Author: Jake Huolihan

A curious thing occurs when wort is boiled– proteins coagulate in what’s called the hot break, initially causing a terrifying period of foaming, and eventually leads to a kettle of boiling liquid that looks more like egg drop soup than beer-to-be. A similar thing occurs during the rapid chilling of the wort at the conclusion of the boil, which is referred to as the cold break. Both of these are accepted by many as being an important component of the brewing process, as it allows the brewer to more easily transfer only clear wort to their fermentors, which is believed to reduce haze and improve shelf stability. While a good boil, proper wort pH, and quick chilling will contribute to a good break, brewers often rely on additives to encourage stronger coagulation of these proteins, with a popular option being Whirlfloc.

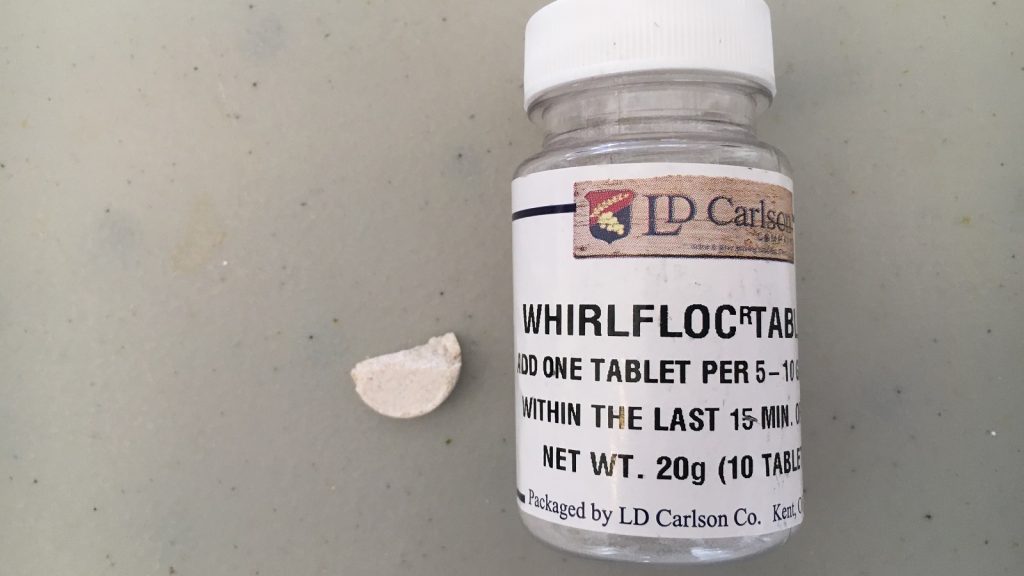

Whirlfloc is like the younger, more virile cousin of Irish moss, a seaweed based kettle fining containing natural carrageenan, which is negatively charged and assists in clarifying wort by attracting positively charged proteins. Purportedly invented for use on the commercial scale, Whirlfloc is made of both Irish moss and purified carrageenan held together with a wax binder in the form of a tablet. Adding just half of one tablet during the last 5-15 minutes of the boil results in the observably rapid coagulation of proteins into chunks heavy enough to easily drop out of solution once the wort is chilled. With all of the those extra proteins out of the way, the brewer is able to fill her fermentors with the clearest wort, thereby reducing the chances of a hazy finished beer.

Or at least that’s what we’ve been told.

I’ve used Whirlfloc as a matter of course since my first batch, it has seemed to do it’s job well, as my beers tended to come out fairly clear even before I began fining with gelatin. With a prior xBmt showing tasters couldn’t distinguish between an Irish moss fined beer and one that received no finings while still having an impact on clarity, I was curious to see what kind of an impact this sup’d up version would have.

| PURPOSE |

To evaluate the differences between a beer fined in the kettle with Whirlfloc and one that received no finings.

| METHODS |

Continuing on my quest to English Bitter enlightenment, I designed a new recipe that I thought would work well for this xBmt.

