Author: Marshall Schott

I fermented my first 10 or so batches of homebrew in the 6 gallon plastic bucket that came with my equipment kit. It worked, but it had its drawbacks, namely for me the fact it required rigging up a siphon to get the beer out. So I replaced it with a new spigoted bucket that made racking as simple as opening a valve. I loved it!

Then, while preparing to keg a fresh batch of finished beer, probably the 15th batch I’d fermented in the new bucket, I noticed the hard-to-reach internal portion of my spigot had mold growing in it, mold that wasn’t there when I filled the bucket with wort a couple weeks prior. After using an auto-siphon to transfer the beer to a keg, I angrily threw both buckets in the garbage and hit the internet looking for a new option, ultimately settling on 6 gallon PET carboys with a Sterile Siphon Starter. This was over 5 years ago and my experience has been largely positive, the only issue being that I end up replacing 2-3 carboys per year because of a scent or discoloration that persists even after a good cleaning. In total, I’ve gone through 16 of these plastic fermentors, which considering how often I brew, isn’t that bad. Still, at $26 a pop plus tax and shipping, that’s over $420. For plastic.

After sharing the results of a recent xBmt comparing glass to PET carboys, I received a ton of requests to add stainless fermentors to the mix. Coincidentally, I’d been chatting with the folks from Ss Brewtech around the same time about a product I thought fit the bill perfectly.

Disclosure: The product reviewed for this article was provided by the manufacturer in exchange for an honest review; no other compensation was provided. The opinions expressed in the article are solely those of the author and a concerted effort was made to approach the review from an unbiased perspective.

Less cumbersome than a conical with many of the same benefits, the Brew Bucket seemed like a nice middle-ground for those seeking the durability of stainless with the convenience of a plastic bucket.

In typical Ss Brewtech fashion, the Brew Buckets arrived to my house in very stylish and attractive packaging that protected the stainless it held from any dings during shipping.

Only after unboxing one of the units did I realized a little work was in store, and by a little, I mean screwing a few things together. No big deal. The instructions were easy to understand, helping me to complete the “build” for two Brew Buckets in under 10 minutes. Once together, they were filled with an oxygen based cleaning solution and left alone for 10 minutes to remove any residue leftover from the manufacturing process. This also served as an initial leak test of the ball valve and thermowell– not a drop! After emptying the cleaning solution, I gave the Brew Buckets a hot water rinse then proceeded to fill them to the brim with StarSan solution in order to passivate the stainless, an important step to ensure corrosion resistance.

The stainless vs. glass carboy xBmt brew day arrived three days later. I prepared the fermentor during the boil by spraying it out with water from my hose then adding 3 gallons of StarSan solution, which I swirled around to coat the entire inside. Once the wort was chilled and ready to rack, I ran a few liters of StarSan solution through the valve then slowly poured the remaining liquid out while rotating the Brew Bucket to again fully coat the surface. To fill, I attached a small length of silicone tubing to the barb on my kettle, opened the valve, and let ‘er rip with the lid positioned to hold the tubing in place.

With 5.5 gallons of wort in the Brew Bucket, I cut off the flow, secured the lid, placed a piece of sanitized foil in the airlock hole, and moved it into my fermentation chamber.

Once the wort had dropped to my target fermentation temperature, I removed the lid, pitched the yeast, re-secured the lid, then swapped the foil with an airlock. Piece of cake.

So far, so good! Fermentation happened. I ran into the first issue when I went to take a hydrometer reading once signs of activity had diminished.

Initially enticed by the option to pull off samples from the valve, I realized doing so would be difficult given how low the barb is positioned, to the point even my smallest taster glass wouldn’t suffice.

I considered attaching some sanitized tubing to the barb and collecting the sample that way, but due to my propensity for keeping things as simple and clean as possible, I eventually opted to take samples directly from the top of Brew Bucket using my trusty stainless turkey baster.

Not ideal, but also not a big deal. During the cold crash step, similar to what occurs with other well sealed fermentors, some of the sanitizer from the airlock did get sucked into the Brew Bucket, which I’ve learned not to fret too much over. Finally, it was time to package, the part of the process I was looking most forward to as I felt this would be where the valve would truly prove its convenience. I moved the cold Brew Bucket to my work bench and, while it was settling, came up with a simple idea for oxygen reduced kegging.

