Author: Marshall Schott

For those of us who prefer our beer crystal clear and don’t mind dosing that which we will soon swill with nasty sounding animal stuffs, gelatin is a remarkably effective solution. In the time since completing the first gelatin xBmt, I’ve brewed nary a batch without this fantastic fining agent, and I’ve absolutely no regrets, my beers have been beautifully bright with all the hop character I expect. While the procedure I’ve settled on has worked really well, a chat I had with another brewer I trust immensely got me thinking if it is the only effective way or if perhaps certain tweaks would simplify, maybe even improve, the process. Of the few xBmt ideas that stemmed from this conversation, the one I was most curious about had to do with whether gelatin requires hydration prior to being added to the beer. A sure sign of my laziness since my current gelatin process requires all of 3 minutes, I was excited to see if my beer would achieve a similar level of clarity if the gelatin was sprinkled onto the chilled beer dry, as well as whether it would create a distinguishable difference.

| PURPOSE |

To evaluate the impact fining with gelatin added to the beer dry (not hydrated) compared to the same beer fined with hydrated gelatin.

| METHODS |

Having never fermented a beer with WY1450 Denny’s Favorite 50 yeast and hearing many good things about it, I bought a pack and thought it perfect for use in this xBmt, as my understanding is it isn’t known for clearing very quickly.

American Pale Ale

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 11 gal | 60 min | 42.7 IBUs | 5.6 SRM | 1.052 | 1.011 | 5.4 % |

| Actuals | 1.052 | 1.01 | 5.5 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Brewer's Malt, 2-Row, Premium (Great Western) | 19 lbs | 87.86 |

| Munich 10L (Gambrinus) | 1.625 lbs | 7.51 |

| Honey Malt (Gambrinus) | 1 lbs | 4.62 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 20 g | 60 min | First Wort | Pellet | 11.2 |

| Columbus/Tomahawk/Zeus (CTZ) | 20 g | 25 min | Boil | Pellet | 13.1 |

| Columbus/Tomahawk/Zeus (CTZ) | 20 g | 15 min | Boil | Pellet | 13.1 |

| Columbus/Tomahawk/Zeus (CTZ) | 30 g | 1 min | Boil | Pellet | 13.1 |

| Centennial | 20 g | 1 min | Boil | Pellet | 9.9 |

| Apollo | 15 g | 1 min | Boil | Pellet | 18 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Denny's Favorite (1450) | Wyeast Labs | 75% | 60°F - 70°F |

Download

| Download this recipe's BeerXML file |

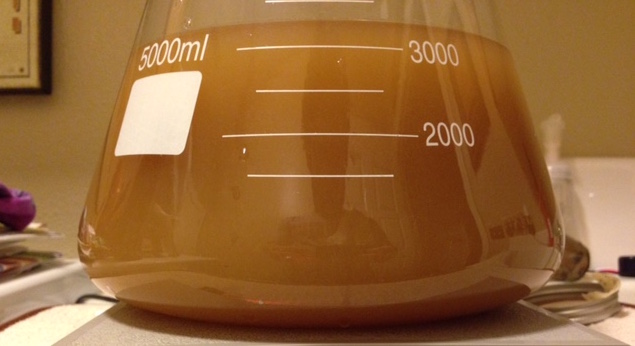

I produced an appropriately sized starter to split between 2 carboys a couple days before brewing, overbuilding by just enough to save some for future use.

I gathered the required volume of water, adjusted the mineral profile, and milled my grain the evening prior to brew day.

Early the following morning, I awoke and got the flame going under my kettle full of strike water.