Not Best Yet Strong Bitter

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 48.9 IBUs | 13.6 SRM | 1.056 | 1.014 | 5.5 % |

| Actuals | 1.056 | 1.014 | 5.5 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Malt, Maris Otter | 10 lbs | 87.43 |

| CaraMunich I | 12 oz | 6.56 |

| Corn, Flaked | 8 oz | 4.37 |

| BlackPrinz | 3 oz | 1.64 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 20 g | 60 min | Boil | Pellet | 12.5 |

| East Kent Goldings (EKG) | 30 g | 30 min | Boil | Pellet | 4.8 |

| East Kent Goldings (EKG) | 15 g | 10 min | Boil | Pellet | 4.8 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| London Ale III (1318) | Wyeast Labs | 73% | 64°F - 74°F |

Notes

| Water profile: Ca 80 | Mg 0 | Na 8 | SO4 104 | Cl 68 | HCO3 16 |

Download

| Download this recipe's BeerXML file |

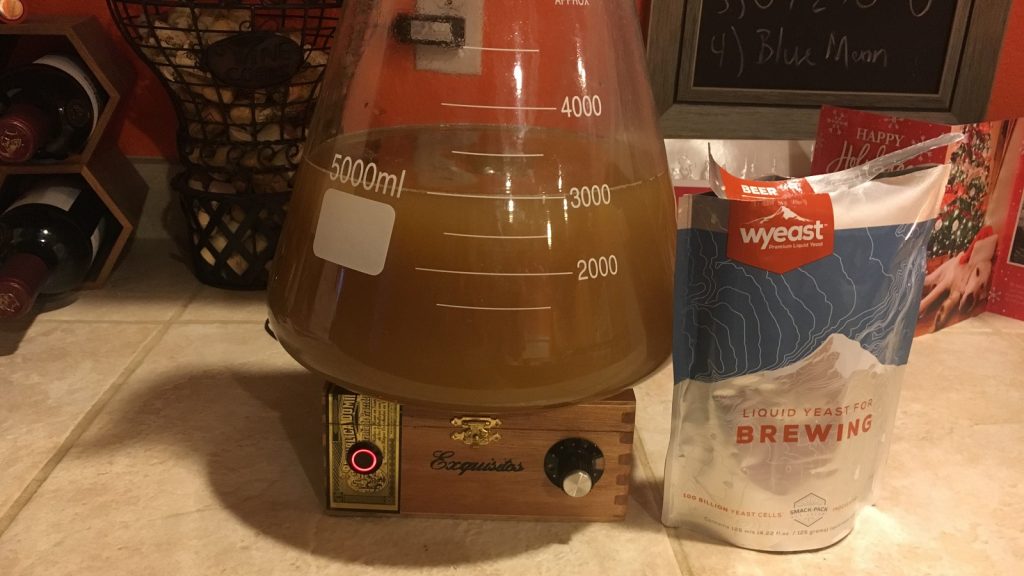

I made a nice sized yeast starter with a pack of Wyeast 1318 London Ale III the night prior to brewing.

At the same time, I began the fairly long yet worthwhile process of collecting RO water that I would later adjust to my desired profile.

The following morning’s brew session started with me lighting the flames under my kettles to begin heating the water to my calculated strike temperature.

As the water was heating, I weighed out and crushed the grains.

When each equal sized batch of water was properly heated, they were transferred to separate MLTs with the crushed grain and gently stirred to hit my target mash temperature.

The mashes rested for an uneventful 60 minutes, after which I collected the sweet wort from both in a single kettle for homogenization’s sake before splitting off half to another kettle.

Hitting the burner under the non-fined batch 15 minutes before the Whirlfloc batch, both worts were boiled for 60 minutes with hops added per the recipe.

With 10 minutes left to go in the second boil, I added half of a tab of Whirlfloc.

Once the boils were complete, both worts were chilled to my target pitching temperature.

After racking equal amounts of wort to separate fermentation kegs that were placed in my temperature controlled fermentation chamber, I took a look at the trub in each kettle and observed a rather noticeable difference.

