Author: Matt Del Fiacco

Some of the most astounding xBmt results for me have been those showing the same beers fermented at different temperatures are largely indistinguishable by blind tasters. Of the 6 completed xBmts focused on this variable, only 2 have returned significant results– tasters could tell apart Milds fermented with WLP002 English Ale yeast at either 66°F/19°C or 76°F/24°C as well as Helles’ fermented with Saflager W-34/70 at either 60°F/16°C or 82°F/28°C. These findings just do not jibe with what I’ve learned about fermentation, and based on the number of accounts from homebrewers who swear that fermentation temperature control was key to the improvement of their beer, it’s clear I’m not alone.

Why can’t tasters tell apart beers fermented at such drastically different temperatures?!

One of the more common speculations has to do not so much with the actual temperature, but rather changes in temperature during fermentation. It seems a valid point given most new homebrewers rely on closets and corners without much in the way of temperature control other than their home’s thermostat. It’s entirely possible a correlation exists between newness in the hobby and off-flavors typically associated with poor control of fermentation temperature; however, as anyone who has taken Stats 101 is aware, correlation does not causation make, which is why I decided to see what would happen if temperature during fermentation was a bit less stable!

| PURPOSE |

To evaluate the differences between a beer fermented at a stable temperature and a beer of the same recipe fermented in an environment where the temperature was intentionally varied by 20°F up and down throughout the fermentation process.

| METHODS |

With so many non-significant prior xBmts on this variable, I thought it’d be best to brew a clean and simple beer so that any differences are more easily identifiable, which worked out well since the Willmette beer recently evaluated for the recent The Hop Chronicles fit the bill nicely.

Smooth & Steady, or Go Down Swingin’?

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 30.1 IBUs | 3.4 SRM | 1.049 | 1.012 | 4.8 % |

| Actuals | 1.049 | 1.012 | 4.8 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner (Weyermann) | 11.25 lbs | 100 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Willamette | 28 g | 60 min | Boil | Pellet | 3.6 |

| Willamette | 39 g | 25 min | Boil | Pellet | 3.6 |

| Willamette | 67 g | 5 min | Boil | Pellet | 3.6 |

| Willamette | 28 g | 3 days | Dry Hop | Pellet | 3.6 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| American Ale (1056) | Wyeast Labs | 75% | 60°F - 72°F |

Notes

| Water Profile: Ca 80 | Mg 2 | Na 10 | SO4 125 | Cl 62 |

Download

| Download this recipe's BeerXML file |

I made a starter of Wyeast 1056 American Ale yeast a couple days beforehand, sizing it such that it would provide enough yeast after being split between 2 batches.

The next morning, I immediately began by heating RO water for a full-volume no sparge batch, adjusting it to my mineral profile.

Grains were weighed out and milled as the water was on the flame.

Once the water had reached strike temperature, I added the grist filled Brew Bag to the water and gave it a gentle stir to ensure there were no dough-balls.

The temperature stabilized nicely at my target mash temperature of 153°F/67°C.

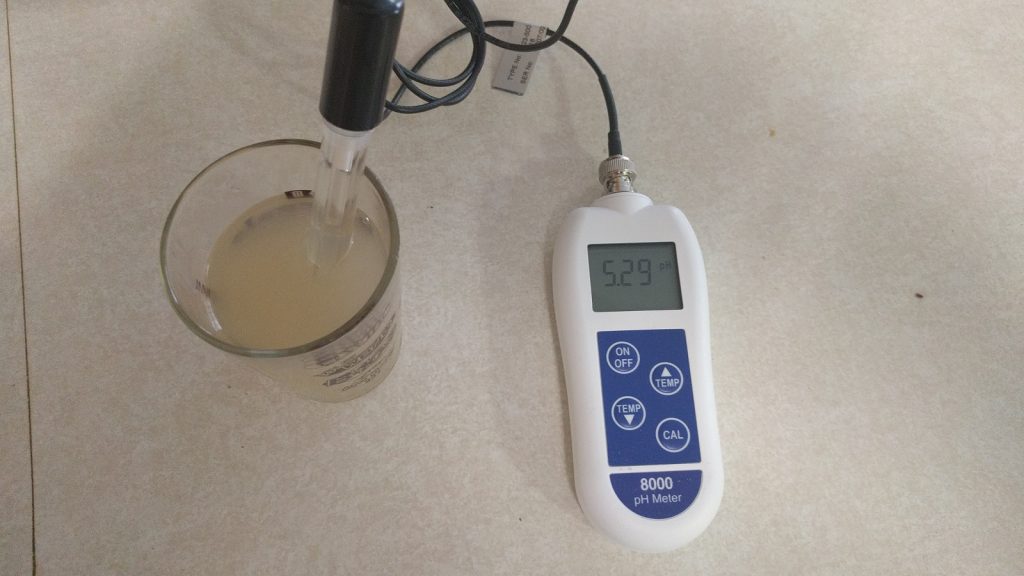

The wort was continuously recirculated throughout the mash rest. After 15 minutes, I stole a small sample for a pH measurement that showed I’d hit my target.

