Author: Ray Found

I like to think of the different variables we can tweak as adjustment knobs on a big brewing control board, and the exBEERiment series as shining some light on those knobs I can turn for greater effect. If you’d asked me a couple years ago, I would have unhesitatingly claimed that mash temperature is a variable that has a profound impact on the final characteristics of a beer. In fact, as we were planning the first xBmt on the subject, I was convinced the batches would be easily distinguishable given how disparate the mash temperatures were. Similar to what I trust many experience when reading results that fail to confirm my beliefs, I would like have questioned the veracity of those results if it hadn’t been for the fact that I tasted them for myself during a stopover in Fresno while they were on tap. I could not tell them apart. Despite being fully aware of the 14°F/8°C difference in mash temperature, I not only failed a triangle test, but wasn’t even able to detect a difference when sampling the different beers side-by-side.

In follow-up discussions after those results were published, Nik Stevens of the Thunder Dog Brewery blog suggested an interesting hypothesis as to why these beers were so similar. In essence, the dextrins present in wort from mashes that favor alpha amylase are tasteless, not sweet as many expect, and will decrease fermentability, while wort produced from lower temperature mashes is highly fermentable, thereby reducing the amount of perceivable dextrins in the finished beer. Dan Paris from the In Bounds Brewing blog posited a less extreme difference in mash temperature may in fact produce beers that are more readily distinguishable by tasters.

It seems counter-intuitive that less extreme conditions might produce a greater difference, but the reasoning behind the hypothesis was intriguing enough to inspire a revisit of this xBmt!

| PURPOSE |

To evaluate the impact mash temperature has on 2 beers of the same recipe where one was mashed at 149°F/65°C and the other at 153°F/67°C.

| METHODS |

I wanted to make a beer for this xBmt that would really highlight any extra body or perceptible sweetness and went with a deliciously simple Pilsner recipe.

Czech It Out Pilsner

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 37.7 IBUs | 3.6 SRM | 1.058 | 1.011 | 6.2 % |

| Actuals | 1.058 | 1.009 | 6.4 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner (2 row) (Gambrinus) | 10 lbs | 91.95 |

| Vienna Malt (Gambrinus) | 14 oz | 8.05 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 12 g | 60 min | Boil | Pellet | 12.1 |

| Saaz | 33 g | 30 min | Boil | Pellet | 3 |

| Saaz | 40 g | 20 min | Boil | Pellet | 3 |

| Saaz | 40 g | 10 min | Boil | Pellet | 3 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Saflager Lager (W-34/70) | DCL/Fermentis | 75% | 48°F - 59°F |

Notes

| Water Profile: Ca 55 | Mg 0 | Na 8 | SO4 45 | Cl 68 |

Download

| Download this recipe's BeerXML file |

I began collecting the copious amounts of RO water required for this 20 gallon batch the day before brewing, it would later be adjusted to my target profile.

I brewed the following afternoon, milling the grain as my strike water was heating.

With the help of my little girl, I mashed in on the lower temperature batch, followed 25 minutes later by the higher temperature mash.

I came close to hitting my target mash temperatures of 149°F/65°C and 154°F/68°C, the higher temperature mash falling slightly lower than expected.

After 60 minute rests, I collected each wort in separate kettles that were placed over full-blast flames, both reaching a rolling boil quickly.

Following completion of each 60 minute boil, I quickly chilled the wort to about 80°F/27°C, the lowest I could get it with my balmy Summer groundwater.

My temperature controlled fermentation chamber would have to finish the task overnight.

Each batch was evenly split between two 6 gallon PET carboys, one for the xBmt, one for quenching the thirsts of a parched xBmt’r.

