Author: Matt Del Fiacco

There are a few purported benefits to chilling wort quickly including the promise of clearer beer, the reduced risk of certain off-flavors, and perhaps most importantly, the hastening of the overall brew day. When I first started homebrewing, I employed the cumbersome and inefficient method of setting my kettle full of barely-not-boiling wort in a bathtub filled with ice water then letting it sit until it dropped to an adequate pitching temperature. It was simple enough but resulted in an annoyingly ice-free house, plus it took too long, so I upgraded to a 25′ stainless steel immersion chiller that hooked up to my sink. This move certainly reduced my chilling time, taking it from over 45 minutes to roughly 20 minutes, but it still required me to lug a kettle of hot wort to my sink, which was a problem.

With my move to the Unibräu eBIAB system, which comes with a pump, my options for wort chillers opened up. Looking to try something that would reduce both chilling times and my involvement in the process, I settled on going the counterflow route, which was right around the same time the ExChilerator folks reached out seeking an honest review.

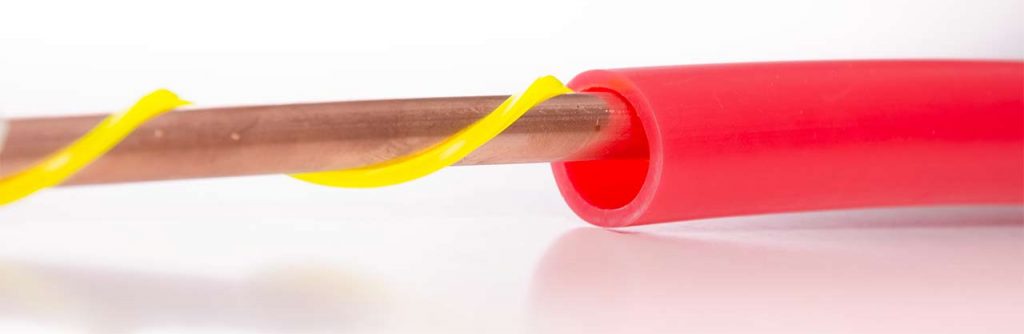

Similar to other convoluted counterflow chillers (CFC), the ExChilerator Maxx has at its heart 25 ft. of copper tubing, which due to its high thermal conductivity assists in quicker chilling. Where ExChilerator breaks from the pack is in their use of a proprietary co-helical wrap on the internal copper tubing, which they claim “causes your cooling water to tumble, providing the maximum surface contact possible against the heated copper coil as your wort flows through it.”

Furthermore, rather than encasing the internal copper tubing with more copper or a flimsy garden hose, ExChilerator relies on a PEX plastic shell that’s purportedly longer than other CFCs and thus “gives your wort more contact time with the cooling surface.“

The product reviewed for this article was provided by the manufacturer in exchange for an honest review; no other compensation was provided. The opinions expressed in the article are solely those of the author and a concerted effort was made to approach the review from an unbiased perspective.

The ExChilerator Maxx works like any other CFC– cold water is run through the outer PEX shell in one direction while hot wort is run through the internal copper tubing in the opposite direction. While gravity can be used with the ExChilerator Maxx, the use of a pump makes for a faster and more efficient process.

SETUP & USE

I unboxed the ExChilerator Maxx when it arrived at my house to find an attractive and sturdy unit that was very well packed. After tossing a camlock fitting onto the 1/2″ ball valve, the unit was pretty much ready for use.

I’ve used the ExChilerator Maxx a few times since receiving it and the first thing I have to say is how incredibly easy it is to prepare for use. All it requires is 4 simple connections:

- Garden hose from spigot to water input.

- Tubing from water output to drain or collection vessel.

- Tubing from pump output (or kettle valve) to wort input on chiller.

- Tubing from wort output on chiller to fermentor.

Piece of cake!

The wort enters the top of the unit at the same place the used warm water is expelled, chilling as it makes its way through the 25′ of copper tubing. A thermometer attached to the ball valve provides the temperature of the wort as it exits the exChilerator Maxx.

I could go on about how solidly built the chiller is, how all of the fittings are securely attached, or how the red PEX made my brewery pop, but I know that’s not what most people are here for.

SPEED TEST RESULTS

The groundwater temperature where I live in Illinois was a bit warm during testing, as it was summer, and since I wanted to test the chiller on its own (sans pre-chiller), I wasn’t able to chill the wort to typical pitching temperatures. This is pretty normal for me, as I usually allow the wort to finish chilling in my fermentation chamber, so I wasn’t too concerned.

One of the nice things about a quality CFC is that wort runs from the kettle through the chiller and directly into the fermentation vessel, requiring only a single pass to achieve the proper temperature. However, with my process and brewery setup, I’ve found it’s occasionally more convenient to leave the wort recirculating in the kettle (from the sanitation step) when I turn the water on then transfer the chilled wort to a fermentor afterwards. For this reason, I tested out both methods so as to avoid leaving any rocks unturned.

