked to a sanitized Brew Bucket and placed in my fermentation chamber to finish chilling to my desired pitching temperature of 48°F/9°C.

Once the worts were stabilized at the same temperature the following day, I evenly split the starter between the batches then hit both with 90 seconds of pure O2. Fermentation kicked off within hours. I let the beers ride for a week before bumping the temperature up to 54°F/12°C to encourage clean-up of any potential off-flavors. Hydrometer measurements taken another week later indicated both had reach their expected FG, the CaraFoam predictably a little higher.

At this point, I transferred the beers to kegs without cold crashing or fining with gelatin.

The filled kegs were placed in my cool keezer where I let them lager for 3 weeks on gas, at which point they were clear, carbonated, and ready to serve.

| RESULTS |

A total of 23 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the beer that did not include CaraFoam and 1 sample of the beer made with CaraFoam in different colored opaque cups then asked to identify the sample that was unique. While 12 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 9 (p=0.35) were capable of doing so, indicating participants in this xBmt were not able to reliably distinguish a beer made without the use of CaraFoam from one where it was included at the recommended rate.

Since CaraFoam is marketed as a product intended to positively impact foam quality and retention, which are things we don’t ask participants to evaluate, I filmed a timelapse of each beer after being poured in a way to produce equal amounts of foam.

Beer Made Without CaraFoam

Beer Made With CaraFoam

My Impressions: Over multiple semi-blind triangle test attempts, I simply could not consistently select the unique sample and ultimately resorted to guessing every time. To me, the beers were identical not only in flavor, aroma, and mouthfeel, but appearance as well– I couldn’t even tell them apart when served to me in clear glasses, the foam looked exactly the same on both.

| DISCUSSION |

Being that CaraFoam is a product specifically marketed to brewers as an ingredient to improve foam quality and head retention, the fact tasters couldn’t reliably distinguish a beer made with this malt from where it was left out while it also had no noticeable impact on foam surprising and, at least for me, somewhat disconcerting. Considering the non-significant findings from our previous xBmt on CaraPils, it would seem these popularly used dextrine malts aren’t all they’re cracked up to be.

What gives? Why haven’t we been able to produce the effect these malts are supposed to produce? Giving the maltsters the benefit of the doubt, I dug into some brewing science and came up with a couple possible explanations. Brewers of today have available to them highly modified malts that allow for high mash efficiency without the use of a step mash, a method that’s known to degrade proteins, proteins that contribute to a beer’s foam. It seems plausible that using a small percentage of dextrine malt such as CaraFoam when step mashing might serve to counteract this protein degradation and thereby improve foam quality.

Another thought I had has to do with the use of dextrine malts by brewers relying on malt extracts. Again, it seems plausible that the process used to make extract in some way strips the malt of its foam producing potential, which a dose of CaraFoam or Carapils replaces.

Additionally, like most brewing ingredients, dextrine malts are marketed primarily to large scale breweries who often rely on adjuncts such as rice and corn, which possess lower amounts of foam positive proteins. Perhaps using a relatively small amount of dextrine malt contributes the necessary proteins make up for the adjuncts shortcomings.

As for me and my brewing, these findings along with those from the previous Carapils xBmt have influenced my decision to stop using dextrine malts. I’ve brewed many batches without the use of dextrine malt that have had fantastic foam, and I know plenty of others in the same boat, so it seems pointless to me to spend more on a specialty grain that doesn’t produce the intended effect. To each their own.

If you have thoughts about this xBmt, please feel free to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

35 thoughts on “exBEERiment | Dextrin Malt: Impact CaraFoam Has On A German Pils”

You havn’t specified how you have altered the variable? I’m assuming that one grist had no carafoam and the other had 10%?

Exactly.

Facts are it’s a carcinogen and no further data will be replied to.

wutnow?

Maybe carafoam would have had a bigger impact in a neipa recipe where foam stability is more often a problem?

It would be cool if you guys did a test on your adjunct hypothesis. I personally use adjuncts in a lot of my light beers. I’ve made a number of blondes with rice, and all have been light and easy drinking. About a month ago though, I made a lager with rice and rye, along with about 8% flaked barley for additionally protein. The beer is light, but also has a creamy mouthfeel (it surprisingly works well together this beer). I’m curious to see if the flaked barley had that much of an impact on mouthfeel, and what the difference would be if I had used carapils/carafoam in its place.

