Author: Jake Huolihan

Easily overlooked by those of less nerdy and/or obsessive persuasion, grain crush is believed by many to play various roles in the brewing process. Like most homebrewers, I started out by purchasing grains on a batch-by-batch basis from a local shop where they were milled for me, leaving me with no control over the crush. Looking to save some dough, I started buying ingredients in bulk and milling my own grains, which is really when grain crush became something I thought about. My mill came preset with a 0.045″ gap that I left alone per the manufacturer’s suggestion. It worked well and allowed me to achieve predictable, albeit somewhat low, efficiency between batches.

With no pressing reason to change, I became intrigued after hearing that some brewers, particularly those utilizing the brew in a bag method, were experiencing improved extract efficiency by mashing grains milled extremely fine. This made practical sense to me, but based on information I’d previously read and heard suggesting fine milling led to increased tannin extraction, I was curious if the resultant beers ended up with more astringency or perhaps some other unique character. Results from our first xBmt on this variable showed crush size seemed to impact not only efficiency but overall beer character, as tasters were able to reliably distinguish between the samples. Interesting, indeed, but I was left wanting for more, as I don’t brew too many high OG styles, so I decided to replicate it on something a bit more tame.

| PURPOSE |

To evaluate the differences between an American Pale Ale made with either a coarse or fine crushed grist that are otherwise treated identically.

| METHODS |

I thought a simple Pale Ale would be a good fit for this variable and doubled the size of a recent batch for The Hop Chronicles for a twofer brew.

Hüllmühle Pale Ale

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 29.4 IBUs | 5.6 SRM | 1.054 | 1.012 | 5.6 % |

| Actuals | 1.054 | 1.008 | 6.0 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Briess Pale Ale Malt | 11.25 lbs | 95.74 |

| Weyermann Vienna | 8 oz | 4.26 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Huell Melon | 26 g | 60 min | Boil | Pellet | 4.5 |

| Huell Melon | 31 g | 30 min | Boil | Pellet | 4.5 |

| Huell Melon | 31 g | 5 min | Boil | Pellet | 4.5 |

| Huell Melon | 31 g | 0 min | Boil | Pellet | 4.5 |

| Huell Melon | 30 g | 5 days | Dry Hop | Pellet | 4.5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| California Ale (WLP001) | White Labs | 77% | 68°F - 73°F |

Notes

| Water Profile: Ca 64 | Mg 0 | Na 8 | SO4 75 | Cl 61 | pH 5.4 |

Download

| Download this recipe's BeerXML file |

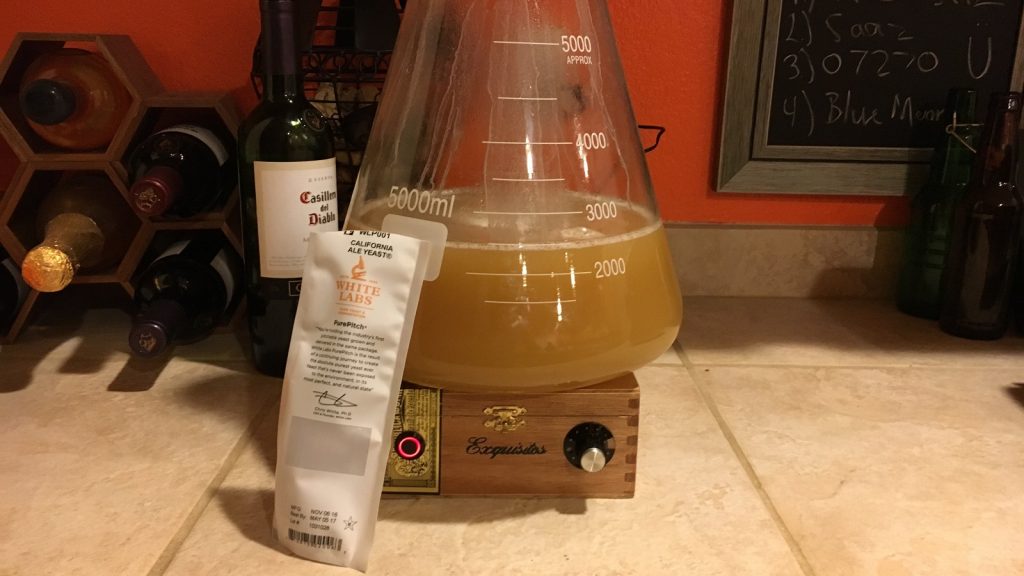

After determining the amount of yeast each batch would require, I built a single large starter that would later be split between fermentors.