Method 1: Kettle to Fermentation Vessel

For these trials, I measured the time it took to chill a couple different volumes since this particular method made doing so easy. Without fail, and as expected, the time it took to chill 1 gallon of wort was consistently 1/5 the time it took to chill 5 gallons. With a groundwater temperature range of 69-70˚F/20.5-21.1˚C, the average time to chill 5 gallons of wort to 5°F/3°C warmer than groundwater was only 3 minutes 23 seconds.

Method 2: Batch Recirculation In Kettle

In 3 timed trials utilizing the batch recirculation chilling method with groundwater temperatures of 70-74˚F/21-23˚C and 5 gallons of wort chilled immediately after flameout, the average time to chill to 5°F/3°C warmer than groundwater was 4 minutes 39 seconds.

I’ll be honest, I completely expected the batch recirculation chilling method to take about double the amount of time as the more standard kettle to fermentor method. The fact I was consistently able to chill 5 gallons in under 5 minutes completely validates my laziness, now I won’t worry a bit when I forget to sanitize a fermentor until I start chilling! I was also impressed by the fact these chilling speeds were achieved with such warm water and look forward to seeing how this beast works with my icy winter water!

| THE VERDICT |

Needless to say, I thought the results of the ExChilerator Maxx speed test trials were pretty astonishing, not only was this the quickest I’d never chilled wort before, but it was done with warm groundwater. While such hasty chilling times are likely the best feature of the ExChilerator Maxx, it has some other rad things going for it as well. I particularly appreciated how the unit arrived well packaged and essentially ready for use, though I did run some hot PBW through the copper tubing beforehand to ensure it was free of any remnant dirt and oil from the manufacturing process. I was also seriously impressed with the build quality of the chiller, all fittings were securely in place, the coiled tubes were held together tightly, and not a single leak was sprung despite the chilling water being cranked to full blast. I had no issues with the more hop forward beers I ran through the ExChilerator Maxx, and according to the website, it can be used for even heavily hopped beers without the risk of a clog due to the smooth coils and diameter of the copper tubing. Finally, cleaning this unit requires little in the way of time or effort, in fact I found running hot water through the copper immediately after use does the trick just fine, though I do plan to give it a proper cleaning between every 3-4 batches.

Of course, no good review is proper without pointing out a few negatives, so I did some thinking and came up with a few things. First, when researching PEX, I discovered one of the more common complaints is that it degrades when exposed to UV light and is used primarily for indoor purposes. I’m doubtful this is an issue for most brewers, especially given how quickly the chiller works, but it’s something to consider. To counter such concerns, ExChilerator offers a full 5 year warranty on their chillers to provide customers with piece of mind, simply contact them with issues and they’ll repair or replace the unit for free. Another aspect of the ExChilerator Maxx some may take issue with is the fact the part of the unit that comes into contact with the wort cannot be seen, though this is the case for nearly all counterflow style chillers. Either way, immersion chillers have an edge when it comes to ensuring cleanliness. The last potential negative I can think of is that I used a pump to get the speedy chilling times I did, it’s likely brewers with gravity fed systems will have a different experience.

Overall, I couldn’t be more happy with the ExChilerator Maxx and would definitely recommend those who prefer or require counterflow chillers to give it a good look. Competitively priced, easy of use, incredibly effective, and quite nice to look at… what else could you ask for in a quality wort chiller?

ExChilerator counterflow wort chillers can be purchased directly from ExChilerator.com. If you have any experience using an ExChilerator Maxx CFC or questions about the unit, please share in the comments section below!

Brülosophy Merch Available Now!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

29 thoughts on “Product Review | ExChilerator Maxx Counterflow Wort Chiller”

What about the accuracy of the in-line thermometer? That would be a helpful feature for dialing in temps if it is accurate.

It seems accurate, but I (unfortunately) didn’t take temperature readings during the rack to the keg (fermenter). I’ll double check that tonight and get back to you on it!

Thanks Matt! Great review btw. I’m leaning towards buying this to replace my old cheapo CFC that is starting to leak and wastes a lot of water chilling 10 gallons…

And one more thing: I’m curious how long the thermometer takes to adjust to an accurate (or close to accurate) reading. I’ve seen some dial thermometers that are too slow to really be helpful when you’re trying to quickly dial in temps. Even just your subjective opinion/experience would be helpful!

Like you I have run the gamut of chillers; from immersion to a 25 ft immersion to a 50 ft immersion to the exchillerator and then to Jaded brewing’s Hydra. I do use a pump and recirc system so counter flow seems the obvious choice but my experiment results differ from yours. The exchillerator took roughly twice as long (10 min vs 6 min) to cool 8 gallon of boiling wort to pitching temp using the same ground water.

You have used both, what do you prefer?

I haven’t used the Jaded products unfortunately, but have been loving the Exchilerator. I know that Marshall swears up and down about the Jaded products, I’ve heard nothing but good things! I think it really comes down to what works for your system.

Christopher- How you do like the Exchillerator compared to Jaded’s Hydra?

