Listen to The Brülosophy Podcast about this variable:

[soundcloud url=”https://api.soundcloud.com/tracks/320606948″ params=”color=ff5500&inverse=false&auto_play=false&show_user=true” width=”100%” height=”20″ iframe=”true” /]

Author: Marshall Schott

There are few things I worry less about when it comes to brewing than the type of fermentor I use, mostly because it seems like a variable inconsequential enough to have little if any impact on beer quality. I’ve heard arguments regarding the effect of fermentor geometry, amount of headspace, and O2 permeability, but in my experience, it has never seemed to matter.

Then I did the first fermentation vessel xBmt and was shocked that a majority of people were able to distinguish the sample fermented in a PET carboy from one fermented in a bucket. Given the small sample size of only 10 participants, I wondered if the results were a fluke, but 7 out of 10 people is pretty nuts, certainly enough to keep me curious. I was inspired to revisit this topic after reading a comment left by someone in a popular homebrewing forum about how they can “taste oxidation in beers fermented in plastic.”

Really?

| PURPOSE |

To evaluate the differences between beers produced using the same process where one was fermented in a PET carboy and the other in a glass carboy.

| METHODS |

Viewed by some as boring, California Common (aka Steam Beer) is one of my favorite styles, and thankfully I have friends who enjoy it as much as I do. Recently, a group of us agreed to make our own versions of Cal Common to be ready at the same time for an informal side-by-side comparison. With the results from the latest fermentation temperature xBmt still fresh on my mind, I designed a recipe somewhat different than What’re We Here For? and let the standard San Francisco Lager yeast sit this one out.

Vapor

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 33.7 IBUs | 12.0 SRM | 1.053 | 1.010 | 5.6 % |

| Actuals | 1.052 | 1.009 | 5.6 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Malt, 2 row (Gambrinus) | 9 lbs | 82.76 |

| Caramel/Crystal Malt - 60L | 12 oz | 6.9 |

| Vienna Malt (Gambrinus) | 8 oz | 4.6 |

| Victory Malt | 6 oz | 3.45 |

| Pale Chocolate Malt | 4 oz | 2.3 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Northern Brewer | 16 g | 40 min | Boil | Pellet | 10.1 |

| Northern Brewer | 25 g | 15 min | Boil | Pellet | 10.1 |

| Northern Brewer | 35 g | 1 min | Boil | Pellet | 10.1 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Saflager Lager (W-34/70) | DCL/Fermentis | 75% | 48°F - 59°F |

Download

| Download this recipe's BeerXML file |

Per my typical routine, I collected the water, made mineral and acid adjustments, then milled my grain the night prior to brewing.

The next morning, I immediately hit the flame to heat the strike water to temp.

About 15 minutes later, I transferred the slightly overheated strike water to my MLT, let it sit for a few minutes to preheat, then mashed in with the help of a couple cuties.

With the grain well incorporated, I measured the mash temperature to confirm I’d hit my target.

