Author: Marshall Schott

I built my first mash tun for all grain brewing over 7 years ago out of an old 52 quart cooler that’d previously been used to ice Miller Lite while camping. It didn’t hold temps very well and it was a tad small for batches larger than 5 gallons, so after a few months, I upgraded to a couple 70 quart coolers with better insulation. Besides a few hinge replacements, regular disassembly for cleaning, and some warping and staining of the plastic, these MLTs have worked great and I’ve little doubt they’d continue to work for years given a little TLC.

However, there are times certain upgrades, costly as they may be, serve to improve one’s experience. While I’m usually wont to look past the bling and settle instead on gear that gets the job done for less, I’ve been curious about the utility of Ss Brewtech’s relatively new InfuSsion insulated stainless steel mash tun for awhile. Considering the numerous requests I’ve received from readers asking if/when they’d see a review of this product on Brülosophy, I hesitated only briefly when Ss Brewtech offered to send me a couple in exchange for an honest review. As always, I reiterated our philosophy on product reviews, particularly that it would be approached from as impartial and honest a perspective as possible. To be clear:

The product reviewed for this article was provided by the manufacturer in exchange for an honest review; no other compensation was provided. The opinions expressed in the article are solely those of the author and a concerted effort was made to approach the review from an unbiased perspective.

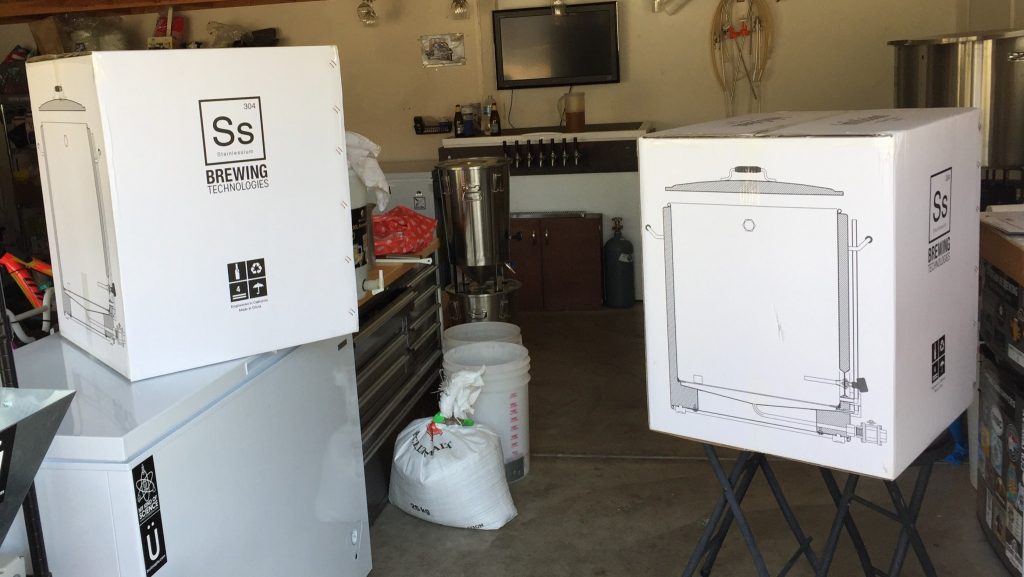

In chats with Ss Brewtech leading up to this review, I’d mentioned my desire to be able to make 10 gallon batches using the no sparge method, something I could only do with very low OG beers using my 70 quart converted cooler. Since the 10 gallon InfuSsion is only 50 quarts, they sent me the larger 20 gallon units… and by larger, I mean gargantuan. I was at work when the delivery person came to the front door, offering to place them in the garage after seeing the look on my unsuspecting wife’s face. When I got home, I immediately began un-boxing these beasts and, in typical Ss fashion, found the packaging to be both protective and rather appealing.

In chats with Ss Brewtech leading up to this review, I’d mentioned my desire to be able to make 10 gallon batches using the no sparge method, something I could only do with very low OG beers using my 70 quart converted cooler. Since the 10 gallon InfuSsion is only 50 quarts, they sent me the larger 20 gallon units… and by larger, I mean gargantuan. I was at work when the delivery person came to the front door, offering to place them in the garage after seeing the look on my unsuspecting wife’s face. When I got home, I immediately began un-boxing these beasts and, in typical Ss fashion, found the packaging to be both protective and rather appealing.

