Author: Marshall Schott

If there’s one style of beer I expect to be dry as a bone and endlessly crushable, it has to be Saison. To me, there’s no other example that hits this mark better than Saison Dupont, a crisp and refreshing beer that derives its unique peppery flavor from the signature yeast used to ferment it, a yeast lauded for its classic heritage yet loathed by some for being a finicky fermenter. Homebrewers using isolates of this strain such as Wyeast 3724 Belgian Saison and WLP565 Belgian Saison I have been reporting issues with stalled fermentations for years, which has led to various theories as to the reason for the attenuation issues as well as techniques for combating the fermentation foibles. Fellow experimental brewer, author, and podcaster, Drew Beechum, who is known for his love of farmhouse styles, espouses such a theory and technique.

a crisp and refreshing beer that derives its unique peppery flavor from the signature yeast used to ferment it, a yeast lauded for its classic heritage yet loathed by some for being a finicky fermenter. Homebrewers using isolates of this strain such as Wyeast 3724 Belgian Saison and WLP565 Belgian Saison I have been reporting issues with stalled fermentations for years, which has led to various theories as to the reason for the attenuation issues as well as techniques for combating the fermentation foibles. Fellow experimental brewer, author, and podcaster, Drew Beechum, who is known for his love of farmhouse styles, espouses such a theory and technique.

According to Drew and some smart folks he consulted with, the popular Dupont strains are sensitive to the back pressure created by airlocks and blowoff tubes, thus performing an “open fermentation” by covering the opening of the fermentor with sanitized foil is one way he found to reduce the risk of the dreaded Dupont stall.

I’ll be honest, I don’t fall into the crowd of cool people who have a genuine passion for Saison. I like the style and all, but it’s not a favorite of mine, so in the rare occasion I brew one, I want it to be good enough that my friends and I will drink the entire batch. I’ve messed around with reliable yeasts such as Danstar Belle Sasison and Wyeast 3711 French Saison, but I avoided Dupont because I didn’t want to deal with it. This all changed when I realized an opportunity to make Drew look like an ass!

| PURPOSE |

To evaluate the differences between two Saisons of the same recipe where one was fermented with an airlock, creating back pressure, while the other was “open” fermented.

| METHODS |

The last Saison I made, over a year ago, was fermented with Wyeast 3711 and came out quite good, so I borrowed that recipe and swapped out the yeast for this xBmt.

Say You, Say Me… Saison

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 11 gal | 60 min | 23.7 IBUs | 4.9 SRM | 1.052 | 1.006 | 6.0 % |

| Actuals | 1.052 | 1.006 | 6.0 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner (2 row) (Gambrinus) | 9.5 lbs | 46.34 |

| Vienna Malt (Weyermann) | 7 lbs | 34.15 |

| White Wheat Malt | 2 lbs | 9.76 |

| Honey Malt (Gambrinus) | 1 lbs | 4.88 |

| Corn Sugar (Dextrose) | 1 lbs | 4.88 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Willamette | 50 g | 60 min | Boil | Pellet | 5.6 |

| Willamette | 40 g | 15 min | Boil | Pellet | 5.6 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Belgian Saison (3724) | Wyeast Labs | 78% | 70°F - 95°F |

Download

| Download this recipe's BeerXML file |

I made a single yeast starter out of two packs of Wyeast 3724 Belgian Saison yeast a couple days prior to my brew day.

The day before brewing, after gathering my entire volume of brewing liquor and making any adjustments, I weighed out and milled the grains.