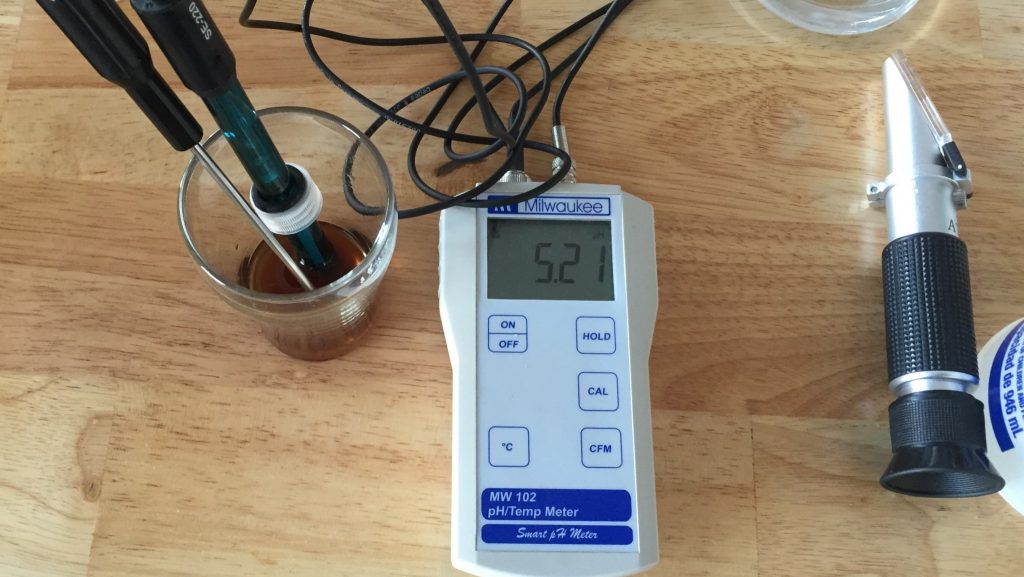

About 15 minutes into the mash, I pulled a small sample of sweet wort into a glass that had been chilling in my keezer, swirled it in a bowl of cold water until it reached room temperature, then took a pH reading. Bru’n Water works!

After a 60 minute rest, I performed a batch sparge, collecting my target pre-boil volume of wort and bringing it to a boil.

Hops were added during the 1 hour boil, after which the wort was quickly chilled to a few degrees warmer than my groundwater temperature, which at this time was 72°F/22°C. I then proceeded with racking equal amounts of wort to each carboy, gently stirring throughout to ensure equal distribution of kettle trub. The filled carboys were covered with foil and placed in a cool chamber, it took about 4 hours for both to stabilize at my target fermentation temperature of 60°F/16°C. I rehydrated two packs of Saflager W-34/70 in warm water for 15 minutes then evenly split the slurry between the carboys.

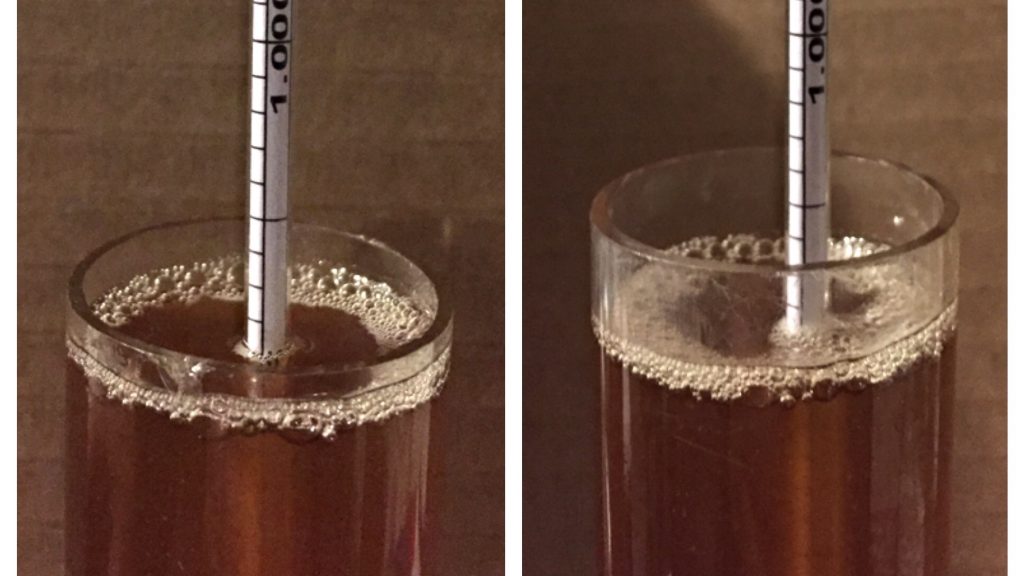

I returned 28 hours later to find the beer in the glass carboy actively fermenting, while the beer in the PET carboy looked dead.

I wondered if perhaps what I was seeing wasn’t kräusen but residual foam from the day before– is there something different about the foam retaining qualities of PET compared to glass? Either way, at 40 hours post-pitch, both beers were actively fermenting.