I weighed out the kettle hop additions during the 60 minute saccharification rest.

Once the mash was finished, I removed the grain bag and brought the remaining wort to a rolling boil.

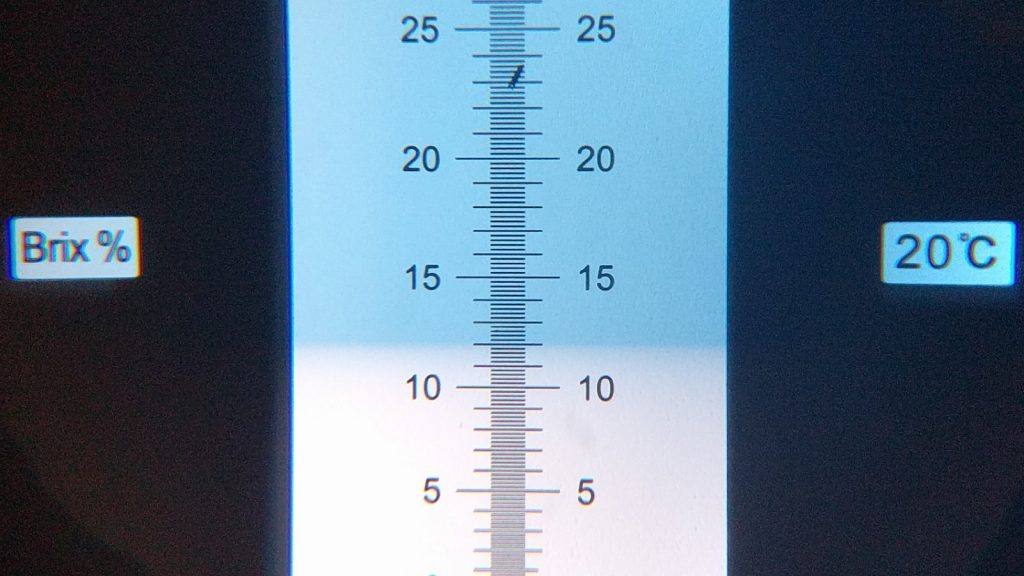

After 60 minutes and a few hop additions, I quickly chilled the wort then took a refractometer measurement.

The wort was evenly split between two 3 gallon Better Bottles, each placed in a cool chamber to finish chilling to my target pitching temperature.

