Author: Jake Huolihan

In traditional step mashing, the grains were doughed in at a relatively low temperature (113°F/45°C) and brought up through a series of steps to encourage enzymatic activity that made up for poorly modified malts. However, in this day and age of highly modified malts, such low temperature rests are no longer necessary and, as John Palmer notes, can actually result in a beer that’s thin and watery. While some brewers continue to use the more traditional approach, those who see value in mashing at different steps yet don’t want to risk a making a pallid beer can rely on an alternative method. Purportedly used by many German breweries today, the Hochkurz mash is a somewhat simplified step mash method that involves doughing in at a warmer temperature (hoch translates to high) and performing fewer steps that result in faster conversion (kurz translates to short). A typical Hochkurz mash might involve an initial beta amylase (or maltose) rest at approximately 144°F/62°C, a step up to about 158°F/70°C for an alpha amylase (or dextrinization) rest, then finally raising them temperature to 170°F/77°F or so for a mash out step.

For all that exists online about step mashing and the praise this particular version receives, I was surprised with the paucity of documented benefits of using a Hochkurz mash schedule. Most of what I could find focused on how each step assists with conversion of under-modified malts, which really isn’t an issue with today’s modern malts. As far as beer quality goes, it seems proponents of this method laud it most for improving malt character and head retention.

As a lover of German lager who sought to make the most stylistically appropriate versions of Pilsner, Helles, and Vienna Lager, I used a traditional step mashing method numerous times. Eventually, I ditched step mashing and settled on the common single infusion mash, partially because it didn’t seem to be having much of a noticeable impact on the quality of my beers, but I’ll admit it was also somewhat out of laziness– I was using a converted cooler MLT, which required adding boiling water to hit each step temperature, and that got really annoying. Still, I remained unconvinced that step mashing served no purpose and, once I converted my brewery to electric, was excited to see how a Hochkurz mash compared to single infusion.

| PURPOSE |

To evaluate the differences between a beer made using a standard single infusion mash method and the same beer made using the Hochkurz step mash method.

| METHODS |

I designed a Helles for this xBmt in order to let any subtle differences between the beers shine through. Plus, I was craving a simple yellow beer to crush in the Denver summer heat.

High & Short Helles

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 6 gal | 60 min | 20.3 IBUs | 3.5 SRM | 1.050 | 1.012 | 5.0 % |

| Actuals | 1.05 | 1.013 | 4.9 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Weyermann Pilsner Malt | 10 lbs | 85.47 |

| Weyermann Vienna | 1.2 lbs | 10.26 |

| Acid Malt | 8 oz | 4.27 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 10 g | 60 min | Boil | Pellet | 11.5 |

| Hallertauer | 15 g | 30 min | Boil | Pellet | 4.8 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Harvest (L17) | Imperial Yeast | 72% | 50°F - 60°F |

Notes

| Water Profile: Yellow Balanced in Bru’n Water |

Download

| Download this recipe's BeerXML file |

I whipped up a large starter of Imperial Organic L17 Harvest yeast a few days ahead of time.

The night before brewing, I weighed out my grains then collected and RO water, which was adjusted to my target profile.

Since my parents were in town, I was able to introduce my Dad to this hobby by having him help out with brew day tasks, it was awesome! We started by turning the heat on the brewing liquor for the single infusion before milling the 2 sets of grist.

With the grain milled, we began heating the Hochkurz brewing liquor to the proper strike temperature to hit the first step. For the single infusion batch, I opted for a mash temperature of 150°F/66°C, which we nailed.

The Hochkurz mash rested at 143°F/62°C for 30 minutes before I raised the temperature to 158°F/70°C and let it sit for another 30 minutes. Finally, the temperature was raised to 168°F/76°C for a mash out step.

Both batches were continuously recirculated the entire duration of the mash. At the completion of each, the grain bags were hoisted out and allowed to drain as the sweet wort was being heated.

Both worts were boiled for 60 minutes with hops added as noted in the recipe..

After the boils were complete, the worts were quickly chilled to slightly warmer than my groundwater temperature before being racked to carboys that were placed in my cool fermentation chamber to finish chilling to my desired fermentation temperature. Hydrometer readings showed the single infusion mash produced a wort of slightly lower OG than the Hochkurz mash, consistent with the last step mash xBmt.

