Author: Marshall Schott

Like many, my interest in brewing at home was sparked by a combo of a joy of making stuff myself, frugality, and my love for the hoppy/bitter IPA. Having had a single unpleasant experience with a dark beer, I’d written off brewing anything darker than the beautiful mahogany hue of an Irish Red or Amber Ale, focusing the large majority of my attention on paler styles. It wasn’t until years later, inspired the deliciousness of Deschutes Brewing’s Black Butte Porter, that my allegiance to hop bombs began waning. I realized I’d been ignoring something special. I’ve since brewed numerous dark beers ranging from Schwarzbier to Russian Imperial Stout, they’ve become some of my favorite styles.

And yet, I was confounded by the very ingredient responsible for giving these delicious beers their dark color. When it came time to design my first dark recipe, I found myself torn between what seemed the two most popular roasted grain options– Roasted Barley, an unmalted roasted grain said to impart a smooth chocolate and coffee character, and Black Malt, aka Black Patent, a malted option many people claim imparts acrid and ash-like flavors. One was better for Stout, the other better for Porter, and a blend of both worked well for certain styles.

I only recently stumbled on a BYO article from 2007 where the differences between Roasted Barley and Black Malt are discussed, within which is the comment:

If there ever was a malt equivalent of the crazy uncle that lives under the stairs, black malt (also called black patent malt) would be it. Few people use it, most people don’t think they like it and everyone is afraid of it. Why, you ask? Because all the current literature tells you so. A usual description goes something like this, “Black malt lends a very sharp, acrid, burnt flavor whose harshness is beyond that of both chocolate malt and roasted barley.” Sometimes, it is additionally described as “ashy.”

Without a doubt, I fall into the category of people who “don’t think they like it,” as I’d used it only a handful of times, usually because I was out of Roasted Barley and needed something for color adjustment. I was afraid, to be sure, and wanted to avoid producing 5 gallons of ashtray water. But I’ve come to trust Kristen over my years of reading his articles and watching/listening to interviews with him. The dude knows what he’s doing and the fact his nearly decade old comment went against the conventional wisdom made me all the more interested to put this one to the test.

| PURPOSE |

To investigate the differences between Roasted Barley and Black Malt when used to make an otherwise similar Porter recipe.

| METHODS |

In order to emphasize the potential delta caused by the variable in question, I went against my regular Porter approach by limiting the roasted malts in the recipe to either Roasted Barley or Black Malt, using a bit more than I usually do.

This Is a Porter Recipe

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 28.4 IBUs | 34.5 SRM | 1.055 | 1.012 | 5.7 % |

| Actuals | 1.055 | 1.012 | 5.6 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Brewer's Malt, 2-Row, Premium (Great Western) | 8.5 lbs | 73.91 |

| Caramel/Crystal Malt - 15L | 1 lbs | 8.7 |

| Roasted Barley OR Black Malt | 1 lbs | 8.7 |

| White Wheat Malt | 1 lbs | 8.7 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 15 g | 60 min | Boil | Pellet | 11.2 |

| Fuggles | 30 g | 15 min | Boil | Pellet | 5.2 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| San Diego Super Yeast (WLP090) | White Labs | 80% | 65°F - 68°F |