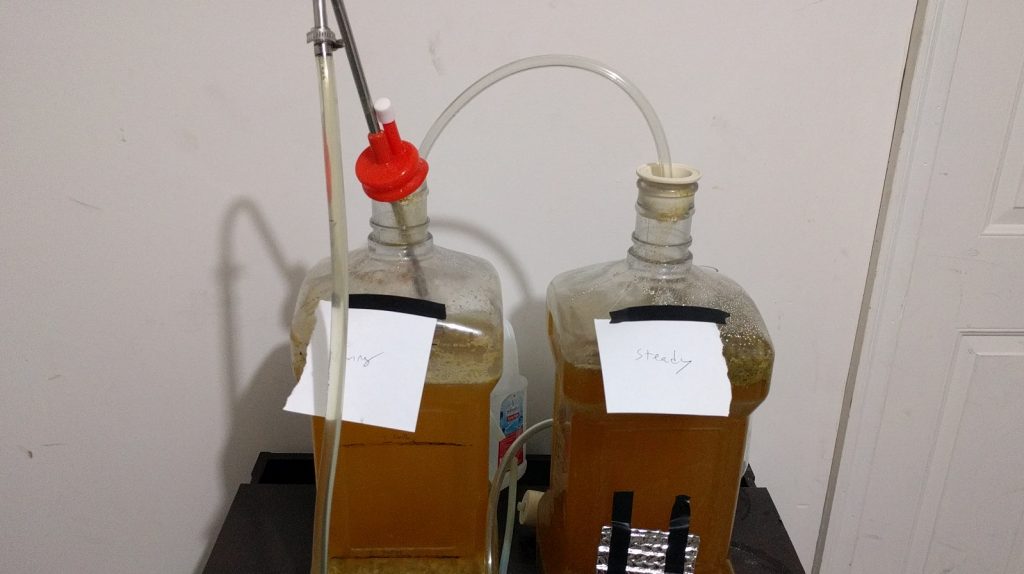

Once at 64°F/18°C, I pitched identical amounts of Wyeast 1056 starter into each carboy and set the chamber for the stable temperature batch to maintain my desired 66°F/19°C; however, the variable temperature batch was allowed to free-rise during the first eight hours of fermentation. After those first eight hours, I plugged the heat wrap in to the temperature controller and ramped it up to 86°F/30°C. After the first 12 hour window was over, the swing temperature beer (right) was showing more aggressive signs of fermentation than the stable temperature beer (left).

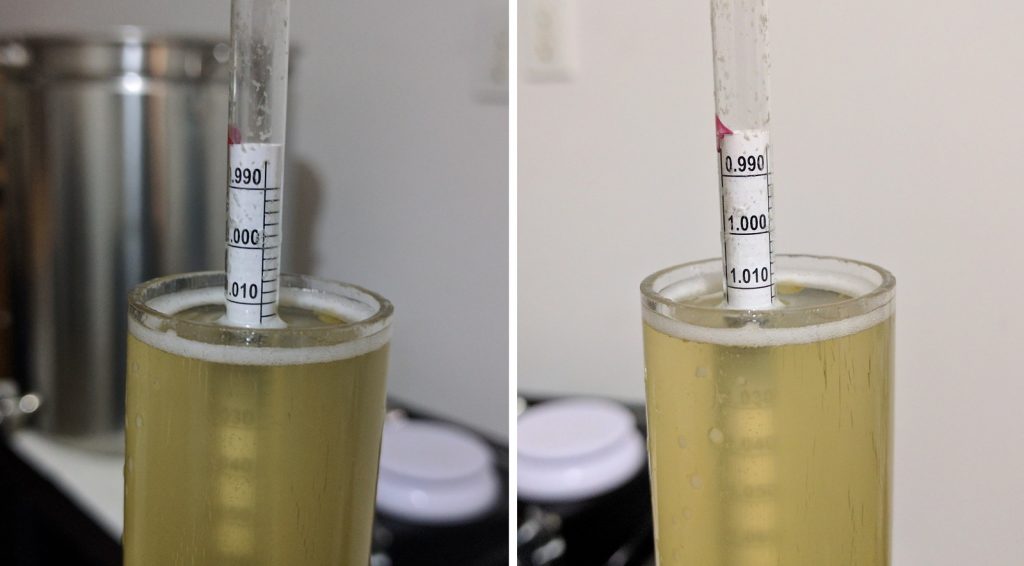

Over the course of the next 7 days, I forced the variable temperature beer up or down in temperature ranging from 66°F/19°C to 86°F/30°C every 12 hours. At the end of that week, with signs of fermentation having diminished, I took hydrometer measurements showing both beers appeared to have attenuated the same.

Dry hops were added to both batches at the same time, when fermentation was dying down, and they were left alone for 48 hours before I proceeded with cold crashing, fining with gelatin, and kegging.