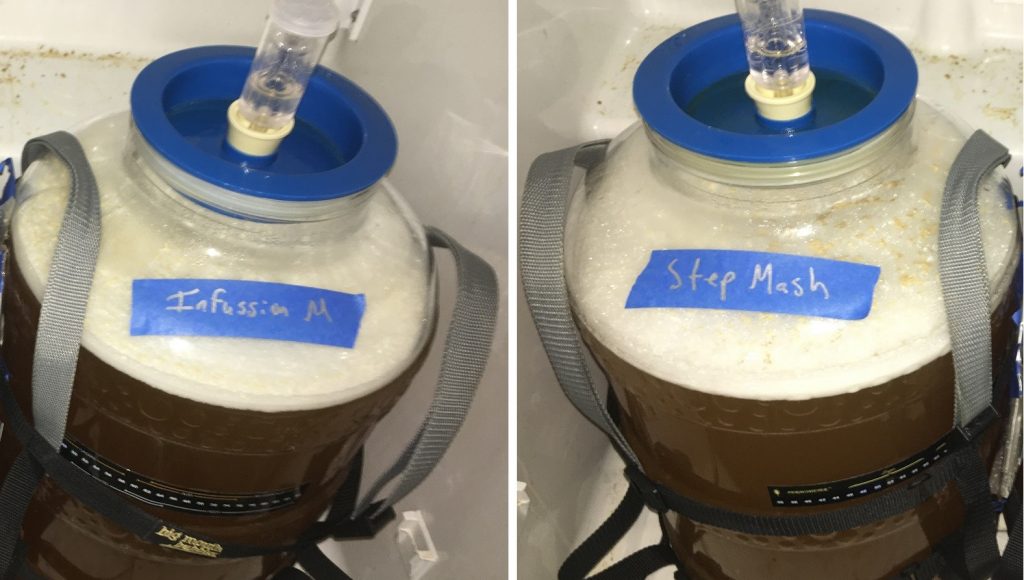

The following morning, both batches stabilized at 48°F/9°C, I evenly split the yeast starter between the batches then hit them both with an equal dose of pure oxygen. I returned 24 hours later to find both fermenting with a seemingly identical level of activity.

After 10 days, I ramped the temperature up to 60°F/16°C for a diacetyl rest. With activity all but absent a couple days later, I took hydrometer measurements confirming both beers had reached nearly the same exact FG.

I proceeded to cold crash over a couple nights then keg the beers.

After a couple weeks of lagering on gas in my keezer, both beers were clear and ready to serve to participants!

| RESULTS |

A total of 26 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer made using a Hochkurz step mash and 2 samples of the beer made with a single infusion mash then asked to identify the sample that was unique. While 14 tasters (p<0.05) would have had to correctly identify the unique sample in order to reach statistical significance, only 7 (p=0.81) picked the odd-beer-out, indicating participants in this xBmt were unable to reliably distinguish a Helles made using a Hochkurz step mash from one made using a 150°F/66°C single infusion mash

My Impressions: I’ll admit I resorted to guessing on the numerous triangle tests I attempted and I chose wrongly more often than not. The beers tasted so similar that if served one after the other and told they were the same, I’m certain I wouldn’t think twice about it. As to the beer itself, it was good though had what I perceived as a grainy and hay-like character, which isn’t something I find insanely enjoyable. Going forward, I plan to keep the same recipe but explore Pilsner malt from different maltsters.

| DISCUSSION |

Back in the early days of brewing, when both technology and knowledge were extremely limited compared to today, brewers were forced to develop methods that allowed them to accomplish the task of making drinkable beer. Necessity being the mother of invention, brewers of yore who had only malt of poor modification to rely on ingeniously discovered that by mashing in a series of temperature steps, they were able to achieve the conversion required to produce the beer they desired. As time marched on, our understanding advanced rapidly as people began to scientifically explore the many different aspects of brewing, ultimately leading to malting practices that drastically improved modification that resulted in easier and quicker conversion of starches to fermentable sugar. Many accepted step mashing as it was originally designed as largely unnecessary, though some remained convinced there was something to the warmer temperature steps, and so was born the Hochkurz method.

