Author: Marshall Schott

I’m sort of obsessed with efficiency. Not necessarily of the mash or brewhouse variety, what I’m referring to is time, tasks, and ease: the efficiency of process! In the years I’ve been making beer at home, I’ve discovered/developed a few ways to make brewing more convenient, allowing me to brew more beer more often!

I did not develop all of the following ideas, many are techniques others who are much more clever than me have come up with that I’ve adopted to make brewing easier. The purpose of this post is to spark some ideas, not advocate for any of these tips as being the best or only way. With that in mind, let’s get to it!

Pressure Can Starter Wort

About a year ago, I read Drew Beechum’s killer how-to on pressure canning starter wort then immediately went out and bought a large pressure cooker. In a matter of a couple hours, I was able to whip up 14 quarts of 1.040 OG starter wort, which would sit on a shelf in my garage awaiting use. When it came time to make a starter, all I’d do is pour however much wort my preferred calculator said I needed into a sanitized flask and pitch the yeast, it couldn’t be much simpler. I recently read that Mike Tonsmeier of The Mad Fermentationist uses pressure canned wort to wrangle wild yeast and bugs for experiments, which is badass! I realized a caveat to this method is that it seems to work best for folks who brew less often than me– at 4+ batches per month, often using lager or hybrid yeasts, and overbuilding starters for yeast harvesting, I was blowing through 8-10 quarts for every brew day. However, I still view it as being a very effective way for a majority of homebrewers to shave some time from their brewing preparation. If pressure canning isn’t for you…

went out and bought a large pressure cooker. In a matter of a couple hours, I was able to whip up 14 quarts of 1.040 OG starter wort, which would sit on a shelf in my garage awaiting use. When it came time to make a starter, all I’d do is pour however much wort my preferred calculator said I needed into a sanitized flask and pitch the yeast, it couldn’t be much simpler. I recently read that Mike Tonsmeier of The Mad Fermentationist uses pressure canned wort to wrangle wild yeast and bugs for experiments, which is badass! I realized a caveat to this method is that it seems to work best for folks who brew less often than me– at 4+ batches per month, often using lager or hybrid yeasts, and overbuilding starters for yeast harvesting, I was blowing through 8-10 quarts for every brew day. However, I still view it as being a very effective way for a majority of homebrewers to shave some time from their brewing preparation. If pressure canning isn’t for you…

Boil Starter Wort for Less Time

After posting my yeast starter how-to, I received a message from a dude who suggested I try making a no-boil starter, just mix DME with hot water in a sanitized flask, chill, then pitch yeast. While I have yet muster the courage to try this (let me know if you do), I have started boiling my starter wort for only a couple minutes before chilling and pitching, it has worked great for well over 20 starters! I definitely have plans to try the no-boil technique at some point… later.

Prepare the Day Before

It feels so good to wake up knowing everything is ready and waiting to be used to make beer, all I’ve to do is throw on some old clothes (optional), walk to the garage, and get the fire going under my kettle. The evening prior to every brew day, I gather all of my water, mill grains, pull out my brew day tchotchkes (whisk, refractometer, spoon, hop scale, etc.), and set up my mash tuns. The next morning, I’m usually

throw on some old clothes (optional), walk to the garage, and get the fire going under my kettle. The evening prior to every brew day, I gather all of my water, mill grains, pull out my brew day tchotchkes (whisk, refractometer, spoon, hop scale, etc.), and set up my mash tuns. The next morning, I’m usually  mashing in within 20 minutes, cup of coffee in hand. Even for those who brew later in the day, your milled grains won’t stale in 24 hours, especially if you keep them in a fairly airtight container (I use buckets with gamma lids). This simple change in my process has contributed greatly to making brewing a more relaxing and enjoyable activity.

mashing in within 20 minutes, cup of coffee in hand. Even for those who brew later in the day, your milled grains won’t stale in 24 hours, especially if you keep them in a fairly airtight container (I use buckets with gamma lids). This simple change in my process has contributed greatly to making brewing a more relaxing and enjoyable activity.

No-Sparge

I’ve started utilizing the no-sparge method nearly every time I make a 5 gallon batch of beer. If I had MLTs large enough to fit the grains and brewing liquor required for bigger batches, I’d use it there too, it’s so incredibly convenient. Brew In A Bag is usually categorized as a no-sparge approach, though some folks do rinse their grains following the mash… I don’t. The beauty of no-sparge methods is that you get to skip heating sparge liquor and collecting a second runoff, which for me means a 15-20 minute reduction in time. Sweet! The only consideration is a slight hit to your efficiency- I get about 75% with no sparge, 3% lower than when I batch sparge, which is negligible in my book. If your kettle isn’t large enough to fit all of your brewing liquor, that’s fine, start mashing with whatever amount will fit, then heat the remaining portion to about 175°F and add it with 10-15 minutes left in the mash. Bada-bing, bada-boom.

