Author: Jake Huolihan

I’ve been aboard the water adjustment bus for most of my homebrewing tenure, a decision validated by prior xBmt results demonstrating such manipulation has an appreciable impact. While I tend toward a slightly more convoluted approach using various mineral and acid additions, many homebrewers successfully employ a more simple method involving the adjustment of two commonly discussed ions, sulfate and chloride, the ratio of which can purportedly be used to predict the balance of malt and hop/bitter character in finished beer. Considering the accepted position that higher amounts of sulfate produce a more pronounced bitterness and chloride rich water favors maltiness, a brewer making a Porter might choose a ratio of 50 ppm sulfate to 100 ppm chloride (0.50), while she might go with something closer to 200/50 (4.0) for a hopped up IPA.

Co-author of Water: A Comprehensive Guide For Brewers, John Palmer, ran an interesting experiment at the 2014 National Homebrewers Conference in Michigan comparing two beers brewed with either a “pale hoppy” or “dark malty” profile, the results of which were corroborated by a similar and statistically significant Brülosophy xBmt. In both of these examples, the sulfate to chloride ratio was different between the beers, but so were various other aspects of the water chemistry. My interest in this variable piqued after learning NE-style IPA is often brewed with a ratio strongly favoring chloride, bucking the sulfate loving trend of the West Coast, which some have posited also contributes to their hazy appearance. I’ve accepted small differences in water profile can have a noticeable effect on a beer, but I was curious to explore how vastly different sulfate to chloride ratios might be expressed in an IPA in the absence of other water chemistry differences and designed an xBmt to test it out!

Co-author of Water: A Comprehensive Guide For Brewers, John Palmer, ran an interesting experiment at the 2014 National Homebrewers Conference in Michigan comparing two beers brewed with either a “pale hoppy” or “dark malty” profile, the results of which were corroborated by a similar and statistically significant Brülosophy xBmt. In both of these examples, the sulfate to chloride ratio was different between the beers, but so were various other aspects of the water chemistry. My interest in this variable piqued after learning NE-style IPA is often brewed with a ratio strongly favoring chloride, bucking the sulfate loving trend of the West Coast, which some have posited also contributes to their hazy appearance. I’ve accepted small differences in water profile can have a noticeable effect on a beer, but I was curious to explore how vastly different sulfate to chloride ratios might be expressed in an IPA in the absence of other water chemistry differences and designed an xBmt to test it out!

| PURPOSE |

To evaluate the differences between two batches of the same IPA made with either a high (150:50) or low (50:150) sulfate to chloride ratio.

| METHODS |

Thanks to Love2Brew for hooking me up with a couple of Ray’s MACC IPA recipe kits to brew for this xBmt!