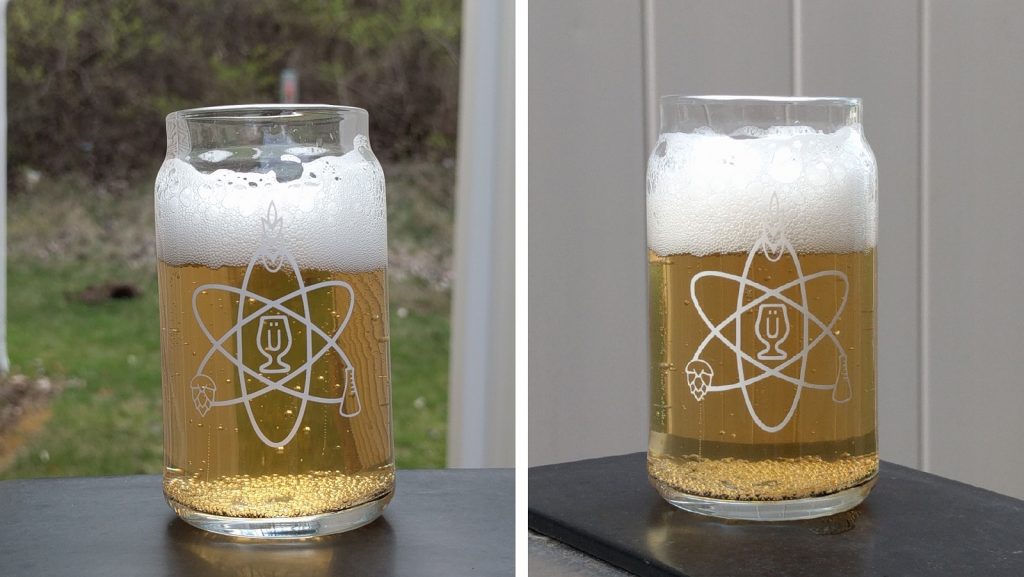

I burst carbonated overnight then reduced the CO2 to serving pressure where it sat for a few more days before I began serving it to participants.

| RESULTS |

A panel of 22 people with varying levels of experience participated in this xBmt. Each taster, blind to the variable being investigated, was served 1 sample of the beer fermented at a stable temperature and 2 samples of the beer fermented at variable temperatures in different colored opaque cups then instructed to select the unique sample. While a total of 12 correct selections would have been required to achieve statistical significance, 11 tasters accurately identified the unique sample (p<0.05; p=0.08), suggesting participants in this xBmt were unable to reliably distinguish a Pale Ale fermented with the popular Wyeast 1056 at a stable 66˚F/19˚C from the same beer fermented at varying temperatures.

While “but dude, it was so close!” doesn’t really matter, I figured I’d share some of the preference data, just please interpret with a grain of salt. Of the 11 people who correctly chose the unique sample in the triangle test, 2 said they preferred the one fermented at a stable temperature, 6 reported preferring the variable temperature beer, 2 had no preference despite noticing a difference, and 1 person felt there was no difference between the beers.

My Impressions: To quote my friend Tim, “The swing temp tastes like cake”. In three blind triangles, I could identify the swing temp beer every time. Not only did I taste what I typically associate with diacetyl, but there was a dough-y sort of sweet character that just wasn’t present in the stable fermented beer. I was blown away by these results, I’d even go so far as to say that I’m uncomfortable with them. At the same time, I’m excited by the possibility that there may be methods for new brewers to produce good beer without temperature control, and excited that we may open up other avenues of “what sets good beer apart”.

| DISCUSSION |

For those who might currently be feeling like these results were “close enough” to significant that it’s possible variable fermentation temperature does have a noticeable impact on beer and this xBmt missed it for whatever reason, you’re not alone. In situations like this, where if 1 more taster had been right instead of wrong the conclusion would be different, particularly with a variable as sensitive as fermentation temperature, I feel a strong pull to explain away and minimize the findings, which I’m aware is at least in part due to the fact they don’t align with my expectations.

But then I took a step back and thought about things a little deeper…

In this xBmt, the batch fermented with swinging temperatures was treated in a way that’s arguably unrealistic for most homebrewers in that I forced vast temperature variations in order to coax out a difference. Whereas the typical homebrewer who ferments their beer in a 68°F/20°C basement or closet may experience relatively gradual swings of about 7°F/4°C, I forced intermittent changes of 20°F/11°C (66°F/19°C to 86°F/30°C throughout fermentation, more than double what one might expect to occur naturally. If variations in temperature during fermentation were to have a perceivable impact, I have to believe the comically bipolar environment I created would have done the trick, and yet participants in this xBmt were incapable of reliably detecting a difference.

There’s no way I’d say these results prove that temperature variations during fermentation don’t matter, just as we’d never claim that fermentation temperature when using traditional lager yeasts doesn’t despite numerous xBmts demonstrating it doesn’t seem to produce a reliably distinguishable difference. It’s entirely possible two of the tasters had coffee before our test, and that is why this did not come back significant. Or, it’s possible that if you throw enough healthy yeast at something that there’s more room for errors. Or, as our previous xbmts suggested, maybe it really depends on the yeast strain. I’m of the opinion that a combination of those things is likely true, and if there’s anything I personally am going to walk away from this xbmt with it is a hope to see more testing and reports on this variable.

If you have thoughts about this xBmt, please share them in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

59 thoughts on “exBEERiment | Fermentation Temperature: Stable vs. Variable In An American Pale Ale”

Just anecdotal “evidence”… I have a friend who loves saisons and brews them regularly. I only brewed one. I fermented it in our upstairs closet that was approaching 78-80 degrees (no central air in our home in W.PA but the temp was, in my mind, closer to “style” than a cooler temp). He was really impressed with the flavor. We both used the same recipe (from Brewing Classic Styles). The one factor we could distinguish between our two beers was fermentation temp. He fermented in his central-AC basement at around 66-68 degrees. Not that this would in any way hold up to the scientific method but still an interesting outcome.

