Author: Malcolm Frazer

I use the same multi-step but simple process every time I make water adjustments for a beer. Based on the style, I select my preferred water profile, calculate the mineral additions, then check to see what the mash pH is predicted to be. Relying on my moderate alkalinity (~145 ppm) municipal water for at least some portion of the brewing liquor, my mash pH is often higher than I prefer, which I remedy by using liquid acid.

Readily available at local homebrew shops, 88% lactic acid is a popular option for pH adjustments due to its low cost, effectiveness, shelf stability, and relative safeness. Phosphoric acid is also used commonly by homebrewers for pH adjustment, though it’s maligned by some due its reaction with calcium, and it’s also a bit weaker at the commonly available 10-15% strength. While the decision of which acid to use is likely made without much forethought by many homebrewers, both react in their own idiosyncratic ways that are worthy of consideration. For example, phosphoric acid adds flavor neutral phosphate that precipitates out a small amount of calcium, thus lowering the total calcium potential in the beer, which can have a negative impact on yeast health and beer clarity. Lactate ions, on the other hand, may have a noticeable flavor impact when used in higher amounts.

As a brewer who uses water with a decent level of alkalinity to make beers with low mineral character, I came to rely on liquid acid to achieve my target pH. While I developed a personal preference based on my own system and experience, I began to wonder if acid type contributed to the character of the beer and decided to put it to the test!

| PURPOSE |

To investigate the differences in beers produced using the same recipe and process where pH adjustments to the mash were made with either lactic acid or phosphoric acid.

| METHODS |

I chose to brew a simple Kölsch-style beer to test this variable, a recipe I’ve used many times and one of my favorites to have on tap at home. While I typically dilute my water with 60% distilled when brewing this beer in order to reduce the mineral content and total alkalinity, I opted not to dilute for this xBmt, as this would require me to use higher amounts of acid to counteract the alkalinity of my tap water and hit my target mash pH. Ultimately, my goal was to amplify the potential impact of the respective acids.

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 70 min | 22.4 IBUs | 2.6 SRM | 1.041 | 1.008 | 4.3 % |

| Actuals | 1.041 | 1.008 | 4.3 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner (2 row) (Gambrinus) | 7.75 lbs | 88.57 |

| Wheat Malt, Ger | 1 lbs | 11.43 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Perle | 24 g | 70 min | Boil | Pellet | 6.5 |

| Hallertauer | 14 g | 10 min | Boil | Pellet | 4.1 |

| Perle | 8 g | 1 min | Boil | Pellet | 6.5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| German Ale/Kolsch (WLP029) | White Labs | 75% | 65°F - 69°F |

Download

| Download this recipe's BeerXML file |

I made a single large starter about 24 hours before I planned to split it between the two batches.

I then crushed the grain in preparation for the following morning’s brew.

The next morning, I heated the strike water, readied the different acids, and staged the hops.

I started the phosphoric acid mash 20 minutes before the lactic acid mash to make managing things easier. While a difference of 1°F/0.6°C is likely negligible, my hunch is the temperatures were within a few tenths of each other.

Using the Bru’n Water spreadsheet, I determined reaching my target mash pH of 5.4 would require 4.1 mL of 75% phosphoric acid and 4.5 mL of 88% lactic acid. Using a medical syringe, I measured out the suggested amounts, added them to their respective tuns, and took confirmatory pH measurements 15 minutes into each mash.

While the batches were mashing, I collected sparge water and acidified each to pH 6.0 using 2.4 ml of 75% phosphoric and 2.7 ml of 88% lactic acid. I proceeded to batch sparge each batch then it was flame on!

