Author: Jake Huolihan

One of my first purchases when I started buying my brewing ingredients in bulk was a vacuum sealer to remove oxygen from the bags I stored hops in. It’s commonly touted this step, particularly when combined with cold storage, can prolong the life of hops in terms of both bitterness potential as well as flavor and aroma. While I can’t be too sure I ever experienced the perils of poor hop storage, the fact that hop suppliers often made it a point to ship their product in the most oxygen-free manner possible was enough to convince me it mattered enough, and the relatively low price of a vacuum sealer was at the very least good insurance.

But not everybody owns, or has a desire to acquire, a vacuum sealer, and I’m aware of some homebrew shops who sell hops packaged loose in plastic baggies. Furthermore, I recall reading a post in a brewing forum about a person who received bulk hops in which the package had been compromised, allowing oxygen in, which had him worried they were ruined. I immediately thought back to the times I used to keep leftover hops in a sandwich baggie stored in my freezer for weeks, and while I often thought the character changed over time when smelling them fresh, I can’t say it ever seemed to have a negative impact on the finished beer. Needless to say, I became curious as to how these different storage methods impact hops and designed an xBmt to test it out!

| PURPOSE |

To evaluate the differences between a beer made with hops stored in a non-purged plastic baggie and the same beer made with hops stored in a vacuum sealed bag.

| METHODS |

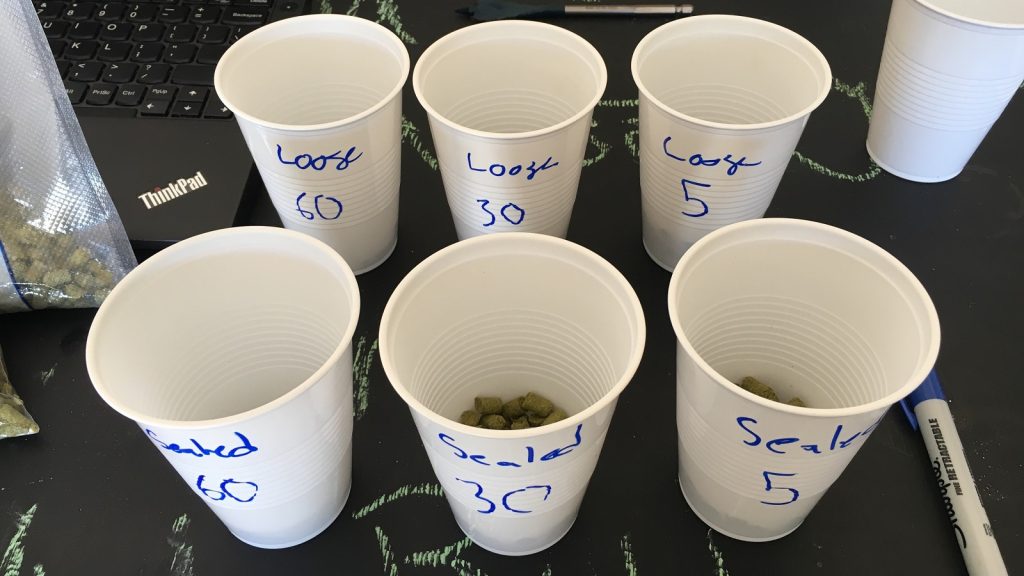

I received a sealed 1 lb/0.45 kg bag of fresh Motueka hops on November 16, 2016 and immediately split them up, placing half in a vacuum sealed bag and the remainder in a standard sandwich zipper bag that was not purged of oxygen.

The hops were placed in my freezer where they remained until May 31, 2017, nearly 6 months, which the crew and I agreed was long enough for any impact of storage to occur. Given the nature of this xBmt, I thought a fairly hop forward beer using notably flavorful hops was appropriate.