All I did was attach a liquid disconnect to a short length of 5/16″ vinyl tubing, nothing genius. The open end of the tube gets placed over the sanitized barb on the Brew Bucket, the disconnect gets attached to the liquid post, then with either a pin lock valve depressor or an extra gas disconnect on the gas post to relieve pressure, the valve is opened to start the flow of beer into the keg.

Because of the airtight seal, the exiting beer will create a vacuum that can suck in the airlock liquid, so I’ve been swapping it out with a small piece of paper towel dipped in sanitizer when kegging. It only took about 8 minutes for the keg to fill, after which I closed the valve, removed the disconnect from the keg post and barb, then placed the keg in my keezer to be force carbonated. Hands down, the easiest kegging experience I’ve had in years, and I haven’t complained about kegging since the aforementioned mold incident.

My next order of business was cleaning the fermentors, which frankly couldn’t have been more of a breeze. After dumping the trub, I sprayed the inside of the Brew Bucket out with hot water, this removed probably 95% of the mess. Since it’s made of stainless, rather than filling the fermentor with a cleaner and leaving it to soak, I made a small amount of alkaline brewery wash solution, just enough so that it was above the racking arm, then used the scrubber side of a sponge finish removing any debris. Once spic-and-span, I ran the solution through the racking arm and valve into my sink’s drain, loosened all of the connections, and gave the Brew Bucket another hot rinse. With the valve open, I place the unit upside down to drip dry and await another brew day.

I’ve since used the Brew Buckets numerous times, in fact they’re fermenting an xBmt as I type, and they work great! But of course, nothing is perfect. What follows are some pros and cons I’ve noted through my experience with the Brew Buckets.

Stainless Steel

The most obvious benefit of the Brew Bucket over other fermentors I use is the fact it’s made from stainless steel. With proper care, this is a piece of equipment that will last most homebrewers a lifetime. Unlike plastic, stainless can be scrubbed without risk of scratching, reducing the chances of contamination or off-flavor carryover from prior batches. And unlike glass, dropping the Brew Bucket won’t lead to an ER visit. The downside of stainless is that it costs more, which up front can be difficult to swallow. However, considering the savings of not replacing plastic fermentors when they turn, the Brew Bucket may in fact be a better value in the long-run.

Thermowell with Digital Thermometer

An option only available on the Brewmaster edition, the thermowell is a nice touch that allows brewers an easy way to monitor the temperature of their fermenting beer. This is one of those features I thought was pretty cool, but wondered if I’d end up relying much on it.

I really didn’t since I secure the probe from my temperature controller to the side of the Brew Bucket and trust it to maintain a steady enough temperature. For the sake of this review, I did do some temperature comparisons between the controller when attached to the side of the Brew Bucket, the digital thermometer in the thermowell, and the actual temperature of the fermenting beer as measured by my ThermaPen. The greatest differential I observed was 1.3°F/0.7°C between the controller and the digital thermometer in the thermowell, which read 66.0°F/18.9°C and 67.3°F/19.6°C, respectively. Since my calibrated ThermaPen read 66.3°F/19.1°C, which is pretty damn close to what my controller was set to, it’s likely the digital thermometer included with the Brew Bucket was the most off, though certainly not enough to concern me. One scenario I think the thermometer would come in quite handy is when making a Berliner Weisse where the Brew Bucket is used for the wort souring process.

Ball Valve with Swiveling Racking Arm

I’m all about convenience, and being able to keg my beer with the simple flip of a knob is about as convenient as it gets. No siphons to sanitize and clean, just a small length of tubing and, in my case, a liquid disconnect. This alone makes the Brew Bucket incredibly appealing to me. However, as I mentioned before, I was a little disappointed to discover taking samples from the valve was nearly impossible while in the fermentation chamber, as the barb was just too low to the ground. I’m sure there are some workarounds, and stealing samples from the top with a turkey baster doesn’t bother me at all, but it’d be nice to be able to use the valve for more than just kegging. Finally, the swiveling racking arm is badass and makes transferring clear beer off the trub super easy, all that’s required is a gentle twist of the ball valve.