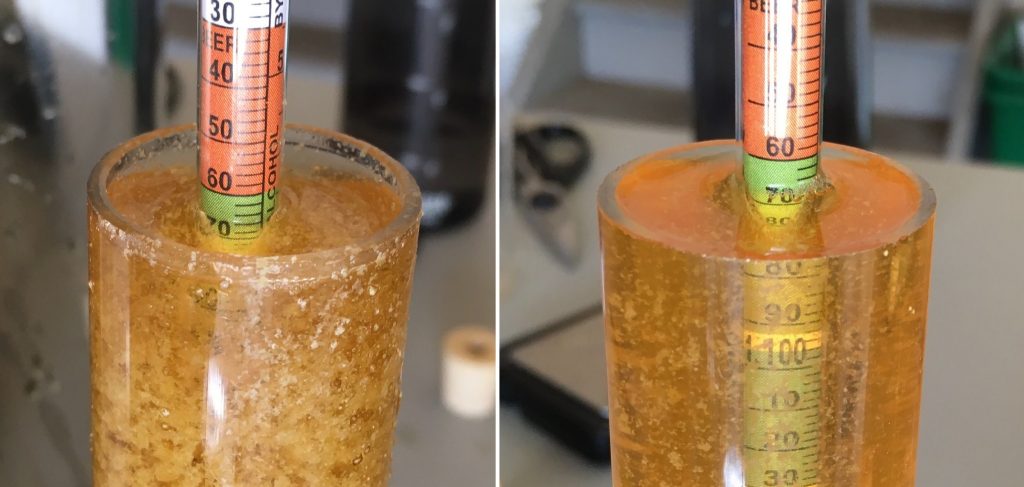

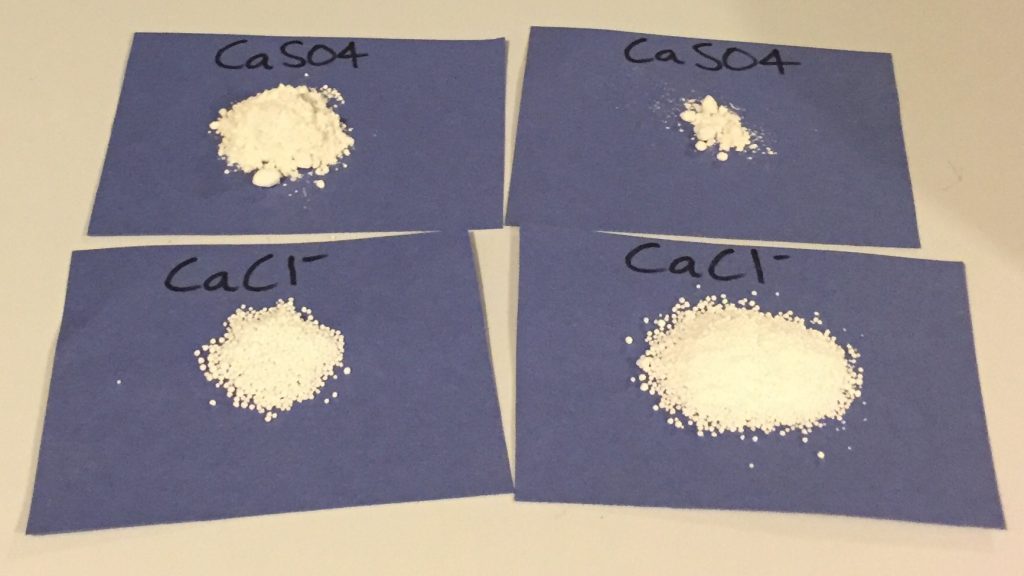

A dual-batch brew day was warranted for this xBmt since the variable would be introduced prior to the boil, and since both batches would be 5 gallons in size, I went with the no sparge method to simplify things a bit and collected two full volumes of brewing liquor. It was at this point I measured out the appropriate amounts of gypsum and calcium chloride to achieve sulfate to chloride ratios of 150:50 (3.0) and 50:150 (0.33) then added them to their respective kettles of water.

This was the first time I’d brewed from a recipe kit since my very first batch, to say it was enjoyable is an understatement, I forgot how convenient it is to have every ingredient pre-measured and parceled just waiting to be brewed. I woke up the next morning and began heating the water to strike temperature, staggering the batches by 20 minutes to ease the stress of brewing two batches at once.

Both batches were mashed in and hit the same target temperature.

Each mash rested for 60 minutes before I began collecting the sweet wort.

At this point, the wort with higher chloride content seemed to be ever so slightly hazier than its sulfate rich counterpart.

A standard 60 minute boil was employed with hop additions occurring as stated in the recipe.

Once each boil was complete, I added the hefty charge of flameout hops and let them steep for 20 minutes before proceeding to quickly chilling the wort to 72°F/22°C in just over 5 minutes.

I was pleased with the similarity in OG between the batches, as well as the fact it was precisely what BeerSmith predicted.