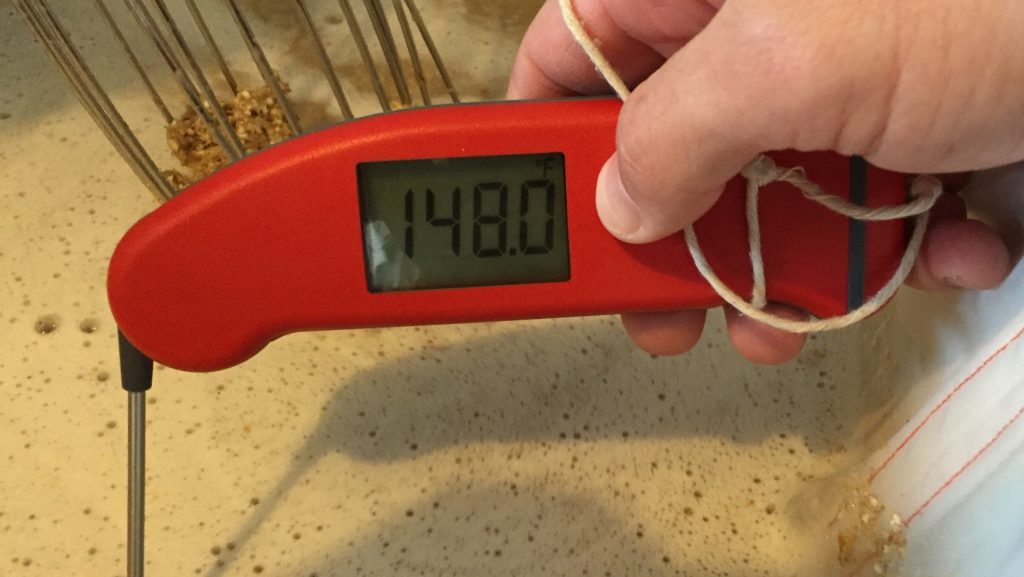

My first order of business the following morning was hitting the flame under my kettle of strike water, mashing in about 15 minutes later to hit my target temperature.

This would be a standard batch sparge batch using a BIAB bag in my MLT.

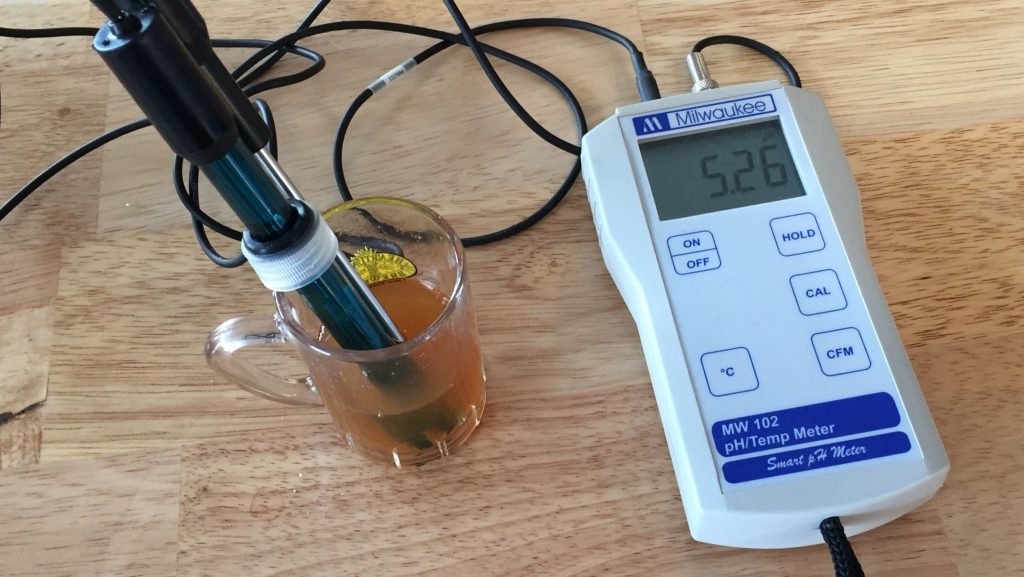

Around 10 minutes into the mash, I pulled a small amount of wort, chilled it to room temp, and took a pH reading that showed I was close enough to my 5.3 pH goal.

After a few brief stirs over the course of a 1 hour rest, I collected two rounds of sweet wort and quickly brought it up to a boil, during which hops were added as stated in the recipe.

At the completion of the 60 minute boil, I very quickly chilled the wort to 82°F/28°C, which was 6°F/4°C warmer than my groundwater temp at the time.

Two carboys were filled with the same amount of wort, which was gently stirred throughout racking to ensure equal distribution of kettle trub, then a standard 3-piece airlock was placed on one while the other was covered with sanitized foil. The carboys were left to chill to my target pitching temperature of 64°F/18°C for about 6 hours before the yeast was divided evenly between each batch. When I returned early the following morning, both had developed a kräusen.

At 24 hours post-pitch, things were looking pretty similar, which never really changed.