After spending 30 minutes breaking down the boxes to fit in my recycle bin, I got on with assembly, which didn’t take long since it consisted of was screwing on a ball valve, thermowell, and recirculation port.

After a good cleaning with alkaline brewery wash and a quick StarSan rinse, the tun was ready for use! Brewing with the InfuSsion is about the same as brewing with any other mash tun, it’s really the features that make the difference and hence what I’ll focus on here. Wanting to have enough experience with the product, I mashed 8 batches in it before penning this review, each time paying close attention to what I believed to be the pros and cons.

Of course, these are just my opinions influenced by my own brewing setup, process, and preferences, thus they should be taken with a grain of salt and adapted to fit each brewer’s needs.

Stainless Steel

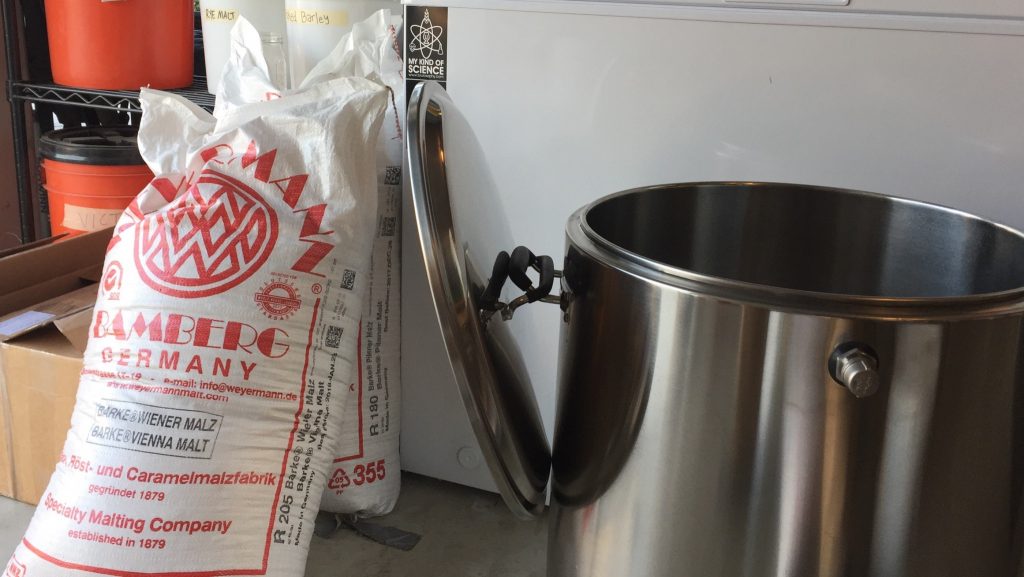

“Ss” is in their name and they do it well. The InfuSsion mash tun is made from double-walled 304 stainless steel making it not only durable but very easy to clean. While stainless certainly makes the InfuSsion comparably heavier than an ice chest (~70 lbs/32 kg), the upside is that it will stand the test of time. Those concerned about leeching chemicals from plastic (I’ve never been) have nothing to worry about, as it’s a non-issue with the stainless steel. The stainless also looks just a little nicer than my beat up cooler MLT.

Insulation & Heat Retention

It’s what lies between the double-walled stainless that really makes the InfuSsion so unique– a thick layer of foam insulation. Whereas other stainless mash tuns generally require externally applied insulation or the use of a heating element to maintain precise mash temperatures, the insulated InfuSsion promises to eliminate the need for either.

Given the similarities in insulation thickness between my converted cooler MLT and the InfuSsion, I assumed heat loss throughout the mash would be comparable, between 2-4°F/1-2°C over the course of an hour. However, out of the 8 mashes I’ve put through the InfuSsion so far, the greatest loss was only 0.9°F/0.5°C on a 5 gallon no sparge batch, while I only lost 0.4°F/0.2°C on a recent 10 gallon no sparge batch. Pretty nice for those of us with a penchant for precision.

Volume Etchings

A feature of convenience, the etched volume markers on the inside of the InfuSsion mash tun make transferring the proper liquor volumes a piece of cake!