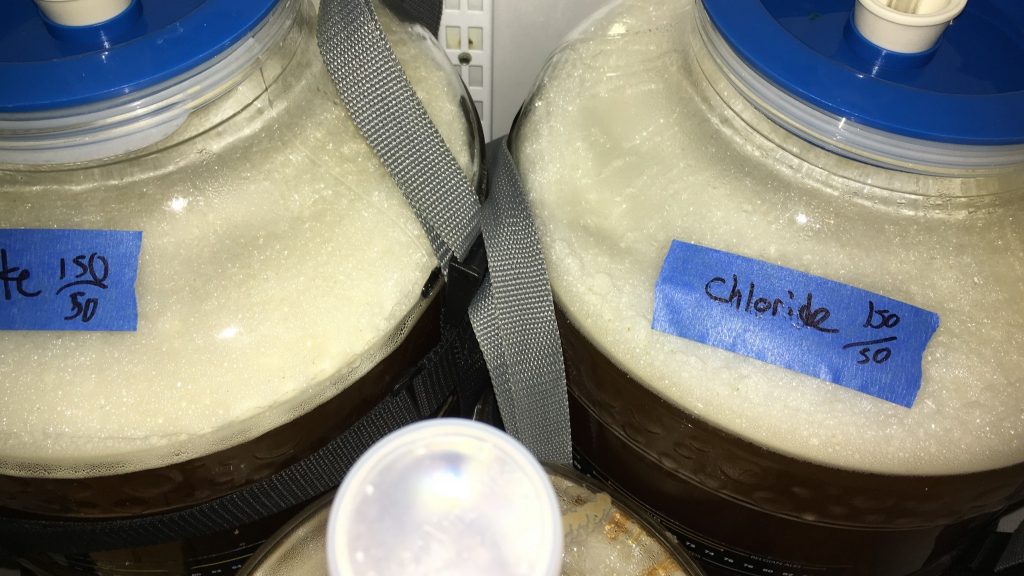

Each wort was racked into a fermentor and placed in my cool chamber where they were allowed to continue chilling to my target fermentation temperature of 66°F/19°C, which took about 4 hours. I proceeded to rehydrate 4 packs of Safale US-05 in a single mason jar to ensure homogeneity, then I evenly split the resulting slurry between two flasks and each into their respective worts. Active fermentation was observed the following day, 18 hours after pitching the yeast.

I added the dry hop charges after 5 days and, given a noticeable decrease in fermentation activity, bumped the temperature to 72°F/22°C where it would remain for another 5 days. Hydrometer measurements taken a couple days apart revealed both batches were done fermenting, though it appeared the batch with a higher proportion of chloride finished 0.001 SG points higher than the sulfate batch. I can’t be sure if this was a function of the variable or some sort of measurement error, but I thought it interesting nonetheless.

After a brief cold crash, I fined both beers with gelatin then kegged them a couple days later.

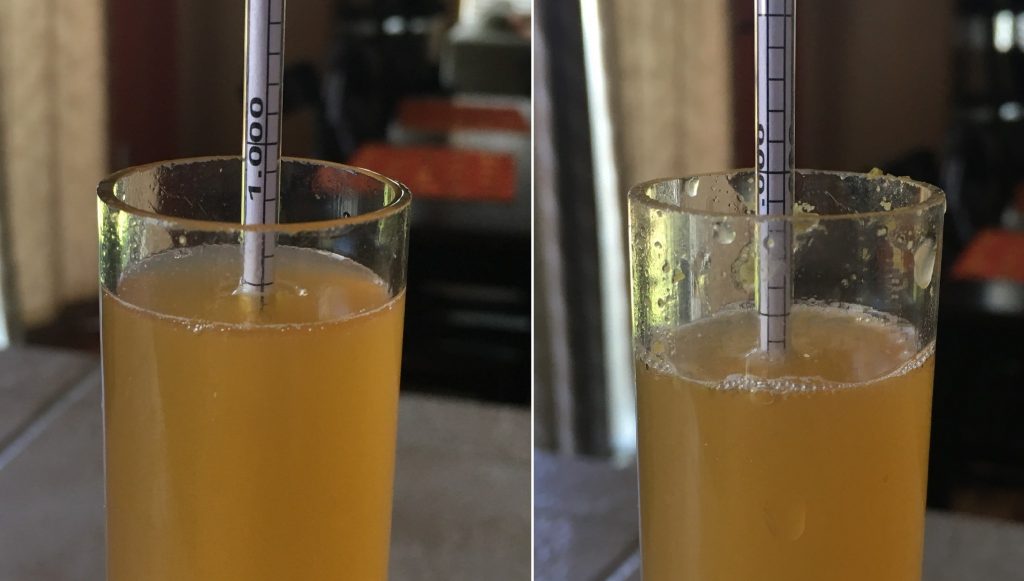

The beers were burst carbonated overnight before I reduced the CO2 to serving pressure. When it came time to collect data, both were nicely carbonated and shared a very similar level of clarity.

| RESULTS |

A panel of 22 people with different levels of beer drinking experience participated in this xBmt. Each blind taster was served 2 samples of the beer whose water had a sulfate to chloride ratio of 150:50 and 1 sample of the beer whose water had a sulfate to chloride ratio of 50:150 in differently colored opaque cups then instructed to select the unique sample. At this sample size, 12 tasters (p<0.05) would have had to accurately select the unique sample to achieve statistical significance. In the end, 14 tasters (p=0.003) chose the different beer, suggesting participants were indeed able to reliably distinguish beers made with water consisting of opposite sulfate to chloride ratios.