Things were looking a tad more similar 4 days in, the point at which I bumped the temperature in the chamber to 72°F/22°C to encourage complete attenuation and clean-up of any fermentation byproducts.

A check of the Fermometers on either batch revealed both were sitting squarely at my target.

Three days later, with fermentation on both beers appearing complete, I took hydrometer measurements that showed each was sitting at a desirably dry 1.009 SG.

I let them sit another 3 days before taking a confirmatory FG reading then starting the cold crash. The following morning, I fined each batch with gelatin then left them alone for another 2 days before packaging. The kegs were placed in my 38°F/3°C keezer and hit with 50 psi of CO2 for approximately 18 hours, after which I reduced the pressure to 14 psi where it remained. Both beers were beautifully clear and carbonated by the time I began collecting data 3 days later.

| RESULTS |

A total of 25 people participated in this xBmt, each blindly served 1 sample of the beer fermented in a PET carboy and 2 samples of the beer fermented in a glass carboy. While 13 tasters (p<0.05) would have had to accurately identified the odd-beer-out at this sample size, 14 (p=0.016) were able to do so, suggesting participants in this xBmt were reliably able to distinguish a beer fermented in glass from the same beer fermented in PET.

Following completion of the blind triangle test, those who correctly chose the unique sample were asked to compare only the 2 different beers and provide feedback on the one they preferred most. Strikingly, a majority of 10 tasters reported a preference for the beer fermented in glass, while 2 preferred the beer fermented in PET, 1 perceived no difference, and 1 reported no preference despite perceiving the samples as different.

After all of the data was collected, I disclosed the nature of the xBmt and asked my friends how confident they were in their selections, not a single one felt with any certainty they got it right. We proceeded to our planned Cal Common comparison. Standing in a circle of six, the few of us who participated began pouring samples for each other, the glass fermented beer was the first I shared. One round down, it was my turn to fill taster glasses with more Cal Common, only this time I poured from the growler of PET fermented beer, something I intentionally failed to inform my friends about. No one seemed to notice, all comments were consistent with those from the first round. I share this only to illustrate how similar these beers were despite being reliably distinguishable by participants intently focused on their differences.

My Impressions: I could not tell these beers apart. I thought I could after I correctly selected the odd-beer-out in the first blind triangle test served to me by a friend, but I was wrong more often than not in follow-up attempts. In the end, I had to accept I just couldn’t tell these beers apart, not in a triangle and not in a blind side-by-side comparison. The aroma, flavor, and mouthfeel were the same to me, which was curious given my generally congruent-with-results performance on the xBmts. Huh. As for the beer, it is, in my opinion, the best example of the style I’ve made to date. More dry, toasty, and quaffable than my What’re We Here For? recipe, which I have to believe is due to the different yeast given how similar the rest of the recipe is. Sorry, San Francisco, I’m sticking with Germany on this one.

| DISCUSSION |

“Are you effing kidding me?”

This was, in essence, the response I got from my friends once they completed the survey and I revealed the nature of this xBmt to them, most commenting that it seemed like a pretty lame variable to test since we all know it doesn’t make a difference. I don’t disagree, fermentation vessel wouldn’t seem to matter at all, but the numbers tell a different story. The shift in sentiment when I informed them of the fact a significant portion of participants had indeed been able to distinguish the beer fermented in the PET carboy from the one fermented in glass was hilariously palpable and invariably led to the follow-up question, “Which one did I prefer?” Of the four who were correct on the triangle test, two regularly ferment in glass, and they both preferred the beer fermented in their material of choice.

Boring as it may be, the fact two xBmts demonstrate an effect based on fermentor type has me wondering what exactly is responsible for the difference. For some, these results will serve to confirm the belief that PET’s oxygen permeability, minuscule as it is, has an appreciable impact on beer quality, which seems like the most logical assumption, though more solid data is required before I’m comfortable concluding anything.