Reduce Mash Length

It’s true that the longer grains remain in the mash at saccharification temps, the more conversion occurs. But not much, at least after the 30 minute mark. In my xBmt comparing 60 minute and 30 minute mash times, there was no compelling evidence tasters were able to tell a difference between the beers, even the OG and FG were the same. If your goal is to get in and out of the brewery as quickly as possible, shaving 15-30 minutes off of your mash time will likely have little if any qualitative impact on your finished beer. I know this sounds scary and goes against convention, but I’ve done it quite a few times and not a single person has been able to tell the difference. This technique seems to work best for mashes that are 150˚F or warmer.

It’s true that the longer grains remain in the mash at saccharification temps, the more conversion occurs. But not much, at least after the 30 minute mark. In my xBmt comparing 60 minute and 30 minute mash times, there was no compelling evidence tasters were able to tell a difference between the beers, even the OG and FG were the same. If your goal is to get in and out of the brewery as quickly as possible, shaving 15-30 minutes off of your mash time will likely have little if any qualitative impact on your finished beer. I know this sounds scary and goes against convention, but I’ve done it quite a few times and not a single person has been able to tell the difference. This technique seems to work best for mashes that are 150˚F or warmer.

Clean As You Go

I’ve heard so many stories of people who go out to their garage a few days after brewing to discover a mash tun full of nasty grains. I’m the type of guy who hates having shit hanging over my head, to the point of neurosis, I can’t even come close to understanding how a person forgets to clean their mash tun. Immediately after I’m done collecting my sweet wort, while I’m waiting the 15 minutes or so for it to come to a boil, I spend 4 minutes cleaning my MLT so that I don’t have to worry about it later. I do this with everything as soon as I’m done using it. My MLT cleaning regimen consists of blasting it with the “jet” setting on my hose nozzle and wiping away grain bits with my fingers– no soap, no OxiClean, just water and fingers. I will take a scrub pad to my kettle after each brew day in order to remove the rim of gunk plastered to the top. I easily spend the most time, maybe an entire minute, ensuring my valves are well rinsed. Once every 6 months or so I will give my kettles a good scrub with Bar Keepers Friend, this stuff is amazing when it comes to cleaning stainless steel, and it works well on porcelain too!

Prepare Hops, Finings, and Other Boil Additions During the Mash

I t’s easy for me to get caught up doing inane stuff (like reading a blog) after mashing in, only later, as I’m scurrying to get my kettle additions measured out in time, wishing I’d spent that time preparing a little better. I’m a bit wary of weighing out my hops the day before brewing, so I usually do it toward the end of my mash, that way they’re only sitting out for about an hour before being tossed into the wort. I separate each addition into it’s own vessel and label them with the time it’s supposed to be added to the boil. If I have a hop addition between 15-5 minutes left in the boil, I’ll toss whatever kettle fining I’m using into that same cup.

t’s easy for me to get caught up doing inane stuff (like reading a blog) after mashing in, only later, as I’m scurrying to get my kettle additions measured out in time, wishing I’d spent that time preparing a little better. I’m a bit wary of weighing out my hops the day before brewing, so I usually do it toward the end of my mash, that way they’re only sitting out for about an hour before being tossed into the wort. I separate each addition into it’s own vessel and label them with the time it’s supposed to be added to the boil. If I have a hop addition between 15-5 minutes left in the boil, I’ll toss whatever kettle fining I’m using into that same cup.

Use FermCap-S

Most homebrewers I know brew in volumes that just about top-out their kettle. Unless you’re a fan of cleaning up sticky caramelized wort, you really should be using FermCap-S. Three drops per 5 gallon batch and 5 drops per 10 gallon batch works wonders! Also, I use just a single drop to safely boil starters in an Erlenmeyer flask without risk of a volcanic eruption. At these usage rates, a $4 vial should last most homebrewers 3+ years, pretty cheap insurance.

Ditch the Hop Bags/Socks

Filtering out kettle hops only adds another item to clean while contributing little, if anything, positive to your finished beer. When I first started brewing, I somehow became convinced that clear wort in the fermentor led to better beer, so I used large paint  strainer bags to filter out kettle hop additions. After analyzing the surprising results from The Great Trub xBmt, I’ve since abandoned this practice and haven’t noticed any degradation whatsoever in the quality of my finished beer, in fact most seem to clear even faster these days. For brewers who push wort through a CFC/plate chiller, hop filtration in the kettle will reduce the chances of a clog, so this may not be the best advice for you. In addition, I never filter dry hop additions either, just throw them directly into primary, leave them for a few days, cold crash for 24-48 hours, then package. It works great and the beer comes out just as clear!

strainer bags to filter out kettle hop additions. After analyzing the surprising results from The Great Trub xBmt, I’ve since abandoned this practice and haven’t noticed any degradation whatsoever in the quality of my finished beer, in fact most seem to clear even faster these days. For brewers who push wort through a CFC/plate chiller, hop filtration in the kettle will reduce the chances of a clog, so this may not be the best advice for you. In addition, I never filter dry hop additions either, just throw them directly into primary, leave them for a few days, cold crash for 24-48 hours, then package. It works great and the beer comes out just as clear!