Super interesting outcome! I’d love to try this again with a Saison. I’m also increasingly inclined to believe that type of ingredients, water, and ferm vessels play a bigger role than we give them credit for.

Saison yeasts do seem to “like” higher temperatures than most homebrewers are used to, and most of the belgian saison breweries let their temps rise to the 80’s. I read an interview with the brewer at Blaugies where he said that their yeast “didn’t do anything” below 77F. I will ferment lower than that, but the esters and phenols that they like are more prominent at the higher temps, apparently. Could be another interesting experiment though-fermenting saison yeasts lower than the breweries do vs. high.

I’ve never had a fusel-dominant beer so don’t know how it tastes, but I wonder if drinking 4 or 5 of the the swing beers would make you hate your momma in the morning?

Yes, moar xbeeriments on this one. This just has to be wrong because . . . Because it is. And has to be,

Ha I had the same response! Saw the results and thought “No. No way”. Totally want to do this more, with more yeasts (and same yeast) and variable pitching rates/aeration/etc.

I think this is the key. When I look back at some beers I’ve made that had off flavors when I was new to brewing, I was doing several things wrong… Wasn’t pitching enough yeast, pitched it when it was too warm, let it stay warm too long because I couldn’t get the temp down and the yeast was going nuts, poor temp control in general. Then, after all that mess, didn’t let it sit long enough to give it a chance to clean up. Not to mention I got lax in my cleaning habits…

I find it surprising the beers were dry hopped. I feel a hop aroma can override subtle yet distinguishing malt characteristics.

May not have done that were it not for the fact that this batch was split, the steady batch was the last Willamette THC article, and since we dry hop those batches I had to dry hop both for consistency. When we repeat this variable, that’ll definitely be something I look at!

I thought along these lines too. Hops and malts have strong desirable flavors. More reveal by a lightly hopped pale malt, I’d guess..

Hey Matt, are you doing the gelatin in the cold crash vessel or in your keg?

Hey dude!

I cold crash in those better bottles when I use them, but typically (as you’ll see in future articles now that I have a large fermentation chamber) I will cold crash in my serving.

For a small sample size, it makes sense to have a higher p-value. Which is why I ignore the arbitrary “statistical significance” and look at the calculated probability of these data randomly occurring, the sample size, and the stated method for calculating p. As a mathematician, I’d say this trial confirms the different methods give a different result. Not that it matters because one study is just the beginning of determining the thing and nothing in itself.

Would love to see a ton more repetitions of this variable, in different contexts. Definitely one I would love to see more participants with too!

I think you missed Matts point. With this kind of result it would be helpful if you had calculated at what level of significance the results do hold in addition to testing at an arbritrary prespecified significance level.

Sorry, missed Maxes point.

Maybe time to start screening panelists?

For what? We’ve run analyses showing ability to distinguish differences doesn’t seem to be related to experience (i.e., one’s status as a BJCP judge). I’m not sure what screening would look like, to be honest, and I’m also not sure how applicable the results would be if we could figure out some way to doing it.

Random participants with varying experience levels are fine for detecting huge flavor differences. However subtle differences would be, more than likely, lost on inexperienced pallets.

I just think of my parents who only drink Bud. When they have tastes of my home brew they say “that tastes ok”. If I point out a nuance or subtle flaw it is usually undetectable to them. However, if I give them a beer with a huge flaw (usually oxidation) they pick it up right away and will say something like “this tastes off”. This is not to say that you should screen participants, just that less experience means less detection.

Or rather, attempt to set up an additional panel (with completely different participants) within a close time frame of the original. That would probably be a good idea for all of these experiments independent of the outcome…and it would also provide a larger sample size…

I understand the desire to use a set of independent participants, but you can in fact come to conclusions based on a single person doing the test multiple times – it’s just that it is less generalisable.

You are correct that “participants in this experiment were unable…,” but if you managed to detect it 4 out of 5 times you’d have hit a 95% confidence on your own, meaning that you reliably CAN detect a difference (or you got a false positive). If any participant can reliably detect it, then there is a difference, though it may be too subtle for a broader audience to notice. If the goal is to determine if the temperature changes caused a change in the beer, then take the test a few more times yourself – you want to use the most discriminating palate you can for it, since you’re trying to detect whether a difference exists.

