Author: Marshall Schott

Recent xBmt results seem to support the notion that different types of fermentation vessels have an impact on the character of the beer fermented in them. I did not expect this to be the case, to say the least, as I’ve always viewed fermentor type as being rather inconsequential.

Maybe it’s not?

After releasing the findings from the last xBmt on this topic showing tasters were able to reliably distinguish a beer fermented in a glass carboy from one fermented in a PET carboy, I received a barrage of requests to do some comparisons with other types of fermentors. I was honestly shocked with how interested people were in this variable, particularly given the less than enthusiastic response I got from my friends who participated in the previous triangle tests. Of course, this was before the results were analyzed and released. I’m now very curious whether different fermentation vessel types produce a measurable qualitative impact on the beer we make, as well as if the differences we’ve seen thus far will be consistent between multple xBmts.

Known for being impermeable to oxygen and easy to keep sanitized, stainless steel is the most common material used by modern professional brewers to ferment beer in. In the recent past, homebrew options consisted of pricey conicals that were essentially scaled down versions of what’s found in larger brewing operations. However, less cumbersome stainless fermentors have recently become available that are similar in form and function to typical homebrew buckets. Having recently acquired such a product, the Ss Brewtech Brewmaster Brew Bucket, it seemed only prudent to pit it against another fermentor extolled by many for it’s oxygen impermeability, the popular glass carboy.

| PURPOSE |

To evaluate the differences between beers produced using the same process where one was fermented in a stainless vessel and the other in a glass carboy.

| METHODS |

The beer I chose to brew for this xBmt is a rye IPA designed in collaboration with Love 2 Brew that is now available in kit form!

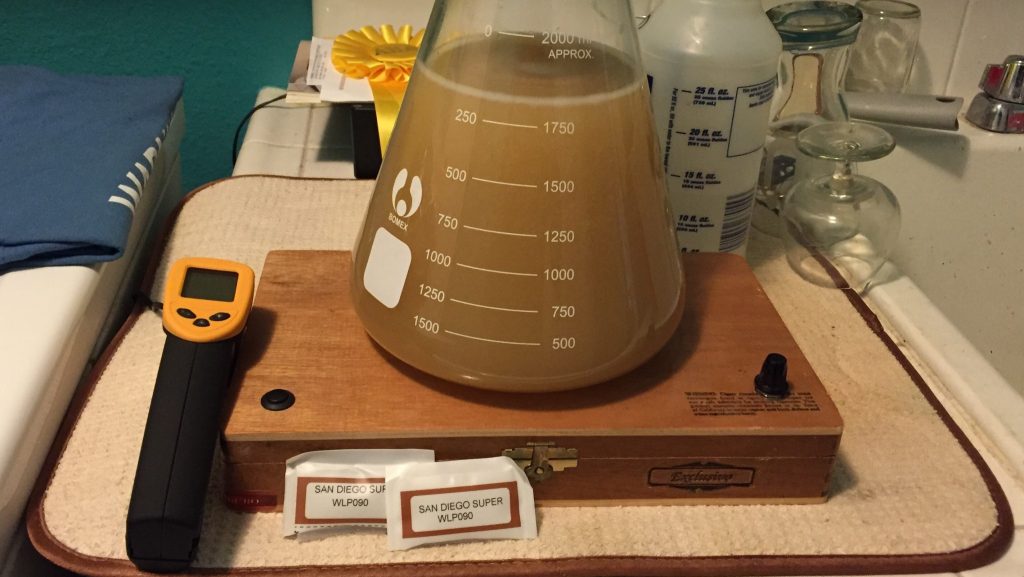

Including hefty doses of rye malt and El Dorado hops, Collabrüation Rye IPA is a medium bodied beer that’s uniquely candy-like without being sweet or cloying, a fun diversion from the typical citrus-bomb IPAs out there. Included with the kits were packs of WLP090 San Diego Super Yeast, which I propagated in starters a couple days prior to brewing.

The evening before brewing, I collected my full volume of brewing liquor, which I passed through a carbon filter, and added the necessary minerals and acid to bring it to my preferred IPA profile.

Next, the pre-measured grains from the two Collbrüation Rye IPA kits were milled together by my talented friend, Matt Humann.

I started the following morning off by hitting the flame under my strike water.