The 14 participants who correctly selected the unique sample in the triangle test were asked to complete a brief preference survey, all still blind to the variable. Five tasters preferred the sample with the lower sulfate to chloride ratio, 4 liked the beer with a higher sulfate to chloride ratio, 3 said they noticed a difference but had no preference, and 2 admitted to being unable to tell a difference between the beers.

My Impressions: I first attempted a “blind” triangle test on myself one, ahem, groggy morning, and I failed it. But that was the only time, I was fairly easily able to identify the odd-beer-out in all subsequent tests. However, I perceived the appearance and aroma of the beers to be exactly the same, it was in the flavor and mouthfeel that the differences shone most bright. To me, sulfate-rich beer had a more assertive bitterness with a hop character that popped out, and it left me with what I experienced as a dryness on the back of my tongue and in my cheeks, all things I’ve come to expect from IPA. I felt the beer made with a ratio favoring chloride was smoother, mouth coating, and somewhat chalky/slick with more a muted hop character and bitterness. I actually enjoyed both beers equally and found myself pulling from both taps at different times of the day. I can honestly say that while I experience the beers as being distinct, I have no preference, one is equally as good as the other.

Ray’s Impressions: I sent both beers to fellow contributor, Ray Found, to see what the creator of MACC IPA thought of my version. Fully aware of the variable and thus unable to officially participate, Ray did evaluate the beers “blindly” and even completed a couple triangle tests. Based primarily on mouthfeel, he was able to identify the unique sample in multiple attempts, describing the chloride-rich beer as being “really soft, almost as if it’s warmer/flatter” and agreeing with my experience of the sulfate beer as being dry and crisp.

| DISCUSSION |

Providing further support for the idea that water chemistry has an appreciable effect on beer, the results from this xBmt suggest different sulfate to chloride ratios will produce different end products. Moreover, I found promising the fact descriptions of either beer more or less lined up with expectations in that the beer with a higher sulfate to chloride ratio was typically perceived as crisp, dry, hoppy, and more bitter while tasters felt the lower ratio beer was smoother, characterizations agreed upon by both Ray and myself.

One area I expected to see a difference and didn’t, which I found surprising, is the appearance. There’s been a lot of talk lately about the haze causing components of NE-style IPA with one theory centering on the fact brewers of this style using quite a bit of calcium chloride to achieve their desired low sulfate to chloride ratio. It seemed like a valid theory with evidence previous water chemistry and gelatin fining experience seemingly supporting it, hence my surprise with the near commercial clarity observed in both beers I made. Of course, I didn’t use flaked oats or any of the popular NEIPA yeasts, leaving me wondering if the haze is due to some sort of unique interaction between grain, yeast, hops, and water.

I remain fascinated by the impact water chemistry adjustments have on beer and the fact seemingly minor additions can produce a noticeably different product. While it may be viewed by some as a minor piece of the brewing pie, I’m convinced it may be the key to dialing in the character one is after and look forward to exploring brewing water more in the future.

If you have experience adjusting your brewing water or thoughts about this xBmt, feel free to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

28 thoughts on “exBEERiment | Water Chemistry: Impact Sulfate To Chloride Ratio Has On An American IPA”

nice! i hope you do more extreme versions of this exact test in the future. gypsum definitely is drying. i started adding salts thanks to your first water xbmt. great tool

I’d be interested to see a haze experiment. What gives the most haze; high chloride, high percentage of oats, large amount of dry hops during fermentation. I wonder if gelatin works that well and your beer would have had the typical NEIPA haze if it wasn’t used.

I have found that 2 things have a HUGE impact on haziness / “juiciness” and that’s yeast selection, and timing of All your hops. Need to dry hop the first round while it’s still fermenting in primary, and imo, you need to add a TON of whirlpool hops but after the wort cools past the point of isomerization of the alpha acids. Though without the high chloride levels to provide the full we mouthfeel, you are still missing out on part of the experience. A lot of these beers also use a large amount of wheat and flaked grains that also contribute to the body.

I Disagree.