Typically, likely as a function of bias, I detect the difference in the xBmts at least as often as the participants. That wasn’t the case this time, my performance on multiple triangle tests was no better than random while truly blind participants were able to reliably tell the beers apart. Besides causing me to question my palate, this made me wonder the extent to which my own unconscious confirmation bias was at play, keeping me from admitting that my long-held belief fermentor type has no impact could potentially be wrong. Either way, I’ve no plans to start using glass in my children toe laden brewery anytime soon.

What do you ferment in and do you think it makes a difference? Please share your thoughts in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

82 thoughts on “exBEERiment | Fermentation Vessel: Plastic (PET) Carboy vs. Glass Carboy In A California Common”

With a significance level of 5%, 5% of the time, due to random chance, a “true” null hypothesis will be rejected (this is called type I error). That is to say, even if there truly is no difference in the beers, every once in a while you’ll find there is a statistically significant difference. I think this is probably one of those times 🙂

I though that too, but it seems crazy to me that our 2 false positives were looking at the same variable, because the first FV xBmt was significant too. Crazy!

What I have read before and makes sense to me, is that the significance of the shape of the brewing vessel has a lot to do with surface area and pressures at the bottom of the vessel. So I could see it for a bucket VS a carboy but the carboys VS carboy would seem to not be significantly different in geometry. I guess another factor with these choices could be oxygen permeability and the slight extra amount of oxygen changing the fermentation slightly?

To me a more interesting test of this would be say one fermented in a large SS pot and one in a keg. There you would have very different geometries and a significant difference in pressure at the bottom. I would also stick with the bottom fermenting yeast for this since the pressure would probably not have as much of an affect on a top fermenting yeast.

Here’s another thing to think about. The significance level is (I’m assuming) for “public tasters” which have palates ranging from bad to good. The fact that 14/25 of these tasters chose the correct beer makes you wonder if more refined palates would have a higher significance level. Ultimately these experiments give you an idea of the percentage of the public that can distinguish between the variables. What matters is if you yourself can distinguish the variables, or if the judge in the competition would be able to perceive the difference.

My hunch is probably not: https://brulosophy.com/2016/01/21/investigating-the-bad-palates-argument-a-graphical-look-at-xbmt-performance-based-on-experience-level/

Hello, I’m from Argentina, in my case the problem with plastic is prolonged cleaning uses, there comes a time that apparently the plastic begins to “degrade”

Maybe difference in surface features of the vessels? Was the PET brand new? Or had it seen some use? A difference in cleanliness? Surface pitting in the PET creating nucleation sites for CO2 to come out of solution faster?

Really don’t know, but I’d be extremely surprised if it was a difference in oxygen permeability over such a short time span. Months in PET vs glass I could see, but days?

I agree with the concern over the surface features of the plastic. That’s the main reason I went glass, lifetime of use…if you can avoid dropping them that is.

I can’t, which is why I stay with plastic 🙁

Yeah, oxygen seems a little like the boggy man of brewing these days. Since it is rarely ever possible to be sure there were no leaks, that we fully purged our kegs, that the walls of our fermenter are permeable, we cite oxygen as a source of faults. But even with scientific data from xBMTs, we must admit that those involve selected fermentations, strains, and so forth and may not hold across variations.

I suggest a test with metal/aluminium fermentors vs PET vs glass carboys…

Cheers from Brazil! 🙂

I second this, please test a stainless fermentor next!

Yeah I’d love to see a stainless vs plastic! So many comments like ‘stainless tastes cleaner’ are floating around on the intertubes. I call BS on that and but I’d love to see empirical.

It’s coming!

My question is about the pitch. Were the two packs hydrated separately? Is there any chance that one pack was not up to par? If it wasn’t done already could future experiments be done by hydrating together and then splitting the slurry by volume?

I rehydrated them together then evenly split it between carboys. Not clear in article, my bad.

I have wondered a lot about whether my beer tasted better in my glass carboy compared to buckets. I am still uncertain if they make much of a difference and if racking my brew from glass to plastic after primary fermentation made any difference compared to just fermenting initially in the plastic bucket. I’ll keep playing with it but thank you for this post as it helps set my mind a little more at ease to use my plastic fermentors. Salute!