Forgo Hop Additions During the Boil

Bittering at 60, flavoring at 30, aroma at 5. This is what I was taught about hop schedules when I first started brewing, it was the standard, everybody did it. Over the last decade, thanks to the growing love of all things hoppy, we’ve developed less conventional methods of utilizing this delectable flower that produce incredible flavor and aroma. The majority of the evidence I could find supports the notion that first wort hop (FWH) additions tend to produce a smoother and less harsh bitterness than traditional 60 minute boil additions (xBmt planned to test this), while an abundance of hops at flameout impart intense aroma and flavor along with some bitterness. By combining these methods, one is able to spend 60-90 minutes cleaning up, relaxing, or running through the Taco Bell drive-thru. The first time I did this, I was nervous the resultant beer would have poor hop character, but to my surprise, the hops shone brightly and the beer ended up taking first place in a local comp! I’ve since used this technique many more times to produce tasty beers.

Get a Burner that Will Grow With You

There are many options to choose from when it comes to selecting a burner, make sure you pick one that best suits your brewing needs. If you make, or plan to start making, 10 gallon batches, get a burner that works well for that volume! I was one of those guys who purchased 3 burners before eventually settling on the model I use today, telling myself with each purchase, “these will suffice.” They did until they didn’t and I ended up eating the costs. Do yourself a favor and get a good burner that will grow with you right off that bat, this hobby only gets more addicting with time. To read some of my thoughts on a number of burners, check out my Brewing With Gas article.

Utilize Proper Chilling Techniques

Chilling a 5 gallon batch of beer with an immersion chiller should never take more than 20 minutes. When I first heard this, I was a bit bewildered, as my chill time using a 25′ x 3/8″ copper IC plopped into hot wort with the  water slowly flowing was closer to 45 minutes. The primary reason I bought a pump and plate chiller setup was to reduce my chill times, perhaps a few readers can relate. Not long after making this change, I realized how much I hated all that was involved in this new setup and reached out to JaDeD Brewing seeking advice on how to use an IC more efficiently. I learned 2 important things from that exchange:

water slowly flowing was closer to 45 minutes. The primary reason I bought a pump and plate chiller setup was to reduce my chill times, perhaps a few readers can relate. Not long after making this change, I realized how much I hated all that was involved in this new setup and reached out to JaDeD Brewing seeking advice on how to use an IC more efficiently. I learned 2 important things from that exchange:

1. Keep source water flowing at full blast

2. Constantly agitate the wort by stirring and/or moving the IC around

The following brew day, I was ecstatic to reach 6°F above groundwater temperature in under 10 minutes! Times will vary depending on the type of IC you use and the temperature of your source water, but employing these 2 techniques will absolutely reduce your chill times. For users of CFCs, faster source water flow rates will improve your chilling efficiency as well.

Skip Transferring to a Secondary (most of the time)

I believe it was Sam Pink who said, “If I ever find a dead horse, I’m going to beat the fucking shit out of it,” a sentiment I experience every time the topic of whether or not racking to secondary is worthwhile. No, I couldn’t care less if others use a secondary, but I have no qualms referring to it is a hugely unnecessary step in brewing that’s most likely a remnant of our shitty-yeast past. Not only do some of the biggest names in the industry advocate for primary-only fermentation, but results from my recent xBmt suggests it makes no difference. While I have yet to formally test it, I do have quite a bit of experience adding other ingredients directly to primary including cacao nibs, vanilla, fruit, and coffee– it works just fine! If you like to bulk age big beers for longer than 5 months, racking to a second vessel may be of some benefit. I’ve even left sours in primary for 12+ months and they came out fine.

Don’t Drink and Brew… Too Much

As a morning brewer, my usual brew day beverage is a hot cup of coffee. The few times a year I brew later in the day are usually because someone wants to come over to watch, assist, learn… and drink my beer. I’ve no problems with sharing, not one bit, I do it often, and I especially like imbibing with those I’m sharing with. We’ve all been there:

Mash-in… time for a beer… runoff and sparge… that Pale is delicious… let’s get this thing to a boil… mmmmm, beer… boilover, shit, forgot the FermCap… I can’t believe I made this deliciousness… was I gonna add hops at some point?

I remember one brew day where the boil timer went off, I silenced it, then got back to shootin’ the shit with some buddies before turning the burner off. It took 15 minutes for me to remember the timer had gone off and I hadn’t cut the flame. Not only do we run the risk of screwing up a batch of beer, but brewing while drunk can be quite dangerous. I don’t have any hard and fast rules for drinking while brewing, though I’ve learned I tend to do better when I hold off on pouring that first pint until my wort is boiling.