The night before brewing, I readied my equipment, weighed out the grains, and collected two volumetrically equal sets of water that were both adjusted to my preferred profile. Since this variable required separate mashes, I started off the next morning by hitting the flame under one of the kettles, staggering the start of the second batch by 20 minutes.

I milled each set of grains as the strike water was heating. Since I’d been using my mill for awhile without making any adjustments, I figured there was no good way to determine what the exact roller gap was.

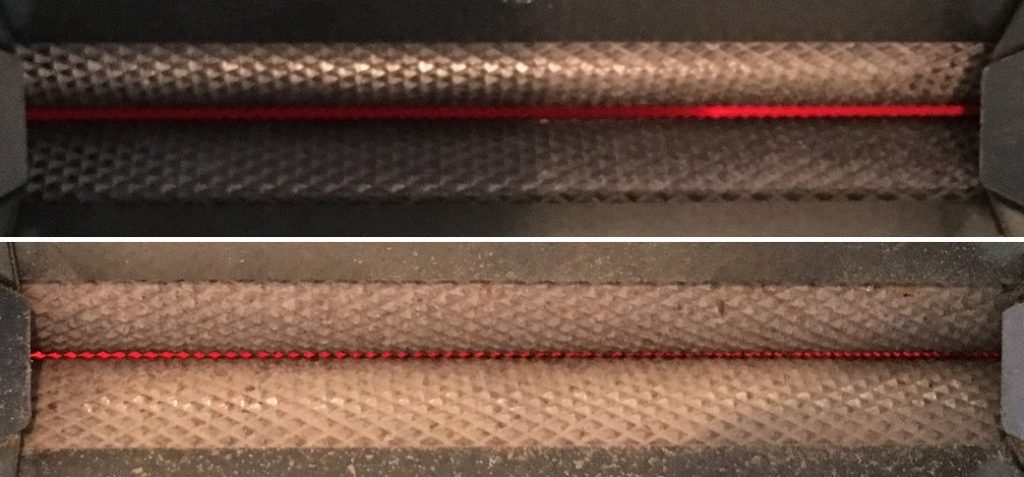

Given the common advice to use a credit card as a way to achieve a 0.030″ gap, believed by many to produce a pretty ideal crush size, that’s what I did for the coarse batch. For the fine crush, I tightened the gap all the way down then backed off a very slight amount, just enough so that no knurls were touching.

My experience milling the first batch was pleasant, the grain flew through the rollers without issue. On the other hand, the fine crush batch took a few minutes longer and resulted in my drill slipping off the drive shaft a couple times.

The resultant grist appeared quite pulverized, a stark difference from the familiar looking crush of the coarse batch.

As each batch of strike water was done heating, they were transferred to separate MLTs before mashing in to achieve the same target mash temperature.

Each batch was briefly stirred at 15 minute intervals throughout the 1 hour mash rest. Using the no sparge method, I collected equal volumes of sweet wort from either batch.

Lautering time between the batches was about the same, which may be a function of the fact I used fabric filters in both MLTs; it’s possible the finer grain bits would have clogged a false bottom or stainless braid.

Both batches of wort were boiled for 60 minutes with hops added at the times listed in the recipe.

At the completion of each boil, I quickly chilled the wort to my target fermentation temperature.

