Author: Marshall Schott

Following my barely successful attempt at wrangling wild yeast from my front yard, I knew there had to be a better way to get a funky/sour beer naturally, sans professionally cultured organisms. The few friends I have who’ve tried the sour mash technique spoke rather strongly against it, using words like “puke,” “baby diaper,” and “rotten cheese” to describe the flavors and aromas of the resultant beers. Despite the success stories I’d read online, I knew this wasn’t the route I wanted to go. I started looking around for ways to sour wort using the lactobacillus residing naturally on grain, as it seemed to me a potentially safer alternative would be to sour the wort (in a fermentor) rather than the mash. Sure enough, after some googlin’, I came across a few blog and forum posts by people who have done exactly this using myriad methods. I knew I was going to try it, I just wasn’t terribly excited about chancing an entire batch of beer. Halfway through a Helles brew day, I got the idea to try this out on a small portion of the leftover wort. Once both fermentors were full, I poured off about 2 quarts of wort from the kettle into a sanitized 1 gallon aluminum pitcher and tossed in a handful of uncrushed 2-row.

The wort was just above 90°F at this point, a temperature I’d read would encourage the lacto to do its thing. Immediately after tossing the grains in, I wondered if using acidulated malt may have been better, something I may try in the future. I covered the pitcher with a BIAB bag and left it sitting in my very warm garage.

By the next morning, the temperature was hovering right around 89° and there didn’t appear to be much going on.

Curious as I am, I came back to check on the beer a few hours later and what I found was the beginning of what looked like some form of fermentation.

It still smelled mostly of sweet wort at this point, nothing terribly funky. The temp had dropped to about 85°F, so I moved the covered pitcher into a warmer shaded area outside of my garage and left it for a couple hours, which brought the temp back up to about 96°F.

The kräusen definitely continued to develop in the warmer environment, covering nearly the entire surface of the liquid once I brought it back in a few hours later.

Approximately 40 hours after adding the grains to the wort, the beer seemed to develop more character, smelling sort of how I had hoped– subtle lactic funkiness. Since I was expecting something much more akin to baby barf, I was pleased and decided it was time to taste it. I approached this, again, with low expectations. While not blown away, I did think there was something sort of pleasurable about the flavor, mostly the sort of noticeable lactic tartness. Definitely not terrible.

This is the point I opted to move forward with stove-top pasteurization by pouring it through a strainer into a pot, which I held at about 150°F for about 10 minutes (my precision with this was about as good as my precision aiming at a kids’ urinal).

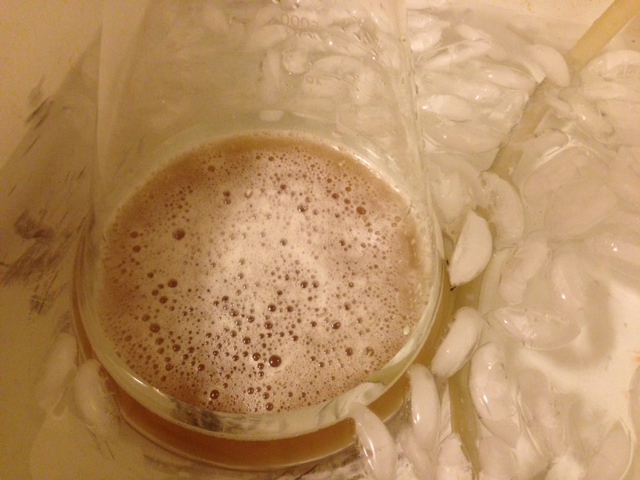

The warm, pasteurized beer was then transferred into a sanitized flask and chilled to 60°F via ice bath.

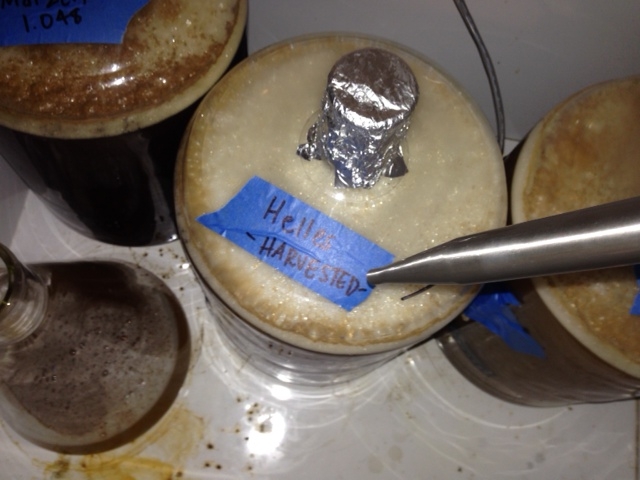

Once chilled, the flask was moved to the ferm chamber and a couple squirts of actively fermenting Helles (WLP029 yeast) were added.

Activity was visible within 24 hours.

The bubbles were interesting to me, much different than the thick milky looking krausen I usually see sitting atop my fermenting beer.

Ten days after the yeast was pitched, the beer was cold crashed then bottled in a single 22 oz bomber.