Next up, steel versus glass?

Potentially… 😉

No, don’t. My Chapman fermenters will be here today and I don’t want to hear that they suck…..

Haha.

Stainless vs plastic pleeeease! 🙂

It’s coming!

I could do conical vs carboy. If it’s insignificant I may get bride payoffs to take it down from the “Big Conical” lobbyists. Or if it is significant, if people “prefer” the carboy. Lol.

I’m guessing the key is in how the fermentation started. The glass took off and the PET did not. Were the dates on the yeast the same? And nothing weird happened in the rehydration? If that still checks out, then I’d then start looking at how glass may retain heat differently that got the glass batch going quicker and led to a healthier fermentation. Just some guesses. FWIW I switched from PET to glass 10 beers ago and have been really happy with them

The yeast packets were from the same lot, I always make sure of that, and they were rehydrated together then evenly split between carboys.

with no airlock and the increased time to start fermentation in the pet bottle, more o2 would have been in contact for longer with the pet fermented beer. the batches i have made in glass with an airlock, especially the really hoppy ones, are noticably ‘cleaner’ than my latest efforts in larger plastic fermenters and also the no chill method in cubes. I have been trying to work out the responsible variable, but oxidation is my current conclusion. i’m going back to a 5gal glass carboy next time and sticking with an airlock…

Also the beers are on a different temperature schedule related to the fermentation. If the glass was ahead of the PET, but both were warmed on day 4, that would also change yeast behavior at different stages of the process.

Marshall,

I love reading about your xBmt’s…. thanks, and keep it up!

Anyhow – just another thought, it appears that the two vessels you used are different volumes? Is that a 6.5 glass carboy, and the PET looks smaller to me. Perhaps the volume of the container could affect how the yeast behaves?

Also – did you use foil throughout fermentation, as opposed to bungs and airlock?

6.5 glass and 6 PET. Could be that’s the culprit, I don’t know!

Bottle a few and try them one month apart in parallel over a number of months. That’s really the only way to test if its an O2 permeability issue. I’d also consider repeating your testing bias test. Maybe your test groups are getting so accustomed to trying to pick an off-beer that they are subconsciously grabbing some element of your testing process to determine the odd beer out.

They’re all gone, both were delicious!

My test groups are pretty random, maybe 4-5 people who participate the majority of the time, otherwise it’s different folks.

More testing bias exBeeriments would still be interesting. One of your small list of exBeeriments with significant differences was a testing bias one after all 🙂

I agree… but my goodness, they lead to more vitriol than anything else I do! Haha. The sacrifices we make for science.

I use the FastFerment, a conical PET. I think it is the best thing to use as far as ease of use. I started with a glass carboy, but it was a PITA to clean and to move around. I don’t notice any difference.

I wonder if the difference may have been flavour carry-over in the plastic-fermented batch. I use both plastic and glass fermenters, and I’ve noticed what I’ve interpreted as a flavour carry-over in the plastics even with throughout cleaning – i.e. a recent pilsner had a hint of red wine, which was the previous resident of that fermenter. Given how badly some plastics stain, it wouldn’t surprise me much to find that flavour carry-over does occur.

B

I wonder this as well.

I ferment in buckets, but plan to upgrade to a conical in a year or so. Would it be possible to request a comparison between all three? Eg: Plastic, Glass, and Steel. Thanks for the awesome info Marshall, always a pleasure.

Not all 3 at once, as we prefer triangle tests, but certainly multiple comparisons using different FVs!

I would of liked to see some actual O2 readings between the two samples to see if there is a difference .

DO meters aren’t cheap!

Same here. The results support the hypothesis that there is a difference between the two beers, but I think that oxygen permeability is way down on the list of what is likely to be the actual cause of the potential difference. On a beer like this, with a relatively short fermentation schedule, there is plenty of active yeast to pick up any extra O2 coming into the vessel. What would be telling for O2 pickup would be something with a long secondary like a barleywine.