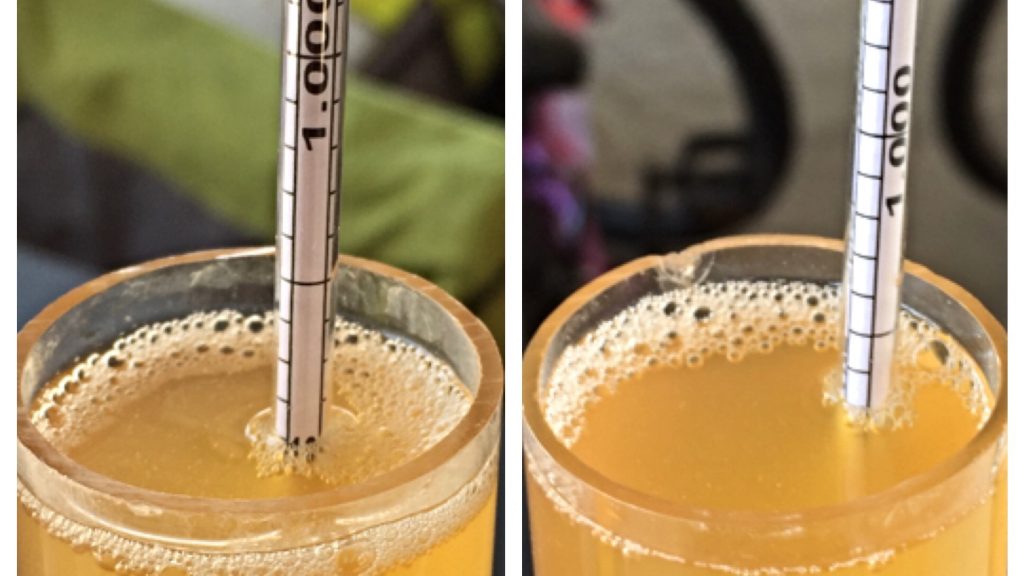

Given the nature of this variable and the claim that reducing back pressure will decrease the risk of a stall, I took regular hydrometer measurements starting 3 days into fermentation. The foil and airlock batches looked to be chugging along similarly at this point.

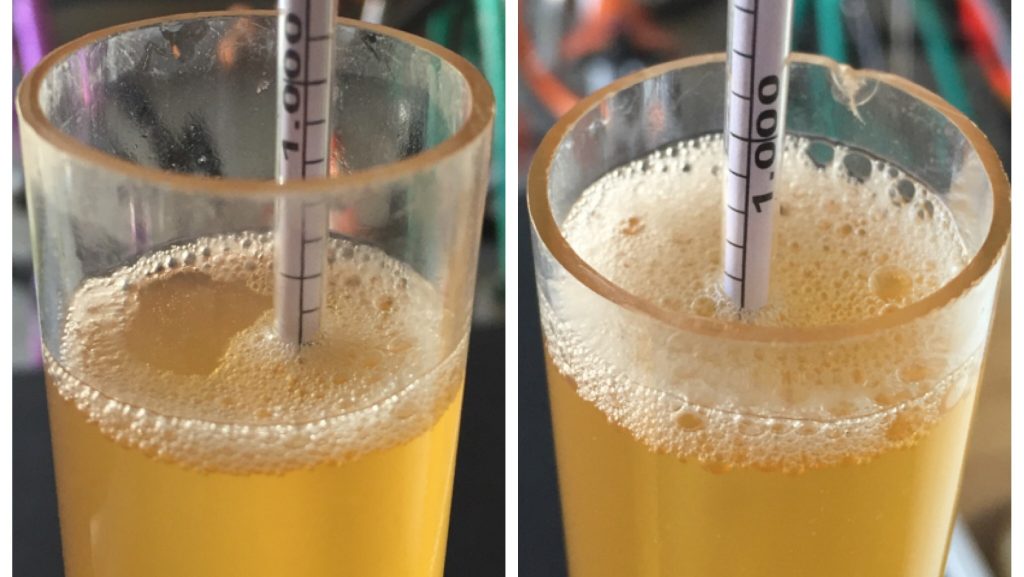

At this time, I set my temperature regulator to 90˚F/32˚C and allowed the beers to free-rise to that point. I took another hydrometer measurement 4 days later that revealed a slight difference in SG I wasn’t expecting based on the back pressure theory, though I figured the airlock batch could easily make a come back. Both batches were sitting at about 84˚F/29˚C, so I gently began to apply heat over the next few days until ambient temperature reached 90˚F/32˚C; the warmest the beers got was about 87˚F/30˚C

Another 4 days and the difference remained, the foil beer trailing a bit behind the airlock batch.

Hydrometer readings 3 days later revealed the gap seemed to be closing.

I measured the SG again 3 days later, 18 since pitching, and a final time 2 days after that and saw no change, suggesting the batches were done fermenting.