While the water was heating, Josh Evans, a local homebrewer I’d met online, stopped by with some delicious Berliner Weisse he’d made. Perfect for a warm morning brew session! Once the water was about 7°F/4°C warmer than the recommended strike temperature, I transferred it to my MLT then let it preheat a bit before Josh assisted me with mashing in.

After ensuring the grist was well incorporated with the liquor, I measured the temperature and found we’d pretty much nailed the target.

The mash was left to rest for an hour, receiving a brief stir every 20 minutes, then I performed a standard batch sparge to collect the proper volume of sweet wort, which was then put on the flame and quickly brought to a boil.

Kettle hops were added over the course of a 60 minute boil, after which I quickly chilled the wort to 170°F/77°C and tossed in the large hop stand charge. Twenty minutes later, with everything else all cleaned up, I finished chilling the batch. Given my warm groundwater temps this time of year, I was only able to get the wort down to 82°F/28°C, which is 16°F/9°C warmer than my preferred fermentation temperature, but it only took 9 minutes.

I filled both the stainless Brew Bucket and the glass carboy with equal amounts of warm-ish wort, stirring gently throughout to ensure equal distribution of kettle trub, then I placed them in my cool chamber to finish chilling. About 6 hours later, both batches having reached my target fermentation temperature, I divided the large starter equally between the two fermentors. As I’ve come to expect from WLP090 San Diego Super Yeast, the beers were fermenting happily the following evening.

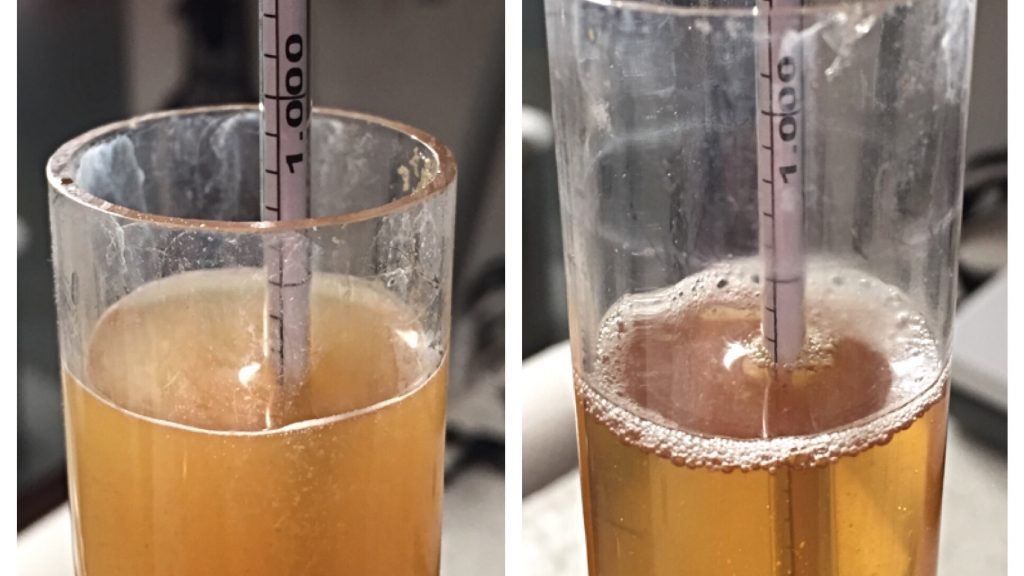

Minimal though it may be, one downside to fermenting in stainless is that it makes observing fermentation characteristics impossible, which I think can be interesting for some variables. This one, not so much. After 3 days at 66°F/19°C, I bumped my regulator up to 72°F/22°C, allowing the temperature of the beers to rise naturally in order to encourage complete attenuation and clean-up of any undesirable fermentation byproducts. I dry hopped 2 days later and let them mingle with the beer for 5 days before I pulled a hydrometer sample confirming I’d reached the target FG.

The beers were another couple of days then cold crashed, fined with gelatin, then transferred to kegs.