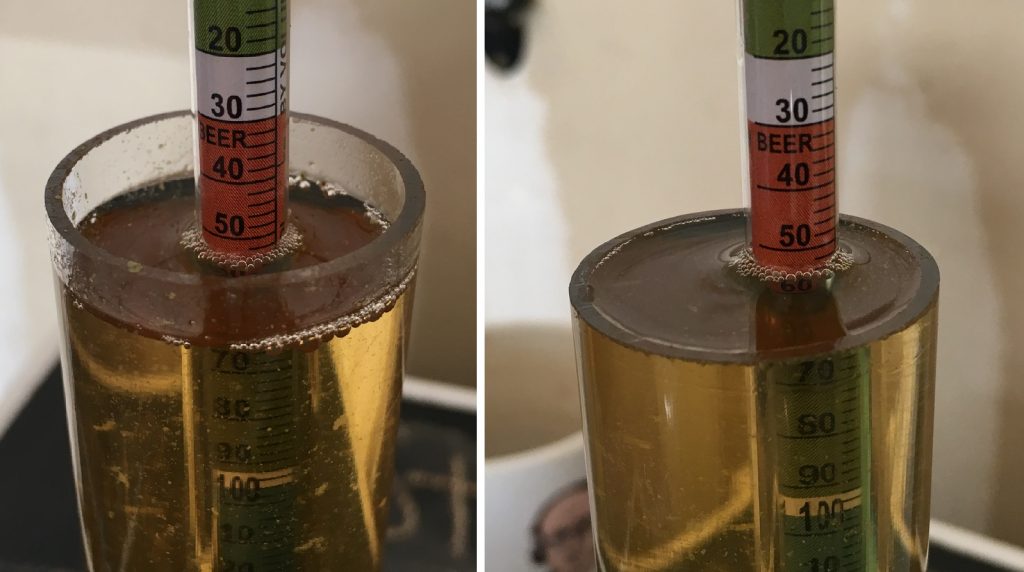

It was at this point I took hydrometer measurements, admittedly expecting to find a stark difference, yet was shocked to discover both batches at the exact same OG.

Identical fermentors were filled with equal amounts of wort from either batch then placed in my cool fermentation chamber set to maintain 66°F/19°C. I split the yeast starter into equal amounts, pitched, then hit each batch with 60 seconds of pure O2. Fermentation activity was observed within 12 hours, and both were fermenting vigorously enough the following day to require a swap from airlocks to blowoff tubes.

With signs of activity appearing to wane a week in, I bumped the temperature up a but and added the dry hop charges. After 5 days on the dry hops, all observable indicators of fermentation were absent, so I took hydrometer measurements confirming both batches had attenuated to the expected FG.

I transferred the warm beer to kegs and let them cold crash overnight in my keezer before fining with gelatin.

After a brief period of burst carbonation, I reduced the CO2 to serving pressure and let the beers condition another few days before presenting them to tasters. Both appeared equal in terms of clarity and carbonation at this point.

| RESULTS |

A panel of 20 people with varying degrees of experience participated in this xBmt. Each taster, blind to the variable being investigated, was served 2 samples of the coarse crush beer and 1 sample of the fine crush beer in different colored opaque cups then instructed to select the unique sample. Given the sample size, a total of 11 correct selections (p<0.05) would have been required to achieve statistical significance, while only 5 tasters (p=0.85) chose the different beer. These results indicate participants were unable to reliably distinguish a beer produced with grains crush very fine from the same beer made with more coarsely crushed grains.

My Impressions: As is often the case, there were a few times I was drinking these beers side-by-side where I nearly convinced myself I was perceiving a slight difference, though describing that difference was difficult. However, multiple “blind” triangle tests proved whatever I thought I was detecting was more likely due to bias than actual differences, as I was incapable of reliably distinguishing the odd-beer-out. The beers were fantastic, for more on that, check out the recent The Hop Chronicles on Huell Melon.