What’s better is how surprisingly accurate they are, lining up perfectly with my calibrated measuring bucket as well as the volume etchings on my Ss Brewtech Brew kettle.

Thermowell & Digital LCD Thermometer

The InfuSsion comes standard with a stainless thermowell that juts out about 4.5 in/120 mm into the mash tun. Also included is a simple LCD digital thermometer with a probe that easily slides into the thermowell, the unit held in place by a silicone cover.

I initially thought this would be a neat and potentially convenient feature, though my experience so far has left me feeling like it may not be totally necessary, at least for my purposes. The temperature inside the thermowell takes longer to stabilize than the actual temperature of the mash, which makes sense since the probe is housed a stainless tube. Not a huge deal, except I’m already used to quickly measuring the temperature at mash-in with my precision thermometer, so I’ve stuck with that. Also, the temperature readings on the LCD thermometer are consistently inconsistent with my calibrated precision thermometer. For example, during a recent brew day where my ThermaPen confirmed I’d hit my target mash temperature of 150°F/65.5°C, the LCD thermometer on the InfuSsion was showing it to be at 154°F/67.7°C. On a positive note, the difference between starting and ending mash temperatures has always matched my ThermaPen, so it’s probably just a calibration issue, which I’ve taken no efforts to fix since I prefer my standard method anyway. Ultimately, this is in now way a deal breaker for me.

I’ve already been asked a few times about how The Brew Bag fabric filter is impacted by the thermowell. It has not been an issue at all! Besides the bag being made of a very strong fabric, the edges of the thermowell are rounded, allowing the bag to easily slide around it without getting caught.

Manometer

Perhaps the feature of the InfuSsion most suited to those utilizing practices more commonly found in commercial breweries is the manometer. Briefly, a manometer allows the brewer to observe the speed at which wort is flowing through the grain bed via a pair of sight tubes attached to the side of the mash tun where, from the inside of the tun, one starts below the false bottom while the other starts above it.

If during lautering the wort is being collected too fast, a pressure differential within the grist will create a difference in wort level that can be seen in the sight tubes, allowing the brewer to adjust the flow rate to avoid a stuck sparge. Pretty damn nifty, if you ask me, and while I’ve employed alternative methods for avoiding such a problem, I did toy around with different flow rates and found the manometer worked exactly as expected. For those who prefer continuous/fly sparge methods, I trust this cleverly designed feature would likely come in very handy.

False Bottom

The false bottom that comes with the InfuSsion Mash Tun is made of 16 gauge perforated 304 stainless and has a handle welded onto the top, making it very easy to move. A silicone gasket wraps around the outside of the steel mesh, allowing for a tight seal that keeps any grain from sneaking through.

This was the first time I’d ever used a false bottom and any concerns I had about them mostly vanished after my first batch using the InfuSion. Even with a grist containing a high percentage of unmalted high glucan flaked grain, I experience no issues with lautering whatsoever and was easily able to collect the proper volume of wort without any negative impact on my efficiency.

Still, there were a few aspects of using a false bottom I wasn’t terribly fond of. In order to transfer clear wort to the kettle, a fairly lengthy vorlauf was required, a task that wouldn’t be an issue for those who recirculate their mash. Most annoying to me was the clean up– given the weight of the mash tun, I couldn’t pick it up to dump the spent grain, which meant I had to scoop it out with a plastic pitcher. My guess is this wouldn’t be an issue with the 10 gallon InfuSsion and, truthfully, it wasn’t that bad. Regardless, I’ve since added a relatively inexpensive custom fabric filter that swiftly resolved both of these issues.

Nowadays, I use the false bottom as a support for the fabric filter so that it doesn’t block the bottom drain, it works like a dream.

Bottom Drain

I absolutely love this feature of the InfuSsion, both because it completely eliminates the need for a diptube (notice the false bottom has no center hole) and, with its 5° slope, reduces the tun’s deadspace to zero!

Prior to my first batch, I created a new equipment profile in BeerSmith where I set the deadspace to half of what it was in my converted cooler MLT, just to be safe. Lo and behold, I was left with a bit more liquid in the tun than I’m used to. I’ve since zeroed out my deadspace settings and continue to nail my predicted volumes, a wonderful thing for nerds like me.

Insulated Lid

The lid that comes with the InfuSsion is packed with the same insulating foam that’s sandwiched between the walls of the tun itself, making it heavy enough to keep the heat right where it belongs.