The translation of statistical results to human interpretation is often a challenge. I would agree with your logic. The same could be said about some previous experiments with different hop use.

But he knew the variable ahead of time, which makes it easier to distinguish and look for that difference.

So take the other participants who did detect a difference but do not know the variable and have them do the test a few times to see if it was chance.

Is letting people with questionable pallets participate in these excersises a flaw? Someone who drinks Budweiser all the time is much less likely to notice any difference than someone who has tuned their pallet in high quality craft beer. Just a thought that I had.

On a personal note. The quality of my pales and IPAs increased exponentially when I switched from room temp to temp controlled fermentation chamber.

I saw no difference with my Belgian style ales.

I am sure I have seen/heard of another experiment with very similarly surprising results.

My personal opinion is that pitching temperature has a massive affect on the character of a beer and is under rated as a variable. If I read this correctly, the pitching temperature was equal in both and then the variable beer was left to free rise after 8 hours. The growth stage of fermentation is responsible for much the flavours and after 8 hours this would practically over.

I would love to see this experiment but in reverse, ie. very different pitching temps but then rapidly (a few hours) brought back to equal fermentation temperatures and kept there for the remainder of the fermentation.

I love these experiments, thanks for all your information and keep up the great work.

This is such an awesome idea, I’ll throw it on the list! Would love to see more regarding pitching temps in different styles too.

Id be interested to know the temp of the free rise beer 8-10 hours after pitching the yeast.

Perhaps a follow up experiment to this could be to test the effects of a temperature controlled yeast starter (grown at pitching temp) to one that is prepared at ambient temperature. If the temperature in the growth stage is the crucial factor, wouldn’t it be important to ensure that the initial growth stage in the starter was controlled?

Really looking forward to future experiments in the fermentation temperature area!

I was going to suggest this as well. Plenty of new brewers that I talk to get impatient and get the wort down to a “roughly” cool enough temp – say 26-30 degrees C and then pitch. Would be interesting to see it pitched at 30 and left to naturally drop to the fermentation temperature

They did test this a while back, but didn’t find significance. I’m wondering if that’s related to the yeast, or is it a lack of nutrients/oxygen, etc.? I’ve always found my brews (~3 gallon batches) finish fermenting within 2-3 days, so I’d kind of expect any temperature swings after that would be a bigger issue with long term stability. I need to try and hook my keg cleaner up to recirculate ice water.

What was your own preference between the two? Did the difference that you perceived make the beer inferior in taste? It’s interesting too, the possibility that people might actually associate diacetyl with a better tasting beer.

I feel that fermentation temperature is the last hope I have to improve my IPA’s. I have been trying to nail them down for the last year, and am controlling water, recipe formulation, yeast health, oxygen/no oxidation, and am kegging. I still get this very noticeable (to me) “homebrew” flavor that almost makes them impossible to drink. I ferment in fairly controlled conditions such as a tub of water with ice but nothing that is dialed to the T. the results of this make me wonder if it isnt fermentation then… I am just going to stick to sours. They always turn out great!

Some thoughts:

(1) all temperature experiments are yeast strain dependent, so we can’t extrapolate the results to temperature in general;

(2) The binomial probability of 3/3 for an event whose probability is 1/3 is .037. You have statistically significant evidence that you can tell the difference between these two beers even if you don’t have evidence that the “general taster” can tell the difference;

(3) p = .08 is a pretty strong result. If you got this in an initial trial in a psych. experiment, you’d probably consider running the experiment with another 20 subjects to see whether you got to significance at that point.

Agree with most of these comments. I think it is highly dependent on the yeast strain, and Wyeast 1056 is very good at tasting the same from 62F to 82F.

When you have an insignificant result, you often seem to interpret the result as indicating that there is a lack of correlation. From a statistical perspective, this is incorrect — an insignificant result simply indicates that you were unable to prove correlation beyond your confidence interval. Proving a lack of correlation is very different from being unable to prove correlation.

Anyhow, being unable to prove correlation is still an interesting result in this case, especially with those crazy temperature swings. Love the blog and keep up the good work!

I do feel this result really challenges one of the most basic assumptions I have made regarding brewing good beer, and also some of my past experiences. I do find myself questioning the exbeeriments results from time to time, and I have to say, I find myself pretty skeptical about this one, considering the author’s comments and the very close results. While I do understand that this is far from a laboratory setting and there are time and money constraints, I do think greater care could be taken on the sampling method used. I do think a n=30 as a minimum would be far better. The authors could also try to control the environment and instructions given to make sure the testers are in the best possible situation to correctly assess the beers : didn’t drink before (beer, coffee, other flavored drinks) or smoke, are in a semi-quiet place, understand their role and the use of the data (and the seriousness of it all!).