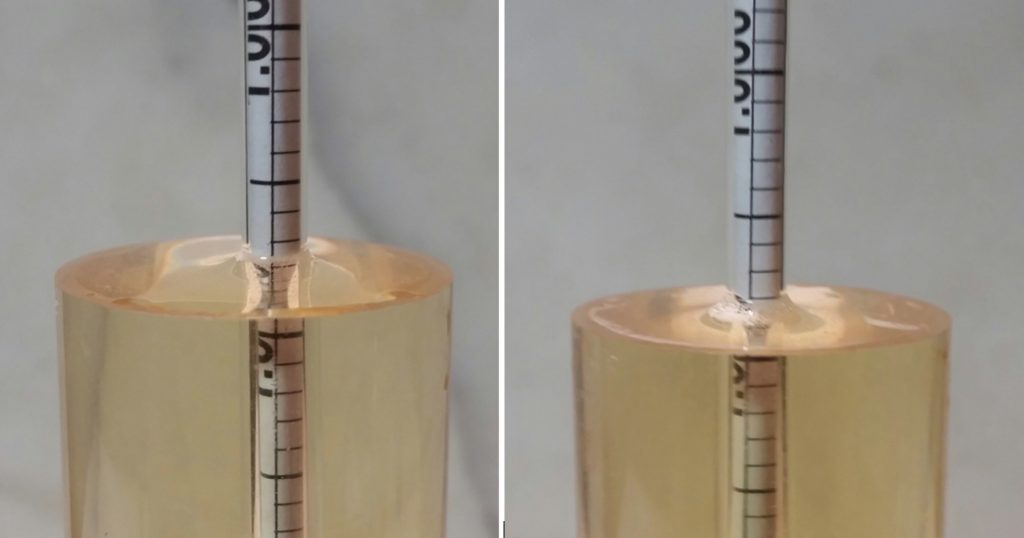

Both beers were boiled for 70 minutes, during which hops were added at the appropriate times, then they were chilled and OG readings taken.

The yeast starter was equally split between each fermentor followed by a 60 second dose of pure O2, then they were left to ferment at 62°F/17°C for 3 days before I gently began raising the temperature to 68°F/20°C over the next week.

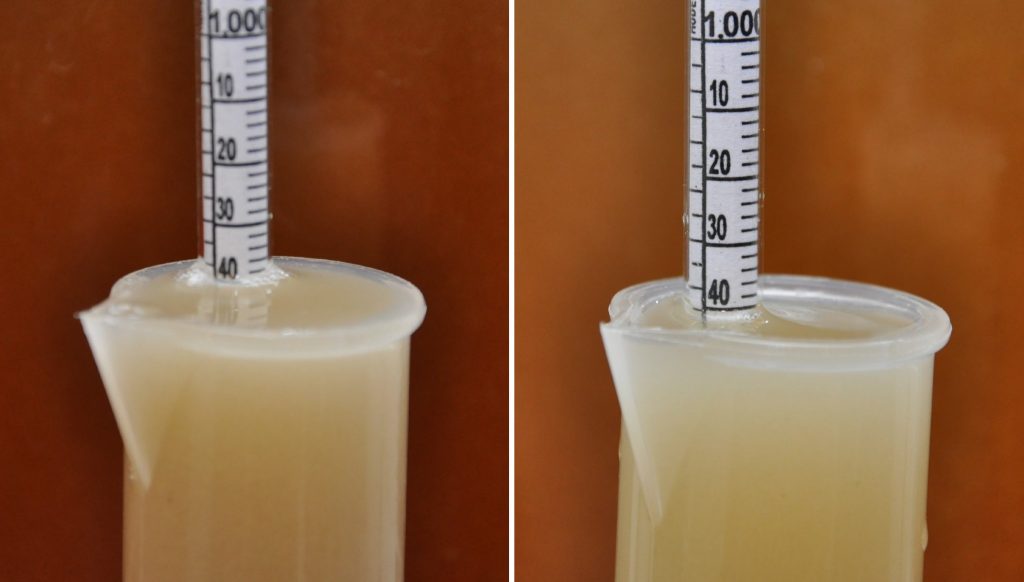

Fermentation activity absent at the 10 day mark and hydrometer measurements confirmed both beers had dropped to the same expected FG.

Well attenuated and no demonstrable off-flavors present, I cold crashed over night, fined with gelatin, then kegged the beers.

