Author: Ray Found

IPA is one of the most popular styles of craft beer, one in which I’ve invested a lot of effort over the last year in my plight to develop my version of the perfect IPA. This is exactly what MACC IPA is to me, a recipe I’ve tweaked multiple times that I’m finally happy to call complete. When it comes to IPA, many interesting variables to test come to mind, but none more on the forefront than those that might bring greater understanding to one of the quintessential components of this delicious style: dry hopping.

We’ve explored dry hop quantities, dry hop length, double dry hopping, and the impact of pellet and whole cone in the dry hop, but we’ve yet to investigate the temperature at which hops are added to the fermented beer. It seems the most commonly practiced method involves adding the hops to the beer at fermentation temperature with many performing a cold crash a few days later. However, we recently heard from a reader who claimed to be getting great dry hop character despite adding the hops to the cold beer post-cold crashing. Huh. While I’ve heard of keg hopping, which involves leaving a charge of hops suspended in a cold keg while serving, I’d never given much thought to the temperature question. Until now.

| PURPOSE |

To evaluate the differences between 2 beers of the same exact recipe where one was dry hopped warm (76°F) and the other cold (36°F).

| METHOD |

As any regular reader of Brülosophy is perhaps aware, I’ve used my MACC IPA recipe in quite a few xBmts, I love this beer. Given the variable being investigated here, I thought it a perfect fit. Having pretty much settled on a final recipe, one that has scored well in BJCP-ranked competitions and is always well received by my hophead family and friends, I’m excited to announce it is the second recipe kit being released in collaboration with our friends at Love2Brew! For anyone looking for a drinkable and deliciously hop-forward IPA, I trust this kit will get you where you want to go, it’s available right now!

Failing to account for my lack of WLP090 San Diego Super Yeast, I decided to ferment this batch with Safale US-05, a benefit being I didn’t need to make a starter ahead of time. My brew day began by heating the strike water, during which I collected and milled my grains.

With the strike water to temp, I mashed in and set the timer to 1 hour, stirring a couple times throughout.

With the uneventful mash complete, I collected the first runnings, performed a quick batch sparge, then hit the flame under the kettle. The boil started off very boring, receiving nothing but a few drops of FermCap-S until the last 20 minutes when the first and only dose of boil hops was tossed in. At the conclusion of the boil, I added the large charge of flameout hops and allowed them to steep for 20 minutes before proceeding to quickly chill the wort.

I evenly split the wort between 2 carboys and placed them in my chamber to finishing chilling to my target fermentation temperature. The following morning, I rehydrated and pitched a pack of US-05 into each fermentor. Signs of fermentation were visible within hours and became quite vigorous the following day.

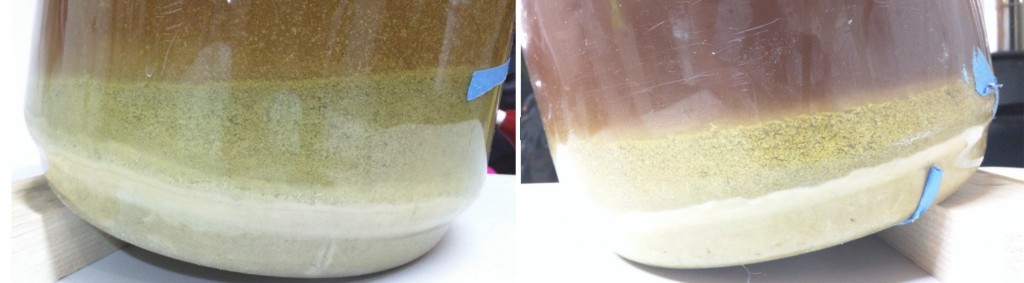

About a week later, both beers appearing finished fermenting and sitting at 1.013 SG, it was time for the fun to begin. One of the fermentors was removed from the fermentation chamber and allowed to sit at 74°F/23°C, while the other carboy was cold crashed to 34°F/1°C. Once the temperature of the cold crashed beer stabilized, identical portions of hops were added to both fermentors and they were left alone for 4 days. While I typically cold crash and fine with gelatin in primary a few days after adding the dry hops, in order to avoid introducing extraneous variables, I opted to keg both beers at the temperature they were dry hopped at, which meant fining would occur in the keg once both were cool. Oh, the sacrifices we make for beer science. The warm dry hopped beer was a complete headache to keg, with extensive hop matter floating about that clogged my siphon multiple times. Regardless of the results, I vow never to keg a dry hopped beer without first cold crashing again, such a pain. The fluffy nature of the trub at the bottom of the warm dry hopped batch increased my yield loss, resulting in about 3 quarts less total beer in the keg. Dammit!