| DISCUSSION |

The fact participants in this xBmt were unable to reliably distinguish a beer made with finely crushed grains from the same beer made with coarser grains is surprising to me. I was confident this variable was going to produce differences in beer character, overall efficiency, and perhaps even appearance, an assumption influenced in large part by anecdotes from other brewers as well as our first xBmt on the impact of crush size. While we’re not interested in pretending to know why things happened the way they did, the other contributors and I spent some time speculating about these results. One theory is that there is a point at which the relationship between crush size and extraction rate plateaus, that milling finer than a certain size won’t increase extraction. This does little to explain the disparity between these results and those of our initial crush size xBmt, as those 2 batches were crushed at similar mill gaps. Is it possible the effect of crush size is positively correlated with OG? Assuming the differences observed between the Imperial Stouts from the first xBmt were a function of crush size and not some extraneous variable, it seems at least plausible the higher amount of grain and resultant OG may have played a role.

We also discussed the possibility of a relationship between crush size and conversion speed, pondering the possibility that the fine crush batch had achieved full conversion earlier than the coarse crush batch. It makes practical sense that fine crushed grain makes starch more easily accessible to enzymes while the larger endosperm chunks in coarse crushed grain will take longer to dissolve. But again, this is just speculation. Since I tend to mash for 60 minutes and highly preferred the ease of milling the coarse grain, I reset my mill gap to the 0.030″ thickness of a credit card, where I plan to leave it.

If you have experience with milling grain at difference sizes, please share your thoughts in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

42 thoughts on “exBEERiment | Impact Grain Crush Size Has On An American Pale Ale”

Nice write up and I’ll be trying that huell melon beer soon for sure! One conment- what were your measured mash efficiencies for each batch? For biab I’ve always been under the impression a finer crush should yield a better mash efficiency (less absorption, etc). Any difference in pre boil gravity and pre boil volumes? Ultimately doesn’t seem to matter I’m more just curious.

No differences in volumes or gravities. I don’t use BIAB but use a mesh filter and mash normally

Great. Good xBmt. Now re-run it using a really crappy LHBS quality crush vs. your “coarse” 30-mil gap. You’ll get different efficiencies and different OGs, although I’m honestly not certain if there would be a flavor impact — I’d be most interested to know that.

Oops, nevermind, I see you’ve already done that. Cool beans / my bad — I should have looked first. https://brulosophy.com/2015/11/23/mind-the-gap-course-vs-fine-crush-exbeeriment-results/

Lovely as usual! Adding to the theory at the end of the post, I do have an increase in gravity when grinding at a powdered level, but I mash for only 35-40 minutes. Cheers!

Wait, did you use US-05 or WLP001? The text says US-05, but you also said you made a starter and the pic has WLP001. Why bother making a starter with dry yeast?

WLP001 was used, as they are the same yeast strain what I put in beersmith initially did not reflect what was used in this batch. Marshall has updated the recipe I believe.

I thought any differences would be most evident during lautering, as coarser malt has the double impact of speeding up the lautering process and slowing down the equilibrium between the malt grains and the lautering liquid – thereby leading to a poorer extraction of both sugars and other compounds. Is it possible that by using no sparge you removed the main difference from the comparison?

I agree with Bob in that BIAB may accentuate this variable more. Perhaps for the next xBmt.

By BIAB do you mean single vessel brewing? I would define BIAB as simply using a bag to separate the grain from the wort, and therefore would classify the brewing method used by Jake to be BIAB. FWIW, I’m a single vessel brewer that uses a bag to lauter.

I’m not convinced changing the number of vessels utilized, and therefore the lautering method, would make any difference. There is the potential to have a lower absorption, but that would be entirely dependent on the lautering method (allowing the bag to hang from an overhead hoist, if so how long to let it hang, or maybe putting it in a colander, or another bucket). I just don’t see how changing the lautering method would have any impact.

I wish you had taken more gravity measurements, especially during the 1 hour mash.

Did you calculate efficiencies (mash and after boil)?

I’m interested to know your efficiency as well. Good or bad, it would be helpful to put it in context.

Both beers were brewed with the same volume of liquor and resulted in the same pre and post-boil volume. Both worts achieved ~72% efficiency which is fairly consistent with my system using Briess Pale Ale and no sparge.