Download

| Download this recipe's BeerXML file |

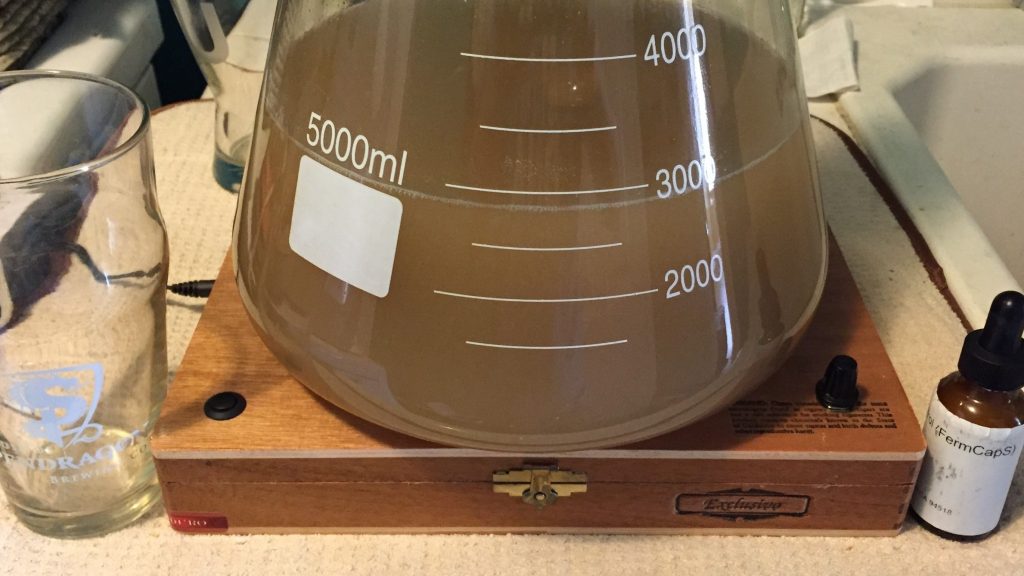

I made a larger than necessary starter of WLP090 San Diego Super Yeast a couple nights before brewing with plans to harvest some for future use before splitting it between the batches.

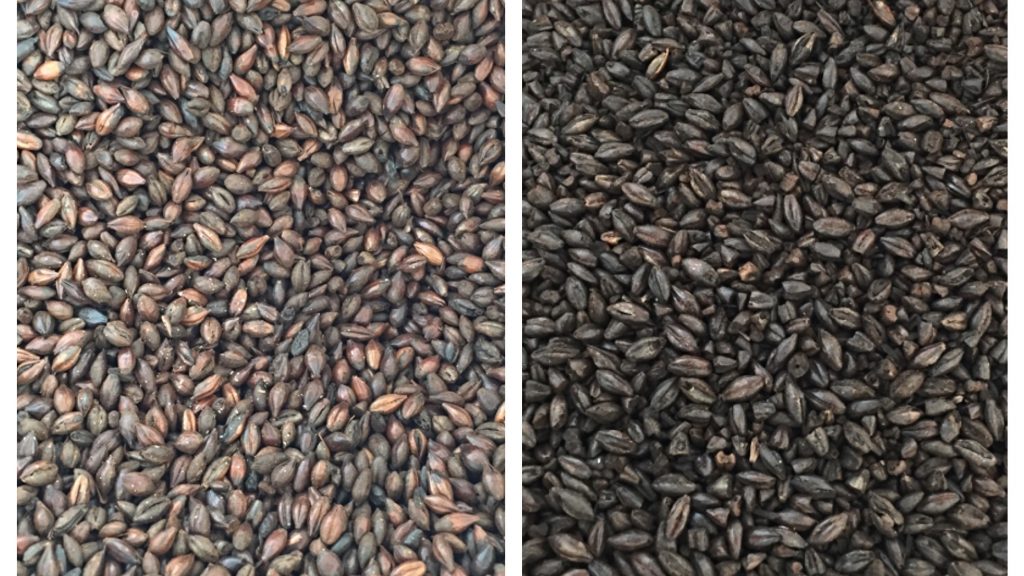

I measured out the grains and water for both batches the evening prior to brewing, adjusting each with the same minerals. I purchased both sets of grain at the same time from MoreBeer in order to ensure any differences weren’t a function of age or storage conditions. Interestingly, Baird’s Roasted Barley and Briess’ Black Malt were listed as sharing the same 500˚ L, though a side-by-side comparison revealed what appeared to be a pretty big disparity that left me skeptical a difference in character or color of the finished beers wouldn’t be noticeable.

I proceeded to mill each batch of grain into separate buckets that I covered and left alone until it was time to brew.