Tight Squeeze Pale Ale

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 32.0 IBUs | 4.0 SRM | 1.054 | 1.012 | 5.4 % |

| Actuals | 1.054 | 1.009 | 5.9 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Malt (2 Row) US | 11 lbs | 91.67 |

| Weyermann Vienna | 1 lbs | 8.33 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Motueka | 46 g | 60 min | Boil | Pellet | 3.4 |

| Motueka | 28 g | 30 min | Boil | Pellet | 3.4 |

| Motueka | 28 g | 5 min | Boil | Pellet | 3.4 |

| Motueka | 28 g | 3 days | Dry Hop | Pellet | 3.4 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Flagship (A07) | Imperial | 75% | 60°F - 72°F |

Notes

| Water Profile: Ca 69 | Mg 0 | Na 8 | SO4 104 | Cl 49 |

Download

| Download this recipe's BeerXML file |

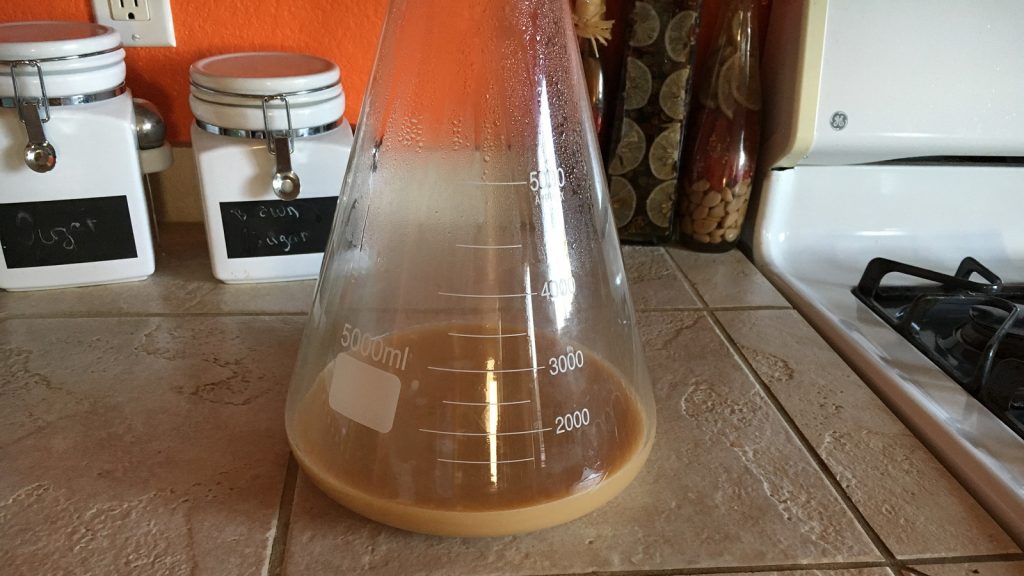

I made a starter of Imperial Organics A07 Flagship yeast a couple days ahead of time, enough to split between two 5 gallon batches. The night before brewing, I weighed out the grains and collected the RO water for the following day’s brew.

After adjusting the water to my desired profile first thing the following morning, I turned the element in my kettle on and began recirculating the water. While waiting for strike temperature to be reached, I milled the previously weighed out sets of grain.

With strike temperature reached, I mashed in one batch then did the same to the second batch about 20 minutes later to make my brew day less hectic. Both batches were mashed for 60 minutes at the same temperature.

At the end of each mash rest, I removed the grain bags and let them drip until the same pre-boil volumes were reached.

As the first mash rest was coming to a close, I dug up the hops from my freezer and weighed out the additions for each batch.

Each wort was boiled for 60 minutes with hops added as noted in the recipe.

Following each boil, I quickly chilled the wort to slightly warmer than my groundwater temperature before racking equal amounts to identical fermentors.