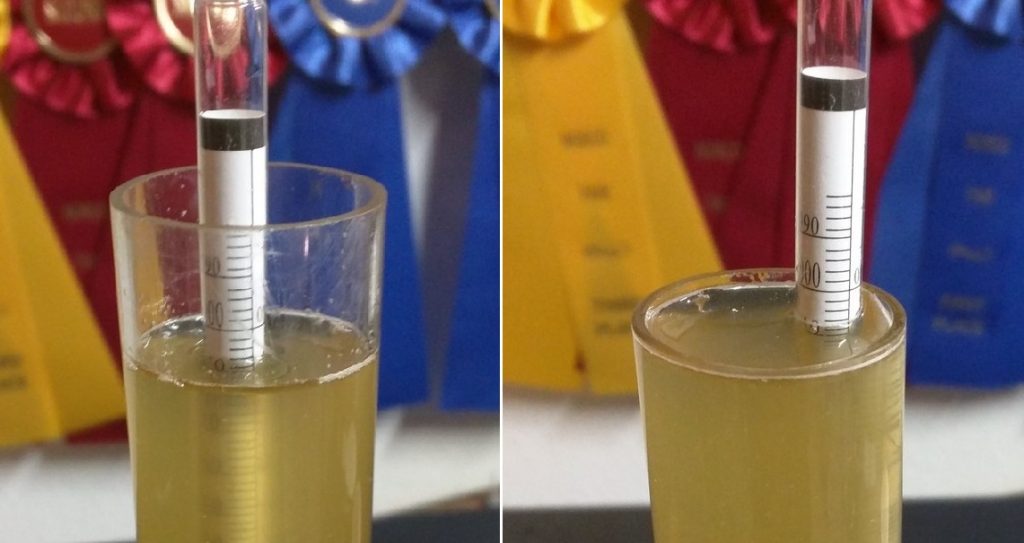

Hydrometer measurements showed the lower mash temperature wort landed an ever so slightly higher OG than the higher mash temperature batch.

The worts had stabilized at my target fermentation temperature of 56°F/13°C by the following day, at which point I pitched rehydrated Saflager W-34/70 yeast into each carboy. When I returned 36 hours later, I was intrigued to discover the lower mash temperature beers had begun to form a kräusen while the higher mash temperature beers hadn’t. An indication of a greater degree of fermentability, perhaps?

The following day, all of the beers appeared to be moving along nicely.

After 5 days, I began gently raising the temperature to 68°F/20°C where I held it for a few more days until signs of active fermentation were absent.

Hydrometer measurements at this point showed the lower mash temperature beer attenuated slightly more than the higher mash temperature beer.

The beers were then cold crashed, fined with gelatin, and kegged a few days later.

After a brief period of burst carbonation and a few days lagering in my keezer, both beers were clear, carbonated, and carried a beautiful golden hue.

| RESULTS |

Data for this xBmt was collected during an OC Mashups Homebrew Club meeting where 25 willing participants of varying experience level lent their palates to the cause. Each taster was served 1 sample of the lower mash temperature beer and 2 samples of the higher mash temperature beer in different colored opaque cups then asked to select the unique sample. In order to reach statistical significance with this number of participants, 13 (p<0.05) would have had to accurately identify the odd-beer-out, while only 6 (p=0.88) were able to do so. These results suggest tasters were unable to reliably distinguish between a beer mashed at 149°F/65°C and one mashed at 153°F/67°C.

My Impressions: While I found myself drinking more of the higher mash temperature beer, it likely had little to do with differences in character, as I readily admit to passing a triangle test just 1 of 3 times. I was also unable to distinguish between the beers when sampling them next to each other. If I hadn’t served myself, I wouldn’t have been able to tell which one I was drinking, I noticed no differences in body, head retention, lacing, or any of the other characteristics often attributed to elevated mash temperatures.

| DISCUSSION |

I’m compelled to believe the small 2.1% difference between the batches in apparent attenuation was likely a function of the variable, confirming what we know to be true about the impact of mash temperature. However, this difference did not appear to have a meaningful corresponding impact on the character of the finished beers, as neither a panel of blind tasters nor I could reliably distinguish a beer mashed at 149°F/65°C from one mashed at 153°F/67°C. While I’d never expect to taste a 0.001 FG difference, I certainly expected to see a bigger variance in OG as a function of the different mash temperatures, closer to the 0.003 difference BeerSmith projected.