Anyway, great write-up Matt and as always very enjoyable to find a new exbeeriment every monday morning posted on the site ! Hope to hear more on this subject on the podcast !

Do you have the testers cleanse their palate before each test? I’ve been on brewery tours and they include a soft pretzel to carry with you to take bites of to cleanse your palate between beer samples.

I’d like to see another one where the controlled temp is higher (like 78 or something) compared with a highly variable temp.

> if there’s anything I personally am going to walk away from this xbmt with it is a hope to see more testing and reports on this variable

Would you have said that if the result was different (significance achieved)? What I read in that statement is that we’ll keep testing until we make it significant.

I’d ask, given the number of these experiments, why we are so anxious to find fermentation temperature significance? *Why* do we come to the xbmt with the expectation that fermentation temperature is so meaningful?

I’ll posit that it’s a carryover from commercial brewers, where it’s critical that the product is absolutely standardized across every bottle or can ever made. They HAVE giant temperature controlled fermentation tanks, so it’s effortless for them to control that variable and eliminate a potential source of inconsistency. After all, the tank has to be set to something, you may as well make it consistent.

That habit leads to received wisdom among commercial brewers, which gets passed onto people who write homebrew books, and suddenly we have statements like “one of the most critical factors in making great homebrew is fermentation temperature control”.

What I love about Brulosophy is that it takes on preconceived norms and puts them to the test. Maybe it’s time to listen to the mountain of data from these experiments – it may just not be as important as we have led ourselves to believe.

Fantastic point man.

So, I want more testing done for two reasons:

1) I always want more testing. Brulosophy is super proud of the fact that we publish it all, sig or non sig. These sample sizes are small and the results are contextual. I 100% believe there is value in them, but more testing is always the answer.

But, more specifically, why did I call it out? Leads to:

2) I’m super, affectively, uncomfortable with these results. Not only does it go against my preconceived notions, but academic results I’ve seen, anecdotal reports from people I trust, etc. Does that mean this is right/wrong? Absolutely not. But that’s why I called it out. It’s backfire effect. Results are against my beliefs, so reject and dig in. Hard to work past.

Very interesting stuff, thanks again.

One minor criticism: the variable batch has continually higher temp, so any difference might be due to that rather than the swings. If repeated, I’d aim for similar average. I’d probably also try to replicate the typical range experienced by brewers without temp control.

Considering the results it makes me think that the reason so many people say fermentation temperature control has made a big difference is because by the time the add temp control they simply have more experience. Nothing improves beer more than experience. Learning your system, hitting your numbers, and making no mistakes.

Really love this! Starting to really believe the difference between good homebrew and bad is the result of doing many things wrong. While you don’t get significant results on one, if you changed 4 or 5 variables to things that are generally considered wrong, I firmly believe you would taste a huge difference. But when everything else is done correctly, 1 variable doesn’t wind up significant.

Great xbrmt. The fact remains that brewing is a combination of so many factors and ingredients. Would the results be different with different malt? different yeast? different hops? what about a beer fermented with 10% simple sugar? the answer we all know is of course it would… maybe more one way, maybe more the other way. One key to making consistently great beer at home is eliminating possible variables that can have a negative impact on your beer. So I think we all feel safe with the advice…”control fermentation temperatures”. And I think we can safely continue to advise people to control fermentation temperature.

“And I think we can safely continue to advise people to control fermentation temperature.”

That is true.

Also true is that home brew forums tend to make people crap their pants if they don’t have fermentation control. Most of these temperature control experiments have shown little difference between the beers, even if a statistically significant number of people COULD detect a difference. (Hell, in the warm-pitch lager one with the massively significant result, Jake said the cool pitch had a whiff of sulfur, the only difference he could detect, which made him prefer the warm-pitch).

Maybe it’s time to lay off of people that don’t bother with temperature control other than fermenting in their consistent-temperature basement. It’s only beer, after all, not life or death.

Incidentally, Matt, this was tied for my favorite all-time exbeeriment (along with 34/70 at ale temperatures). Good job.

What surprising results, eh??!