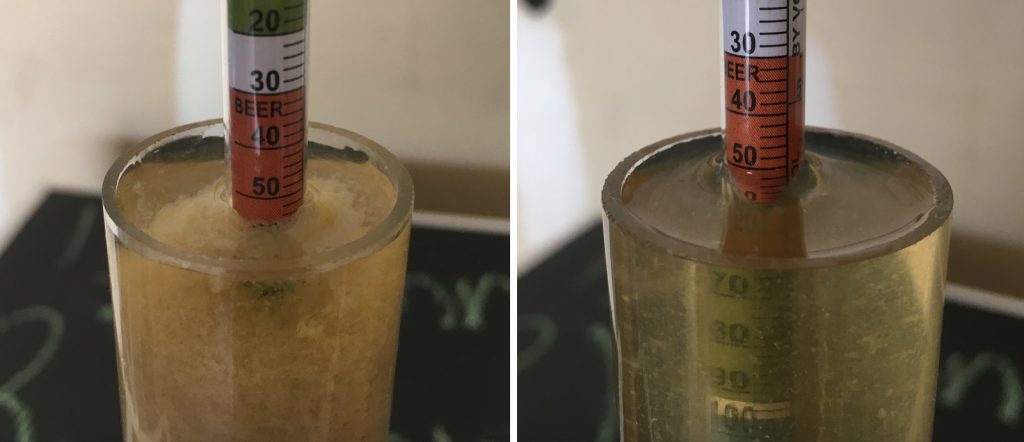

Hydrometer measurements confirmed both worts were at a similar OG.

The fermentors were placed in my chamber and allowed to finish chilling to my target fermentation temperature of 66°F/19°C, at which point I evenly split the decanted starter between them and dosed each with the same amount of pure oxygen.

The beers was showing similar signs of fermentation just 12 hours later.

I noticed decreased fermentation activity 3 days later and added the dry hop charge to each beer.

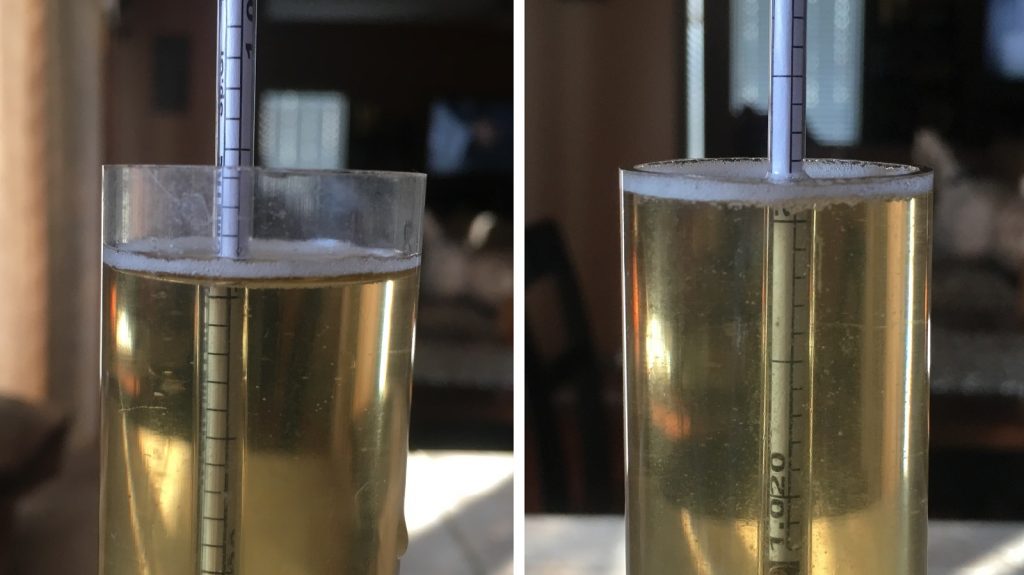

Hydrometer measurements taken 5 days after dry hopping showed both beers at reached the same FG.

I proceeded with cold crashing the beer, fining with gelatin, and transferring them to kegs.

The beers were burst carbonated overnight, after which I set the gas to serving pressure and let them sit another few days before presenting them to tasters. The beers looked exactly the same… condensation sucks.

| RESULTS |

A total of 16 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer made with vacuum sealed hops and 2 samples of the beer made with hops stored in a non-purged baggie then asked to identify the sample that was unique. While 9 tasters (p<0.05) would have had to correctly identify the unique sample in order to reach statistical significance, only 4 (p=0.83) picked the odd-beer-out, indicating participants in this xBmt were unable to distinguish a beer made with vacuum sealed hops from one made with hops stored loose and non-purged in a standard zipper baggie for 6 months.