While milling, I chewed on a couple kernels of each grain to compare the flavor and was surprised how similar they tasted. I’m not sure I’d be able to tell a difference with my eyes closed. The following morning, I heated my strike water then mashed in each batch 20 minutes apart to make for an easier brew day.

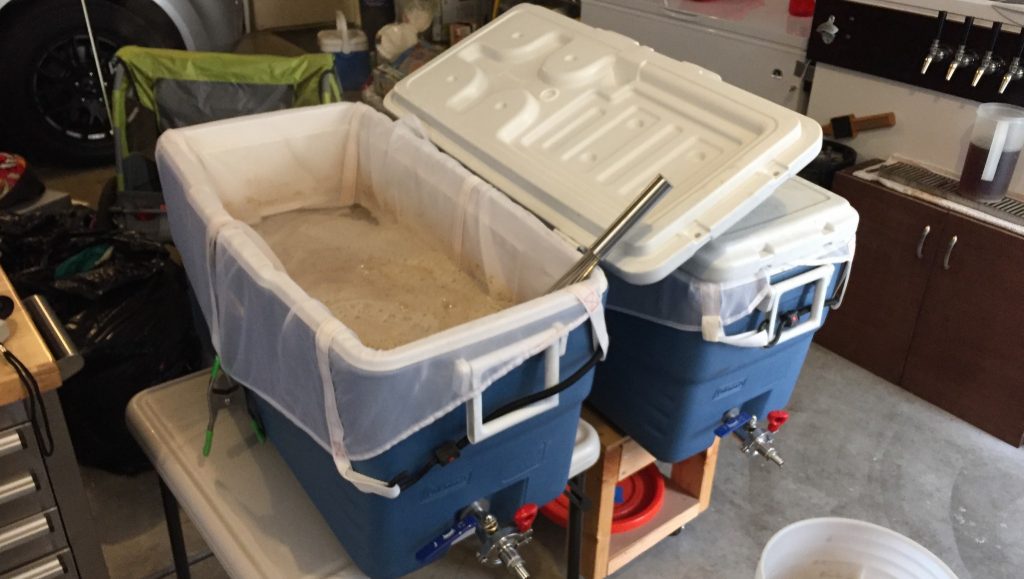

Since this variable required separate mashes, hitting the same temperature was important.

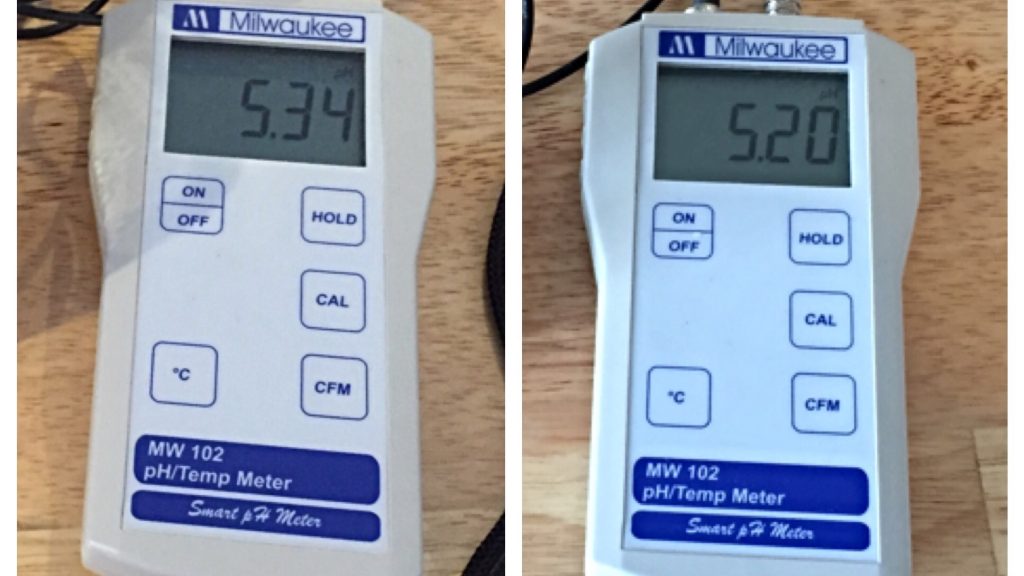

About 15 minutes into each mash, I pulled small samples of sweet wort that I chilled to room temperature for pH measurements. While Bru’n Water predicted they’d be the same based on being the same color, I wasn’t so sure given the observed difference, a hunch my meter confirmed.