If I read the chart correctly, the O2 permeability of HDPE is 53 times that of PET. I know Papazian said “Don’t worry”, but it’s hard not to.

I wonder if forcing triangle participants to choose one sample as different if occasionally causing false positives. Do you think giving participants a fourth option of “no difference” between the three samples would reduce false positives or eliminate an actual subconsious difference between samples?

The triangle test is a forced choice test and the stats used are designed to account for the fact some people simply guess right. Allowing for a “no difference” option would disallow for the use of the triangle test.

Thank you for asking that BigDaddyBrew, as doing so allowed for answering a question I bet many others had!

It seems to me that the difference in the actual fermentation of the two beers would likely create a difference in taste, especially with a lager yeast. One beer started fermenting later than the other, which means it was at a different stage of fermentation when the diacetyl rest began, etc. This would be the most likely factor that would result in taste differences in my opinion.

I’m not convinced fermentation started sooner on the glass batch and wonder if the foam from kettle transfer didn’t just stick around longer.

It is interesting that the pre-pitch photo and the 28-hours later photo look so similar. Foam on top of the glass carboy before, and foam on top after. No foam on the PET before, no foam after. Perhaps you’re right that less is going on after 28 hours than it may appear.

This is such a crazy result considering all of the exBeeriments that were NOT significant for a statistical difference! (eg the lager ferment temp exBeeriment comparing 50F vs 66F.)

What’s even crazier, to me, is that this is the second fermentation vessel xBmt that came back significant, yet all of our lager ferm temp xBmts have failed to achieve significance. Dumbstruck.

Not a chemist but this article hits on one many people were talking about: http://www.ilsi.org/europe/documents/131.pdf

To me, it seems that the time in the PET fermentor is too short. Now, the thickness of the PET itself seems interesting.

Just a note about the foam differences in PET vs glass: one of my chemistry professors told me that the micro-roughness of plastic causes more nucleation sites for bubbles. I believe that is responsible for the differences in foam between the two carboys.

*Throws out all my plastic buckets*

I used to ferment in buckets, but got three glass carboys that each cost the same as the equivalent sized bucket cost and I’ve been using them since. I prefer the taste of the beers I’ve brewed with them, but it could just be that I’ve become a better brewer.

But how does this really play out for the solo brewer at home making a 5 gallon batch. You’d brew, you’d taste and you’d refine the recipe and rebrew. As long as you always used the same fermentor you’d be able to reliably make the beer to your taste or chase down judges comments for competition. And all the palates would be blind to the difference…because you were always “improving” the beer through recipe tweaks. I haven’t tasted the two beers in this experiment, but I assume the flavor differences are minor and not “OMG THAT’s OXIDIZED”. Which means if you were developing a recipe from scratch, I suspect the flavor could get nudged one way or another based on ingredient and process changes. Its a real interesting result, but how it impacts us making beers without the companion variable is an equally interesting debate. -Mike

I wonder whether the difference comes from the insulating values of PET versus glass. I know that temperature xBMTs in the past have found little significance for temperature, but there really looks like a difference in how rapidly the two started fermenting and that could mean that the difference wasn’t the fermentation vessel, per se.

I’m not convinced the beers started fermenting at different times, as the foam on top of the glass beer looks awfully similar to the foam that was there immediately after transfer from kettle. Perhaps glass is more foam positive than PET?

Sugestion: pet vs Glass bottles.

Bottles?

At 40 hours, glass is muddier and looks like what I see when trub and everything is being stirred up by yeast activity, while PET is darker, looking more like “trub still on the bottom” beer.

At 4 days, they look pretty similar. At seven days, the PET looks like it is a little more vigorous than the glass and glass has more trub.

I’m just looking at your pictures, but these beers don’t look to my eye like they are at similar stages of fermentation at any point except maybe day 4.

I have a question. When you carb are you using a splitter between the two kegs or instead are you using separate regulators to set the pressures?