The inner rim of the lid is lined with a strip of silicone to ensure a seal so tight not even a wisp of steam escapes the tun.

Recirculation Port

Recirculating the wort during the mash has been shown to improve extract efficiency and is used by many to set the grain bed while also clarifying the wort prior to transferring it to the boil kettle. The InfuSsion comes standard with a recirculation port conveniently located at the top of the unit, and the included 1/2″ stainless fitting is threaded to allow for use of different types of vorlauf or sparge arm attachments. I run a pump-free brewery and had no need for the recirculation port, so I closed it off with an inexpensive stainless cap.

Welded Ball Valve Fitting

Unlike Ss Brewtech’s Brew Kettles, the ball valve fitting on the InfuSsion is welded in place, which I find preferable for this particular application.

The fitting easily accepts standard 1/2″ ball valves including the 3-piece valve that comes with the unit, though I installed my own valves that fit beautifully. To reduce the potential for leaks, I wrapped the threads a few times with teflon tape and haven’t had any problems.

Soft Handles + Lid Holder

The handles on the InfuSsion are covered in a soft silicone to make moving it around easier on the paws.

They’re also sized to fit the lid handle perfectly, giving brewers a convenient place to store the lid when mucking around with the mash.

| THE VERDICT |

After agreeing to this review, I wondered if I was in over my head, that the InfuSsion was geared more toward people interested in emulating commercial breweries, not simple no/batch sparge brewers like me. What I realized is that the quality and features of the InfuSsion mash tun have definitely had a positive impact on my overall brewing experience. It’s a head-turner, for sure, in fact I can’t think of a single friend who hasn’t commented on how rad they are when drinking with me in my garage. And I’ll be the first to admit the InfuSsion isn’t going to turn anyone into the next Kelsey McNair, but the features are super convenient and have made for very smooth brew days. Made of durable stainless steel with overall fantastic build quality, I imagine I’ll be using the InfuSsion mash tun for decades to come.

As great as my experience with the InfuSsion has been, there are a couple applications I think it’s absolutely ideal for. With kettle soured beers all the rage lately, I plan to use the InfuSsion to make a Berliner Weisse where I perform a MIAB mash then, after removing the grain bag, chill the wort to 105°F/41°C, pitch the lactobacillus culture, let it hang in the tun until my desired pH is hit, then transfer to kettle and boil as usual. I’m also super tempted to grab a couple heat sticks that’ll allow me to heat the strike water directly in the tun, eliminating a transfer and effectively turning me into a hybrid electric/gas brewer.

I’m not going to say I think everyone should go out and buy an InfuSsion, it is definitely a high priced piece of equipment geared toward the more serious brewer. However, I’m confident anyone who has been considering such an upgrade to their brewery would be just as pleased as I’ve been!

MoreBeer proudly carries the entire line of Ss Brewtech products including the 10 gallon and 20 gallon versions of the InfuSsion Mash Tun, both qualifying for free shipping. Items can also be purchased direct from Ss Brewtech’s website.

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

30 thoughts on “Product Review | Ss Brewtech InfuSsion Insulated Stainless Mash Tun”

I’ve been looking at upgrading my tun for awhile (10 gal igloo), and got really excited about this one…until I saw the price tag. Holy smokes! It’s a pretty piece of equipment, and I’m sure it works well, but that price is prohibitive for many folks, I’m guessing. I guess I’ll be shopping for a bigger plastic cooler.

is it possible to get the Recirculation port on the other side ?

thx

I honestly don’t know, but I’m sure Ss Brewtech will let you know right away:

http://www.ssbrewtech.com/pages/contact-us

Do you feel like running a 5 gal batch out of the 20 infusion was smooth because I do both 5 & 10 gal batches. I.e. The probe hitting, headspace heat loss, etc.

It’s been more smooth than I imagined it would be. The tun is large enough that stirring without hitting the probe is a cinch, I’ve not done it once actually.

While that piece of equipment looks pretty dope, I can’t imagine spending that kind of money for so little increase in efficiency/ease/coolness. I’ll stick with the 72-quart Coleman and home-made manifold that totaled up to about $70.