Once packaged, both kegs were purged and hit with CO2 to seat the lids, then they were disconnected from the gas so as to avoid any carbonation differences due to beer temperature. Once the temperature of each keg was stable, I added gelatin to each then cranked up the CO2 to carbonate. By the following weekend, the gelatin had done its thing and the beers were looking great.

| RESULTS |

All told, 16 people participated in this xBmt including craft beer loving family, friends, and members of my homebrew club. Each taster was served two samples of the warm dry hopped beer and one sample of the cold dry hopped beer in opaque colored cups then asked to identify the odd-one-out. While 9 correct response (p<0.05) would be required to suggest a significant difference, a total of 10 tasters (p=0.007) correctly identified the different beer, suggesting these participants were reliably able to distinguish between beers dry hopped at drastically different temps.

Of the 10 correct respondents, 3 reported preferring the cool dry hopped beer, 5 said the liked the warm dry hopped beer better, and 2 had no clear preference despite noting the beers as being different.

Interestingly, 7 of the 10 correctly identified the beer of the two was dryhopped warm and which was dryhopped cool.

My Impressions: My personal experience was represented well by the tasting panel in that I was able to tell the beers apart with decent consistency, though it was by no means trivially easy. I noted greater aromatic intensity in the warm dry hopped beer with a more pungent fruity note. In fact, it was similar to the difference in aroma I notice when I pour myself a cold IPA and it warms over time. The flavor was a similar story, I thought the cold dry hopped beer was slightly smoother and less intensely hoppy, while the warm dry hopped beer exhibited a bit more hop bite or sharpness, though it didn’t come across as harsh.

I absolutely love this beer and have honed the recipe over the course of a year that included 8 batches, each with only minor adjustments. It could be my personal bias and preference for the familiar talking, but I preferred the warm dry hopped beer , I felt it possessed the sharp fruit punch of hops I enjoy so much. It smells and tastes like MACC IPA is supposed to smell and taste!

| DISCUSSION |

Frankly, I’ve no inclination to dry hop with the exact processes used on this batch again. Adding the dry hop charge to cold beer failed to extract enough of the really bright hop aroma I prefer, and while I felt the warm dry hopped batch was great, kegging prior to cold crashing was a pain in the ass. I’m inclined to continue dry hopping warm and cold crashing in the fermentor because it works well for me. But for whose process is different than mine, dry hopping cold is certainly a valid option, as that beer maintained totally adequate levels of aroma and flavor.

These results may not have motivated a change in my process, but it definitely got my gears turning. I wonder how dry hopping warm then immediately cooling the beer would impact the final product? And while I’ve no interest in performing it myself, I would like to know more about the impact of cold crashing when the dry hops are added at the same time and temperature. And the list continues to grow!

How do you dry hop? If you’ve messed around with different temps, timing, or otherwise, please share your experience in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

43 thoughts on “exBEERiment | Impact Dry Hop Temperature Has On An American IPA”

Great, pertinent experiment. I typically dry hop at fermentation temp using mesh bags, as I don’t have the capacity to cold crash. While this works very well for keeping hop particles out of the siphon and keg, my concern is that I get less exposure of the hops to the beer. Would be very interested in an experiment on loose vs. bagged dry hopping!

I’d probably bag too if I normally dry-hopped without a crash after. Someone on reddit linked me to this, that did note a significant difference with bags: http://hopsteiner.com/wp-content/uploads/2014/03/Dry-Hopping-A-Study-of-Various-Parameters.pdf

I suspect the difference is mainly the ability for the liquid to move/circulate around the surface area, so the larger the bag for a give amount of hops, I suspect the smaller your impact will be.

Just a hunch though.

I know I’m late to the party here, but thought it worth mentioning that an alternative is to add the dry hops directly to the carboy for max exposure, and slip the mesh bag over your racking cane (held it in place with a hose clamp) instead. That’s how I used to do it and it kept the hops out of my kegs. Cheers

Great read. Though I’ve always dry-hopped at ambient temperatures, it’s been done more out of convenience than anything. With this new info I now know to avoid any mistakes in the future and to let cooler beers warm up a bit before adding my hops so as to extract maximum aroma. Thanks!