Hydrometer measurements pleasingly revealed both batches achieved the same OG.

A look at both hydrometer samples from a different perspective with better lighting revealed a pretty drastic difference in appearance.

I proceeded to decant the yeast starter and split the slurry equally between each batch, dosing each with a 60 second burst of pure O2. Both batches were showing signs of active fermentation 24 hours later as evidenced by bubbling in the blowoff reservoir.

A week into fermentation, things seemed to be slowing down, so I raised the temperature in the chamber to 70°F/21°C to promote complete attenuation. After another week, I took hydrometer measurements showing both beers had stabilized at the same FG.

I poured the hydrometer samples in glasses to see if there were any differences in clarity, which there really didn’t seem to be.

I cold crashed the beers for 36 hours before pressure transferring them to serving kegs, forgoing my standard gelatin fining process in order to best exemplify the impact of Whirlfloc.

After a brief period of burst carbonation, I reduced the CO2 to serving pressure and let them condition for 9 days before I began pulling samples. Though not terribly drastic, the Whirlfloc batch was slightly ahead of the non-fined beer in the clarity race.

It was around this point that I started collecting data, though for good measure, I documented appearance changes over the following few weeks. At 3 weeks in the keg, the non-fined beer maintained a noticeable haze while the Whirlfloc beer was brightening up nicely.

Just 1 week later, a full month after kegging, the Whirlfloc beer was as brilliant as my gelatin fined beers usually are after a few days in the keezer, which was not at all the case for the non-fined beer.

I was beyond curious to see if the clarity differences caused by the Whirlfloc would carryover into flavor, aroma, and mouthfeel.

| RESULTS |

A panel of 19 people with varying levels of experience participated in this xBmt. Each taster, blind to the variable being investigated, was served 2 samples of the non-fined beer and 1 sample of the beer fined with Whirlfloc in different colored opaque cups then instructed to select the unique sample. While 11 correct selections would have been required to achieve statistical significance, only 9 tasters accurately identified the unique sample (p<0.05; p=0.15), indicating participants in this xBmt could not reliably distinguish a beer fined with Whirlfloc from the same beer that received no fining agent.

My Impressions: I was able to distinguish the beer fined with Whirlfloc from the non-fined sample. It wasn’t easy, but I was consistently able to identify the unique sample because I felt the Whirfloc fined beer was slightly cleaner with a smoother overall character, while the non-fined beer had what I a sort of odd sharpness to it that’s difficult for me to describe, not necessarily unpleasant, just different. Overall, the beer, both batches really, were fantastic, I definitely plan to use this as a base to tweak from as I continue to strive to perfect my English Bitter recipe!

| DISCUSSION |

As a longtime user of Whirlfloc, I went into this xBmt expecting to see a difference in clarity, and to this end it would appear it lives up to its reputation, as the non-fined batch maintained a hazier appearance. While this observation alone is evidence enough for me to continue using Whirlfloc, the participants’ inability to reliably distinguish the fined beer from a non-fined sample encouragingly suggests its use doesn’t have much of an impact on aroma, flavor, or mouthfeel as well.

Based solely on comparisons with images from the Irish moss xBmt, the beer fined with Whirlfloc was noticeably clearer than the one fined with Irish moss, which may indicate something about the addition of the purified carrageenan; however, it’s also wholly possible this observational difference is a function of some other different aspect of the brewing process or ingredients use.

What I find most curious about this xBmt is the fact I was able to consistently identify the unique sample in “blind” triangle tests while tasters could not. Given what we know about bias, I wouldn’t be surprised if my knowledge of the variable didn’t in some way influence my performance, though since I did prefer the beer fined with Whirlfloc and it was clearer, I see no reason to stop using it.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

20 thoughts on “exBEERiment | Impact Fining With Whirlfloc Has On A Strong Bitter”

Another excellent xbrmnt. I’m quite surprised that this one failed to reach significance. I for one will keep using whirlfloc.

Not a fan of Whirlfloc preferring Irish moss instead.