I don’t usually take pre-boil gravity as I’m generally testing variables where i would do nothing to adjust that as it may be a function of the variable. Since both worts had the same pre-boil volume and post boil volume along with the same gravity I’m pretty confident in saying the gravity pre-boil was in fact the same in each.

since they were boiled for the same time, evaporation losses should be identical or very similar. Since post-boil gravities were the same, I am willing to bet anything that pre-boil gravities were the same as well. Taking more gravity during the mash can only tell you about how quickly conversion happens. Since most of us do full 1 hour (or more) mash, the details of whether most conversion happens in the first 10 minutes or over the next 50 minutes is sort or irrelevant.

I also think .030 is a tight gap. I believe if the husk is split open and the contents are released crushing the shell more does not help efficiency much. The problem comes when some of the grains make it through unbroken or just nicked. This seems to be a problem when people order precrushed grain.

I switched to pulverizing my grains and have noticed more dough balls in the mash, before I was getting them. Minor consideration perhaps.

I too have noticed this issue with more finally crushed grains

I close the gap as much as I can on my mill and I’ve never gotten a stuck sparge, unless I’m using a lot of flaked grains, and I always over shoot my gravity. I’ve learned over the years to account for over shooting the OG but it does seem to save me 1-3 lbs of base malt per batch. I have found that too course of a crush may give my beer a grainy taste and less fermentable sugars. Great exbeeriment!

I have found the same thing, I get about 5% higher efficiency for no extra effort on a finer crush.

You may be saving $1-3 on base malt (over 5G batch) but per John Palmer you may be sacrificing the flavor if you increase efficiency too much.

So I would say the take away here is – if you have your gap set small enough for you to get an efficiency you like – there’s (perhaps) no point in going to the bother and mess of crushing down to flour.

Perhaps there is a point where you reach your maximum efficiency in regards to milling. It is possible that for this grain bill .030 is where your efficiency tops out and milling any finer couldn’t change the efficiency. Perhaps you could see a difference at say .045 and .030? Also I have always been told not to squeeze the grain bag or you’ll get astringency. I have no idea if this is really true or not but judging by these results I do wonder if that is false or if it has more to do with the grain bill used than the squeezing.

I’ve always heard and wondered about the squeeze the bag method for BIAB so i always fly sparged until recently. Noticed my BIAB batches gained more flavor when just squeezing the bag until running’s suffice or are very minimal

I have read and heard that tho only things that have this affect are PH and mash temp. Squeezing the bag will not cause this.

Great xbmt and I was pleasantly surprised that you got identical OGs from both. For my setup its quite critical and I would have seen big difference. Actually the flour setup I would have had a stuck sarge for sure. As others have said perhaps a larger crush gap you may have seen some differences in OG and beer flavor. I am currently doing .95mm on my setup and getting good efficiencies but on Pilsner grains I increase the gap a bit more as its a larger harder grain and have had a few stuck sparges with it.

Cool experiment. I mill grains at my LHBS for BIAB and double crush the grains. Comes in between your two side by side mill photos. Efficiency BH has been anywhere between 74-79% on batches

Really good your blog! I have noticed an increase of finer grinding efficiency, but insisting still with more finesse, things do not change much. It ‘important to have a good filter for the purpose (the classic Bazooka may be obstructed). This is

my simple experience . Greetings from Southern Italy

Hey, can you comment on why this experiment did not lead to difference in OG whereas the precious was around 12% different between batches.

Comment, sure; explain, no. One of the glaring differences between this xBmt and the previous one is the OG, leaving me speculating that maybe all that extra grist in the mash tun played a role. Similarly, grist make-up, perhaps all of the roasted malt in the first xBmt had an impact. It’s also possible the first result was a false positive caused by some extraneous variable, which is why replication is important.

Cool experiment!

I will note that I went extra geeky (or at least extra measurement-tool-y) and got a feeler gauge to set and check my mill gap. (they’re reasonably inexpensive and handy for other applications, too)

To fully put the tannin extraction issue to rest, I think you might need to run a 3rd experiment with sparge of some sort – either fly- or batch sparge.