Fine with Gelatin

I’d heard of people using gelatin as a way to get their beer clear, but for some reason I was hesitant to try it for myself. I decided to give it a go after comparing beers with a few friends who all used the same ingredients and brewed on the same date, the one person who fined with gelatin served a beer that was remarkably brighter than the others. I have an xBmt planned to test the impact gelatin fining has on a beer, as there is some speculation it reduces certain flavor and aroma characteristics, but one thing’s for sure- it works great for clarity! Here’s the process I’ve been using:

– Once fermentation is complete, cold crash beer to 30-32°F for 24 hours

– Combine 1/2 tsp gelatin into 1/4 cup water, microwave for 5 seconds at a time, stirring in-between, until it reaches 150° and the gelatin is fully dissolved

– Pour gelatin solution into fermentor and let sit another 24-48 hours

– Package

A single sachet of gelatin has enough for three 5 gallon batches of beer, making this an incredibly inexpensive option. I’ve yet to bottle condition a beer I’ve fined with gelatin, but I know plenty of people who have and it works beautifully, their beers come out crystal clear and well carbonated.

Keep Your Brewery Clean & Organized

There’s little more annoying to me than needing something and not being able to find it. If I need a hydrometer, a thermometer, or scissors to open a bag of hops, I want to know exactly where it’s at so I don’t waste time looking for it. Some people like to use plastic storage bins and I know a few guys who keep their smaller wares in a toolbox, both great options. I prefer shelves, personally, and I make sure to put everything back in its designated spot after each brew day. If you stock bulk grains, something that can save you time and money, make sure you label your containers so you don’t get things mixed up.

looking for it. Some people like to use plastic storage bins and I know a few guys who keep their smaller wares in a toolbox, both great options. I prefer shelves, personally, and I make sure to put everything back in its designated spot after each brew day. If you stock bulk grains, something that can save you time and money, make sure you label your containers so you don’t get things mixed up.

Don’t Worry So Much

You invested $40 in a Pliny The Elder clone kit, spent 5 hours brewing, pitched the starter you made a couple days prior, and got it all situated in a temp stable area for fermentation, then the self-doubt and internal questioning kicks in.

Was my yeast good? Did I pitch enough? Maybe the fermentation temperature is too high? Where is that damn krausen? Is it… infected?!

Truth is, beer isn’t all that difficult to make, people have been doing it for thousands of years. As long as your sanitation is at least decent and you added yeast to sugary wort, beer will be made, without question. Is it going to be perfect every time? Of course not, that’s why there’s a next time! Brewing is a fun hobby, not a task to be stressed about.

FREE LABOR!

Hey, they’re there, may as well put them to work.

I’m sure there are many things I missed and I’d love to know what others do to increase the efficiency of their brew days, please share in the comments section below!

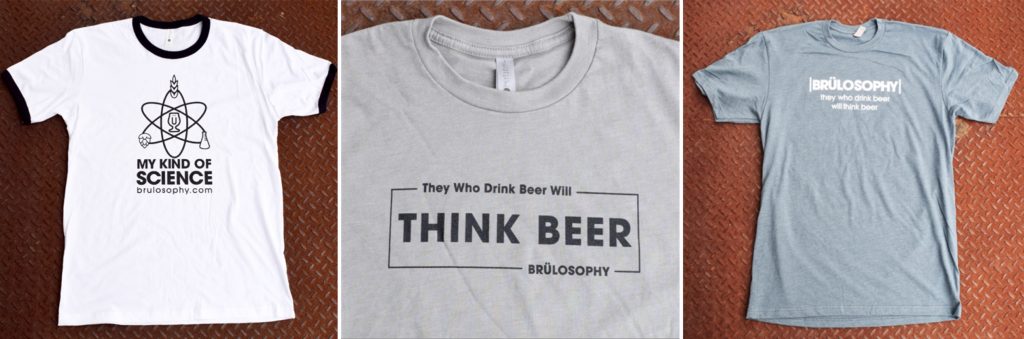

New Brülosophy Merch Available Now!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

71 thoughts on “18 Ideas To Help Simplify Your Brew Day”

Awesome post as always

Sent from my iPhone

>

What Would we do without hon! Great stuff yet again!

i’d be interested in that gelatin experiment. i’ve actually just recently started using it and on super-hoppy IPAs recipes that I’ve brewed several times, i’ve noticed that ones fined with gelatin have a noticeable decrease in hop aroma. they’re clear as hell, but it definitely seems to strip out some aroma compounds in my experience.

I’ve heard that hop aroma/flavor compounds like to stick to yeast cells, which may be one reason that people experience a drop-off in hop flavor/aroma as hoppy beers age. It could be that what you’re experiencing is an acceleration of this process – you don’t experience the beer when it still has lots of suspended yeast.

I know those who filter their beer (like Tasty McDole) say that filtering can strip out some flavors, but you can compensate for that in the recipe – in other words, hop your beer enough so that it will still be super hoppy even after you fine/filter it.

I’ve got an ESB that’s been in primary for 6 days that I’m going to dry hop loose in the fermenter, cold crash, gelatin fine, force carbonate, and try to serve for New Year’s Eve – I’ll see how that goes!