Based on what I’ve done, I brewed a simple Tired hands clone, added my dryhop after fermentation had completed (as normal) i used a hopstand as i normally do (no reduction in temps) just simply added at 0min and recirculated for 15-20mins.

I also used gelatin (i like my beer clear)

Gelatin only had a minimal effect on the haze, and the hops were very forward, the taste and aroma was exactly that “Juicy” a friend of mine commented that it was like drinking grapefruit juice.

Good head retention – haze despite trying to clear (it appears to be a reaction between flaked oats and hops.

I brewed a stronger beer without oats (lots of hops and lots of wheat. with the same yeast, and its crystal clear)

This experiment reflects what I have found with pale ales. I have found that a balanced CL:SO4 50/50 ratio makes for the best malt/hop presence vs the higher sulfate way.

Interesting, so I blended both beers equally and preferred either extreme to the balanced profile. Maybe a less hop forward beer would make me like the balance more I guess.

I’ve said it before and I’ll continue to say it to all my brewing buddies who won’t don’t do anything to their water – water manipulation has had the single highest impact to my beer out of any other variable I’ve improved on, even more-so than temperature control and yeast starters.

Because it’s so simple and has such a huge impact on the beer, it seems like a no-brainer to try and integrate this into one’s process possibly before other investments like stir-plates or fermentation chambers.

I agree with this, if for no other reason than to understand more completely what your core components are actually contributing in terms of flavor and experience.

As always a great article.

One question that I would love to see investigated is whether there was a difference between beers with the same sulphate to chloride ratio but varying total amounts. For instance would an IPA with 60:20ppm taste different to one with 420:140. Very different amounts of minerals but in the same ratio.

People often say it is the ratio that is important but I’d like to find out if total mineral content has an effect too.

Years ago you would read a lot about the ratio. Now I think it is a combo of the ratio with actual amounts. Just saying 2:1 does really say much. 20:10 is much different than 200:100 but having a ratio, I think, is still needed just along with actual amounts.

Yes the ratio, as I call it the Chloride / Sulfate ratio, can remain the same even when the amounts of Ca and Mg increase or decrease. The missing component, when relying on only the ratio itself, is the differences in both the total alkalinity, the residual alkalinity and pH.

Relying on only the ratio without taking into consideration the amounts of Ca and Mg is like guessing if it takes less time driving home or to work, without knowing the distances to each destination.

I totally agree and it’s definitely on the list.

This wouldn’t have made a difference here, but I’m really not comfortable with 2 people “admitt[ing] to being unable to tell a difference between the beers.” It’s really luck then, isn’t it? Certainly this is included in the whole theory behind, but to think that they were more likely to fail is perplexing.

The p value .003 or .3 % means that if everyone just guessed randomly we would expect these results .3% of the time. So there a chance (a small one) that the results are meaningless.

The method we use assumes that you have 1 in 3 chance to guess right, and the desired strength of the result is selected beforehand with our p value. Depending on sample size (number of people tested), the number of people ABOVE 33% (what we would assume would be achieved by chance) changes.

Hey Jake, are you bringing bottles to GABF?

=)

Haha, I have a hunch that will not be allowed and I’m much more interested in trying other ppl beer for a change 🙂

I’ll be at the Friday and both Saturday sessions though. Stop me and get a sticker

Sounds great! Where are you guys at?

It’ll only be me, no one else could make it out. I’ll just be walking around the convention center, see me in the brulosophy t shirts

Great experiment! I’m recently getting into water chemistry. Not that it really matters but calcium chloride is CaCl2 not CaCl-

Thanks! I have definitely made that mistake, but I can’t seem to fine where it was made in this article…

Edit– in the image, yes, my bad.

Great info. Do you start with 100% RO? What was the actual water profile?

Thanks!

I do start with 100% RO. Water profile was 150:50 each way on the SO4:Cl and whatever that shakes out to for Ca. That’s about it

Hi Jake:

Excellent experiments. I just want confirm with you: (150 :50) and (50: 150 )are ppm or weight (grams)?

with best

Aldo

They are ppm not weights. 150 grams in 10 gallons of water would be insanely high ppm lol

So how many grams of each did you use?

With posting that this IPA was done without adjunct, high protein grains, would you ever do another version to simulate the difference in a New England IPA?

I know it’s a little while ago but I was wondering what the actual respective ppm of calcium and sulphate (rather than just the ratio) was on these two recipes?

Thanks,

Jacob