Seems like a more narrow temp swing would be more realistic – maybe first is to gain understanding of an uncontrolled ferment swing temps first? My guess is say +5-10 ambient in first 3-4 days with some, but not terribly dramatic day night swings? No idea really. However knowing this first would help to set up a “realistic” exbeeriment.

Also not sure if you’re temp swings were ramped during the period or immediate?

I think you should test with conditions you are truly attempting to challenge.

Keep up the good work! Love these!

As a group ya’all should start considering statistical type II errors in your results. This is the probability that you will fail to obtain a significant result even when there is a real effect because the sample size was too small relative to the variance and the strength of the effect. Turning the math up a notch would provide a lot more insight.

Most of the time your many near misses would be significant with a larger sample size.

This seems like a great one to try at home.

I wonder if having a few “supertasters” mixed in would explain the results. Some people can taste certain things where others cannot perceive.

https://en.wikipedia.org/wiki/Supertaster

I’m thinking that for the experiment results you could also control the tasters panel. Maybe using only people who drink home brewed beer often or a non beer drinking panel. I would count that as a variable too… I don’t brew, I brewed just once in my life because I don’t have space and the ambient temperature here in Guadalajara, México is too high. If I’d was to change anything in your experiment it would only be the tasting panel… and maybe also the serving temperature of the beer, I think that may change results drastically.

Cheers!

Saludos from Mexico!

This has been examined.

https://brulosophy.com/2016/01/21/investigating-the-bad-palates-argument-a-graphical-look-at-xbmt-performance-based-on-experience-level/

Need to rember that your signifance level of 0.05 means that 1/20 times you do the test that turns out to be “significant” is really just due to chance and is in fact wrong. Close calls do mean something! They need to be repeated!

What were the palate experience levels of the people who could not tell the difference between the beers?

Please do an experiment where you give tasters ketchup and mustard and see if they can tell the difference. Maybe for April Fools. You are wrecking my worldview!

The last few experiments have come back inconclusive, making me wonder if anything I do is worthwhile.

Cool experiment, I love it! the random 20°F swings!

Personally I am not sure that you temp swing beers really capture what goes wrong with ambient temp beers. I suspect that later occurring temperature ramps in your swing beer cleaned up yeast off flavours. Similarly in other exbeeriments such as yeast keeping yeast too warm (eg traditional versus shoddy), the temp controlled means that the fermentation finishes warm, ie gets a chance to clean up.

Whereas, your average first time brewer, based on a little reading, mostly likely brews at ambient, basement type temps, so yeast activity warm the beer above optimal levels early, then as fermentation slows- temps drop again, and the yeast do not have a chance to clean up off flavors. Indeed, your first time brewer does a bit of googling during fermentation, panics and starts throwing ice around the fermentor or attaching T shirts and fans half way through fermentation!

Lots of brewing books suggest that too high temperature during growth phase and too low temperature as yeast finish are the most important times for yeast flavor production and yeast off flavor clean-up. Commercial british brewers such as Fullers 64-68-64°F schedule is designed to minimise off flavor production in early fermentation, but maintain a beer with a strong yeast/ester character. US brewers on the otherhand start low and finish higher to maintain that clean beer taste.

I’d love to see a cold basement ambient simulation (lets say 64 72 64°F) vs temp control 68°F exbeeriment!

I feel like this says more about the tasting panel than the experiment itself. The fact that you could pick out the difference so obviously every time (as I would expect) makes me doubt the efficacy of the whole process. Granted, we’re all brewers and probably have a more sensitive palate to most things beer related, but damn…

My first brew was not temperature controlled and tasted strongly of green apples (acetaldehyde). Too hot. That’s what taught me the importance of temp control.

“The fact that you could pick out the difference so obviously every time (as I would expect) makes me doubt the efficacy of the whole process.”

He was not blinded to the variable. He was biased having been on loved in the process.

“Granted, we’re all brewers and probably have a more sensitive palate to most things beer related, but damn…”

Being a brewer doesn’t give you a more gifted palette any more than going to basketball camp makes you taller. Go to a small local Brewery. 7 out of 10 make some pretty bad beer. Made by brewers, unable (or unwilling) to detect their own flaws.

Be interesting to see what impact a 5 – 10 degree swing (or even less) would have in a similar experiment. I suggest few brewers would achieve multiple 20 degree the swings you tested, yet many (like myself) often have 2-3 degree variance in their fermentations.

I brew in the basement, where summer temps might reach 74 degrees, yet winter is a nice cool 62. In my 2-3 week ferments, this temp may move 2 degrees up or down. Am I going to improve my beer by controlling temps? I suggest not.