I’m all about convenience, and being able to keg my beer with the simple flip of a knob is about as convenient as it gets. No siphons to sanitize and clean, just a small length of tubing and, in my case, a liquid disconnect. This alone makes the Brew Bucket incredibly appealing to me. However, as I mentioned before, I was a little disappointed to discover taking samples from the valve was nearly impossible while in the fermentation chamber, as the barb was just too low to the ground. I’m sure there are some workarounds, and stealing samples from the top with a turkey baster doesn’t bother me at all, but it’d be nice to be able to use the valve for more than just kegging. Finally, the swiveling racking arm is badass and makes transferring clear beer off the trub super easy, all that’s required is a gentle twist of the ball valve.

Conical Bottom

The cone shaped bottom of the Brew Bucket provides a place for trub to settle once fermentation is complete, which is easily avoided during transfers by properly positioning the racking arm, which I’ve found allows me to transfer more clear beer to the keg. While I’m not too concerned with kettle trub making it to my fermentor, the Brew Bucket allows those who are the ability to drain off trub after a period of settling prior to pitching yeast. Finally, all one needs is a sanitized spoon to harvest yeast from the top of the cake where the creamiest slurry resides while leaving all the other gunk at the bottom of the cone.

Volume Markings

I can’t think of anything about volume markings I don’t like, they’re easy to read, accurate based on my measurements, and make equally splitting batches of wort a cinch.

Dimensions

My biggest issue with other stainless fermentor options is that they’re often so large I’d have to build a new temperature controlled room to store them while in use. At only 20.5 inches/52 cm tall, the Brew Bucket is squat enough to fit in most chest freezers. Where it seemes Ss Brewtech made up for the slightly larger than normal volume of 7 gallons/26.5 liters is in the diameter (12.5 inches/31.75 cm), which made it such that I was unable to fit two in my 7 cu.ft. fermentation chamber. A non-issue for those who brew single 5 gallon batches, the footprint of the Brew Bucket is something to consider for folks who tend to ferment dual batches in the same chamber. I like these units so much, I bit the bullet and swapped my small chamber for another 10 cu.ft. freezer. One final feature that might appeal to folks who ferment in upright freezers is the fact the Brew Buckets are designed to be stacked, even with airlocks in place.

Cleaning

If I’ve one complaint about carboys that tops the list, it has to be cleaning. Angled carboy brushes are a pain in the ass, plus they can scratch PET, creating perfect hideouts for beer spoiling microbes. Because of this, I adopted the “sit-and-wait” approach that involves filling the rinsed out container with a cleaning solution and letting it do its thing for a few hours. Sometimes kräusen bits hung around and required the clever use of a wet rag to dislodge them. Not so with the Brew Bucket! Cleaning consists of taking the lid off, spraying out the fermentation remnants, scrubbing, and rinsing again. I noted the time it took me to clean both Brew Buckets last time I used them, just a hair under 5 minutes, and they were sparkling!

Handles

I’m glad Ss Brewtech put handles on the Brew Bucket, it’d sure be tough to move them in and out of my chamber without them, I just wish they were covered with something to make lifting a little more comfortable, like the silicone used on their brew kettle handles.

It’s really not that bad since I usually transport the full fermentors a max of maybe 10 feet, but I do think a softer grip would positively impact the overall quality of the Brew Bucket.

| THE VERDICT |

I did my best to list and share my honest thoughts on everything I could think of about Ss Brewtech’s Brew Bucket. To me, the downsides are minor and far outweighed by all of the good stuff. I’m a huge fan! This doesn’t mean I now think other fermentor options suck, they all serve the same primary function of containing fermenting beer, but I’d be lying if I said I don’t like these units more than I expected. Buckets and carboys are fine options that will definitely make good beer, but the convenience and durability of the Brew Bucket have won me over. It may not be for everyone, as we all have different ideas of what makes something valuable, but for the brewer looking for a long-lasting alternative to buckets/carboys with a similar footprint and unique features, the Ss Brewtech Brew Bucket may be just the ticket.