I’ve started dryhopping in the keg at room temperature before carbing. I use a hop bag that I boil for 15 min or so with some stainless steel marbles and pull the bag after about 4 days. Have also stopped using gelatin in my ipas or any beer that I dry hop…not sure why it is…but they don’t seem as fresh or nearly the amount of aroma as a brew that I would use gelatin with. Perhaps a new exbeeriment?

I am also interested in this. I have read at some points that gelatine is bad for hop aroma and bottle conditioning but never experimented on this.

They ran that one a while back, they couldn’t distinguish a flavor or aroma difference.

https://brulosophy.com/2015/01/05/the-gelatin-effect-exbeeriment-results/

I’d be interested to see if a larger dry hop charge in the cold hopped beer was distinguishable from the warm dry hopped beer.

Are you thinking that I could increase the amount of dryhops to overcome the shortfall from temperature? Interesting thought.

This xBeerMnt intrigues me. I would have thought the opposite. Since temperature is high I would have thought that aroma might have left due to more CO2 leaving the fermenter.

Maybe one interesting variable to consider here is the time the beer was dryhopped. You might probably need more time for a chilled beer to integrate the flavour…

What do you think?

Interesting thoughts.

re: co2 offgassing and taking aroma – yes – but consider that that should have basically happened BEFORE the dryhops went in. co2 should have been basically at equilibrium point during dryhop. (lots of shoulds and in theory kind of thinking here, hahah)

re: Duration interesting idea – but yeah, it may be that you could extend the duration to overcome the shortfall. This test creates a baseline that we and others can kind of explore from.

These documents might be able to explain some of the results:

http://hopsteiner.com/wp-content/uploads/2014/03/Dry-Hopping-A-Study-of-Various-Parameters.pdf

http://ir.library.oregonstate.edu/xmlui/bitstream/handle/1957/34093/Wolfe_thesis.pdf

Especially the time factor, meaning how long you dryhop seems to be important in correlation with the temperature seems to matter. The warmer the less long you need to dryhop. According to the papers above, more than one week of dryhopping doesn’t seem to make sense.

A lot of options for further experiments 😉

This.

As a professional brewer, based on the results of this thesis we’ve been playing with dryhopping warm and under pressure, recirculating with a pump for 24 hours if we can swing it, or just 12 hours overnight then letting it settle a day or so before crashing and fining as normal. We’ve noticed improved effectiveness in a fraction of the time (we used to just drop the dry hops in through the top for 3-4 days at 68, bubbling up the cone once or twice with co2). A larger regional brewer once told me with a hop torpedo-type device (no, not Sierra Nevada…) they can dryhop a 200bbl batch in about 4 hours. So for future tests, maybe one batch where the carboy gets swirled manually every hour or two (or a pump is rigged) for a day vs one where the hops just sit a couple days.

Also, I heard a talk by a brewer from New Belgium at the last CBC who talked about what they noticed when they dryhopped before and after the beer was centrifuged. The biotransformation on the dry hop chemicals that the yeast can get into can really make it a totally different beer.

Interesting. I’ve seen references to British breweries (at least in the 50s) having conditioning tanks with propellers to circulate the beer including dry hops. Then bottling when condition is reached (in matter of a day or two rather than weeks).

I just toss the hops in 3-4 days before I cold crash.

I usually dry-hop in the keg…my procedure varies a tiny bit from batch to batch (depending on how much of a hurry I am in to get the beer on tap), but the overall procedure is the same:

1) Transfer beer to keg;

2) Immediately add one or two hop sacks (depending on volume of hops) to keg, weighted with steel washers and suspended in the keg with string;

3) Close up keg, purge headspace with CO2, and begin carbonating at ambient temperature (this time of year, 55 to 60 degrees in my garage).

4) Once I’m ready to serve (sometimes a matter of a few days, sometimes a week or more), I chill to serving temperatures and tap the keg. The hops stay in the keg.

I have found that it generally takes a week or two to get to optimum hop aroma and flavor; if I chill it too soon, it takes much longer! I made that mistake with a recent IPA, which went into the keezer after about 3 days of carbonating and dry-hopping; it took an additional 7-10 days to get up to decent hop aroma/flavor. Lesson learned: dry-hopping takes some patience. For the last half of the keg, though–wow! An excellent beer.

Just reading this in 2018. This just happened to me. Keg hopped and dropped to 40F immediately. Basically no hop flavor or aroma. I am going to try and raise the temp to 50F for a couple days to see what happens. Otherwise beer is nice, light and crush-able. I just need some more aroma and flavor.