This observation caused me to think about something that’s come up a few times in recent conversations, a concept referred to as “hot malt.” As it’s been explained to me, some modern malts are so robust in enzymatic activity that they convert fully, quickly, and easily. Such malts are fantastic for large scale commercial operations looking to cut costs by saving time with the process, though there’s some evidence an element of process control is sacrificed in that mash temperature seems to have less of an impact. This is a very new idea to me that I know very little about, so I’m hesitant to accept it as the sole explanation for the results of this xBmt, but I definitely think it’s deserving of a closer look.

These results provide further evidence that mash temperature may not be as powerful a “knob” when attempting to make a beer sweeter or drier, which is a huge diversion from convention as well as my my long-held dogma. On one hand, it’d be nice to know mash temperature isn’t as critical an issue as we’ve been taught, but on the other hand, I don’t like that it further removes me, the brewer, from the control loop. Perhaps this is part of the reason some brewers are drawn to using more unique base malts like Maris Otter, Golden Promise, and Vienna Malt, among others. Could it be that in addition to the purported flavor differences these “less advanced” malts allow the brewer more control over the wort from the mash tun? I don’t know, but I look forward to further investigation.

Whether you’ve experimented with different mash temperatures or just have thoughts about this xBmt, please share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

31 thoughts on “exBEERiment | Mash Temperature: Testing A Moderate Difference In A Czech Premium Pale Lager”

The one thing I’ve wondered about these mash temperature tests (and perhaps an idea for a future exBEERiment) is whether the differences would be noticeable in a style of beer which is supposed to have a large mouth-feel, and which relies on a lot of dextrinous character grains to achieve it.

Perhaps with something like an oatmeal stout a bigger difference would be observed – e.g. a loss of the expected body at the lower mash temp.

you may get fooled by the oatmeal addition. i would try a scotch ale.

I agree. Something like a 160F mash compared to a 148F while using a low attenuating yeast. That might tip the scales a bit.

How about 147 vs 161 with WLP002?

https://brulosophy.com/2015/10/12/the-mash-high-vs-low-temperature-exbeeriment-results/

I was just about to ask this same question. I wonder if in a beer where there’s not a lot of “body” (pilsner) the variable would not be as noticeable if at all, compared to an oatmeal stout where body is everything and mashing temp would seem to have an impact.

Maybe – though the opposite argument could also be valid – use a medium bodied recipe and the slight change in body would go unnoticed, but make a really crisp lager (pilsner) and extra body would be easy to identify. It is really just conjecture, and I won’t hazard a guess until I test it.

I was thinking the same thing. I’d like to see this done with a beer style with a lot of body.

Maybe would it have created a more significant diffecrence with more modified malts. Who’d know ?

It has always been my contention that; as long as you are in the correct range for a particular enzyme, be it Phytase, Glucanase, Peptidase, Protinase, Alpha or Beta Amylase, you will achieve the desired enzymatic activity for that particular step in the mash. Obviously there is a sweet spot. But my take away from this xbrmt is this; with respect to alpha and beta amylase moderate variations in temperature have little impact on final product. Where as much larger variations do impact final product. I also agree with Bryan, and with my own emperical observation, that these differences would be amplified in a much higher OG beer.

To me this is another great argument for learning and embracing the technique of step mashing. That technique truly is a “knob” that you can use to dial in your beer.

Great xbrmt. And a good one for new brewers to read… it all comes back to RDWHAHB!

A 2.1% difference doesn’t affect us very much on a homebrew scale but I bet when you are dealing with hundreds of lbs of malt the savings can be significant

I don’t know if it would be–so much of the cost of commercial beer (even micros) is labor, packaging, marketing, etc. The cost of ingredients is minor.