The full kegs were placed in my keezer and hit with 45 psi of CO2 for 18 hours before I reduced to serving pressure. By the following weekend, both beers seemed to share identical levels of carbonation, though curiously, the one fermented in stainless was noticeably clearer.

| RESULTS |

A total of 19 people participated in this xBmt, each blindly served 1 sample of the beer fermented in a stainless steel Brew Bucket and 2 samples of the beer fermented in a glass carboy. While 11 tasters (p<0.05) would have had to accurately identified the odd-beer-out at this sample size, 5 (p=0.81) were able to do so, suggesting participants in this xBmt were not reliably able to distinguish a beer fermented in a stainless steel vessel from the same beer fermented in a glass carboy.

| DISCUSSION |

Perhaps the most common theory regarding the significant findings from the first two fermentation vessel xBmts had to do with dimensional and volumetric differences between the fermentor types. On a commercial scale, I can sort of wrap my mind around how this might have an impact, but it seemed rather far-fetched to think such relatively small differences as an inch in diameter or a half-gallon more head space would matter all that much. Considering the Ss Brewtech Brew Bucket is different in terms of both dimension and volume than a glass carboy, yet tasters weren’t able to reliably distinguish between beers fermented in either, I’m left skeptical this is really the culprit.

Then what is it?

While impossible to know for sure based off of these few bits of data, it’s curious to me that the only time tasters haven’t been able to perceive a difference between beers fermented in different types of vessels has been when the material the fermentors are made of are know for disallowing any oxygen into the beer. Prior to buying my first PET carboy years ago, I anxiously scoured the web for information about oxygen issues with PET. The general consensus, based on experience and research, was that buckets allowed the most oxygen in and PET allowed much less. Assuming this is accurate and oxygen is the culprit, the findings from all 3 fermentation vessel xBmts actually make sense.

What’s your experience fermenting in different types of vessels? Please share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

33 thoughts on “exBEERiment | Fermentation Vessel: Stainless Steel vs. Glass Carboy In An American IPA”

your kids don’t like Matt do they? i see them scheming in the distance.

Cool writeup!

Noticed in the paragraph describing results from the tastes you say PET carboy when you mean glass.

Now I need to go back and read the other exbeeriments about fermentation vessels.

Just a sidebar how did you rig the transfer from carbon to keg? Any special fittings and gravity only?

I have a pin lock disconnect on the end of the siphon hose, it gets connected to the liquid out post on the keg. Gravity only.

Similar sidebar, but on your transfer from the bucket. Is the keg sealed? It looks like the lid is on but anytime I have tried a closed transfer out of my bucket to the keg it never works. And the bucket won’t hold co2. I assume it’s cracked a bit but maybe you found a trick or I am totally overlooking something.

Second sidebar – when you cold crash with your “open aluminum foil fement” don’t you oxidate the shit out of the beer? Even with an airlock it can be an issue with the temp drop and pressure change.

I use a depressor on the gas post to relieve back pressure.

Great article. I recently got a 1/2 BBL Chronical from Ss Brewtech and love it. As a designer, though, I have to say that some small things are off for as much as you pay for it. For instance, the spring clamps on the lid line up with the handle. This is only an issue when it is full and two people are carrying it. However, all they had to do was line them up so the space was over the handle…not the clamp. Simple things, but things to think about when shelling out hundreds of dollars for a Chronical.

Not really a comment on the xBmt, though I’m starting to come to the realization that I need to use more glass and less plastic. Would love to get one of those SS brew buckets, but don’t really want to shell out the dough right now.

Do you filter your kettle hops at all when transferring to fermenter, or does it all go into the carboy?

I don’t filter them out, but I also don’t try very hard to keep them out of the fermentor.

I got the chapmann version in 14 gallons. Considerably cheaper than an SS brew bucket and I like them a lot. https://www.chapmanequipment.com/collections/fermenters/products/7-gallon-steeltank-fermenter?variant=19577013249

I’m interested in the brand and capacity of your grain bins that are under the workbench in the mashing pic.

Vittles Vault 60 Lbs. They’re great!

It would be really neat to see the differences between stainless and plastic now. As if you all don’t already have tons of experiments to get to.

It’s on the list!

awesome!

I’m betting that a plastic and stainless test would see results similar to glass vs. PET carboy or glass vs. bucket. Oxygen permeability would slightly affect each fermentation, so the differences in taste (which are tiny and hardly noticeable) aren’t too surprising. I doubt it’s the shape. Maybe if you got one of those no-chill cubes and get the wort down to a temperature that the PET carboy can handle (like 125 degrees), you’d have a experiment testing really differently shaped vessels. I just can’t imagine one being slightly rounder or having a slightly larger diameter would matter, but maybe. Having a drastically differing shape like a cube (or triangle or whatever, though I doubt you can find a pyramid vessel or something) would determine that, so long as they are the same material. Even then, you have to wonder if one man’s PET is the same as another. I am guessing that some PET is better than others. Some PET is certainly going to be more degraded than others due to sun exposure, handling, washing, etc, so why not differing qualities straight out of the factory?