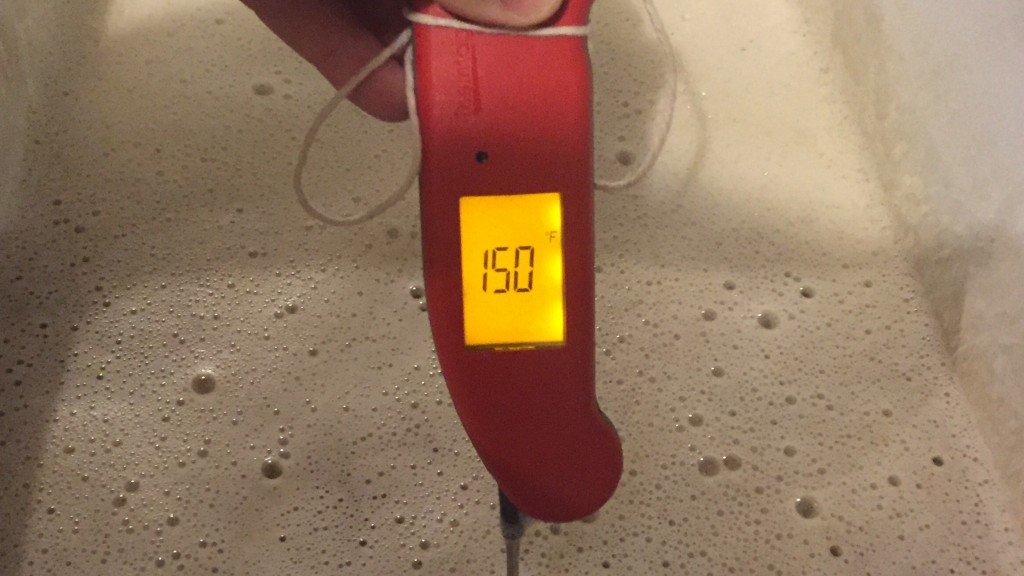

Thanks to my powerful burners and BeerSmith, I was mashed in and sitting at my target temp not even 20 minutes later.

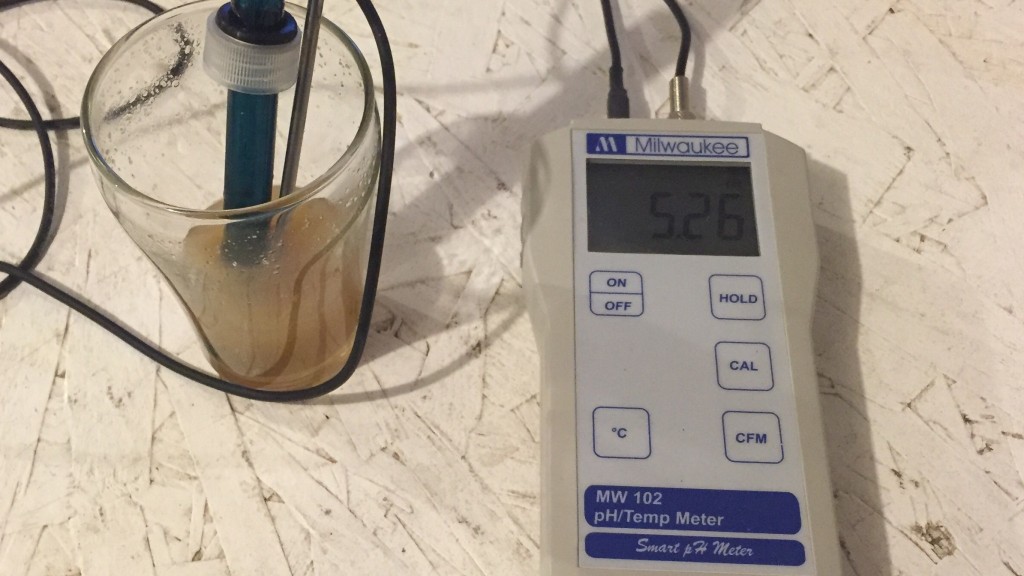

I took a pH reading 10 minutes into the mash ensuring things were where I intended.

Following a 45 minute saccharification rest, I collected the first runnings, performed a quick batch sparge, then added the second runnings to the kettle and brought the wort to a boil, during which hops were added as stated in the recipe. With the boil complete, I quickly chilled the wort to 80˚F/27˚C (warm groundwater), split it between two 6 gallon PET carboys, then placed them in my temp controlled chamber to finish chilling. I returned a few hours later to discover both worts had stabilized at my target fermentation temperature of 66˚F/19˚C, the yeast starter was evenly split and pitched into each batch.

Fermentation happened.

A week post-pitch, both beers appeared to be finished, which 2 hydrometer measurements over 2 days confirmed. I crashed the beers for 12 hours before introducing the variable of interest, the beer was at 45˚F/7˚C.

Both batches received the same amount of gelatin, 1/2 tsp, only 1 was rehydrated in 1/4 cup of water then heated while the other was added directly to the beer without being hydrated. The following day, just over 30 hours later, it was time to get the beers kegged.