Since reading the first xbmt on mash temperature, I have taken high temperature mashing to a new level. I have done multiple (over 10 at least) beers since reading that, all over 160F with a mashout. I routinely mash at 165F now for most of my beers. What is the result? My beers have the body and flavor expected given a particular OG, but the alcohol level is much lower. I really love that. Most of my beers are coming out b/w 3-5% when before they would have been 5-7%. I don’t find the finished beers to be sweet at all. I think it sometimes is taking a little longer to get to the final gravity though when I mash high for some reason.

Also, I seem to be seeing anecdotally that the foam on the beer and the head retention is maybe reduced some when I mash high. I’m not sure if that is real or not, I’d have to do a side-by-side test. It would be an interesting xbmt though.

I have to confess that I don’t understand the hypothesis of this xbmt and why a different result was expected.

Thanks for that report. I’d like to reduce the alcohol in some of my beers without reducing the flavor.

try a 165F mash with a mashout and see what you think.

you could test the theory of the well-modified malts by doing a mash temp exbeeriment with the less-modified floor malted bohemian pilsner malt some malsters offer. I have never used said malt but heard it’s “less modified” as people generally use it in decoction mashing. Interesting read once-again!

I brewed a few Doppelbocks a couple years ago and mashed at 156 for the first two. First beer finished at 1.030 with a good starter of 833. 2nd beer finished at 1.029 with a repitch slurry from a bock that finished at 1.015. 3rd beer got mashed at 149 and finished 1.021. Big difference in sweetness perception. I think the bigger the beer the bigger the swing.

Probably worth testing if this still holds true at 1.086 instead of 1.056.

Hello, long time reader, first time commenter (great site by the way).

I’m interested to know whether drawing conclusions from a failure to reach statistical significance is as robust as drawing one where results are statistically significant? In other words, if your conclusion is that the results were consistent with participants identifying the odd beer out only by chance, isn’t the correct conclusion that it’s impossible to tell whether small differences in mash temperature produce differences in the finished beer? Your conclusion (“tasters were unable to reliably distinguish between a beer mashed at 149°F/65°C and one mashed at 153°F/67°C”) reads to me as a positive conclusion that small differences in mash temperature don’t make a difference.

I’m not in any way qualified in statistics (and am in fact a lawyer) – just interested!

I just question all the variables that go into this experiment, how accurate are the temps in this experiment, same crush, same grain temp/strike water temp. What are the samples of yeast used as far as viability. What is the ‘control’ in a experiment like this? And like many before said, who is really going to be able to the the difference in .001 gravity points, also what is the margin of error for the equipment used to calculate all of these things. And as many have said before a pilsner is probably not a great beer for this test as well.

Please do repeat it, in your own way!

I recently had an “Unplanned Outcome”. About a year ago, I brewed a spiced Amber ale (with New Mexico Chile Peppers) and it ended up sitting in a keg for about 4 months – its a great beer, but you can’t drink several a night – and when I tasted it, it ended up being a sweet and spicy beer.

As I looked over my notes, I saw nothing abnormal. I went through the process of narrowing down an infection and didn’t really find anything. So I brewed another batch and, for some reason, I put a second thermometer and found my main Blichman Brewometer was reading low and when I was mashing at 150*F, I was really mashing at 158*F. I contribute that to more unfermentables.

Whether that is correct or not, I choose to believe it. Now, the big thing that I noticed was that I had to let it sit for several months to get that flavor and I was able to nearly duplicate it with my last batch.

FWIW, Prost!

I love these exbeeraments but I feel for the more engineer oriented brewers. I like the toys but I would probably be bummed if I spent $$$$ on a computer controlled XYZ and then found out that in the end such tight control doesn’t really make much/ any difference.