As far as I can tell, the only difference between the standard and Brewmaster edition Brew Buckets is the thermowell and digital thermometer. I’ve never used a thermowell before and I’m not really sure if I’ll ever feel the need for one on my system, but it was definitely a step up from LCD strips I’ve been using for years. I’m sure there are applications or brewing systems where having this option is far more appealing, and for only $30 more, it’s not like it’s going to break the bank.

Just as important to me as the product itself is the company who makes and sells it. I started chatting with the Ss Brewtech folks over a year ago and have consistently been met with thoughtful responses. They’re passion for creating quality brewing gear is obvious to anyone who uses their products, it’s no surprise I’m hearing from more and more people happily using Ss Brewtech gear. While they’re moving into the professional brewing realm, they remain committed to providing homebrewers with affordable and effective stainless options. When I buy something, I like knowing the people behind it are tip-top, which couldn’t be more true in the case of Ss Brewtech.

MoreBeer proudly carries the entire line of Ss Brewtech products including both versions of the stainless Brew Bucket, all qualifying for free shipping. Items can also be purchased direct from Ss Brewtech’s website.

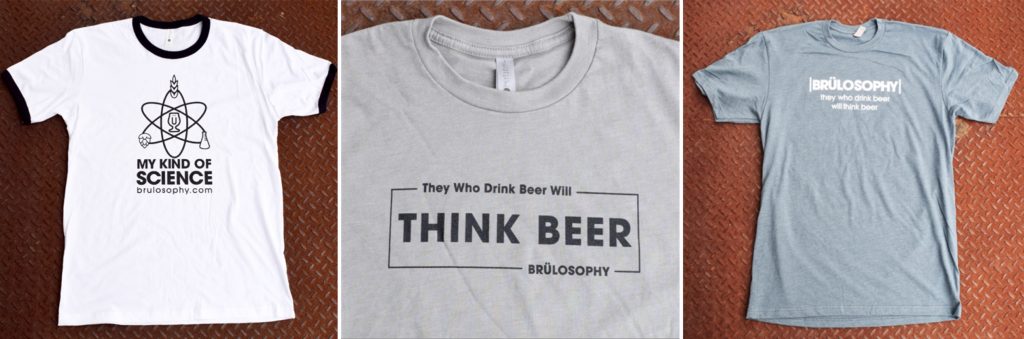

New Brülosophy Merch Available Now!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

64 thoughts on “Product Review | Ss Brewtech Stainless Steel Brew Bucket”

Mine arrived last week and the first batch is fermenting happily away as we speak. I use a refrigerator with a front door, I’m not having problems taking samples trough the barb. Not a lot of experience yet, but I like this shiny thingy in my fridge 🙂

Great review!

When you filled the bucket with Starsan to passivate the stainless, did you use the typical ratio (.2oz per 1 gal), that you would use for everyday brewing use or did you use the higher ratio (1oz per 1 gal) as mentioned in their before first use guide.

The reason i ask is when I prepped my 15gal kettle that required a LOT more starsan than i had at hand. Is it worth me passivating again at the higher level?

I did use the higher concentration per the instructions. I’d guess you’re probably good.

I wouldn’t worry either. I used a slightly lower that prescribed ratio on my kettle for the same reason, and I’ve had no issues several months later. Furthermore, I’d call the starsan a precautionary step if anything. True passivation of stainless requires a couple of soaks in heated chemical baths, it’s mainly a concern after something like heavily machining stainless steels (mills, lathes etc.). The starsan is certainly better than nothing but if you were a light on it I wouldn’t sweat one bit.

Marshall,

Do you have any concern about mold growing inside the barb while in the chamber?

Since it’s a pretty direct route, and I sanitize the barb well before racking, I’m not concerned. I’ll definitely look every time.

I take samples (usually for taste and refractometer readings) with a shot glass, fits nice under.

Do you have to fill the shot glass 8-10 times to fill a hydro jar?

Yeah, but unless you are a cave man or incorrigible Batchelor, a bowl from your kitchen will solve the problem. A small clear measuring cup is great because you can fill it to 125mL or whatever your hydrometer flask requires and it has a pouring mouth.