This would be a very difficult purchase to get past the wife. I think I’ll stick with doing step mashes using my brew kettle and thermal blanket for the time being. At the end I dump everything into my Igloo with a false bottom so I can sparge anyway. Been working great so far.

Sight tube. Named because it allows “sight” or seeing the fluid.

NOT “site” which means location

Haha, honest mistake, embarrassing.

C’mon, man. That’s pedantic. Don’t call him out in front of everyone. Send a private message for that kind of thing.

Nah, that is some funny stuff!

Homophones can make for some funny communication!

No doubt this is a great product, and it would look very cool and impressive in my garage. If someone wanted to buy this for me, I would most definitely NOT resist. But, it’s $400-$550, depending on volume. A cheap cooler functions just fine and will make equally superb beer. The important thing is understanding what you’re doing, why you’re doing it, etc. If all else is equal, simpler is ALWAYS better. In fact, that’s the main thing I’ve learned from this website! Keep up the great work.

What size bag did you get?

Custom. The Brew Bag does custom sized bags 🙂

Do you have the dimensions of the bad you ordered? I just purchased the 20 gallon version, based in part on this excellent review, and the bag looks like a great addition.

They’re custom sized, as the 20 gallon kettle bags won’t fit the 20 gallon InfuSsions. Here are the dimensions I sent Rex:

Outer diameter: 20″

Internal height: 20″

External height: 23.75″

Thanks for the review Marshal!

how do you like this compared to the Chapman?

(looking to replace a 17 year old Coleman cooler)

Based on Ray’s review and what I’ve heard from him, they both are great tuns with their own pros and cons. What the InfuSsion has over the ThermoBarrel is the bottom drain hole, which means no need for a diptube and zero deadspace. Of course, the ThermoBarrel is a bit less expensive.

I found this review, which is also a vote for the SS Brewtech mash tun: http://blog.craftbeertraders.com/choosing-a-mash-tun-part-1-insulated-mash-tuns/

Would you mind sharing some info about you mill gap and efficiencies from batches brewed with the SS Infussion with and without the bag please?

I didn’t change my very tight mill gap when I first got the InfuSsion and had no issues with lautering, even when using 18% flaked oats. However, toward the end of the lauter, the sweet wort did become more turbid.

I snagged some custom sized fabric filters from The Brew Bag that I’ve used for every batch since and would highly recommend doing so, no issues whatsoever.

Thank you sir!

I got my hands on one this weekend and had a very similar experience to yours. My MM-3 gap setting is 0.035, mashed at 1qt/lb, brewhiuse efficiency landed at 70%. Not bad for a first run. The lauter was clear until the last quarter gallon or so but I planned for it and diverted into a separate container. I discarded this portion but I was thinking now that I could have poured it through a hop bag or something like that as I don’t want to use a bag when mashing 😉

I’d give a strong advantage to the SS infussion, for the available thermo-control unit. I plan on using this for kettle souring @ temps over 110 degrees for 48 hours, something the chapman can’t do.

Hello, something popped into my mind and I haven’t found the answer yet when searching the web, so I pose it here: Has anyone used the SS brewtech or Chapman thermobarrel BIAB-style and then pulled the grainbag out and used a heating element (such as the hot rod) to do a boil in the SS mashtun?

I have not tried this but I have the 20 gallon version of the InfuSSion. It could work but it’s worth noting that there are no triclamp fittings for e.g. the Hot Rod on the mash tun. It would have to be inserted from the top or modified to support a heating element.

I have used a heat stick to preheat mash water in the mash tun, though, and it worked great for that.

Great read. Thanks!

I have the larger 30 gallon Ss brewtech kettles. I bought a small wet/dry vacuum to remove the last of the grain and wort from the tun and kettle. No more lifting!

Thanks for the review.

I am a bit surprised about the temperature drops you are seeing. I live in Singapore with 28-30C ambient and I mash at 67C for 60 minutes. I do see a very big temperature drop. Like 4C.

Most heat seems to leave from the thermo well as the wall is very thin there.

I have the 10 gallon tun so there might be a difference.

Do you know if the thermometer can be removed and plugged up with some type of fitting?

I’m interested in using a stainless steel mash basket from Utah Biodiesel instead of the false bottom. The probe from the thermometer would get in the way of the basket.

Yeah, they sell steel blanks that fit in those holes.