Anecdotal, but I went to a ton of breweries on a recent road trip. I hadn’t known about this stuff but had this funny situation at one (fantastic) brewery where the beer tasted incredibly crisp, but not empty in the way a lot of filtered beers do for me. It turns out the brewer was using this to fine. I have a very good feeling it’s more complicated than that simple difference but I’m incredibly excited to try it.

As someone who likes to try simple beers with non-traditional ingredients, but also wants a little more ‘crisp’ mouthfeel, I like the idea of being able to get there without filtering out all the goods.

Or maybe this is all wishful thinking. I care little about cosmetic clarity, so hopefully it’s more than that.

Interesting! One of the things I’ve dealt with in my professional life is disinfection/sterilization/sanitation and this idea of boiling starter wort for ten minutes has been bothering me.

There are two levels of bacteria-killing involved in heat sterilization; killing the live bacteria, and killing the spores. If you’re trying to store something bacteria-supporting for a long time you need to go all the way up to killing spores, which is where your pressure-canned wort comes in. If you’re only killing off the live bacteria so your yeast can run rampant for a day or two, then heat death happens a lot lower – 80°C/176°F for two minutes should do it for almost everything. In heat sanitation, higher temperatures drastically (logarithmically) reduce kill time – at 95°C you’d kill any common food-borne bacteria in a handful of seconds. It’s not like we could ever heat a body of liquid to the precise a temperature for that short a time, but still, once it’s got to 95, and short of worrying about heat-resistant strains, what does leaving it there any longer do?

(The answer, in my head, is making sure to sanitize the vessel it’s being boiled in, especially the pouring edges of it; steam is great for getting to bits you’d otherwise have to be sure to heat by conduction. But this is clearly a justification, as the same thing could be done in other ways.)

And yet at the same time I’ve seen a friend use a wort-concentrate kit that tells you to just add cold tap-water straight to the mix in later dilutions, because tap water is sanitized so there’s no live bacteria in it. (I live in the Netherlands, the water here is very clean and not chlorinated either – they do some clever stuff with sand-bed filtration.) And sugar/DME doesn’t have any live bacteria in it either because of its dehydrating ability… so what are we sanitizing anyway? Why does a clean thing plus a clean thing equal a thing we now have to boil halfway to spore death? And yet I still don’t have the nerve to knock the heat off before it’s even boiled, even if I do usually stop after about a minute…

(P.S. First comment from me, but I found this blog a few weeks ago and started following it because I really appreciate your approach of taking a good hard look at what’s actually necessary, rather than following what we’ve been told, so keep up the good work!)

This is great, thanks!

I keg all my beers. Every brew day I always mix up a 5 gallon batch of Star San. At the end of the day I take what’s leftover and dump it right into the next keg I’ll be using for primary on the next brew day.

Shortens the length of time I spending sanitizing and usually works perfectly with my keg rotation schedule after the one I just scrubbed clean. Also if I ever need it I always have a batch of Star San laying around to refill my spray bottle or clean out my tap lines.

Awesome post, tons of good stuff!

Nice! I make a fresh batch of StarSan every brew day (every other week, usually), store it in an old 8 gallon fermentation bucket, and use it to sanitize everything from carboys, kegs, thief, tubing, etc. It works great.

I recently moved from Colorado to Florida and quickly discovered the groundwater wouldn’t very effective with my IC. The LHBS recommended buying several bags of ice and using a 1/6 hp submersible pump to circulate melted ice water from a cooler through the IC and back to the cooler. Three 20 pound bags will easily and quickly get a 5-gallon batch of wort under 70 degrees!

I can definitely relate! However, I just chill to about 6F above groundwater temp then throw the carboys in my ferm chamber to finish chilling, never been an issue. I do have plans to try recirculating… at some point.

Very interesting post, thanks for your advices. I’m not sure about to reduce mash time, but I have to try it 😀

Bye!

Man, I never heard of FermCap-S. That’s a huge find for me!

It is great stuff!

Agreed, It’s awesome for keeping foam down during fermentation as well, which is very useful for starters on a stir plate.

I always use a lot more then 3 drops in my kettle, like 10 or so. 3 seems to be plenty for ya?

I have heard rumblings that FermCap-S can cause off Flavors and reduce head retention in your final beer.

Have you thought about doing FermCap exBEERiment?

I’ll add it to the list!

Great post!

I use a electric boiler water, something like this:

http://www.amazon.com/Kitchen-Appliance-Capacity-Electric-Kettle/dp/B00H86ELZE

to heat my water for the mash. I save a lot of time.

Make your no boil starters using Star San solution. Works like a champ for me.

Wha???

Seriously. I’ve done it with WLP002 and WLP007. Make up your Star San as per usual, add 50% of your starter volume into your erlenmeyer and shake to sanitise the rest of the flask. Mix in the DME, pitch your yeast vial and make to volume with tap water.

Intriguing.

Also, do you double up on the full volume mash and 30 minute mash times? Seems like you’d slice the best part of an hour out of a batch doing that.

Double up?

Do a full volume mash with only a 30 minute rest.