I’ll admit, as much as I’ve researched step mashing and particularly Hochkurz, the argument that less temperature steps leads to improved quality while either more or a single infusion doesn’t seems flimsy. Moreover, I can’t help but wonder what the brewers who had to rely on step mashing would think about being able to use malts that didn’t require all the hassle. Did they view this necessary step with such romantic fervor as brewers like me? Despite coming to question the merits of step mashing, I’ll admit the fact so few tasters were able to distinguish the single infusion beer from the Hochkurz beer in this xBmt was pretty surprising. Then I recalled the mash temperature xBmt where tasters couldn’t tell apart beers mashed at either 147°F/64°C or 161°F/72°C, which isn’t too far off from the temperature steps used in the present xBmt. While this certainly isn’t enough for me to accept the Hochkurz method has no impact, whatever impact it might have isn’t enough to pull me away from the more simple approach of a single infusion.

If you have any thoughts on this xBmt, please share them in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

45 thoughts on “exBEERiment | The Mash: Single Infusion vs. Hochkurz Step Mash In A Munich Helles”

How do you rig up the carboy cap on the big mouth lid? What is this sorcery that keeps it all together without falling?

I get questions about that setup a lot, though usually it’s how to start the siphon. The orange lid is larger than the opening, so it simply rests on the opening without falling

I´d just choose a style where having a thin beer would be considered a fault.

But good to know that you actually increased your efficiency doing the steep mash.

I’ve done a three step mash before and I have to say, for those extra 2 points of gravity it might have added, I’d just go with an extra .25 pound of grain over the extra hassle and time the multi step took 😉

I would like to see the results of an iodine test done just after the first 143 degree rest. I would not be surprised if the malts were totally converted at 143 degrees.

Conversion doesn’t necessarily mean that all the enzymatic activity has taken place or that one has gotten all they can out of the grain. I do a 2 step mash for most of my beers now. I wish the pours were more volatile so we could have seen the head and retention difference between the two beers.

I noticed no difference in head retention or quality when drinking these as normal pints

Definitely possible

Hmm. . . Infusion Hochkurz, not a decoction? Not surprised at results.

Thank you for doing this exbeeriment! I have been interested in trying the Hochkurz method for different styles, but there really isn’t a lot of good information out there (especially anecdotal evidence of people that have actually tried it).

Although I don’t think it would make a difference, I would like to see this experiment with a traditional Hefeweizen with a ferulic acid rest at 110 F vs standard single infusion mash. Because this low temperature rest is supposed to produce a more noticeable clove character, it might’ve brought a significant result. Again, I don’t think it would matter but would be interesting to see.

Thinking the same thing.

On the list

Any difference in parameters that would not be tested during the triangle test? Visually from the photo they look pretty similar but am wondering if just maybe the single infusion is a bit brighter. Any differences in head or head stability between these beers?

I noticed no difference in color, clarity, head retention, foam quality. That’s not to say it didn’t potentially exist I just didn’t observe any differences

I think the traditional HochKurz step mash is a 90 minute mash, isn’t it? If overall time on each were extended to 90 minutes (more grain contact time) I wonder if both OGs would go up, but perhaps the step mash even more compared to single infusion. (?) “Should”… Following that, both “should” have a tad more body, with the step mash having a tad more body than the infusion mash (but maybe not).

HochKurz Step Mash is something I do often. Since I mash with traditional full volume BIAB and normally do 90 minute mashes, it is very easy to do and normally have to check and adjust temperature in the middle of the mash anyway. Interesting results… Strictly self-interest, wish your mash times were 90 minutes. 🙂

Most people that use step mashing do so because they prefer to use less modified malts. You’re not going to see much of a difference with this grain bill. Switch that over to a floor malted Pils and it would be more noticeable a difference. In my opinion. I have not experimented with this myself.

According to Braukeizer and others, the Hochkurz Mash is used by most German brewers to “maximize fermentability”… Jake’s test results – even with just 60 minutes of mash time – would seem to back this up. 4.86% ABV vs. 5.12% ABV. German brewers normally would use a fully modified German malt, so they’re not doing this for conversion. (Most do not use the not fully modified, Weyermann floor malted Bohemian pilsner malt).