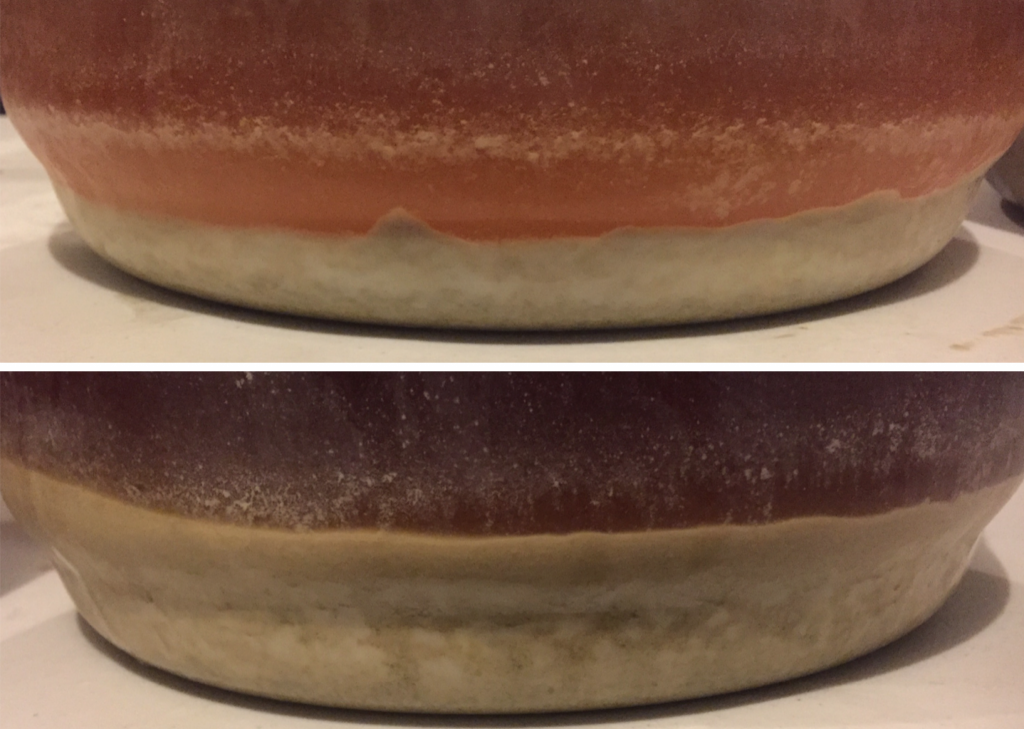

The trub on each appeared slightly different, the hydrated batch looking like what I’d come to expect with a thicker, more dense cake.

The filled kegs were placed in my keezer and hit with 45 psi of CO2 for about 18 hours, after which they were purged and set to my preferred serving pressure of 12 psi. Five days later, differences were clearly apparent.

Out of curiosity, I took another comparative picture 2 weeks later, once the data had already been collected.

Looked about the same as before. Would this difference in appearance effect tasters’ perceptions?

| RESULTS |

A total of 18 BJCP judges, experienced homebrewers, and craft beer drinkers evaluated these beers, of which 10 (p<0.05) would have been required to accurately detect the odd-beer-out in the triangle test to imply statistical significance. Each participant was blindly served 2 samples of the dry batch and 1 sample of the hydrated batch in different colored opaque cups then asked to identify the one that was different. A mere 3 tasters (p=0.933) made the accurate choice, meaning 16 chose one of the other samples, indicating this panel of tasters was not reliably able to distinguish a beer fined with dry gelatin from the same beer fined with hydrated gelatin based on flavor, aroma, and mouthfeel.

For fun, following each tasting session, I poured the remaining sample beers into clear glasses and asked each participant to identify which one was different. Not surprisingly, every single person got it right, and most correctly identified the clearer beer as being the one fined with hydrated gelatin.

My Impressions: Given my drinking and beer evaluation history, in addition to my intimate engagement with this xBmt from start to finish, I thought I might stand a chance at distinguishing them. In multiple attempts, I’d guess 6 or more, I was right twice, and I’d be lying if I said those weren’t total guesses. To me, these beers tasted and smelled exactly the same, despite the obvious disparity in clarity. As for the beer, I’m not really sure what to think. Not that it was a dumper, I’m still working through both kegs, it just didn’t turn out how I expected, which I can only assume is a function of the yeast, as I’ve made similar recipes using WLP090 San Diego Super Yeast that didn’t have the earthiness and subtle spice character this beer did. Will I be using WY1450 again? Likely not for hoppy Pale Ale, though I look forward to trying it out in a Brown Ale at some point!

| DISCUSSION |

Assuming the dry gelatin had no real impact on the beer, truly just an assumption at this point, this xBmt might be viewed as a repeat of the first gelatin xBmt, which the results appear to corroborate– fining with gelatin does not seem to produce a distinguishable difference in beer character. Of course, that’s a terrifyingly bold claim, one I won’t be ready to make until we’ve performed more xBmts to flesh this shit out. Perhaps the most poignant thing one can glean from these results, something I’ve absolutely no qualms with, is that gelatin’s clarifying power kicks ass!