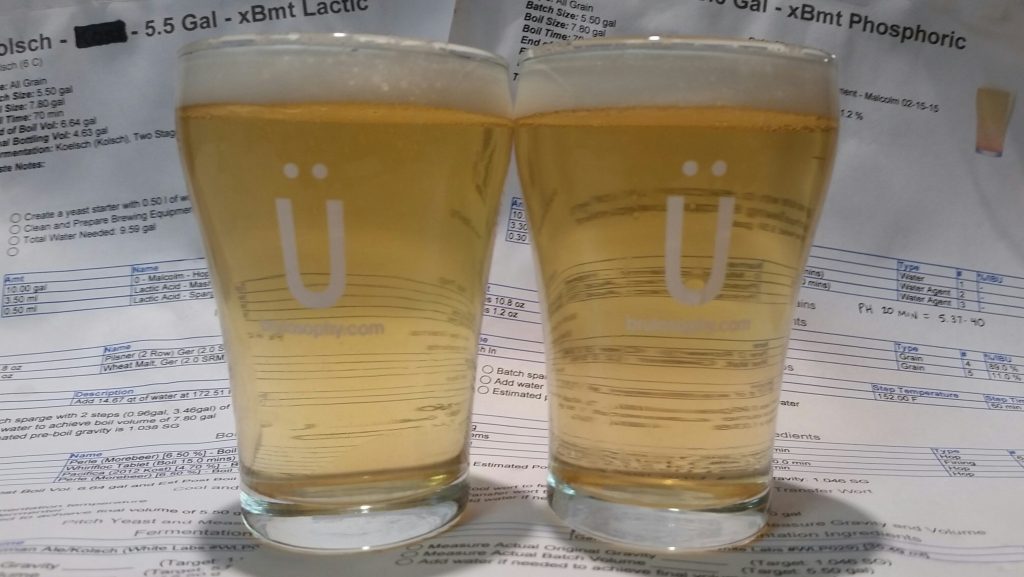

After a week in my keezer, they were clear, carbonated, and ready to serve!

| RESULTS |

A total of 23 people participated in this xBmt, all blind to the variable of investigation. Each taster was served 1 sample of the beer acidified with lactic acid and 2 samples of beer acidified with phosphoric acid in opaque cups then asked to identify the one that was different. In order to achieve statistical significance at this sample size, 12 tasters (p<0.05) would have had to accurately identify the odd-beer-out, though only 11 participants (p=0.11) were capable of doing so, suggesting this panel of participants were not able to reliably distinguish a beer made with lactic acid from one made with phosphoric acid.

But it sure was close. Because of this, and the fact others may choose to use a different standard to determine significance, I thought I’d share the post-triangle preference ratings of the 11 correct participants. In prudence, I caution anyone from imbuing this data with much meaning since the results did fail to reach significance. When asked which sample was preferred, 4 selected the beer acidified with phosphoric acid, 1 liked the sample acidified with lactic acid more, 1 reported they couldn’t detect a difference, and 5 had no preference despite noticing a difference.

My Impressions: I’ve tended to use phosphoric acid for pH adjustments since I always perceived a butter-like aroma from lactic acid itself and was concerned of it carrying over to the beer. This bias likely played a role in my perception of a similar buttery character in the beer made with lactic acid, despite the fact it went through a lengthy diacetyl rest. I was sure I’d be able to reliably pick the unique sample in “blind” triangle tests, yet I failed my first attempt, an indication they weren’t as different as I thought. However, in later trials, I was consistently able to detect the different beer, a task that became easier for me as the samples warmed. Were they strikingly different? No, but knowing what to look for and tasting both beers multiple times made the differences more obvious to me.

I trust the data from our panelists and believe prior research findings are valid, perhaps I am just swayed by my bias and slow to change. More experiments are needed for me to completely accept that there is no difference at least to my impression. Great, now I feel like a science denier.

| DISCUSSION |

It’s been said that the flavor threshold for lactate is approximately 300-400 ppm, which corresponds with Kai Troester’s experiment findings where he concluded it’s difficult to detect lactate at a level of 400 ppm or below. The results of this xBmt provide even further confirmation since the beer made with lactic acid contained approximately 433 ppm of lactate by my calculation (7.2 ml at 88% in 5.5 gal) and yet was not reliably distinguishable from the beer made with phosphoric acid. As such, it can be said with at least some degree of confidence that brewers can use either lactic or phosphoric acid without risk of impacting beer characteristics in an appreciable way.

Prior to this xBmt, I’d avoided using lactic acid primarily because every time I opened a bottle I was greeted with an intense buttery aroma, and the thought of that going into my beer made me cringe. Kai’s findings in conjunction with information gleaned from Martin Brungard regarding the potential positive impact lactate ions can have on beer certainly reduced my concern, the results of the present xBmt serving to push it down even further. I certainly look forward to ongoing investigation of this variable, perhaps using water with different levels of alkalinity, but as for me, I’ll no longer hesitate to use either lactic or phosphoric acid for pH adjustments.

One last note– some may view these results as being too close to imply anything meaningful, and that’s perfectly fine, use whatever standard you choose to interpret the findings. However, it’s important to remember that the amount of acid I used to hit my desired pH, while not terribly extreme, was pretty high given my intentional use of moderate alkalinity water. Using my normal 60/40 blend of distilled to tap water, the amount of acid required to hit the same pH is markedly lower, presumably making detection even more difficult.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

New Brülosophy Merch Available Now!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

42 thoughts on “exBEERiment | Water Chemistry: Phosphoric vs. Lactic Acid for Mash pH Adjustment In A Kölsch”

Where is your water report? How much alkalinity were you eliminating with the acid? Did you neutralize all of the alkalinity or just a portion of it? Enquiring minds want to know!