My Impressions: When I opened the hops for this xBmt after being stored for 6 months, I expected there to be a difference in flavor and aroma between the beers, as the vacuum sealed hops smelled fantastic and fresh while the hops store loose in a baggie had a noticeable “freezer” scent to them, a mix of meat, plastic, and freezer burn. In 6 blind triangle test attempts, I was able to tell the beers apart 5 times, perceiving the subtlest hint of that freezer flavor in the beer made with loose stored hops. I’m convinced my performance likely would have been worse if I hadn’t smelled the hops beforehand, the difference was just that slight.

| DISCUSSION |

The focus of this xBmt was specifically on whether vacuum sealing hops helped to preserve quality as compared to hops stored in a regular sandwich baggie without having the oxygen purged. Oxygen is absolutely present in any normal freezer, which led me to believe this xBmt would lead to easily distinguishable beers, but apparently I was wrong, as tasters were unable to reliably tell apart a beer made with vacuum sealed hops from one made with hops stored in a plastic baggie, even after a whopping 6 months.

Well, there you have, vacuum sealers are a waste of money, hops can be stored in baggies without issue.

Except that’d be a really stupid conclusion to draw from this single xBmt result, particularly since oxidation is very real and vacuum sealing hops, at the very least, provides cheap insurance against staling. My hypothesis at this point, admittedly influenced by my ability to detect a very slight difference between the beers, is that the non-purged hops had begun to oxidize but that the cold temperature of my freezer slowed the reaction down. If this is the case, a future iteration of this xBmt where both sets of hops are stored at room temperature ought to produce a different result.

I certainly have no intent to ditch the incredibly simple process of vacuum sealing my hops, as it not only lends me some peace of mind knowing they’re less exposed to oxygen, but it also allows me to store more in my freezer because the bags take up less space. That said, I no longer believe storing hops loose in a baggie for a few days is anywhere near as detrimental as I used to think.

If you have any thoughts about this xBmt, please share them in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

36 thoughts on “exBEERiment | Impact Using Hops Stored In A Non-Purged Baggie Has On An American Pale Ale”

This one was interesting. Still, I think it’s better to err on the side of caution, but good to know that storing them loosely (if planned to use relatively soon) isn’t going to hurt anything.

Nice! For the last year I’ve been using baggies (low-budget home brewer, here) to store left overs until I make a combined leftover-hops beer. I just bought some bulk hops from Yakima Valley Hops and used our new vacuum sealer to package and store the unused bulk hops. Still, I’m glad my low-budget methods weren’t too compromising.

I don’t think conclusions can be definitively drawn for your situation based on this one Xmbt (there were only 16 total tasters, which is a really small sample set). I think you’d still need to evaluate your beer independently of this to determine if your specific process is compromising your beer.

For what it’s worth, your own 5/6 correct “guesses” is statistically significant. The panel obvious isn’t. That’s really cool, because it means that (1) some individuals are sensitive to the variable and (2) the population at large (assuming your panel is more or less representative) is not.

More likely that having knowledge of the variable and looking for it specifically tips the scale in terms of being able to identify it.

Totally, also we taste these beers throughout the entire process and pick up on certain identifiers that sometimes make it to the finished beer. Our tasting notes should be taken with a grain of salt and more attention paid to the blind taster data

@Marc T. That’s consistent with everything I said. I didn’t mean to suggest that his sensitivity wasn’t learned. We don’t know all the ways one could learn (or otherwise) be sensitive to this variable, so we must keep an open mind to the possibilities.

@Jake. Statistical significance is statistical significance. In a one tail test, the probability of a 5/6 positive rate with a 1/3 chance rate is .0178, which is highly significant. I don’t know why you think that your ability (learned or innate) to tell the difference would be unimportant. We don’t know why you can tell or even what you can tell–except that there is a difference.

I disagree (respectfuly) with Jake – if the purpose is to tell whether there is a detectable difference, using the most sensitive person with the most information on repeated trials is a fine process.

You don’t need the data to be representative to make a claim that two things are different. Even if only one person in the world can tell the difference between the beers, if they can do so repeatedly in a blind setup they have demonstrated that they are different. On the other hand, if you are trying to show that the difference would be detectable to most groups, you do need a representative sample involved in the tasting.

On this note, I wonder how many sips it took to detect the difference on the 5 successful triangle tests.

I’m sure this has been suggested before but I’ll throw it out there anyway, could palate fatigue be playing a role in a role in the taster’s failure to detect the differences in the beer? I assume the tasters typically take quite a few sips just to get their bearings and It may be that taste buds might get less precise after repeated sips of a hoppy beer. Do your tasters typically take steps to try to reset their paletes over the course of a tasting? Wonder if a method could be devised to test this aspect of the process.