If you’re using separate regulators, maybe a very slight carbonation difference (due to difference in regulator or even check valve tolerances) could explain the differences between the beers.

I use secondary regulators set to the same psi. Any differences are small enough for me not to notice and for participants not to point it out.

I’m looking forward to the stainless experiment. I currently brew using plastic buckets, but thinking of switching to stainless. The reason being is that I think I might be losing a lot of hop aroma to the plastic – similar to the comment above about flavours from previous batches carrying over. Even after a good clean, there seems to be a lingering hop aroma in the bucket. Star San seems to clear that up. However, it’s aroma that I would have preferred stayed in the beer. Therefore, Marshall, how about using a really hoppy beer for the experiment?

Stainless fermentors are on the way!

hi Marshall 🙂

I have been doing some thinking about the ferment temps for US-05 dry yeast, and I know so many people who run this yeast at so many different temps, to get what they conside “The best out of it”:

I’d Love to see an ExBeeriment on this.

1 at a nominal 20deg C

and One at a lower temp, with slight raise, to a D-Rest type temp. to see what difference there could be?

I can’t see you having done this with one ofthe most popular yeasts. but might be worth a try, food for thought

Marshall, thanks for another interesting experiment. How sure are you that you put equal amounts of wort in each fermenter? The glass fermenter appears to have a larger diameter yet it appears that the height of the beer in each fermenter is the same.

I gauged the amount into each carboy based off of the volume markings in my kettle. It’s definitely possible one had a quart more/less than the other, and if that is what’s responsible for the difference, I’d be beyond shocked.

If I had any more glass fermenters I’d try this experiment myself. But over the course of 25 years of brewing I think I’ve broken enough of them to send a glass blower’s kid through graduate school.

Seems like alot of us are chalking this up to oxidation? How about an xBmt to test how bad O2 really is during fermentation? If you have a set up for oxygenating your wort at pitch time you could do the unthinkable and chuck it into the fermenter at a couple of points during the ferment to really give it a chance to oxidize? Pure O2 and a stone would be ideal, but an aquarium bubbler with a filter would probably do without adding too much wild bacteria and yeast? Might be a good candidate for that super significant difference number to?

It’s on the list 🙂

I know you’ve answered this before on here somewhere, but do you cold crash in your PETs with just the foil cover? I generally crash in kegs, but have a batch in a PET carboy that I would like to crash prior to kegging. Don’t want the airlock suck, but also want to be sure I’m not going to have oxidation issues with just foil. Thanks!

Airlocks usually, I keep StarSan in them, so a few drops in my beer isn’t worrying.

Just listened to podcast #4. I use a Fermonster. I was having moisture problems in my chest freezer I use as a fermentation chamber. I found some people suggest using DampRid to keep the moisture out so things don’t mold. The only kind I could find was a lavender vanilla scented kind so I used it. The vessel should be air tight, so who cares, right? The beer tasted flowery. Not in a good way. Like straight up flowers and it was borderline undrinkable (didn’t stop me though). This is the second time I had done that recipe and it tasted nothing like that the first time. I have since removed the scented DampRid and I haven’t had that problem since.

Oh man, that sucks! I haven’t found those dehumidifiers to work very well at all…

Would love to see a PET versus HDPE (fast fermenter or other) comparison.

Thanks for all the great work!

Hi, thanks for the nice xBeeriment!

What is the water profile you typically use for California common?

Cheers!

Amber Bitter in Bru’n Water

I can believe the results. For instance, I can reliably discern whether or not a beer was packaged in a can or not. I’ve even had bartenders challenge me, and have reliable won bets. Leeching of plasticizers is well known in plastic containers in general.

Can you repeat this exact same experiment? I am thinking about running to the home brew shop and buying a glass carboy.

Love this site and this is one of the most surprising results. Perhaps plastic wasn’t 100% sterile? I can’t imagine that little O2 making a difference but some microbes/wild yeast might.

I wonder if polypropylene oxygen permeablity (even bigger than of PET) will make any difference in ester production in wheat beer fermentation. Especially interested in isoamyl acetate.