I wonder sometimes…if we boil our wort for 60…why don’t we boil our starter wort for 60…it is going into the fermenter…I usually boil a starter for 10…just wondering…

Isomerazation of alpha acids? I don’t really know. I boil my starters for 2 min.

The BJCP officia)y lists a bunch of reasons to boil your wort:

1. Sanitization

2. Concentrate the wort (reduce volume)

3. Volatize and drive off undesirables (e.g., DMS)

4. Isomerize alpha acids to make them soluble

5. Denature enzymes

6. Coagulate proteins (hot break)

7. Formation of color and flavor compounds (e.g. Millard reactions)

If you account for these things in your recipe, you should be able to reduce boil time considerably. I have done a few batches with short (15 minute) boils with no adverse effects, by increasing the bittering hop charge and avoiding pilsner malts.

You usually don’t pour the whole starter in, it tastes pretty terrible (fermented warm, super oxidized, etc.). You don’t need it to be like a normal, fully boiled wort, all you want a starter to do is provide a good place for yeast to grow, which doesn’t require 60 minutes.

Best homebrew blog 2014 award for you sir! Keep up the awesome experiments!

Haha, thanks! Your private award makes me very pleased 🙂

This is a great post, thanks.

On this: “1. Keep source water flowing at full blast”

In this case I’m actually a little more sensitive to water use than time. This used to kill me, letting water run for so damn long, especially in the summer when my city water seemed to come out of the tap so warm. I’m on a well now and actually run things very slow (I had a bad connection from hose to IC that used to leak with too much pressure, something I just recently fixed).

Stirring the whole time (usually with my first beer in the other hand) has been revolutionary in terms of time, and now I’m on a well and I care a little less about water use, but I’d still love to know the science of the tradeoff between flow and water use.

Totally talking of of turn here, but I suspect there’s an optimal temperate change? or maybe optimal exit temperature?

My understanding is that we can’t push water through our ICs fast enough to reach even the optimal rate… if that makes sense. I live in the Central Valley of California where water conservation is a big thing, I skip a couple showers to make up for the water I waste chilling wort 😉

Okay, awesome and good to know. On saving water, I also used to feel a little guilty if I cleaned before I had IC waste water, but the benefits of having that done before chilling and probably saving more water stirring than I did reusing it seems to have won over.

In the summer we catch the water in buckets and use it to water the garden. In the winter, I did the same and used it for laundry back when we had a top loader. Haven’t brewed since we got a side loader but I can’t think of much use for the water now.

“…but I’d still love to know the science of the tradeoff between flow and water use.”

Rate of heat transfer through your chiller is proportional to the flow rate across both the hot (wort) and cold (water) sides, and on the “average” temperature difference between the hot and cold. More surface area also helps, but that characteristic will be fixed for any given chiller.

Agitating the wort to increase the hot side flow rate goes a long way to decreasing the overall chilling time. You can do this by stirring, moving the immersion chiller through the wort, or recirculating (as in a whirlpool chiller setup). The most effective simple solution, without adding any new equipment, is to move the immersion chiller as demonstrated on the JaDeD Brewing site.

On the water side, assuming your inlet water temperature is fixed (i.e., the temperature out of your tap) your only other practical control is the flow rate, and higher flow rate will *always* increase your heat transfer rate. Part of this is due to the level of turbulence in the flow, but more significant is the relatively lower temperature of the chilled water at any point in the IC. Colder water temperature means a larger “average” temperature difference compared to the wort, so heat is pulled more quickly into the chiller water.

But if you are (rightfully) concerned about water usage, a lower flow rate would probably strike a better balance between the total time to chill the wort and the amount of water used to do it. The complication is that this optimum flow rate will change over the course of the chilling process.

At maximum flow rate, the water coming out of the chiller will be at its coolest (depends on the water inlet temperature, the design of the heat exchanger, and the temperature of the wort). At the start of chilling, this temperature is not at all “cool”, and you can save this water for either clean-up or for mashing in your next batch, as suggested in an earlier comment. If you were to reduce the flow rate of the water (and keep doing whatever you were doing on the wort side), the outlet water will get warmer.

As the wort cools, the average temperature difference compared to the chilling water will become smaller, and each additional degree of temperature drop will require increasingly more water flow. If you wanted to quantify this for any given water flow rate, you could record the wort temperature every 15 seconds, and plot this temperature against the total time. The plot would show that temperature drops very quickly at the start, and progressively slower as the wort chills.

So what is the “optimum” between flow rate and chilling time? That depends on your own personal criteria for what is important. Conventional wisdom is that you want to quickly get down below ~160°F to halt the production of DMS, and then down below ~80°F to get through the “danger zone” for bacterial activity. Another effect of this rapid chill is to form the cold break, if that is something you care about. Below 80°F, the time to get to your desired pitching temperature is dictated more by your level of patience.

For my money, I agitate the wort with my IC and keep the water at its maximum until the wort temperature drops to 80°F, then I reduce the water flow rate way down and leave the chiller alone, agitating only once a minute or so, while I deal with other post-boil/pre-pitch tasks.