Each batch endured a 60 minute mash rest with an equal amount of stirs every 15 minutes. I then performed a batch sparge to collect the same volume of sweet wort from each batch and brought them to a rolling boil, the two hop charges added at the appropriate times.

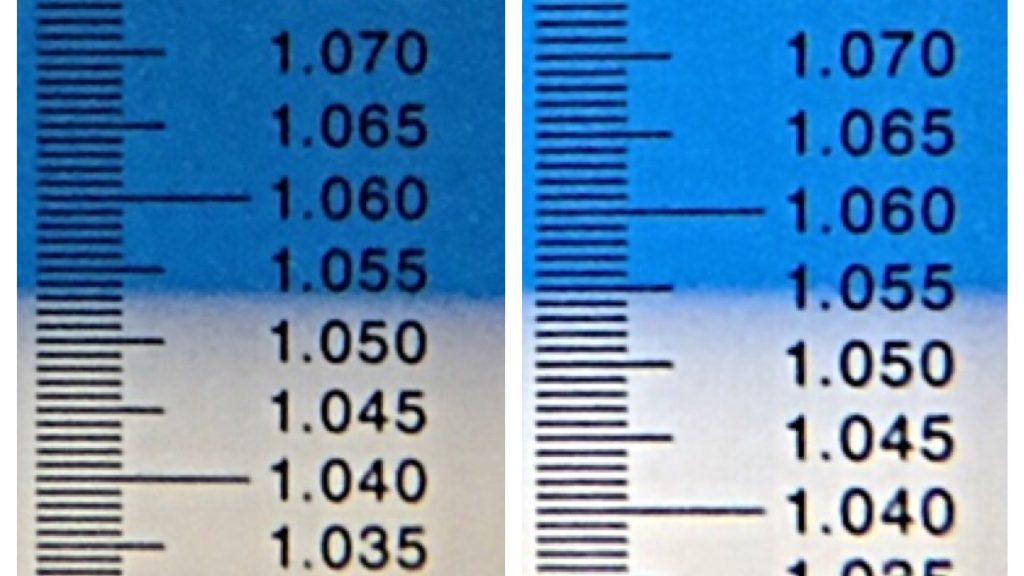

At the conclusion of each boil, I rapidly chilled the worts then took refractometer readings and observed a small but noticeable difference in OG.

Two 6 gallon PET carboys were filled with 5.25 gallons of either wort, placed in my fermentation chamber to finish chilling to 66˚F/19˚C, then eventually pitched with equal amounts of yeast. Both beers were fermenting nicely 18 hours later.

I expected the kräusen on the beers to look at least somewhat different, but that wasn’t the case, both appeared identical for the 5 days they were active. I raised the temperature to 72˚F/22˚C and let them sit another 4 days before cold crashing, fining with gelatin, then kegging.

The full kegs were force carbonated at 40 psi for 22 hours then purged and reduced to 12 psi for serving. When it came time to collect data the following week, the beers were nicely carbonated and had a very slight difference in head appearance.

| RESULTS |

A total of 26 people participated in this xBmt including local craft beer lovers, homebrewers, and a few podcast hosts. Each taster was blindly served one sample of the Roasted Barley beer and two samples of the Black Malt beer in different colored opaque cups then asked to identify the unique sample. In order to achieve statistical significance with this sample size, 14 tasters (p<0.05) would have had to correctly identify the odd sample out. The total number of participants who made the correct identification was 10 (p=0.36), which is consistent with chance and suggests a beer produced with 1 lb of Roasted Barley was not reliably distinguishable from a similar beer made with 1 lb of Black Malt by this tasting panel.