I often brew a summer lager with 20% rice. Single step infusion, no dextrin or cara malts. Always had good foam and nice lacing. Often wondered if I should give cara a try, now I know it’s a non-issue. Thanks for all your work.

I second the idea about effect of adjuncts on lagers. Say a CAP vs German lager, would be an easy starting point. Could be a series of experiments.

On the topic of dextrine malts….I always add a pound of carapils for “body”, because that’s what the real brewers do, right?

Two key factors inhibiting The detection of flavor and impact differences in this test…

1. 36.7 ibus of noble hops is going to hide any subtle flavor differences between these two very light, extremely subtle malts.

2. Mashing at 154F is leaving enough body in the beer that carafoam is moot.

Try again with 18-20 ibus and mash at 148-150F.

Even if your hypothesis about mash temp and IBU level were to be accurate based on further testing, that still doesn’t account for the lack of improved foam which to me is as interesting as participant data in this specific xbmt

At 154 you’re making a dextrinous malt regardless of carafoam’s addition. You’re into alpha enzyme range. You might not see any difference even if you bumped it to 20% or even mote maybe.

A bamforth study I referenced in writing this article claims no difference in head retention from a mash of 62C (143F) to 68C (154F) in all malt wort.

Until I see something to indicate otherwise I’ll likely skip carafoam in all malt worts though I’d be interested to try it in adjunct heavy beers which may not contribute the same foam forming particles as an all malt wort.

154F is still at the low end for alpha – I’d say upwards of 158-160+ is truly the range favoring alpha. Beta still hums along nicely unless you get pretty high on the temp.

Seriously… the methodology for this one is completely flawed. Needs to be mashed and fermented like a proper lager, as that’s how pretty much anyone interested in Carafoam would be brewing.

I know this is almost 10 years old at this point, but still… disappointing.

Low attenuating yeast (72% here) is going to bolster foam and body as well. Dextrin malts would be more impactful on high attenuating yeast.

Sorry. Not trying to be argumentative. I’m just trying to point our that your methods and recipe may have been more sharply tailored to try to highlight the true impact of the malt on the beer. Eliminate variables.

And furthermore…everyone knows you can’t brew a “German” lager without a decoction!

On a serious note, where does Weyermann(or Briess) describe that only certain mash regimes will bring out the benefit of Carafoam/Carapils?

I’m sorry to be a stickler here, Motor, but diction is important and your comment about eliminating variables is simply inaccurate. The IBU level, mash temperature, and yeast attenuation are constants in this XBMT. There was exactly one variable and it was the presence or absence of Carafoam malt (and not any other dextrine malt). You may disagree with the choice of parameters used as constants in the experiment, but there was a single variable, as prescribed by the scientific method.

I think the dextrin malts could make diference in head retantion and mouthfeel in session pale beers (OG<1.040).

Certainly possible!

Dr Charlie Bamforth and his mob did some tests to show Pilsner and Roast malts have far more foam positive characteristics, where malts like Munich in particular are very poor on foam properties.

Please run this test again using 90/100% Munich malt grist and lets see how effective carafoam and carapils are. If its the same result, I would be surprised, but will too stop using these regularly.

You’re completely missing the point clayof2day. Should you test for flavor differences of a 2L crystal in a RIS or a very light beer? Isnt it obvious that >30 ibus are going to completely wash out any potential flavor differences of such a light malt?

If you’re testing its effects on foam wouldn’t you create a beer profile that would best illustrate potential difference? The fact that the beers were the same is meaningless. I can brew 2 1.100 barleywines, one with no carafoam and one with, but i wouldn’t expect any noticeable differences and I’d certainly expect random taste testers to not taste the differences.

To be fair your extreme examples are just that, and not what this xbmt was. This was a light beer mashed at a moderate temperature with a calculated ibu of 36. In all of the instances we’ve had beers tested, actual ibu come in much lower than calculated, so the calculated 36 is likely misleading you. I’d be surprised if this beer was over the 18-25 range in actual ibu.