Also according to Braukeizer, he shows 90 minutes plus ramp up and mashout…so 110 minutes in total. Would this make a difference if compared to 60 minute mash…? Not sure; I do it and it works well, but maybe it would work as well with single infusion for 60 minutes… (?) I don’t have double equipment so is difficult to do side-by-side tests. (Future test…folks at brulosophy.com…? 🙂 )

Your comment about the Weyerman Pilsner, …”grainy and hay-like character”, reminded me of the No Chill vs Quick Chill exbmt. That’s the only brand I use and I had that flavor happen twice, once on a single infusion Kristallweizen and again on a Grolsch clone. Both took several hours to chill.

They were chilled in under 10 min each. It’s the flavor of the malt to me, descriptors obviously suck because taste is so subjective I simply think I don’t enjoy the actual flavor of that malt as a majority of the grist

I just brewed a helles with an eerily similar grain bill. I used Best Pilsner malt. It tasted the best to me when going through chewing on grain. I’ll try to remember to report back on flavor profile.

I must have misread that. I thought they took 24 hours. Glad you mentioned the subjective nature of taste. One of my friends says everyone tastes everything the same, it’s just the vocabulary we use to describe it that makes the difference. I call BS on that one every time. I have weird issue with smoked wheat malt. My wife and friends love the Polish knockoff I make (bacon in a bottle) but to me, it tastes like there’s a cigarette butt floating in my beer.

Thanks for another informative writeup.

Unrelated question but…I was reading up reviews on the imperial yeast and a lot of people commented on how the cans were “exploding” when opened (think opening a shaken soda can vs hand grenade hyperbole). Out of curiosity, have you had this issue with their yeast packaging?

No I’ve not, their instructions in fact say not to shake or open it warm due to that fact

I’ve used it numerous times and have had no problems. Keep it cold ,don’t shake it. They say the can should be a little squishy, if not carefully vent.

“then finally raising them temperature to 170°F/77°F or so for a mash out step.”

There’s an error in this sentence, you forgot to change the F to a C.

Thanks forgot to convert to C

I’ve heard from several proponents of step mashing that you need to target an alpha rest of at least 162F to be sure you’ve denatured all the beta and are getting purely alpha activity in your second rest. It’s hearsay, but I’m putting it out there.

As far as getting too much grain/hay character, I find that the Weyermann floor-malted Bo Pils gives me the most of that, but their normal pils malt has it as well. For pale styles I’ve started to use a 60-40 or 70-30 mix of Pilsner:Pale Ale malt, and I like that a lot. I’ve gotten good results with Avengard, Best, and Swaen maltsters using that blend.

I used my steps based on Kai’s recommendation from research. I couldn’t find anything to support the 162 but would be interested to try step mash with the user being 158 v 162.

Thanks for the malt recommendations, I’m trying Briess Pilsen next but I’ll likely try Best after that if I’m not a fan of briess

Hi Jake, An off subject question. Your mash system seems very similar to mine and I am curious about the flow rate you use while recirculating as well as the gap setting on your grain mill. Iv’e been using 25 mils and about 2 gal / min flow rate, but I have to watch it closely or the recirculation will stick. Any advice on this type of process? Thanks for the great XBMTs.

My mill gap is probably closer to .030″ but I’ve not measured it since it works well. Not sure on my flow rate but it’s fairly restricted when mashing and have not yet had it stick. 1/2″ valves and tubing with the outflow restricted at like 30-40 degrees from closed

I’m amazed that both batches finished at the same FG- you’d think that the different steps would maximize enzymatic conversion, giving you a more fermentable wort. I’m also surprised that that FG was so high- you’d think that a batch made of all base malt, with the maximum amount of opportunity given for conversion, would finish drier. I’d think you’d get a FG of 2.5P/1.010SG or lower.

Since moving to my electric system I’ve noticed FG are about .005 higher than I’m used to, which actually lines up exactly with BS predicted FG now most of the time

Jake, thank you for doing the work to brew these beers, compare them, and document your methods & results here. For an earlier investigation into step mashing folks should check out the test trials, “An Analysis of Brewing Techniques” By George & Laurie Fix (1997 Brewers Publications).