Hey Marshall,

great write up, I just picked up one of the stainless buckets. Very well made.

I think i posted it previously, but I’d love to see an exbeeriment with US-05 on fermentation temps, probably for a simple pale ale.

Lots of talk here in our homebrew club regardign the correct temperature for fermentation, and when to do a D-Rest etc.

Thoughts?

It’s on the list 🙂

That list must be getting pretty long.

Uh huh.

Been wanting to try fermenting beer in a corny keg for the simple fact that I can fit more of them in my fermentation chamber. But I heard that due to lack of surface area, the beer may not fully reach attenuation. Any plans on doing a corny keg vs carboy xbmt?

Headspace is an issue for fermenting in corny kegs. Some use 10 gal cornys for fermenting. Otherwise needs to be a three or four gal batch. Dip tubes frequently get clogged as well.

I Just did my first fermentation in a 10 gallon Keg. No problems hitting final gravity. It was a saison that finished at 1.003. I also cut the dip tube ½ gallon short so I don’t pick up the yeast cake or trub.

I’m not too sure about the lack of surface area thing. Never heard it myself. The only thing I’ve heard is that if your fermentation vessel is too shallow (wide bottom and not much depth) it can cause attenuation problems, as the yeast has much less distance to travel to flocculate.

How big was your batch you fermented in the 10 gal keg? I’m thinking of doing a 10 gal batch split between two 5 gal cornies.

I’ve heard about the dip tube clogging thing, yes. I’ve also heard of home brewers using ferm cap to reduce the krausen, due to lack of head space.

Again, a lot of research online points to a lack of full attenuation. (But what do they know ????)

Any plans to repeat exBEERiments so that you have an n>1? That could be a culprit too!

In stats, “n” is the sample size, which is 15+ in all of our xBmts, usually 20+. That said, we absolutely plan to continue performing repeats!

N is a sample size, however there are multiple types of samples sizes in statistics. The one you reference is observational sample size, based on a single experiment. There is also replication sample size. Evaluation of a single item (exBEERiment) does not allow for batch-to-batch variation and may skew results. Replication is needed to account for this variation

With that said, I love what you guys do. From my lab days it was just drilled into me that you must repeat experiments to increase your replication number.

I hear what you’re saying. Replication is important to us. Thanks for the support!

Another factor to consider is migration of aroma compounds into plastic fermentation vessels, which might explain significant results in fermentation vessel exbt part 1 & 2:

http://pubs.acs.org/doi/abs/10.1021/acs.jafc.6b00031?journalCode=jafcau&

No plastic in part 3, which is consistent with the result.

Both stainless steel and glass are quite stable. Plastic out gasses throughout its life. You can smell a plastic bucket or fermentor, that will impact your beer. Even more so when it is new, once it is old it will hold other flavours. I also think having your tasters taste in glass would also be a step forward.

On a side note is there a colour of cup which is generally favoured as the odd one out. I bet there is a small factor for that if you go through enough results.

You might be missing the difficulty of getting 3 clean, opaque glasses for each of 20-40 tasters. I get your point, and in a perfect world, that would be the case, but we all use the same cups, everyone gets them the same. Color favoritism could have an effect, but that would require separate testing, but as a whole its not likely enough of an effect to make a difference.

This was an interesting article, although I doubt I could replicate it given the qualitative description of your methods. Maybe a detailed methods section akin to a journal article, since you are basically following the style of scientific journals? If so, I don’t know what your hypothesis is, nor whether you believe your conclusion. Just offhand I’d say since both glass and stainless steel are non-reactive and hermetically sealable, I wouldn’t expect any difference except for their rate of heat transference. Since you didn’t reach your target temp, but moved into the two containers and let them drop on their own, I would think the steel container would have cooled faster than the glass. One thing would definitely be interesting though, is if you replicated this using an aluminum fermenter. The general myth is that aluminum would impart flavor, but I don’t know why. Aluminum doesn’t leach, nor would it be expected to oxidize in an anaerobic environment. No significant acid. Just yeast that don’t know aluminum from Adam. And aluminum stock pots are a lot cheaper than stainless steel, for us budget brewers. Just a thought. Thanks for the article. Very well done IMHO.

I would be curious to see this done again with a more delicate beer like a lager or kolsch.