I’m more of a “cook” brewer so it’s all good news to me, though I liked the idea that if I really locked it down I could make small changes in process to tune the result. It never seemed that it worked out that way and I figured I just wasn’t being anal enough about the process. So it’s nice to find out that it probably wasn’t me but that the change just didn’t make much of a difference.

That said I did do an accidental mash temp experiment that had a significant impact. My HLT thermometer had gone wonky with out my knowing it and I had been mashing about 20 degrees lower than my aim, so probably in the high 130’s to low 140’s. All was working but the grain bill had grown to compensate. When I discovered the problem and corrected it the first two batches I made were VERY high gravity versions. I have since adjusted the grain bill and I’m back where I want to be but some mash temp differences are noticeable in the end.

I was just wondering the other day when we’d see another mash temp exBeeriment – good read!

Do you have these on your future list? They would be very easy to do:

1 – the same beer served at different temperatures

2 – the same beer served at different carbonation levels

I’ve been making a mild ale recipe for a few years and experimenting with mash temperatures between 149 and 154F. Any differences are very subtle, and in my unprofessional opinion are more perceptible in terms of mouthfeel rather than other factors. The type of yeast I use (Windsor vs Nottingham) have more bearing on the final product than the mash temp does.

I think your rest is not long enough and your OG not high enough. When making big IPAs I will overnight mash at 145F, which can result in a 1.085 OG beer finishing at 1.009 (yes 90% ADF). If you mashed this at 165F I doubt you would drop below 1.022 (about 75% ADF). The reason for the long rest is that beta amylase cuts starches from the ends working off maltose pieces that are more fermentable, which takes much longer. Alpha amylase just goes around cleaving the starches in half basically and finishes rather quickly. I don’t know that you need to overnight mash with beta, but for me it is very convenient to start a big beer mash the night before, go to bed, wake up in the morning and finish the brew.

I think in both of these experiments you have used too short a rest and have brewed beers that will finish out below a detectable threshold. If you have a beer with a 1.025 FG next to a 1.009 FG and your tasters don’t notice it you need new tasters. These experiments are good in that they have shown that in small beers with short duration rests the mash temperature is not critical to within a few degrees. But if you are looking for what the difference could be then you are missing the point. Also in neither of these experiments have you completely denatured beta, it denatures at 72C, about 162F. So if you do a long rest you absolutely must hit the mash temp above 162F for awhile to make sure you kill all the beta in the high temp beer.

If I were going to do this experiment I would mash both batches for minimum three hours, one at 145F, and the other at 165F. It won’t matter for the high temp batch that its three hours but you don’t want people saying that you didn’t test them the same. The longer you can maintain the high temp batch above 165F the better your odds of killing off all the beta will be. A lot of people worry about doughing in too hot but alpha doesn’t denature until 80C about 176F which most people don’t even hit at “mash out” time.

Just checked and 70C is the commonly accepted inactivation point for beta, not 72C my mistake. So your first experiment was good that it denatured beta but again I would have done a higher OG beer and mashed much longer.

You should perform this experiment and report back!

Also, how long do you think the primary saccharification enzymes are active before becoming denatured – at the above temps – and assuming typical mash pH ranges?

nice experiment.

if you ran this again, i would choose different end points even if you stuck with a 4 degree differential. 153F is right around the point where alpha amylase takes off and beta fades in activity.

Hi Ray,

Great exbeerment.

When doing water chemistry additions using RO source water, do you assume a zero base, i.e. the RO source water is the same as distilled?

I would like start brewing with RO water, but don’t know what I should assume as a starting total dissolved solids value.

Cheers and keep the exbeerments coming.

Yes. My RO measures 14-21ppm total TDS, so it is close enough to zero on all ions.

Picked up some RO water form my LHBS with a TDS of 11ppm. So when building say a Balanced water profile using Bru’s water calculator, I can assume RO is the same as distilled.

Thanks Ray!