First of all you can get a feeler gauge very cheaply to measure you mill gap size. Secondly, I would be very surprised if there would have been no difference in OG if some sort of sparge step was used. I have found especially with BIAB where you can get very high mash efficiencies that crush makes a big difference. Also from a flavour point of view if you grind too fine and are using a more traditional false bottom, enough fine particulate will make its way into the boil and result in tannin extraction……speaking from experience on that one. It does not taste good.

Question about your hop additions.. You list HM as having a 4.5% alpha, but as far as I know the range is in the 7’s – is this a typo, did you source a low-alpha version?

Noted from the supplier as 4.5% AA

Interesting stuff. I received a grain mill for Christmas and have brewed 5 beers crushing my own grain. The first couple of batches were in the 75-78% range, then I tried conditioning the grain with a much finer crush.

The next batch was 79% and the last two have been way off, down to 62% on today’s brew (a Veinna Lager,)! Have you considered looking into the effects of conditioning the malt before crushing?

I’m going to keep the gap I used tonight (not measured but plenty of flour, much more than grain brought pre-crushed ) and see what affect not conditioning has on my next beer.

Cheers,

Jamie

We’ve definitely discussed it! Probably will get to it at some point for sure. Cheers

I will be brewing next week ,than we’ll see.so far I’ve been using store milled grains and my brew house efficiency is at crappy 58%.i will report back next week.cheers.

I know, old post, but I had the same experience with BIAB. I gained at least 10% once I started crushing on the smallest gap in my own mill instead of the crush I get from the stores. I average 75 to 80% brewhouse.

Do you ever do iodine tests during your mash? I would love to know if this has the potential to significantly shorten a brew day. 10-15 minutes here or there can add up…

Have you considered a difference with crush size in regards to grain/water ratio?

I’ve started brewing doing BIAB because the space I have is very limited. The biggest limitation I have is a 4 gallon stock pot I use as my kettle and I often brew 5 gallons batches by simply adding a gallon of water at the end. I was assuming that practice brought my efficiency down from when I do 2.5 gallon batches but I seem to see a difference in extraction on bigger grain bills. Which is why I was reading your articles to begin with! Would love to hear your thought on that or if anyone could point me towards anything that could help.

(I realize this is an old post; I’m just coming across it today). Just a few quick comments:

* I don’t know about credit cards, but 0.030 seems like a fine crush to me.

* You can use a feeler gauge — the type sold in automotive stores for spark plug gapping, etc — to set your mill. Be sure to set both ends and check the middle. Depending on the desire gap and your feeler set, you may need 2 sets and stack them (ex: use .020 + .019 to get .039).

* I used a sharpie on the side of my mill and the knobs, and marked 0.35, 0.40, 0.45 and 0.50. This makes adjusting without a feeler in the future easier.

* I forget where I saw it, but some large-scale brewery did this experiment and discovered that a slightly _courser_ crush led to higher efficiency (higher OG with less grain), and adopted that procedure as a cost-saving measure. (If I find that article again, I’ll stop back with a URL and reply to this comment.)

* My own experience is that anything finer than about .038 tends to stick the sparge, and I get better efficiency up around .044+, which is what I mill most things at. EXCEPTION: some grains are just smaller to start with; ex: rye. So I turn it down a little based on grain-size. There is also variation brand-to-brand — Brand-X may send big, fat, swollen grain (nice!) while Brand-Y may send smaller grain. Adjustments need to be made.

* Now-a-days, I set what I think it will be a tad course, then adjust after looking at the first handful through the mill. Counter-intuitively, too-much-white = too-much-flour = less-good brew day.

* Interestingly, while your .030 sounds very-fine to me, the picture looks about right. Perhaps you had some “small grain”, and that was the right number, there.

The discussion noted the disparity in results between this, and the initial crush size xBmt (an imperial stout). In that, the coarse crush had a lower OG, but a higher FG, indicating probably incomplete conversion.

The two notable different factors are, this time, it was a smaller grain bill, and you stirred the mash every 15 minutes.