Duh! Trying this when I get home tonight, thanks 🙂

I have owned two ss brew tech conicals for over a year now, great company and products. The “sample valve/port” on most of their products are low to the ground, tho not quite as low as the brew bucket. This indeed makes it hard to collect a beer sample. To get a beer sample, A good “work around” is to hook up 1-2 feet of sanatized silicon tubing to the port so you can collect the beer into a small bucket or glass. This should allow you to collect the samples you need with our taking off the lid. Also, not sure if they have one yet for the brew bucket, but for their conicals, they have a “pressure transfer valve” that allows you to replace the airlock with a co2 connection. This will prevent oxidation from any sucked into the airlock, when you collect beer samples, or transfer your beer to kegs.

“I eventually opted to take samples directly from the top of Brew Bucket using my trusty stainless turkey baster.”

“Because of the airtight seal, the exiting beer will create a vacuum that can suck in the airlock liquid, so I’ve been swapping it out with a small piece of paper towel dipped in sanitizer when kegging.”

Not so great when your trying to avoid oxygen ingress. An option or feature to transfer under Co2 would be ideal. This is especially important for hoppy beers.

Or is it? XBMT?

I have been hoping for a “closed transfer” versus “simple tranfer” xBmt for ages. I’m convinced (but shouldn’t be) that oxygen is the boogy man of brewing.

I’m convinced contamination is the real bogey man, though oxygen ingress, particularly post-fermentation, is something I’m concerned about too.

Closed vs. “open” transfer is on the list!

Easy enough to do a CO2 transfer. Connect tubing from your CO2 bottle. Remove the sirlock, but keep the stopper, and push co2 in that way, then transdfer via gravity to your keg.

Be careful with how hard you scrub the surface of your stainless, and with which materials you use for scrubbing. I personally wouldn’t using anything more coarse than the soft side of a sponge. Anything rougher has the chance of removing your layer of passivation from the SS creating points where it will corrode. If you do need to use something rougher, just make sure you passivate your tank regularly.

I clean all of my stainless with the scrubby side of a sponge, but I don’t really scrub that hard, sort the same concept as brushing teeth– lightly with many passes until the build up comes off.

Hi, nice review

I take the samples of my plastic bucket usong the barb. I put the fermenter in my work table. Isn’t good for my back but for me is better than open the lid. Could do you the same?

I can, but too much work, I’m lazy.

try adding some tubing long enough to pass thru the drain port of your chamber.

For getting your hydrometer samples, why not just pour into a little Pyrex measuring cup (which is pretty squat) and then pour out of there into your hydrometer test tube? You don’t need to worry about being 100% sterile, since this is just a sample and you’re going to use it for testing and then drink it, not pour it back into the fermenter.

Good idea, I’ll try it when I get home tonight!

I’ve owned a brew bucket for over two years and I wanted to mention two minor issues that have come up over time. I brew twice a month, on average, and always use my brew bucket unless it has beer in it.

(1) The o-rings on the interior arm tear and require replacement periodically.

(2) I have replaced one of the ball valve o-rings, but only one of two, in two years. The two currently on it show no signs of wear.

(3) I have low to moderate hardness water (40-120 ppm as CaCO3, depending on the season) but I still have to remove beer stone periodically, which I think owes to the degree of polish inside, which is very smooth but not truly polished. This isn’t hard, but you have to check the fermenter when it is dry for chalky deposits because when wet,you can’t see them. The cheapest way to remove the deposits is with vinegar and a scruby sponge (it’s basically chalk and soluble in acid); the easiest way is star san soaking, but you may need a big (expensive) dose to remove it all. Just filling it with regular star san (something I often do for 30 minutes on brew day) is not enough to remove/prevent the stone.

(4) The barb on my ball valve sucks air when 3/8″ tubing is attached. I think the idea is to make tubing easier to get on and off, but it isn’t tight enough. The solution, of course, is 5/16″ hose.

(5) If someone comes up with a way to use the valve when you have 8 ounces of dry hops in the bottom, which clogged it, I’d love to hear the solution.

Great tips, thanks!

Yeah Dryhops is a small issue for mine.

although a 1/4 turn of the barb, means minimal crap goes through, but i end up missing that little extra at the bottom.

If you find yourself dry hopping with 5-8 oz, go ahead and try adding a small piece, maybe 2-3″, of 3/8″ ID silicone tubing to the end of your racking arm. It just extends it a bit higher to reach above the trub/hob layer. That should do the trick!