If you use or have used a different method for making your beer clear, whether with gelatin or something else, please share your experience in the comments section below.

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

43 thoughts on “exBEERiment | The Gelatin Effect: Dry vs. Hydrated In An American Pale Ale”

I don’t cold crash. As I wait for my syphon to do the work I get the gelatin mixture ready. Half a teaspoon per keg and a small amount of water and about 30 seconds in the microwave, until its all dissolved. I put the warm beer with gelatin in the keg fridge and put the gas to it. A couple days later I have really clear beer. I’m wondering if the cold crash is necessary. Maybe I’m missing something?

Great job on this site! I love reading new posts.

The temp of the beer when the gelatin is added is definitely on the xBmt list 🙂

Awesome! Thanks!

I tried using gelatin once and did not have good results. I racked the beer to my keg added the hydrated gelatin and tossed it in the kegerator. From what I remember it did clear but had a side effect of dirty strings of gelatin in the beer. It only happened if the keg was sitting between beers for a while and usually on the second pour.

The second thing was cleaning the keg after it had the gelatin stuck on the walls of the keg that had to be cleaned off.

From then on I have only used irish moss since i can just toss it in to the boil but I will try gelatin again when I get a fermentation chamber.

that will be interesting. I add the gelatine at the start of the crash, and walk away from it, done in the primary conical fermentor, so can purge out the solids before transferring to keg. no troubles with clarity.

Why are you putting the gelatin into the carboy? I cold crash, then transfer to a keg, and then pour the prepared gelatin into the keg prior to pressurizing. This saves me from having to wait another 24 hours. My beer is clear after dumping the first pint. I’m willing to wager that it’s as clear as yours. ???? (Perhaps another experiment if you don’t think so) Prost! Thanks for all the great articles. I love your site.

Just a preference thing, I’ve done it both ways and simply prefer fining in the carboy, takes no more/less time in my experience. I have friends who fine in the keg who produce super clear beer too.

I used to fine in the keg, but there was just *so much trub* that collected in my kegs. It’s not so much a problem if you never move your kegs, but if you even have to gently lean the keg you’ll get another pint or two of crud to get through.

Simple enough to just wait one more day and keg the “clean” beer.

I don’t know, maybe I’m just lucky *KNOCK ON WOOD* but I’ve found a simple cold crash yields the most clear beer. I’ve tried hydrated gelatin a few times, and each time I was left with gelatin globules that I couldn’t avoid siphoning into my bottling bucket or keg. I’ve tried Clarity Ferm too, and that didn’t leave any particulate behind but it was no better than just crashing. I always use Whirfloc tablets but I think that’s pretty much standard for any home brewer. I also pretty much use Safale S-04 dry yeast exclusively so maybe that has something to do with it.

I apologize if you’ve answered this elsewhere: Will you do a comparison between whirllfloc and gelatin? I know you’ve done one with irish moss. I wasn’t sure if you do another with a different product.

We’ve got a few fining xBmts on the list, I’m sure we’ll get to some with Whirlfloc at some point!

Whirlfloc and gelatin are are also used at different times, kettle vs fermentor or “brite tank” and not necessarily targeting the same clouding agents,

I would not think that gelatin would work dry into the cold beer. It has to have that “warm up” for it to work properly doesn’t it? Just like on the package to make Jell-O……. boiled water mixed with cold water then refrigerate.

Had to test it out 🙂

Do you find a gelatin has any impact on yeast slurry? I like to collect it and use it few times.

Great job with this site!

I’ve only ever repitched slurry with gelatin in it, hasn’t been an issue.

Great stuff as usual. Would love to see a comparison between gelatin and filtering.

Gotta get a filter, but once I do, it’s on!

Interesting experiment! Do you rehydrate the gelatin, for some time, before heating?

Nope, I blend the gelatin with cool water, nuke it for a couple 15 second bursts, then dump it in the carboy. Easy peezy.

Is there a reason you only cold crash to 45˚F? I tried using gelatin for the first time using your same method (microwave to 145˚F), only difference being that I tossed my gelatin mixture straight into the keg that was already at serving temp(approx. 34˚F). The beer is still very cloudy after multiple pints.