After fermentation is complete I cold crash primary, fine with gelatin and then transfer to a co2 purged keg that has my dry hops in a stainless steel dry hopper for corny keg and I leave this at room temperatures for 5 days. Next I put the keg in the kegerator (40 or so degrees) and set the psi for force carbing, leaving the dry hoppers in the keg. I serve this way and never take the dry hoppers out. I have also done this experiment and have had very similar outcomes to what you have found. I’ve been doing this method for about a year and I am really enjoying the results. If you’re wondering, clearity is affected but only when using pellets, as they can get through the dry hopper screen. However, this is only for the first few pints.

Generally out of laziness and a desire to capture as much clean, clear finished beer as possible I dry hop in primary at ~70ºF, cold crash, fine w/ gelatin, then transfer to keg. That gets me a nice compact cake of trub and hops that I can easily rack off of.

Having tried it both ways, I’ve come to prefer cold dry hopping. I think that fact that there seems to be a difference is an opportunity for people to try both and decide for themselves. FWIW, I have heard that a test at SS Steiner about a year ago found a distinct preference for cold dry hopping, but I don’t know a lot more about it than that.

What do you like better about the colder dryhopped beer? The one panelist in my group that preferred that, is admittedly not a big IPA fan. I also can’t help but wonder if this would be something very hop-variety dependent, and individual – for example, I am thinking that personally I could see liking hops like chinook, centennial, CTZ, etc… dryhopped cool, while the fruity/bright hops like Citra and Mosaic I’d prefer warm.

Do you extend the time or increase the amount of dryhops to try and overcome any potential intensity shortfalls?

I know of a couple of beer (I’ve even brewed clones ofthese beers) that are dryhopped twice. once cwarm then cold.

Charge 1 is dryhopped 7 days prior, and left 3 days, then cold crashed, and a second dose is added at crashed temps for an additiona l2-3 days, to givewhatthe brewery have called a layering of hop aroma.

Epic Pale Ale if you haven’t tried it, would definitely be interested in a similar exbeeriment with this type of process.

it does appearto have an effect based o nthe above, given the slightly different aromatics.

I have also played with hopping at various temps. (bearing in mind it Deg Celcius)

3 dryhops in a pale ale\dryhops 1 – 20 deg C 2 days

temp is dropped to 15/16 and dryhopped with the same amount again and left for 2 days, then cold crashed to 1 deg C and dryhopped again with same amounts.

Amarillo/simcoe 14/15gof each(0.5oz of each) for 2 days at a atime.

with good results, it certainly came out different to other dryhopped beers.

Its very funny that every brewer I know have their own version of a Quad Hopped IPA. Mine I actually call it Quad Hopper IPA! I use this…

Centennial [10.0%] – Boil 60 min

Simcoe [13.0%] – Boil 60 min

Amarillo Gold [8.5%] – Steep 10 min

Cascade [5.5%] – Steep 10 min

Centennial [10.0%] – Boil 60 min

I also have done both cold and warm dry hopping. I find the warm does work heaps better however its harder to clear afterwards!

I would have loved a 3rd element to this experiment, with a beer set half way in between the two temperatures, e.g. 53F/12C.

Hi, I’m testing this very thing right now with a Double IPA heavily dosed with Citra. I’m dry-hopping slightly cooler than my fermentation range at around 55F, will see how this affects the brew.

Good read. It made me think about a few things though. Is 76 degrees too warm and maybe some of the fruity notes you picked up came from the warmer temperature? You noted a FG of 1.013 in both, before dry hopping. Maybe the warmer temp kicked up the yeast a bit more? Also, would this exbeeriment been better suited on a style not so hop aggressive? Again, great read. Made you really think about how we all do our dry hops and maybe causing us all to switch it up next time to suit our tastes.

I tend to dry-hop my IPAs at fermentation temps (66-68º F) and my saisons at warmer temps (75-78º). Both typically get cold-crashed and fined before I bottle. I have noticed that the saisons get a lot of hop aroma, even though I typically use less hops than the IPAs. Sounds like that’s not a coincidence.

By coincidence I tried to dry hop in the carboy, and then while still warm, push using CO2 through a racking cane into a keg filled with more hops in a bag. Clogged up so many times I gave up. Wondering how the author of this was finally able to get the job done.

I will cold crash and then try again.