Hello John,

All good questions for sure.

I can upload my numbers when I get home but here is the rough ranges per memory.

Alkalinity (as CaCO3) was ~145 ppm. As you know, b/c you effectively taught me (lol), once recipe and water is considered, my RA (residual alkalinity) for this beer was ~85-90 ppm.

It would have only taken about 1ml of 88% lactic acid to get RA at 0, but pH would have been ~5,8, that is of course with no other mineral additions. I believe was at a VERY negative RA when done adding my acids. In the range of -300 RA.

From memory my water is:

56 Ca, 20 mg, 78 SO4, 67 Cl, Alk 145,

Food grade HCl might also be good. I’ve thought of trying that, but I’m pretty happy with phosphoric acid.

Out of curiosity, which water profile do you prefer for your Kölsch beers?

For kolsch-like beer, I use low TDS/ mineral content water. I rarely chase a specific “profile” and never try to recreate a region’s specific profile. I concern myself with a few things Ca, S04 to Cl ratio, and alkalinity. FWIW, I don’t consider my method to be the right way – it’s just my way.

I like to make sure Ca is ~ 50 ppm. Then I adjust SO4 to Cl ratio for the beer. For kolsh(y) beers I go balanced or slight higher on Cl. What I mean to imply is I do as little as possible. If it’s balanced – I leave it. If it leans twd Cl, I leave it.

Because I would normally want low total minerals yet adequate calcium I take my water into consideration.

My water is roughly 50-60 ppm Ca, 18-25 ppm Mg, SO4 ~ 78 ppm, Cl ~ 67 ppm, Alk ~ 145 ppm.

So, I dilute my water 50-60%. Let’s do 50% for this example. So all my numbers are now at half the above listed value. But that would take my Ca to < than I desire (~50 ppm). I add it back with CaCl in this case for THIS beer. Just a 1.2 mg addition of CaCl gets me to about 55 ppm Ca (this assumes a 5.5 gal batch). And after the additions I have 81 ppm Cl and 39 ppm SO4. That’s a bit heavy twd Cl but I leave it. The other option would be to add some CaS04 to change the S04 to Cl ration twd being more balanced but I just leave it. Less it more IMO. Now, if it were a bitter pilsner (German), a hoppy lager etc – I would consider adding CaSO4 instead of CaCl , but for a malt fwd Kolsch or Helles – I am ok with 2:1 Cl: SO4 I still have some RA - residual alkalinity, what left after the water’s hardness (Ca, Mg) and the malt’s buffering capacity is considered – and the RA is reduced by acid.

Interesting! What’s the impact of nosparging when it comes to that? My understanding of pH adjustment is that it helps mashing, so I’ve never really understood why sparge water should be adjusted. Maybe this article can be slightly improved by indicating what is the purpose of pH adjustment, and how it is expected to impact the final product. Cheers!

pH is important regardless of methods – BUT different brewing processes may requirement more monitoring or adjustment. If you use “no sparge” brewing methods and check your pH and it ok (5.2-5.5 at room temp) – then when you sparge you are not adding any more water so pH should remain in that range. However, if you are batching or fly sparging, you may need to add additional acid to counter act the water’s alkalinity. You took the water into consideration for the mash, set the pH – more or less – and then after the predetermined time, you add more water with more alkalinity. You have the potential to overcome the buffering ability of the mash and have your pH get higher than what may be desired.

I’m reading Gordon Strong’s ‘Brewing better beer’ at the moment and he states that sparge water pH is important as pH higher than 5.8 will strip tannins from your grain husks… Incidentally, he uses phosphoric acid rather than lactic.

In the book did Gordon state to adjust to a sparge water pH of 5.8 (many references site 5.6-6.0) or adjust so that mash pH doesn’t rise to above a certain value?

With most things I need to know WHY. He may have explained but just in case –

Reducing the alkalinity of the sparge water (by using acid), is a good practice and many resources state 5.8. This value typically correlates to an alkalinity of 20-50 (<50 ppm as CaCo3 is often recommended). If your mash was at proper pH, you haven't excessively sparged, and your sparge water has a low alkalinity the mash should have enough buffering capacity to prevent the total mash pH from rising to the point where tannins are more soluble.