My Impressions: In 6 separate “blind” triangles served to me by others, I was only able to select the unique sample twice, and both of those were admittedly guesses. The only way I was able to tell the beers apart was by foam color, the Black Malt beer being slightly whiter than the more tan head of the Roasted Barley beer. Otherwise, they tasted the same to me. And unlike one of the aforementioned hosts, I experienced both beers as being very smooth, possessing a really nice mouthfeel with an ideal touch of sweetness that was nowhere near cloying, and having much less roasty character than I expected. I’ve made many batches of Porter over the years and I’d have to say this is probably my favorite one to date… both of ’em.

| DISCUSSION |

When it comes to designing an xBmt, there are a few important things we always consider, one of which has to do with the extremity of variable under investigation. In this particular case, I chose to use what I believe to be a moderate amount of either Roasted Barley or Black Malt for the comparison in hopes any differences might be amplified. But that’s not what happened, tasters could to reliably tell the beers apart, which might leave some wondering if the malts can be used interchangeably. The Session co-host, Mike “Tasty” McDole, pondered whether using a larger charge of roasted grain in future iterations of this xBmt might be warranted, as it would presumably boost the character each contributes and make the differences more easily identifiable. Makes sense. But then I started thinking about the oft touted “less is more” adage when it comes to using certain ingredients in cooking and brewing. For many, 1 lb of roasted grain in a 5 gallon batch of anything other than Dry or Imperial Stout is quite a bit, these grains tend to be used more judiciously to add the “essence” of what they’re purported to impart. This left me wondering if smaller amounts of roasted grain would have yielded a larger between-batch delta. I suppose there’s really only one way to find out.

For the sake of clarification, in no way do the results of this xBmt imply Roasted Barley and Black Malt are the same. By nature of the processes used to produce these grains, they are different. The fact participants in this single xBmt were unable to distinguish between beers made with either grain suggests that, in certain applications, they seem to impart a similar character.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Brülosophy Merch Available Now!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

33 thoughts on “exBEERiment | Grain Comparison: Roasted Barley vs. Black (Patent) Malt In An American Porter”

What always gets me is how different the lovibonds of black malt, chocolate malt, and roasted barley can be between maltsters. I think Briess’ roasted barley is only 300L, while the stuff from Simpsons is up around 600L. Always makes me wonder if I should be going by SRM estimates in the finished beer or by weight alone when using one or the other.

Wow, this is surprising! I thought that I could pick out the flavor of black malt would be different from roasted barley. interesting. i liked on the Session that Doc was very confident! ha ha!

Did you happen to check the final beer pH? Just curious if the yeast evened things out somehow b/w the two beers.

Not sure if Marshall took final pH of the beers. I know I always even if it is not referenced in the article.

Chris Colby also had some positive things to say about black malt, back in 2015 on Wine and Beer Journal.

It;s a good malt!

I’ve found myself in a similar conundrum of choice, but with a much different style.

I make a Hoppy Red Ale that’s really popular with my friends. It’s basically a single hop mosaic IPA that I just color red with 350L Chocolate malt. Many recipes call for 500L black malt in a smaller quantity, but the acrid descriptor has kept me away.

I wonder if the difference would be more pronounced in a red colored ale?

Good question. If you run an experiment, let us know how it turns out.

In his book, Gordon Strong suggests steeping an ounce or so of roasted barley in the strike water until it turns red, pulling the grains out, then using that to mash in. I imagine you get no character from the roasted barley since it’s only in the water for a very limited time. Haven’t tried it myself though.

Gordon provided yet another technique for us homebrewers to use and discuss!

This is really interesting, I’m definitely going to try it!

The only positive benefit I get with the dark malt, besides color, is the drop in mash ph, which means I can leave out my typical acid addition. I’ll just add acid next time!