My question focuses on mash temperature profiles and lagering (maturation) of the resulting beer. In your methods section you state you, “After a couple weeks of lagering on gas in my keezer, both beers were clear and ready to serve to participants!”

I respectfully disagree. In my experience lagers need to be cold aged, more than two weeks, to allow them to full mature and reach peak flavor.

I’ve made lagers of the course of my homebrewing journey, using single infusion, step infusion, direct heat multiple temp steps, and decoctions. They all act a little differently – especially as they age. I lager in corny kegs, also my serving vessel so am able to taste the beers as they are aging. It has been my experience that the more complex mash temp profiles and especially decoction produced beers, need more age. I have found the old German rule of thumb useful, beers should be lagered one week for every two degrees Plato of initial wort. So for a 1.052 SG beer (~13 Plato) I would lager it for 6 or 7 weeks. Check out Zymurgy Sept/Oct 1999 Special Issue Lagers & Lagering.

Have any beer left? If so, perhaps you’d be willing to perform another triangle test and see if more age has made a difference for folks to actually taste!

Really like what Brulosophy has going here, sorry for the ancient reference . . . time to re-visit these topics.

Natron

Hi! There were actually lagered 5 weeks due to some life stuff. I’d be interested to try a 7 week lager v 5 for sure haha

How are you getting away with 4% acid malt? 3% for me is when the lactic is detectable and starts masking the beer flavours.

Thanks, this is just what I was looking for! I’m planning a big barleywine for my next brew day. I have read that raising the temp later in the mash to 158°f will allow the alpha amylase enzymes to break down the more complex starches and can result in a higher mash efficiency. This supports my goal of wringing out all the sugars I can for my barleywine. What is your feeling about this? Will I see a bigger difference in mass efficiency using the Hochkurz method on a big beer than you got with a small beer? Thanks, keep on doing what you do! And thanks for giving me a procedure to follow!!

You could definitely try it, this xbmt would support the notion that a hochkurz has the ability to increase extraction or efficiency. Personally I’d just add more grains and assume a slightly lower efficiency if I were to brew a large beer

Thanks for your quick response. Adding more grain won’t be an option for me since my mash tun will be at its maximum capacity. I’m going to give it a try! Thanks again!

Why 150 F for the single infusion? As it didn’t seem to matter, it probably was a reasonable choice, but how did you make the decision?

This exBEERiment seems very similar to “Single Infusion vs. Step Mash (BrüDragon Collab) Process 4/4/2016 <0.001", but with very different outcomes. Any thoughts?

It is

Hmm… maybe not so different outcomes. Here are Marshall’s impressions from the Results section of said article:

“These beers were incredibly similar, to the point I doubt I’d be able to tell if when drinking one my glass was swapped with the other. In 2 of the 3 blind triangle tests I took, all served to me by different people, I was able to pick the odd-beer-out. Reliable? I’m not so sure. While my performance matches that of the participant pool, it’s wholly possible I was right by chance because, I’m telling you, they tasted pretty much the same to me.”

Interesting that both beers finished with the same FG. I step mash almost all my lagers at 144/158/172 steps and they all finish below 1.010. Last few were 1.006, 1.005, 1.007, 1.005. Latest lager I did single and it finished at 1.014. I pitch at a “pro” rate of at least 1.5M/ml/°P, so maybe that helps my step mashed beers to finish lower, where in this experiment you split a 2.5 liter starter, whereas I am pitching a 2l starter or higher into one beer.

Interesting article. I’m an old school die hard step masher. Started brewing on my 3 BBL stout system and have brewed 5 double batches so far. Looking to open my Brewpub end of Oct. I do a little different step mash schedule. I mash in so that it settles at 134 deg for 20 mins. I then step up to 158 deg for 35 mins and then mash out at 170 deg for 10 mins. My beers tend to finish on the sweeter side with a staring Gravity of 1.052 in my Dortmunder, it ends up around 1.015, this is what I’m shooting for! By starting lower I’m below the conversion temp. By ramping up which takes about 35 mins, I’m going thru a range of conversion temps. I feel this method gives me great head retention, and I like the slightly fuller and sweeter finish in the beer. Just my two cents on the way I’ve been step mashing for years.