I have now done over a dozen head to head experiments between the exchillerator and the hydra. The hydra has dramatically outperformed the exchillerator every time. 35 to 40 percent faster chill time in every test.

I would be interested to hear if anyone has experience using these in a gravity fed kettle-to-fermenter configuration. I’m all about simplicity so I’d prefer not to add a pump to my set up, but this seems just as easy as using an immersion chiller which I currently do.

I’m currently using a Blichmann Therminator plate chiller in a gravity system. I’ve also used a chillzilla CF chiller in the same setup, and both have been great! Wort is chilled to within a few degrees of my water supply as quickly as the kettle can drain. I love the therminator and have never had a problem with it, but I am very careful about cleaning and sanitizing.

Amazing product. I’ve had one for almost a year and am very pleased!

Great to hear! It really is a nice piece of equipment.

Counterflow chillers are the best. Even a homemade version will knock temps out very quickly!

Recirc into the same kettle will not, ever cool quicker because your reintroducing hot wort to cool wort.

Definitely. It was slower for sure, but still quick (much faster than my old immersion chiller).

Reintroducing lower temped wort to hot wort*

Well, that will cool down the wort anyway

I’ve been using the exchillator for a year. Love how quickly it cools from the kettle. I do have a gravity fed system. I control the temperature by how quickly the wort flows out. All depends on how cold your ground water is. I keep the chiller in a cool spot and hose out of sun until ready to use.

Gotta love marketing terms: “proprietary co-helical wrap” aka we wrapped string trimmer line around the pipe 🙂

That said, it should help, and even if the company were to fail, all the parts are standard plumbing bits so you should be able to repair it easily if you breaker something, making it a long lasting unit.

Pex will be way more durable and leak resistant than the garden hoses most use. As for the UV issues – those comments really apply to people running plumbing outside (think putting an outside water hydrant in). Constant exposure will cause issues, but if you store this indoors, you won’t have an issue. Most plumbing pipe is rated for a couple years sunlight exposure to account for storage at jobsites and warehouses.

I have a similar product from NYBrewSupply which uses automotive-grade radiator hose for the exterior. Should be more durable in the long term (it’s designed for boiling water and chemicals), but doesn’t look as pretty. I also had it custom-made with stainless tubing instead of copper.

The tradeoff is that although it won’t cool as quickly as copper, I know that there’s never anything bad happening to the metal where I can’t see it.

Although it should not happen when treated properly in standard brewing applications, Copper could theoretically develop poisonous compounds (verdigris / copper acetate), but stainless could sit full of acid or base or water and nothing will happen.

I wonder how it would compare the the other CFC’s, like JaDeD, ZChiller and Platechillers.

I have the JaDeD Brewing CFC (https://jadedbrewing.com/collections/frontpage/products/the-jaded-cfc) but I never did any tests.

I have one of these and really like it but must be doing something wrong because my times are way longer and I waste more water than I expected. For example, with my cold January ground water, it still took me 20 gal and 20 minutes to transfer and chill to 62F. Any good use tips?

Are you making five gallon batches?

That’s way above my current chilling times. Yesterday I got from boil to 60F in about five minutes (currently about 0F here in IL). Are you restricting the flow of wort at all? Slowing it down should definitely help your chilling times. Also always worth double checking connections are in the right order, the “is it plugged in?” of counterflow chillers.

Yep. All connections are correct and slowed the flow. Had to really restrict it to get 62F. Maybe I was trying to get it too low for our groundwater temps here in Utah.

It is all about ground water temp and flow. During the summer I cannot use my counter exchillerator (without a prechiller ice bath) to get wort to pitching temp because my groundwater is around 75 degrees. No amount of water at that temp will get any lower. During the winter when my ground water is in the 50s the exchillerator works amazingly fast. Even a 10 degree shift in ground water temp can more than double the amount of time it takes to hit your desired pitch temp.

Full blast cold water but very slow wort in

Been using this unit for about 3 months and love every aspect, with a pre chiller (using old immersion coil) I can chill to lager pitching temps typically. Winter no issues.

You mentioned a down side was you can’t see the coil like you can an immersion, however both have same issue, that being you can’t see the inside of either one. The outside is non issue on this type, for me it’s same issue with immersion or counter flow. I get it you have to find something of course otherwise why review.

Thanks for all you do!

I love my Exchillerator Maxx. I’ve used it for about 25 5g batches. both in a straight BK to fermenter chill and to recirc chill in the BK.

My only knock is that the configuration of the hoses is wonkey. I’d much prefer having all the connection facing forward like the standard copper convoluded ones.

I use a large plate chiller here in Corpus Christi. The ground water is in the upper 80’s in August so I have just accepted the fact that no amount of ground water chilling is going to drop the worth to pitch temp, barring an ice bath reservoir. I would switch to this Exchillerator CF if the coil was stainless steel. I had a copper CF many years ago and the copper inlets/outlets turned dark over time. I know PBW would clean it to acceptable cleanliness, but stainless would be a nice trade off between chilling efficiently and sanitary needs. I want to move away from the plate chiller for the unknown sanitary reason. Nice product.