I place my dry hops in a bag (or 2) and with floss suspend them and tie off the floss around the handles. When I transfer to keg, the bags end up hanging just above the racking arm. Works every time.

I’m excited to hear about this, I’m looking at getting some mini’s. I’ve heard some people have stuck a tube in the airlock and applied very light CO2 pressure, but this seems slightly sketchy. Any issues with the seal on the lid? Anyone have experience with their fermentation temp system?

I have 2 mini’s and have used them 3-4 times without any issue with the seal. They are well made and I expect them to last a long time.

For pressurized transfers, we actually have a new TC flange that can be retrofitted to the lid. It gives you the ability to use other TC fittings for blow off, etc. Here is a link:

https://ssbrewtech.zendesk.com/hc/en-us/articles/210211086-Can-I-perform-a-pressurized-transfer-with-the-Brew-Bucket-s-flat-lid-

During our testing the Brew Bucket lid can hold approx 1.5-2 PSI of pressure.Thanks!

Good to know, is there a factor of safety with that, or is that when the seal fails/lid blows off?

It’s a very nice option, and it probably makes sense for larger fermenters. The cost on this retrofit totals at about $80 if I’m reading your guide correctly, is there any thought on putting together a kit or an option that’s a bit cheaper? Even on the brewmaster brew bucket, that’s 1/3 of the cost tacked on top. On the other hand, it looks like you guys have a great product at an awesome price point, but all this kind of stuff does add up.

I wanted to give a quick recommendation for the Brew Master edition. I have a dual stage Ranco controller with my fermentation chamber and the temp. probe fits PERFECTLY into the thermowell. I find it so much easier than taping the probe to the side with insulation and I get more peace of mind that I’m actually controlling the wort temp. I ditched the small LCD thermometer.

How this never crossed my mind is beyond me. Awesome tip!

I have two of the 7 gallon Brew Master buckets for over a year now and thought I’d share my experience:

– Natch on having silicon coated handles. I e-mailed SS Brewtech and they were looking into it.

– The thermowell is perfect if you use probes (Inkbird in my case) for controlling fermentation temperatures

– The design of how their probe is attached to the LCD display leaves a lot to be desired. I was slowly removing one, when the back edge of the probe got stuck in the thermowell. Before I knew it, the probe wire had ripped free of the display. Both of the places where the wire meets other components really should have a reinforced jacket.

– Use scouring pads designed for stainless as they will not scratch the finish

– If you passivate them properly, beer stone shouldn’t be an issue. I’ve always done a 15 minute soak with PBW and then a 2 hour soak with StarSan.

– Always put hops for dry hopping in a bag or container and using the spigot shouldn’t be a problem

– I gave up on sampling and invested in a Tilt (formerly Brewometer). For $130 shipped, it allowed me to leaving the sampling port alone until it came to bottling. Plus I love the fact I can look at the results via Google Sheets anytime during the day on my phone.

Great article! As I’ve said before I love my brew buckets and want two more! I see you didn’t like the thermowell but there is one other thing you should try! The temp probe from a stc-1000 fits perfectly in the well so you get a perfect indication of what your wort temp is inside the beer at fermentation for your fridge controller. Which I found can be very different from the temp you get from the outside of the brew bucket! It’s very handy and as you said cleaning is a breeze. Just about every three brews I take all the o rings off and the lid gasket and I take apart the little ball valve and I soak it all in PBW. Works like a champ!

Hey Paul! It’s not that I didn’t like the thermowell, it’s that I didn’t find it all that useful… but I didn’t even think to stick my probe it there!

I’ve had two SS Brewmaster buckets for approximately one year (12 batches in each)

Cons:

1.The two Small rubber o-rings on the interior arm are paper thin and don’t last long (poor design)

2.The Silicone seal for the lid has small cracks in the inner lining which is a pain to clean properly and it’s hard to guarantee there are no nasties hanging around.

3.Silicone Seal is difficult to re-pack under lid (I might have received an oversized gasket)

4. Rubber stoppers for the feet were too thin and had to be replaced

5. Slow output from ball valve when fully open

6. Etched volume markings are a bit vague eg markings only at 20L and 15L what happened to a small dash for each liter?

7. The thermowell received on one of my buckets was 6mm which was unfortunately too small to fit my temperature controller probe the other one was 6.5mm, SS brewtech was contacted and they said they don’t state the inner diameter of their thermowells I disagree and have seen thermowells on their web page stating that they are 6.5mm (quality control issues?)