Try first wort hopping and see how it work out in your IPA 🙂

I recently read about some brewers who add dry hopping when the fermentation is 70% done, and that the interaction with yeast and dry hops create new aromas. I think that could be in interesting test to do as well: Adding hops at fermentation temp at 70% completion vs Adding hops at fermentation temp after completion.

Personally I tend to cold cold crash, then transfer to a CO2 purged keg with the hops already in it. I leave it there for 4 days, transfer to a new purged keg where I add gelatin and serve.

I recently started dry hopping in the keg after the beer was chilled. It was initially an attempt to add more hop flavor to a lackluster pale ale. I put an ounce of Amarillo hops in a hop bag and suspended it from the keg lid with string. After one day it was a big improvement and very noticeable. I left it in the keg for a week or more and then removed the bag.

I did the same last week for an American Amber. I dry hopped the keg with an ounce of centennial hops for a week. Excellent results. The hop flavor seems to me a little less bitter and more mellow.

Being able to tweek beers that have already been kegged has been a great tool for me.

What have you guys done to maximize your the longevity of hop flavor? My ipa is losing a lot of character after a few weeks

Add a hop tea added halfway through fermentation is my favorite way of “dry” hopping – most dry hopping is too harsh and is overpowering. Hops added after fermentation especially so.

Doddybrewer, this is an interesting comment that you’ve made. Are you saying that when you add hops during fermentation the character is significantly different from adding hops after fermentation is complete, such as in a secondary or in the keg? I have been thinking about this topic, as I’d like to get more of the “overpowering” character of hops into my beers. I switched to dry hopping in primary a few months ago, and I like the beers, but they seem to fade a lot faster than dry hopping in secondary. I’m wondering if it is just the yeast pulling more of the hops flavor out of the beer or if there is something else going on.

There is definitely something different going on when you add hops during fermentation as opposed to beer in cask. It is difficult to say why but the much greater amount of actively fermenting yeast is the obvious candidate. I like to quickly scald the hops in a hop tea and add quickly to the fermenter – I think this gives the best result – for my taste. Not sure that its as simple as the hops indiscriminately pulling flavour out – I think more complicated than that.

Hi. This is not related to the main topic. I hope you can help me.

I recently borrowed a Barley Crusher just like yours. However, I´d like to have a bit finer crush. How can you make it tighter ?.

Regards

Loosen screws and turn knobs to close the gap.

Brew Dog’s DIY-Dog Recipe’s state that they have found 14C to be they’re optimum dry hop temp for max flavour and aroma

I always dry hop warm and seldom every cold crash in general. After reading a few of your articles and experiments I plan on splitting the dry hopping time in half where each portion will be dedicated to warm dry hopping and cold dry hopping respectively. I believe that should achieve a balance between an intense aroma and smoothed off bitterness. I find that first wort hops also help round off the bitter intensity in a brew.

i learned quickly to cold crash after dry hopping (especially when using whole hops). does hop aroma permeate into the beer during cold crashing? such as when the hop matter floating drops to bottom and/or while rest on the bottom. do you add the amount of time required for cold crashing into your dry hopping schedule?

15gl batches: I’ve tried DH at 65F, 68, 70, 73 in FV after 1st trub dump-CO2 headspace then dump pellets in 1lb to 2lb-rouse FV daily 4days to 7days. Based on last 6 batches made use of cryo hops at higher temp has yielded the most aroma in my glass over 1 month

I’d like to see one done where one batch gets cold crashed and then has the hops added cold, and the other gets the hops added warm and then gets cold crashed. The purpose being to identify what the suckback effects are in this scenario, where both beers are dry hopped cold (mostly). Does the O2 sucked in to the first beer still oxidize the hops?

I dry hop in the fermenter 4 – 5 days before kegging day.

Another interesting experiment/discussion. When I first dry hopped, I either used hop bags or just dumped them into the secondary. I cold crashed following either of these two methods. I don’t dry hop much of what I brew, but I eventually decided to try some of the stainless steel mesh cylinders that will fit into a keg. I noticed vast improvements to my hop aromas and flavors, part of which might be to using an increased amount of hops (as it is easy to do so with these cylinders). It can keep a lot of the hop residue inside the cylinder. Sometimes I cold crash, if I want a clear beer…sometimes I just pull out the cylinder. I have also “recharged” a keg that has been in the kegerator by dropping in a cylinder with some fresh hops and just leaving it in the keg.