Sorry for the long-winded answer, but it was a lot of effort to avoid getting overly geeky on this.

heat transfer can (in very basic terms be defined as:

Q = UA ∆Tm

where,

Q = rate of heat transfer

U = mean overall heat transfer coefficient (set for a given device)

A = heat transfer surface area

∆Tm = logarithmic mean temperature difference

As you move the IC or similar you, in effect, increase the A term (effective area).

Awesome read …thanks man!!

I use bucket heaters designed for livestock troughs to heat the strike water using a timer set the night before brewing – I have it set to come on an hour before the start of brewing and my strike water is ready by the time I am ready to brew.

Very cool! I actually use these for livestock, but it’s unclear to me how you’re adjusting the temperature. Did you find an adjustable one that goes that high? Or do some rewiring? (Which is likely over my head).

I used to do this with an stc-1000 to control the heat. The issue I found was it took a while without recirculating, in addition to cool spots leading to a lower temp than I wanted, so I switched to an anova sous vide stick which has the temp control and recirc.

Nice article. Another great time saver is overnight mashing. Works really well with no-sparge brewing as the high volume of hot liquor holds the mash temp well, and you can start the boil almost first thing in the morning. Cuts the brew day down to 2-3 hours.

I use the output of my IC to rinse my mash tun. Nice long hose on each end. I’ll turn around and stir as needed. Also fit a hose barb on one end of IC hose and a fitting for my harbour freight pond pump on the other, so i can recirculate in the summer with ice blocks (bottom half of gallon jugs) and a bucket.

I didn’t quite follow what you meant on the hop addition. Are you saying put them all in at the first addition? Skip the 30 min addition and just do 60 min and 5 min addions?

Thanks

That’s right!

Why are you reluctant to measure out hops the day before brewing? Will their quality really deteriorate this quickly? I typically measure them out in small Pyrex bowls and cover with saran wrap. Then I write boil times on the saran wrap that covers each bowl using a sharpie so I know which is which.

I’ve heard someone (Matt Brynildson, I believe) say that hops can turn cheesy when left out for as little as a few hours. It’s so easy for me to measure them out during the mash that I’ve settled on not risking it.

Never used FermCap-S but I usually wait until my wort gets to ~180, then I start skimming off the scum layer until it boils. Can start at 190, but sometimes it will get to boil too fast and boil over. By being there for the scum layer skim, my kettle doesn’t boil over. Also, skimming off the scum will help get rid of the proteins that you don’t want in your beer anyways.

If you whirpool your wort prior to cooling with a plate chiller, the hops settle in the middle of the kettle and don’t end up clogging the chiller. Have to let some of the wort stay in kettle because once the hops start moving, they will go into you chiller and will suck to clean. To whirlpool, I just take a big sanitized spoon and stir the wort for ~1 minute, then let sit for ~15 min…works like a charm.

Very nice. Only one question. Did you used gelatin for a bottle carbonation batch? Normally the master homebrewing say that gelatin reduce the yeast so much that is not possible to carbonate the beer. Thanks

Gelatin fined beer will absolutely bottle carbonate.

The recipe of 1/2 tsp of gelatin is for 5 gallon batch?

YepZ

Good article, I handle a few of these things, and #1 in improving cooling is to move that I/C around, up/down, side to side. I also have two coils, one smaller one inside the other and chill to ~80 in 10 min or less! I recover the spent water in two buckets, switch over to an ice bath. I’m also cheap. I hate to add buying ice to the list! I freeze 6 2L bottles (used to make ice blocks until learned this from my brother, smart man, runs in the family, 🙂 In addition to free ice, it makes my chest freezer more efficient too! (thermal mass in freezer instead of open air). So after 10 min and two full buckets of water (first one quite hot) I switch over to the ice bath from a large cooler (not my mash tun). Stir for the first 5 min or so, and I do dump the first few min of water, then outlet goes to the ice bath. At this point I can walk away, temps are generally around 70, and do other things as needed. No worries about pump burn out as its recirculating. No worries about cooling, virtually done. I tend if I haven’t already to sanitize my fermenter at that point.

I do like the short mash time. Do you use an iodine test? If so, does it appear complete after a short mash. I plan to test my next mash, so curious.

Like you, I prepare the night before, too easy to mis-measure grains while watching water temps etc… That is truly a big time saver and makes for a smooth brew day. Oh, and I almost never drink any alcohol while brewing. Unless its later in the day and brewing with someone, but even then I limit to one at most.

As for the starter with Star-San. Uh, that just doesn’t sound something I’d want to practice. Regardless of if you can notice it or not.

Always enjoy your work, keep it up!

Cheers.

I don’t use an iodine test these days, but I have tested every 5 minutes multiple times, nearly full conversion was always the case around 20 minutes. One simple way to tell is the sheen on the bubbles in the mash, if they’ve rainbow colors, it’s converted. Works for me.