Pros:

1.Stainless Steel construction (wanted to leave my review on a positive note)

There’s a trick to putting the gasket in: You need to thread the silicone gasket under the outside lip first then press down on the inner ring. It make replacing the gasket much easier!

Thanks for all your work and enjoyable writing. I plan on buying a couple of these units but my biggest concern is sanitizing the racking port ball valve. Are you able to take the ball valve apart for a more through cleaning between fermentations and it you pull a sample from your ball valve how do you sanitize well prior to racking to a keg. I am worried residual beer would sit in there and grow something not so fun that could get racked into your final product. Again, thanks for a great review.

It’s all easily taken apart, yes!

It’s listed as 7 US Gallons max volume (26.5 Litres). What do you think is the max usable volume? You used 5.5 US Gallons of wort (20.8 litres) although there was still some headspace in the pic.

I’m considering buying one but ferment 7 US gallons (27 litres). If the max reasonable volume is only 5.5 gallons it may be too much of a volume loss for me :/

Appreciate your thoughts!

Is say 6.5 gal is feasible.

Much appreciated 🙂

Keep up the exbeeriments, they’re a highlight of my week

I have a pair of the brew buckets as well; my thought on the handles is not just that a covering would be useful, but that they be larger. I’m close to 6’1″ and my hands are perhaps a bit bigger than average, but I find the handles are too small for me to comfortable hold them, I generally end up using three fingers through them. Brewers tend to be male, and It just seems like they are sized a bit too small for larger male hands.

The foot stoppers have worn away/been destroyed rapidly on both buckets.

The racking arm is bent to different degrees in the two I received, one will not pivot fully vertical as it is bent so much that it hits the wall of the bucket as it approaches pointing upward.

The o-rings for the racking arm are small and easily ruined; the other o-rings for the racking arm are a bit tougher, but hard to source (I found Buna-N 70 easily enough, the Buna-N 90 is harder to find). I ended up ordering o-rings for my kegs and brew buckets directly form o-ring suppliers, so I won’t run out any time soon.

I’m hesitant to use the racking arm frequently, as I worry about infection in the arm. I need to come up with a way to clean it out thoroughly, then I could be more confident with it. I have used the needle for filling a football or basketball with a syringe, tubing, and starsan to spray out inside the barb after a sample, but I need a less messy way to do it.

Overall I really like them, they have great capacity, so I can ferment a full batch with lots of room. I can do a no-chill day easily in them, simply pouring the hot wort directly into the SS and setting them outside in the winter (bonus! It sanitizes at the same time!). Kegging is so easy, and I don’t miss trying to clean out an autosiphon. Clean up is mostly simple, though I don’t like the gasket, I always feel I need to take the gasket right out to clean/dry, then have to re-sanitize it to put it back in. Thinking of getting a third.

I have these and I like them so much better then glass or plastic. A suggestion to the sampling issues, would be to order another racking valve and use the thermowell hole as sample valve.

I have two of the Minis. I drilled an extra hole in the lid to accommodate a stopper and a 12″ stainless thermowell. When I dry hop, I just pull the airlock and drop the pellets through the same hole. My only “complaint” is that I can’t seem to deodorize the lid gasket. Doesn’t seem to matter though…

I purchased two of these at the first of the year and they have made an enormous impact on my brewing. No more carrying heavy glass carboys…No more worrying about oxygenation through plastic carboys… These are easier to clean – easier to take samples while fermenting. I did recently drill the 1.5 TC holes in the lid so that I can pressure transfer into my kegs. I use my Inkbird temperature controller with the existing thermowell. It works well.

Heyo! I purchased one of these guys, and was just searching how to transfer thru liquid-out post. Can you describe your keg process? Specifically, do you sanitize, push sanitizer out, and then just fill immediately after a purge? I’m a bit worried about left over star-san in the liquid tube / bottom of keg, but perhaps it’s insignificant?