In terms of mash temp, please point me to literature or even anecdote which refutes the bamforth study? This test, while one test, was absolutely fine for testing this variable imo, you’re fine to disagree with that.

Extreme??? Creating the best possible environment to best evaluate the target factors is prima facie. Just add “in a German lager” to the end of your Purpose statement and problem solved.

“I went with a delicate German lager for this xBmt in order to allow any differences in flavor or aroma caused by the CaraFoam to shine through”

No worries! We good

Cool experiment. Your recipe brings up a good follow up experiment idea. I’ve always read (and BSG publishes) that Acidulated Malt should be capped at 5% for normal (non-sour) beers. Most follow the 2% rule for Acidulated Malt when not wanting any flavor contributions. This is a very high percentage at 8% +. Would be interested to see any flavor differences when using 2% versus 8% in this same recipe…

Weyermann lists “up to 10% (larger charges may be required)” on their spec sheets. I’ve never noticed a tartness from acid malt but I do plan to compare it to other more flavor neutral acid adjustments.

The issue with using 2% versus 8% is that any differences could be attributed to differing pHs as well as acid malt. It’s definitely on the list though cheers!

Building R.O. water to the same mineral specs(ppm) should keep the ph of both mashes within the 5.2 to 5.6 range.

While that’s certainly true pH will still be different. My thoughts were to first try something like phosphoric which is considered flavor neutral compared to a decent charge of acid malt, like 5-10%

HI Marshall, another great malt analysis. I’m really surprised why you always ignore the existence of the 6row base malt. Huge amount of the comercial beer is made from it. Why not try to compare it with normal 2 row. It will be wonderful. Thank you

Ran out of Pilsner for a hefe i did. Subbed in 6-row. Turned out fantastic.

I think it’s really important to note that CaraFoam and CaraPils are NOT the same thing, contrary to what everyone tells you. CaraPils (in the US) is basically a very light crystal malt. The interior is glassy and it has no diastatic power. CaraFoam, on the other hand, is mealy inside. Try chewing on a kernel of each at your LHBS, and try not to break your teeth on the CaraPils. I saw an experiment online some homebrewer performed showing that CaraFoam actually has some diastatic power.

It seems Carafoam is more similar to an undermodified pilsner malt than to crystal malt. This would support your theory that it would be more helpful if performing a step mash, I imagine.

In any case, neither malt has a place in my brew house anymore.

I don’t want to be a critic, but I get above house average head retention on all my lagers, even with 100% pils, and I always step mash lagers. There are other styles that are problematic to head retention, and that seems like the fertile ground for carafoam/pils experimentation. I am a wierdo in that body is on the top of my list for what I strive for in my beer. Given the “hop head” nature of beer drinkers today, I find it reasonble to assume the average palate lacks subtlety, much like people who eat heavily spiced food every day can become relatively “taste blind” to finer flavors. I have a sneaking suspicion this is at play in most all the results of your great and noble work, so I take “triangle test” results with a grain of salt. A great leveler of xbmnts would be to have tasters rate personal importance 1-10 of key beer aspects, or simply what style they most drink. I am guessing “hop heads” would have a signifigantly lower incidence of detecting subtle differences, which you have surely proven nearly all xbmnts are: subtle

Maybe a better result would have been an attempt to use it at it’s max range 40% (according to weyermann) in a simple malt bill compared to a simple malt bill without it. 10% isn’t very much in the grand scheme of things, and we don’t truly know how much those that understand the malt (german brewers) use it and at what quantities.

Super late to the party. An Old Head in the industry a man I respect, swears you get better results with Flaked Barley than any dextrin malt. I’ve done it in several beers to good results, but never a side by side comparison

Have you run any tests on the effects of milled grain size on foam stability? I get my grains milled by the brew shop, and in the last year or so the size seems to have increased significantly. Comparing identical recipes from the past to most recent, the foam stability has gone from reasonably good in the past to non-existent in the most recent. I always use at least 1/2 pound of crystal malt, and in some cases have tried both caramunich and dextrin malt additions. None of these changes have helped. Could the particle size of the milled grains be the cause of little to no foam stability?

Thanks, Tom K