I do an acid rest around 35C (95F) for an hour until my 8.1pH are down to 5.2-5.5. Tried phosphoric acid, lactic acid, 5.2 pH stabilizer and acid malt but must say that my best tasting lagers or pilsners are brewed with old school acid rest.

Then I’d continue performing the acid rests if I were you. You are getting the results you enjoy then you are winning at beer.

Have you ever run a blind side-by-side and put your potential for bias to the test? That too could be fun.

Hey Malcolm,

You posted the clarity picture, but I didn’t notice if you made a final determination on your earlier suggestion that “phosphoric acid adds flavor neutral phosphate that precipitates out a small amount of calcium, thus lowering the total calcium potential in the beer, which can have a negative impact on […] beer clarity.”

Were you able to pick out the clarity difference between the beers?

Ben,

Great question. I was not able to determine any difference. I am not saying there wasn’t one, just not perceivable to me at the times that I was looking and tasting.

Keep in my that I used gelatin and its use may have influenced the clarity aspect of the final product, though at no point of the process were any differences demonstrable [to me].

I did not calculate the degree to which Ca+ may have been removed. I believe appendix B of The Water Book (Palmer, Kaminski) have the resources to do so, perhaps any changes were too minor to matter (this beer, this recipe YMMV).

What was the final pH of the carbonated beers? Was there a noticeable difference in the phosphoric batch v. the lactic batch?

You calculated 433 ppm lactate, while I am only getting 367. Can you tell me what I’m doing differently/wrong?

=(7.2*1.206*0.88)/CONVERT(5.5,”gal”,”l”)*1000 <- Excel formula

7.2mL x 1.026 g/mL x 88 g lactic acid/100 g total x 1/20.8 L water x 1000 mg/1 g = 367 mg Lactic Acid/L water

Daniel,

Looks like you took 88% of the specific gravity while I thought the specific gravity of 88% lactic was 1.209 mg/L. I thought the SG of a 100% solution was even higher. I could be wrong as I’d need to look those both up at home.

Final pH:

Phosphoric Batch – 4.21

Lactic Batch – 4.34

Data sheet with spec grav of 88% lactic.

https://www.google.com/url?sa=t&source=web&rct=j&url=http://www.dogee.org/lab/chemicals/915.pdf&ved=0ahUKEwi47tib683MAhUCSD4KHcqVBB8QFggdMAE&usg=AFQjCNGYY8Ua-aAf-Dkn0LfTWtF-KkRGJQ

Maybe we’re saying the same thing since I agree that 88% lactic has a density of 1.209 (ref: http://www.sigmaaldrich.com/catalog/product/vetec/v800230?lang=en®ion=US)

So using the density 7.2 mL of 88% lactic weighs 8.7 grams

For every 1 gram of that material you only have .88 grams of lactic (the remainder being water), so you end up with 8.7 grams of solution containing only 7.7 grams of lactic

7.7 grams divide by 20.8 L and multiply by 1000 to convert from g to mg and you get 370 (give or take measurement errors)

Only being pedantic because I want to make sure I’m doing the conversions right and not screwing something up! Cool experiment and also interesting pH difference result.

Hey Daniel,

I’m not a chemist, only in my garage. I will have to research to see if I correctly performed the calc or not. If you know you are correct then by all means say so – I’m ok with that. Lol. I am willing to learn here. I took the methodology from AJ Delange and others on HBT, and then from a chem course study page.

FYI – pH were room temp (or close. I’ve over cooled a sample here and there and called it good). Final pH readings were degassed.

Hi, ive been wondering about trying different acids, ive always used citric acid for my ph adjustments along with the usual brewing salts. Anyone else use citric acid, or any negative

affects it may through?

cheers!

I helped a friend use some for a NE Style IPA. Bru’n Water as an option to use it. I felt it was a tad strong in it’s flavor contribution at the level he used it. I cannot give a good suggestion on use rate bc we feel his scale was FUBAR as the amount I suggested should not had been perceivable and he described the size of the “mound” of salt he used and I was shaking my head. I think ti has potential once it use it dialed in, if you desire that lemony citrus like tartness. Many places use it as a sourdough bread flavor enhancer and it’s also found in many sour candies – along with malic acid.

It would be interesting, although perhaps inconvenient, to measure the titratable acidity of both beers. Great work, Brother M!

I am actually set up to perform TA manual calcs (ie no autotitrator) but did not do such for this trial.

I have only been doing water/ph corrections for a few months now so I am just a child in this area of brewing. I have been using acid malt to lower the PH. I think the acid malt is lactic acid to change the PH. What is the thoughts on taste differences between the acid malt and just lactic acid? This exbeerament got me reading and it look as if the acid malt was done for the Germany purity laws. A few mils of liquid would be much easier.