I crash to 30F but add the gelatin when the beer is below 50F.

I used to cold crash down to 34F, wait a couple of days, and transfer to the keg and add gelatin at that point in time. I had various results with respect to clarity. Some beers never fully cleared at all, some took a day to clear while others took their sweet time (dropping clean naturally I thought). I tried your method twice now with two different beers and they were both crystal clear going into the keg. Add the gelatin at 50F while cold crashing, wait a day or two and keg. That seems to work really well now for me. Of course, I only have the two data points. 🙂

How about gelatin with a Hefeweizen which is supposed to be cloudy per style? Wonder if it affects the flavor or perceived flavor by those that recognize Hefe is supposed to be cloudy?

Kristalweiss!

Gelatin versus Biofine Clear. That’d be interesting.

I’ve used gelatin (1tsp per 1/4 cup for 5 gal) for many years, and while it works — and works well — it seems (to me, at least) that 2oz Biofine Clear for 5 gal works much faster (12 hours versus 48 hours).

Interested to see if this might be on your experiment list …?

I can get clear beer in as little as 12 hours with gelatin, but you better believe we have more comparative xBmts on the list!

Hello! I just found your site yesterday and have found it extremely interesting reading through your exBEERiments! It’s great how relevant the topics are!

Anyway, I just wanted to mention something curious that I found just last night regarding gelatin and was wondering if you’ve found the same:

I’ve used gelatin twice, hydrated it in both instances, but in both instances I’ve had very unsatisfying results. Maybe the beer got slightly clearer, but nothing more than that. I think I may have found the solution, though. I believe both times I used gelatin I had used it in kegs that were not connected to CO2. They were just sitting, pressurized slightly for taking samples, but disconnected. 2 nights ago I noticed the pressure in the keg I used gelatin in was getting low so I connected it to CO2 and took a sample. I noticed the beer was very cloudy as I took a sample from it after connecting it. The next night I took a sample: crystal-clear beer.

My quesiton is this: do you think pressurizing the keg has anything to do with gelatin doing its work? I was very surprised to find that it seemed to have had a profound effect since I would be very surprised if I just happened to connect the CO2 just before the day that the beer happened to clear.

I’d like to hear your thoughts!

Based on my experience, I don’t believe pressure as much if any impact on the clarifying properties of gelatin, as the my beers are usually very clear at the time of kegging. Perhaps I’m missing something, but my guess would be your first sample was hazy because more particulate had fallen to the bottom of the keg, while the second sample was clearer due to having pulled that muck from the bottom the night before.

I gel in kegs but I believe many people gel in primary or secondary – which would obviously not have cover pressure.

You guys bring up good points. I read your articles, but forgot that you add it to the fermentation vessel. Darn, I thought I’d figured out my gelatin problem.

Either way, I wonder why it happened so suddenly since I dosed it with gelatin 3 weeks prior with very poor results before then. Perhaps going forward I’ll try it before kegging and see if I get better results. Thanks for your replies!

I assume its just a case of popping the lid open on the FV and pouring in the hydrated gelatine mixture? No need to stir or anything?

(Interesting article as always!)

That’s it!

Hi Marshall. Do you use gelatin in your wheat beers also?

Wheat beers? ????

I would if I made the style, yes.

Sorry. I’m brewing one weissbier with 60% of malted wheat.

Is totally fine that!

Was all this haze attributable too chill haze or just your regular haze-haze?

Have you ever done an exbeeriment in which the wort is cold crashed prior to pitching yeast then raised to pitching temp? I’ve been curious of this lately but haven’t had a chance to try it yet.

Cold crashed? So pitch the yeast when the wort is around 32F then let it rise to ferm temp? We’ve done some pitch temp xBmts, but nothing that extreme.

Actually I mean crash after boil to 32F, raise to pitching temp (60F-ish), then pitch and proceed with fermentation. Essentially, changing the timing of cold crash to pre-fermentation to drop out some of the suspended solids before fermenting.

I can’t imagine that would work as if I look at my carboy when fermentation is happening the solids in there are swirling around like crazy.

It sounds like this would be a great opportunity to brew a large batch (~20 gallons) and test each method side-by-side. Hydrated, Not Hydrated, Biofine clear, etc. Maybe you couldn’t perform a triangle test, but qualitatively it would be very interesting if done on the exact same beer. That might help us choose a single method to use, to understand the differences.

Keep up the great work! Love the show!