I use Roasted Barley (500L or so) for my hoppy red ale, but will cold steep the Roasted (over 24 or 48hrs) and add to the end of the boil…. smooths out the rough edges, but keeps the color.

Was wondering if Marshall, or any of you other guys have experimented with cold steeping these dark grains?

I have not… yet.

I have. I disliked it out of the gate bc of the extra fiddling with my water additions to.compensate for NOT having the dark grains in there – the opposite version of the problem for some people..most of my beers recipes and processes are well practiced at this point. I also enjoy the slightly more roasted bite that having tem in the mash provides. Then, the color of beer needed compensated for….

I think doing it one way vs the other is neither better or worse – just different. It’s a good technique to have in your arsena but must be accounted for in both recipe and process.

I have used it for beers that do not have a locked in recipe for ie when I desire a touch of roast and color but the acrid character would overpower the beer – dark hoppy beers, some browns, black lagers, dark Saisons and so on.

Doesn’t it make more sense to replace a portion of your roasted barley or black malt with debittered black malt so you don’t have to fiddle around with soaking and water changes, etc.?

I’m curious as to why you used gelatin on these beers? I’ve always skipped that step when making dark beers because they are so opaque that I felt gelatin wouldn’t have any benefit.

I use gelatin on every beer, as it seems to speed up the conditioning process, a component of which is clarity.

Man I love your website. I’ve made a few changes to my techniques since I started frequenting here. I certainly use Gelatin now!

I have a few questions (if you don’t mind) on your process of transferring to your kegs? Are you siphoning through what would normally be the beer “out” line? I also see you have the lids in place, which I assume is to have the keg purged of O2. Can you transferred into the keg when it is pressurized or do you have to release the pressure from the keg before you transfer?

I do use the liquid line for kegging, but I do not purge the O2 prior to packaging. I use these little plastic things to release the build up pressure.

Another fun thing to do is to hook up a foodsaver to the gas in connector and you can suck the beer into the keg through the liquid line, then you don’t have to get a siphon started and the keg and carboy can be at the same level. (less lifting)

That actually sounds cool. It has enough suction? Do you use a sterile filter?

Interesting. Next exbeeriment- compare/contrast Roast barley vs. Chocolate malt please. I tend to use all Chocolate malt in my porters and 50:50 Choco:Roast in my Stouts. Why? I’ve thought that Choco gives a smoother, milder roast character. True? IDK.

Michael Lewis wrote in his 1998 Brewers Publication “Stout,” “Only roasted malt is used by Guinness for export beer. But for other beers, Guinness uses either roasted malt or roasted barley, and they have not been able to detect a flavor difference between these two roasted products.”

The pale head has been before a reason to recommend patent malt for colour correction (read it in a couple of places before). I did some porters with two malts: Pale & brown vs pale & black. Matching by colour those had a massive difference in taste (and many more times brown than patent malt).

Seems like a high amount of dark roasted malt for a porter. Most recipes I’ve seen have some chocolate malt and generally 1/2 lb. or less of black patent or roasted barley.

It was, which was intentional, as I thought it might help to emphasize any differences.

This is strange. Everywhere I go online it says that roasted barley will give a lighter head, not a darker one… This experiment shows exactly the opposite. Why?!

Haven’t a clue…

I have found the same as Marshall, that roasted barley imparts a nice mahogany head.

Marshall, it would be nice to repeat the experiment but make a dry stout instead. I think the crystal might be confusing things. In the case of coffee, sugar certainly softens the taste of espresso. Any chance you could do a follow up?

It is on the list 🙂

Cool, I like the mahogany head. I’ll have to try for myself! Thanks!

I just found this site because I wanted to brew this weekend, and am out of roasted barley. I love that you designed a highly scientific study, and employed sound statistical analysis to determine the effects! I’m going to enjoy reading the rest of your site, I’m sure!

What is your water profile in this exbeeriment? I would like to brew one.