For whatever reason … IM produces a more dense trub cake in my brew shed than Whirlfloc; therefore … more clear wort.

been wondering about the haze aspect of this for awhile. thanks!

In the Netherlands hardly anyones uses Irish Moss or Whirfloc or Gelatine. Brewers here do have an aversion against such additives in Beer.

Here it is widely used to correct the water profile with CaCL, CaSO4 and lactic acid.

Also with more attention to sparging you get cleaner wort.

Besides brewers often cold crash the beer during the last 2 days of fermentation at 1 – 4 degrees celcius..

Would love to see a four-condition xbrmnt – control: no additives; condition 1: whirlfloc; condition 2: fined with gelatin; condition 3: gelatin + whirlfloc. I’m curious if gelatin and whirlfloc accomplish the same thing, making each other redundant, or does the combination yield better results than either alone?

That would indeed be a good xBmt.

Thinking more about this, you could give each tester each beer, have them rate the beers on a 1-10 scale, take the mean and standard deviation of each beer’s ratings, and run them through a four way ANOVA test, with null hypothesis that all means are the same. A little different than the triangle setup, but not only would you get a test of significance (can tasters detect differences), you also automatically get rankings of which one they preferred the most, with standard deviations so you could see if differences were due to outliers.

Wave two of the test is to use clear cups and have each taster rate clarity on a scale of 1 (opaque, Guinness) to 10 (transparent, water). Another ANOVA and you can see if participants could detect differences in clarity.

Then combine the two datasets and see if the participants who could perceive differences in clarity had different taste and preference perceptions.

Fun with math!

I love a good old fashioned ANOVA test as much as the next guy, I think you’d want a duplicate of one beer. This might act as a second check.

Any thoughts on ease of recovering yeast with minimal trub between the each flocculant?

Depending on the beer, I do both. I don’t claim to be the most adept person when it comes to keeping trub out of my fermenter but I do a pretty good job. Regardless, I never fail to have anywhere from a half to three quarters of an inch of trub after cold crashing with gelatin.

Thanks for this exbeeriment! I always just throw in a tablet almost out of habit, glad to know it’s actually doing something. I wonder if you would have noticed a difference if you did this AND added gelatin to both at the end?

One thing I’ve actually noticed with most of my beers is a lack of the big chunky hot break formation. In the end, I’ve never had clarity issues and my beers seem to be well received. I wonder why this is… I never check my boil ph, but I always target a mash ph between 5.2-5.4

Thanks for doing this. I guess this means that all fining agents only have an effect on the aesthetics?

These results surprise me because I’ve read that Irish Moss and Whirlfloc only address protein haze, (chill haze). In your exbeeriment, it seems to reduce haze whether warm or cold. I’m not sure whether the Whirlfloc actually reduces yeast haze or if I just misunderstand what I’ve read.

Forgive this, but the previous xBmt “Yeast Comparison: Wyeast 1318 London Ale III vs. Wyeast 1056 American Ale (NEIPA)” has a broken link. I could not find any link on the site to contact any of you, so I decided to inform you here.

I have used whirlfloc since my second brew day after reading about it on the forums. I usually just end up tossing a whole tablet in. Any input on any benefits or drawbacks using more? I just felt like it couldn’t hurt to have more clarity, and tossed in the whole tab.

The recommended dosage is half a tablet for five gallons, however, on a commercial scale dosage will depend on performance in your system.

Generally I throw in a whole table for a batch regardless of size but I doubt the extra increases wort clarity substantially

From the photos it looks like you racked the clear wort off the trub and left the trub behind. Is that right?

For the most part yeah, some certainly carried over for both though.

Any differences in head retention and foam clinging to the glass?

Very good experiment! The side-by-side comparison is amazing. So what is your typical refining process? Whirlfloc, Gelatin & cold crashing?

Well you could dispense with the opinions of 19 tasters and just take a milliliter of each to a college lab with a spectrophotometer and get an optical density reading. Still, invite the 19 over for a party!