I proceeded to cold crash, fine with gelatin, and keg the beers, placing each in my cool keezer on 45 psi for 24 hours before reducing to serving pressure. The following weekend, both were clear, carbonated, and ready to serve.

| RESULTS |

A total of 24 people with varying levels of experience participated in this xBmt, each blindly served 1 sample of the back pressure (airlock) beer and 2 samples of the open ferment (foil) beer in opaque cups then asked to identify the unique sample. In order to reach statistical significance, 13 tasters (p<0.05) would have had to accurately identify the odd-beer-out, though only 8 (p=0.58) were capable of doing so, suggesting a Saison fermented with the Dupont yeast under back pressure from one that was fermented with no back pressure was not reliably distinguishable by participants.

My Impressions: As far as my ability to distinguish between these beers in a “blind” triangle, I sucked at it and simply could not tell them apart. I perceived both as having a peculiarly enjoyable pineapple character with some expected peppery notes in the background. If bubble gum was there, I wasn’t picking up on it. While it met my expectation for dryness and drinkability, I wouldn’t say it was the best Saison I’ve ever made, though certainly tasty enough not to dump.

| DISCUSSION |

The results of this xBmt prove one thing definitively…

Drew is wrong and his brewing advice should be purged from the minds of anyone he has brainwashed into believing him.

Of course this isn’t true, Drew is a great guy with oodles more knowledge on brewing Saison than probably anyone I know. I’m not sure why neither of my beers experienced the oft reported Dupont stall or why the airlock beer attenuated slightly more than the foil batch, it could be that I just got lucky, or more likely some other factor that I’m unaware of was at play. Regardless, I’m inclined to view the method Drew proposes as an easy way to decrease the risk of a stalled ferment when using the Dupont strain.

It just so happens our kindred spirits in exBEERimentation over at the Experimental Brewing Podcast, Denny Conn and Drew Beechum, were playing with the same variable at the same time. Will the results from their army of IGORs corroborate those of this xBmt or will they be different? To find out, be sure to listen to the episode that drops on July 6, 2016, I’ll be on to chat about our collective findings!

If you have any experience fermenting Saison with this strain, or if you’ve come up with your own way to contend with the Dupont stall, we’d love to hear from you! Please leave your thoughts in the comments section below.

Support Brülosophy In Style!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

29 thoughts on “exBEERiment | Pressurized Fermentation: Airlock vs. Foil In A Saison”

I’ve used Wyeast 3724 twice recently- both times, it stalled at 1.030. I then finished off the fermentation with Danstar Belle Saison. The resulting Saisons were pretty tasty 🙂

Could the frequent hydrometer readings have skewed your results here? Every time you sample aren’t you relieving the excess pressure?

I know of plenty of brewers who have experienced the Dupont stall, which they discovered by taking multiple hydrometer readings. Either way, while I’m highly doubtful, that could be the reason for my results. And from a practical perspective, if that’s all one needs to do to reduce the risk (I’m not sure it is), I guess that’s good information.

I’m not at all surprised that you did not detect any differences. The pressure created by the airlock is from the height of the liquid inside the airlock, let’s say an inch maximum. The yeast in the beer are subject to the pressure of the entire wort, varying depending on the where the individual yeast particle is floating within the wort at a given moment. You’re basically trying to detect the difference of having an inch higher level of wort in the fermenter, where most of the pressure is going to come from the level of the wort itself. Let’s say the average carboy will contain about 16″ of wort, you’re trying to detect a difference from a 6% change of this one parameter.

Exactly!

excellent point.

This has been my stand all along. The liquid head pressure by far outweighs any slight air pressure increase made by a bubble having to duck under and airlock cap to freedom! So glad you did this, all I ever got was “if Drew said it, I tend to believe it”. It just never made sense in my head.

Oh how I wish it were Wednesday already

i would be interested in seeing the results of fermenting under pressure on this xbmt.

Couldn’t be that the exbmt failed to achieve significance, because you regularly took hidrometer samples, thus releasing the back pressure?

If there is a real difference between these two methods, it’s more likely due to oxygen ingress than pressure. Airlocks allow pressure to pretty much equalize with atmospheric. The maximum increase in pressure over atmospheric exerted by the airlock is roughly equivalent to the weight of the water in the airlock spread over the surface of the wort, i.e. negligible. However, oxygen can freely diffuse under a foil cap, whereas the water barrier in the airlock almost completely blocks it.

Should also add that hydrometer sampling wouldn’t make a difference. The negligible pressure is released every time the airlock bubble pops.

Okay, a wacky thought on my mind is what would happen (particularly when brew a Saison) if one were to rig a negative pressure setup. Essentially are -2 to -3 PSI vacuum. Should be easy to do.