First post after years of lurking. You guys are doing all of us a huge service with these tests. Thank you!

The thing to keep in mind though is knowledge of the variable can influence the outcome. There is a reason double blind is such a big deal in scientific circles.

I wonder if pellets, with their smaller surface area, fare better than whole leaf hops? I was always under the impression that that’s one of the benefits of pellets, that even if they do get oxidized, it’s only the outer surface that’s affected, which is a relatively small part of the overall hop volume.

The machine you linked to and presumably used, given the embossed bags, might be called a vacuum sealer but it does not create a vacuum at all, it is just a more advanced version of sucking on a straw in ziploc bag before automatically sealing it.

If you really want to remove the oxygen in a bag by vacuum then you need to use a chamber vacuum sealer, this is why you can use bags with liquid in with them.

I’ve been looking for a reference that shows that external vacuum sealers are less effective at removing air than chamber vacuum sealers. Do you have a reference for this by chance?

I just fold over the original mylar bag, trying to squeeze as much air out beforehand, and then scotch-tape it shut. For homegrown hops, I use freezer bags, which are thicker.

As always, very interesting! Just curious, did your tasters all get the unique beer in the same order (e.g. all second)?

I’m beginning to think that brewers obsess over a large number of things that barely matter or don’t matter at all, from pitch rate and fermentation temp to HSA, DMS, sparging, mash length, boil length and so on. What I wonder is where all these obsessive rules came from in the first place. Are they based in brewing tradition or are they contagious internet memes that replicate themselves via home brew forums?

I’ve always believed it was an outgrowth from commercial brewers, where consistency is king, so they develop detailed procedures to eliminate as much variability as possible. Then commercial traditions pass down to the hobby community as it’s the commercial brewers who write hobby books.

That, and the natural tendency on the hobby side (with any hobby) for people to become increasingly obsessed over fine details as they gain more experience. People simply declare something is critical and if they are sufficiently noteworthy (e.g., authors, speakers at forums) people take it as gospel and it becomes a meme.

That’s why I love this site so much – it knocks down myth after myth, even if most articles with insignificant results usually end up with the author stating they will continue with the variable tested even if it failed to achieve significance.

Agree with all that. It’s fascinating to see how many strongly held beliefs are actually groundless. I guess this applies to all areas of life, not just brewing. Politics, religion, health, whatever. We hear plausible-sounding factoids about things all the time and subconsciously internalise all this hogwash as “opinion”, only to regurgitate it onto other people later.

Not only is “consistency king”, but in commercial American lagers, there’s not much flavor to hide behind. Therefore, diacetyl or acetaldehyde would come to the forefront.

I’ve been buying hops from a supplier that doesn’t vacuum seal or nitrogen purge them. They package for shipping every 6 weeks. My experience has been that bitterness is not a problem, but that flavor/aroma is a problem with certain hops. When used for flavor/aroma, Willamette and Fuggle sometimes get a rank aroma (sweaty tennis shoe), but no problem with Simcoe and Mosaic. I’ve hypothesized that the oils in some varieties react badly with oxygen, and that some are very resistant.

I suspect the nitrogen reacts somehow with the hops and ruins that classic sweaty tennis shoe aroma of Fuggle

I wonder if freezing hops in sealed mason jars as opposed to zip lock bags would help reduce the stubble “freezer scent”.

Interesting for sure. I always figured people would be able to detect a change, especially at 6 months. Going to have to try this for myself (but not smell the hops first).

I think the relatively low rate of statistically significant sensory panel results in the ExBeeriment series is related to tasters not receiving prompts about the intended variable combined with lack of tasting experience of the beer being tested. I’m wondering how this compares to sensory panels in commercial breweries. I’d imagine they have sensory panels who have learned over years what their beers are supposed to taste like, and might be be expected to be relatively sensitive to subtle changes without clues. In the Brulosphy trials every panel is being approached with a beer that may be entirely new to them. The lack of reference point “this sample tastes like what our beer is supposed to taste like” makes it much more challenging to lock onto the difference between the samples. It might be interesting to repeat a few Exbeeriments that resulted in non-significant difference but prompt the tasters with the difference before running the panel.