Brad

There are good write ups on the subject of acid malt’s use on HBT (Home Brew Talk) and on Kai Troester’s page or via Weyermann.

Simply, if you like your results I’d keep using it.

But a quick and dirty version is:

It’s almost exactly the same. Some form of LAB (lactic acid producing bacteria) creates LA. For acid malt they either grow it on the malt or grow it in a bio reactor and then spray it on the malt. For the liquid acids they grow it and deliver it to us in liquid form at a known concentration.

The providers of Acid Malt (sauermaltz or acidulated malt) should provide equivalent weight of acid per unit weight of grain. It is typically listed as 1-2% acid by weight. So, a general rule of thumb is for every 1% of the grist, acid malt will reduce the pH of the mah by ~0.1 pH untis.

http://braukaiser.com/wiki/index.php?title=Mash_pH_control

http://www.homebrewtalk.com/showthread.php?t=198460

http://www.weyermann.de/downloads/pdf/Weyermann_TKW_Mash-pH_2010.pdf

FYI – apparently Weyermann actually “soaks” their pils malt in the acid solution vs spraying on. Moot but worth mentioning.

Thanks for the links. Do you think the acid malt adds any different flavor vs the lactic acid?

Broncosaurs,

Any answer I gave would be anecdotal and opinion. I’d also have to give the caveat that it would potentially depend on the source of the malt and the source of the lactic acid.

So maybe, kind of…depends! haha.

i’ve tried acetic acid(vinegar) once – not good..

would love to see mash pH experiment – hi (over 6pH) vs normal. i’ve been battling astringency issues with my light beers and i can suspect its to do with my alkaline water not letting my mash pH drop below 6. cheers

Hi, I’m just starting to dive into water a little bit more. I wonder if there’s a specific ph meter that you’d recommend from your experience. Thanks!

I use the one pictured and I believe if you click the picture it is linked to a site that offers it. I have had the Milwaukee pH56 for close to 7 years. I was going to replace it with the Milwaukee pH 102 but this damn thing just won’t break. I cannot justify the purchase. The first probe was replaced after ~2.5 years so I bought the replacement probe via Amazon, it has lasted nearly 3.5 years. When I bought the pH56 is was nearly $80 and the replacement probe was like $35. I love it. Relatively inexpensive, replaceable probe, 2 point calibration, small, and the whole unit stores easily in a small medicine bottle-like vessel full of pH 4.01 buffer for long term storage.

Perfect! Thanks so much.

How do you think allowing the triangle participants a fourth choice like “no appreciable difference” would effect the statistics?

Does not work with a triangle test. The fact that some people cannot tell and have to guess is accounted for in our statistical method. Some will guess and select one of the two beers that are the same, some may select the different beer by chance.

What was the hydrometer you used in the FG photo? Been looking for a good priced hydrometer kit that includes one with a good scale on FG.

Here Anthony!

Final Gravity Hydrometer

Not sure if you’ve answered this somewhere already, so apologies in advance if you have. I have a question regarding checking mash pH. I just got my first pH probe and plan on making pH adjustment a major focus for my mashes and sparges in the future. Do you have a specific procedure you use for quickly chilling your sample from the mash? Or do you just take readings at mash temp and then adjust those readings based on the temp? Since the wort should be at room temp for an accurate measurement and for the longevity of the probe, I plan on chilling. By the time the sample is chilled down, though, it seems like it will be far too late to actually make any further pH adjustments in the mash. Any recommendations/ thoughts on how you (or others) handle this step in the process would be much appreciated. Thanks!

I learned this from Martin Brungard from Bru’n Water. Keep a thick walled shot glass in the freezer and put your sample into the frosty glass. It will cool to room temperature a lot quicker.

Sounds like a good method. Martin is a sharp individual and I’ve learned a bunch from him.

I ALWAYS take pH readings at room temp.

To chill the ounce or so required for a sample, I place them in a large metal mixing bowl. It’s usually staged in a bucket of cold water and I use it for the multiple pH an gravity reading I take throughout my process.

The combo of the large surface area of the bowl, decent thermal conductivity, and large thermal mass of the water vs the tiny amt of the sample, results reaching sample temp in seconds.

Do you add the acid to the water before or after you add the grains?

Acid into mash.

Allah’la arandaki perdedir. O perdeyi ateşe at ki ardından Allah görünsün.