How would impact the stall back pressure story?

I have brewed multiple batches with the DuPont yeast. The biggest issue is consistency. I have used airlocks and had it rip through fermentation and it has stalled other times. I have found that using the foil provides a more predictable result, i.e. it does not stall. Not sure the oxygen impress is an issue. I figure as long as the yeast is doing its thing and producing CO2, then oxygen should not be an issue. I usually move to an airlock once fermentation drops below about 1.015. Fermentation is still active.

A bit of oxygen ingress is a good thing with this yeast. Lack of oxygen can cause some yeasts to stall because they need O2 to make sterols for cell membranes. If you make a healthy starter, aerate well, or let trub (a source of ergosterols) into the fermenter, the yeast ferment out without problem. But a poor starter or poor aeration etc. can lead to stall. Using foil instead of an airlock allows a bit more oxygen to diffuse in and helps prevent stalling.

Thanks for doing this one!

The Belgian Saison ‘stall’ is a perennial issue in brewing that I’m glad to see tackled here. I’ll admit though that I was disappointed to see you publish results for an ‘exbeeriment’ where the stall didn’t occur. Shouldn’t determining the exact cause of the stall be the point of experimenting at all? As much as I hate to say it (because I love this site and the work done here in support the brewing community), these results just aren’t helpful because they don’t speak to the issue the experiment claims to address.

Not sure what you mean to imply. The results should not have been released because they did not fall inline with predisposed belief? It could be a statistical blip, or it could be that the temp ramp abated the stall.

Not that the experiment didn’t serve the hypothesis, but that the cause of the stall remains a mystery. Neither batch stalled for this experiment, so what can it tell us about the stall itself? The mystery remains.

Well, I dont get the science behind the pressure theory.

I mean… The bottom fermenting yeast lives in the wort, in solution. Not on the top like English strains.

Air pressure above the surface of the wort does not change the pressure of the aqueous phase of the yeast / wort solution to any significant extent. I mean, if at all.

So I dont understand the theory.

I think it may go against basic physics.

Thanks for doing this. I regularly brew with the Dupont strain and (he says as he touches a large piece of wood, and crosses fingers and toes) haven’t had a stall yet. That’s not to say that others have not experienced the dreaded stall. Perhaps the test should have been performed on a yeast sample that had previously stalled. It just seems to be quite a variable yeast and using a known ‘staller’ would have attempted to overcome an important variable. Just out of interest, you didn’t mention whether, and how, you aerated the wort. Keep up all the marvellous work – already looking forward to next Tuesday’s post.

The only method of aeration I use is a small plastic “wort spray aerator” attached to the end of the tubing when I rack from kettle to fermentor. I’ve never, in nearly 500 batches, experienced a stalled fermentation.

Marshall, I would think it would be a good post to have you document how you brew thoroughly. I have read your post on what you do, but find that when you answer questions you often include little tidbits (like above) that never make it into the process. With a post on the details of how you brew, we can fully understand your process and understand what variable you are altering.

I do not think all the authors brew exactly the same though. Similar in certain areas of control. Perhaps listing those areas that we pay particular attention to, but in the end what matters is if the beers were otherwise treated the same.

Ah, cool. I seem to remember an earlier experiment you did explaining that now. Cheers!

I have to agree with others that an airlock is not “brewing under pressure”. With out some $$$$$ pressure gauge you probably couldn’t even see a difference. Actually heating up the wort probably increased the pressure more than the airlock.

I actually brew almost always under slight pressure. It’s not particularly high tech, I cover the top of my fermentors with plastic wrap and use a large rubber band to keep it sealed. The plastic inflates and gets “balloon” tight. I haven’t put a gauge on it but I doubt it’s more than 1/2 psi. But a heck of a lot more than an airlock.

And now for the other shoe…

https://www.experimentalbrew.com/podcast/episode-18-saison-under-pressure

We have always used the White Labs version instead if the Wyeast and always got the stalled result. We always needed to finish with another yeast, and we could never get it below 1.012. Over a year ago, after reading about the back pressure and build up of CO2 affecting the yeast we went with the foil cap approach and we have never had a problem. Our beer always finished near the 1.005 mark now.

The foil looks really tight on your foil cap. I wouldn’t be surprised if that potentially caused more back pressure than the airlock. I have seen this when I make a yeast starter and I put the foil on to tight. If the foil is really tight when I swirl the starter there seems to be more co2 in suspension. Just a thought. ..