My own single data point to add to this – I opened a vacuum sealed packet of Columbus leaf hops in April 2016, then simply folded the top over and sealed with tape. I froze this packet and used the hops again in May 2017. The hops had a distinctly “cheesy” smell, but this didn’t come through in the final beer and the bittering level was exactly as expected. However, I chose not to use them outside the boil and discarded the rest of the packet… and immediately bought a vacuum sealer.

The plastic baggie in the pic doesnt looks like a sandwich bag, those things let air in due to very weak seams. Would love to see this experiment repeated with freezer grade bags

I’m wondering if the use of low AA hops and such a short time period might have resulted in these results? perhaps a hop with 10-14% AA over a longer time period would produce different results?

Chemical reactions roughly double or halve for every 10 degrees in temperature difference (I honestly can’t recall if that is F or C, I want to say C).

So 6 months at -15C in a freezer is roughly equivalent to 5-6 weeks in a fridge or a week or two sitting on a shelf. Pellets are also likely to age slower than loose hops as they will have less exposure.

Way back when I first started brewing I got a pound of loose leaf Cascade hops and stored them in a big gallon freezer bag in my minifridge. I slowly used them over about 18 months. A lot early on and then didn’t brew with them for about 5-6 months until that last batch. I didn’t notice any real impact until those last couple of beers around the 1 year and the 18 month marks. The aroma and some of the taste in a SMASH seemed off and dull in that 1 year beer. At 18 months I used them for bittering only and the IPA ended up very mild even though I doubled the amount of hops for the IBUs they should have imparted.

Hop aging is affected by temperature, oxygen, and time. Variety of the hop also plays a role in how they age. Here is a review of the science on hop aging, which is surprisingly not much (if anyone knows of more studies that aren’t referenced on this page on hop aging, please let me know): http://www.milkthefunk.com/wiki/Hops#Chemistry_and_Characteristics

I’am a spanish speaker, so please, excuse me if there are some mistakes in my writing. I hope not…

This exBeeriment is quite interesting, like always. Your main conclusion is the same to me: I’will continue storing my hops in vacuum sealed bags, but is not only because I keep confortable in mind with that, but I can’t find the exBeeriment conclusive at all.

I think it must be made with other periods of time just like different temperatures. For instance, room temperature, fridge and freezer, all of them 6 and 9 months, obviously, vacuum sealed and non purged baggie. Them we will have a more consistent opinion about the subject.

Understand my comment as a constructive one. I think your site and work is extremely good and useful. Thanks for sharing!

Very interesting, thanks for doing this exBeeriment. Taking you up on your comment at the end, I’d really like to see this replicated at room termperature. As someone who only has space for a small freezer with household demands to store actual food in it, I have to store all my hops (about 2 carrier bags full) at room temperature. I bought a vacuum sealer to do the best I can in keeping them fresh, and it seems pretty effective, especially with pellets. I reseal my 100g bags as soon as possible after opening them.

As room temperature should accelerate any alpha acid degradation and oil oxidation compared to freezer temps, it should not take as long to get a difference.

Check out this paper http://onlinelibrary.wiley.com/doi/10.1002/jib.40/full

Short version is that oxygen + room temperature is Very Bad for hops, but if you can either vacuum them OR get them cold then you solve a big chunk of the problem.

You’ll still suffer with hops like Cascade that have poor stability relative to other varieties.

I know this exbeeriment write-up is over a month old now, but recently I was thinking about whether the vacuum sealed bags are sufficient for storing hops. As I understand it, the bags aren’t oxygen barriers. Also as I understand it, oxygen barrier bags don’t work in a vacuum sealer. Maybe foil (or other oxygen barrier) zip lock style bags with air squeezed out would work better than vacuum sealed bags. Comparing foil bags against the standard loose-in-a-baggie method might show a noticeable difference.

Storage time is the one variable that was not sufficiently explored in this experiment.

I think the more interesting experiment would be to evaluate the hops after increasing longer storage intervals in the freezer.

I suspect flavor and aroma would deteriorate more rapidly in the hops that were not vacuum sealed.

Could you try freezer vs. Fridge?