Starter with StarSan? I make my starters with water. That said, StarSan is really just phosphoric acid and probably wouldn’t hurt anything… but I’m not doing that.

I love the picture of your lil’ one with the refractometer. Very cute. Any plans on xBmts using the new Grainfather? I’ve seen mixed reviews for the lower voltage US version but have been thinking about upgrading to a cheap all-in-one smaller footprint.

I’m not personally interested in the Grainfather, only because I’m really happy with my current setup. I suppose I’d play with one, but I’ve no plans to buy one.

Great article, as usual. Absolutely love this site!

I am looking into doing pressure can wort starters. Do you use DME or do you mash base malt to make the 1.040 wort?

DME

I don’t brew enough to reuse yeast anymore, as a result, I abandoned liquid yeast for the most part. The selection of dry yeast is pretty good. It keeps forever. It provides a huge pitch of yeast and requires no starter.

The other big time saver I found was brewing in place. I setup an electric brewery in a dedicated spot in my basement. No setup or tear down, is both awesome and a huge time savings. I use my pump to CIP by recirculating very hot PBW.

Have you ever cut your boil time to 3p minutes?

3p?

Staging equipment and ingredients the night before is a Yuge time-saver.

—

Walmart’s Baby Gas-X (simethicone) drops works well as an anti-foaming agent and is less expensive than FermCap-S.

In re gelatin; Terry Foster (BYO) recommends 1 tsp / 5G @ bottling time.

Adding gelatin in the bottling bucket at that rate gave me better results than fining in a fermentor.

Look into no-chill brewing. Make a real wort starter by scooping out your desired amount of wort at end-of-boil, cool IT down to 70 degrees or so, pitch your yeast to get your starter going. In the meantime you tap your hot wort directly into a food-safe heat -safe sealable container. It self sanitizes if you make sure the hot wort touches all interior surfaces for 20 minutes. so you stand it on end for 20 min. clean your brew pot. Turn it over at 20 minutes, do whatever remaining cleanup you have. A day or two later when your starter is developed, you dump it in (or transfer to a more traditional primary) and you’re good to go.

Cleanup is quick, no cooling an entire 5 Gallons. When your starter is ready, you take another 5 minutes or so to add it to your wort. Voila! Once you go no-chill, you’ll never go back!

I’ve done no chill a few times and still prefer using my IC. Whatever floats your boat!

https://brulosophy.com/2015/11/09/cooling-the-wort-pt-1-no-chill-vs-quick-chill-exbeeriment-results/

I tried gelatin but hated the smell when making it. I switched over to polyclar and get consistently clear beer. Have you ever tried it? Maybe an exbeeriment?

I have used both. The gelatin smell does not carry over into the beer’s flavor or aroma in my experience, it’s is cheap, food grade, and works very fast.

Polyclar (PVPP) works fine as well.

Some people will not prefer gelatin bc it’s an animal product. Others may not wish to use polyclar bc it’s a highly synthesized polymer akin to nylon. PVPP can also strip beneficial elements of products (color, tannins, flavor and aroma compounds) as well as those we desire to remove.

Use whichever you like!

I’m a big fan of the hop sock. I find it a lot less cleanup overall. Just drain the hop sock while chilling your wort and then dump the remains in the garbage. Quick rinse of hop sock and hang to dry. Much less mess of hops in the kettle and less hops in fermenter. I do many of these tips, except a shorter mash time. Will definitely be trying this next. Any few minutes time savings here and there along the way add up for a shorter brew day is a big plus. No need of ferm cap yet as my 20 gallon kettle is plenty big for 5 gallon batches. Nearly impossible to boil over with all that extra headspace. I’ve only been brewing for just shy of 2 yrs and initially like all the gadgetry of multiple pumps, hoses, vessels, but found the brew day for sooo long. Did my first BIAB yesterday with only kettle as mash ton & kettle and found it awesome with way less setup, less cleaning and shaved 1 hr off brew day. Plus I finally hit my numbers correctly. I just found it a more simplified & quicker method. I also started the recirculating ice bath connected to my DIY IC of 50 foot copper tubing works great. Started this in the winter as no method to use hose up here in Canadian winters so had to be creative. I find it work fantastic especially in hot summer months as using a hose would take forever. Plus, cost of water is pricey where I am so this saves on water bill as I reuse/refreeze the heated resulting water back into the 2L pop bottles. Ice bath recirculating takes about 20 mins to cool to 78F

Is there a flavor difference between clear and not so clear beer? Or is just for the aesthetics? 30

minute boils?

Direct pitch dry yeast?

Just found this website recently and love the work you all have put into it!

Check this out…

Clear vs. Clear Beer:

https://brulosophy.com/2015/01/05/the-gelatin-effect-exbeeriment-results/

Boil Length:

https://brulosophy.com/2015/03/11/the-impact-of-boil-length-ale-exbeeriment-results/

Not sure what you mean by “direct pitch vs. dry yeast,” perhaps you were referring to liquid vs. dry? Either way, search for it on the site, we’ve done a ton of work with yeast!