Thanks for the write-up, it ultimately led to me purchasing this awesome product.

Hey! I do not purge my kegs with CO2 before kegging, but rather fill each about halfway with sanitizer, give them a good shake, despress the liquid poppet to get some sanitizer in the diptube, then open the keg and pour the sanitizer into a bucket before putting the lid back on.

For kegging, I attached a liquid disconnect to about 10″ of extra tubing I had lying around, it all gets sanitizer before I attach the open end of the tubing to the sanitized Brew Bucket valve barb, attach the disconnect to my keg, attach a pin lock poppet depressor to the gas post, then open the valve.

Before kegging, I remove the airlock and cover the whole with a sanitized piece of paper towel.

Sounds like a great way to go – and from your XBMT’s, sounds like the only replacement for Glass Carboys that will yield the same quality.

I brewed a 15 gallon beer (16.5 gal) with two SS Buckets and one plastic carboy. I have noticeably different flavors between the SS buckets and Carboy. The carboy tastes very clean and good while the SS buckets have a yeast banana flavor. I used new US-05 in the carboy and one SS bucket; the other SS bucket had washed US-05 that was then added to a starter. I was shocked both the SS buckets taste the same (new vs washed yeast) but the carboy was different; better in my opinion so not infected.

Are you sure you pre-cleaned your Brew Buckets adequately? I’ve used my buckets a bunch and haven’t had any issues similar to yours.

That’s a valid point. I did scrub thoroughly with PBW and some other stainless cleaner but I’ll hit it again with bar keepers friend.

Don’t forget to passivate! The instructions Ss provides go over the process in good detail.

I have to say that my experience has not be overly great with these. I love them for all the features mentioned, but the beers taste very different. Beers tend to taste underattenuated and grainy compared to fermenting in glass carboys. I need to go back to the xBmt comparing these to others, but I definitely feel there’s a big difference. What’s interesting is that I didn’t feel like a recent extract beer was underattenuated, but all of my all grain beers have been. Anyone else have this issue?

I have not experienced that in the slightest, and I’ve compared various fermentors. I do wonder if perhaps a failure to properly passivate the stainless can lead to issues with the beer, it seems Michael Tonsmeire may have experience such an issue with his first NEIPA fermented in a Brew Bucket.

I have the exact same thing happening right now!! I’m going to dump yet another batch as the gravity samples have been tasting nasty….and go for another round of TSP and citric acid. I’ve been reading in other places that star san may not work for everyone and they’ve been using citric acid.

Interesting. Thanks for mentioning his post. I’m not sure what’s going on. I did wash it well with TSP and then passivate it with 7 fl oz of StarSan, as directed, and I haven’t owned and used it long enough to need to repeat the process. If this were just one yeast, it would be one thing, but I’ve run into this with every all grain beer I’ve done. Strange.

Do you still have the glass carboy? If so, and you’re really interested, split a 10 gal batch between Ss Bucket and carboy then run some triangle tests!

I may just have to do that! 🙂

I really like my Brewmaster buckets. I did have an issue with a lid being scuffed or pitted though. I contacted both Morebeer and Ss Brewtech before I realized all warranty work had to go through Morebeer. Morebeer was awesome and sent me a new lid. I am however disappointed with Ss Brewtech as they never even replied to my email. Makes me question getting my electric system through them.

In review of your process, do you still only place a soaked starsan paper towel in the airlock without fuild during your transfer? “Because of the airtight seal, the exiting beer will create a vacuum that can suck in the airlock liquid, so I’ve been swapping it out with a small piece of paper towel dipped in sanitizer when kegging.”

What process do you use today versus when the article was written? I have a NEIPA, where I will try this process. In addition, I may add a filter within the transfer line.

I’ve actually been doing something sorta weird that we’ll be writing about very soon– I use the BrüLoonLock 🙂

I have a 7 gallon SS fermenter and a 7gallon Anvil Fermenter. The Anvil seems to be better built/designed and the racking arm is bigger and is far superior IMO. I cut some spare tubing and put it on the handles of the SS Fermenter making it somewhat easier to carry 5 gallons of Beer. (The handles on the Anvil are strong but don’t fold down). I use the Anvil 90% of the time until I have to Brews going.

Cheers 🍻