This bottle was left in a 70°F room to carbonate for 3 weeks before being moved to the refrigerator to settle out for another few weeks. To be honest, I was hesitant to open it, partly for fear it would explode in my face and partly because I thought it might taste like donkey gooch. The time finally came…

I took the single bottle to share with friends at the House of Pendragon tasting room. Unfortunately, I completely forgot to take a photo of the beer in the glass. For what it’s worth, it was very pale and hazy, could easily have been mistaken for a Weissbier.

| THE VERDICT |

Blegh! A slight funkiness that I suppose came from whatever wild yeasts were living on the grains; very little tartness, which is likely a result of the fact I didn’t leave it alone long enough for the pH to drop before pasteurizing; and a very (very) noticeable flavor of burnt rubber, possibly because I didn’t pitch enough WLP029 from the krausen of another fermenting beer. The most appealing aspect of this beer, if you want to call it that, was the level of carbonation, which I’m guessing was right around 2.8- a peppy sparkle that would have meshed beautifully with a delicious tart style. Of the 6 other samplers, not a single one described this beer as being pleasurable in any way. It wasn’t gag-inducing, just not at all tasty.

So I’m 0 for 2. At least they’ve all been tiny batches. I soon plan to pitch a huge starter of cultured lactobacillus brevis into pre-boiled low OG wort, let it sit around 110°F for 2-3 days or however long it takes to get super tart, then pasteurize by bringing it up to a brief boil and ferment it out with Notty at 62°F. I may be done with trying to use “nature” to make sour/funky beers… at least for now.

Cheers!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

| Read More |

18 Ideas to Help Simplify Your Brew Day

7 Considerations for Making Better Homebrew

List of completed exBEERiments

How-to: Harvest yeast from starters

How-to: Make a lager in less than a month

| Good Deals |

Brand New 5 gallon ball lock kegs discounted to $75 at Adventures in Homebrewing

ThermoWorks Super-Fast Pocket Thermometer On Sale for $19 – $10 discount

Sale and Clearance Items at MoreBeer.com

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

15 thoughts on “Wort Gone Wild | Attempting To Sour With Grains”

Why did you pasteurize the beer instead of just adding the yeast directly to it?

My understanding is that it at least reduces the risk of wild yeast/bugs continuing to work past a certain point, the point at which I wanted it stopped. This was recommended to me by numerous folks, I just trusted them.

I tried something similar (actually the sour mash you mentioned) and got what are probably similar results, or maybe slightly better judging by your description. Or I’m just more generous in my opinion of my own beers. Either way, I was listening to some Jamil Zainasheff podcast after making my batch and he mentioned if you want to sour a beer this way to drop the pH with lactic acid before adding the grain (I think to about 4.4 he said?) to prevent other bugs besides the lactic producers from taking hold of the wort and giving you those terrible flavors you mentioned. For what its worth, though, he and Tonsmeire both have recommended against this type of souring for getting best results.

– Dennis, Life Fermented Blog

I’m in about day 2 1/2 of a grain-only inoculation of a sour mash using a method you describe above and it’s going really well. What I did was finish the mash, let it cool to ~110ºF then add .75 lb of raw, crushed acid malt and .5 lb of raw, uncrushed grains. The acid malt lowers the pH to ~4.3 and both grains add the lacto.

This post is the model for the method I’m using: http://anarchylane.com/blog/?p=1442

Cool experiment! I don’t know if this was the cause of your off flavor, but my research has led me to think that the right temp for “natural” lacto souring is more like 110-115, and that in the 80s/90s you’re in much more danger of random other bacteria acting up.

I really think it was the underpitched sacch, but who really knows.

Aw jeez bru! I was hoping you made it. I have wanted to try something like this for a while now but haven’t gotten brave enough to risk a batch either. I don’t have much in the way of local guidance and after reading a lot of your expBEERiments, I have come to put some weight in your experience. I will continue to research. If I ever bite the bullet and go off the deep end I will let you know.

Good Luck,

Cheers,

DragonHead

Haha… this is not the end, my friend 🙂

Did it before myself and had good results. The trick is to keep it anaerobic to avoid baby diaper/bile aromas. It’s best done souring the wort instead of a sour mash. Basically just like dry hopping with grains in a bag inside the carboy/corny(a corney is big time easier because of the wideness of the mouth)….basically what you already did on a larger scale. You can bring the temp down pre-transfer to around 130 by spraying the outside of your kettle with water. Transfer into carboy/corny, drop in the grain bag, hit the top with CO2 for 15 seconds or so, immediately cap with an airlock, and wrap in a blanket. It gives great tartness after about 12-15 hours. I’m a fan of this method because it basically breaks brew day into 2 easier chunks. Happy brewing!

Great write up! I personally have had great results with sour-mashing. I do it right in my mash cooler, and the key is to keep the temperature in the 105-115 range and keep the oxygen out! After I cool the mash down to 115 with ice, I throw in a pound of unmilled 2-row. Then I cover the surface of the mash with saran-wrap, flush the cooler with co2, and close it. If you do it this way, there will be no aromas of barf, baby-poop, or garbage and you’ll have a nice funky lactic character after about 24 hours.

Donkey Gooch, heh.

I recently did a sour mash on 20% of a grainbill, and the sour mash (itself) turned out wonderfully. The beer has just been moved to secondary with brett brux and Syrah oak cubes added for long-ish term aging (4-12 months, depending on how it progress).

Anyway, my research into sour mashing prior to performing it was this:

-L. delbruckii is anaerobic

-Clostridium butyricum is anaerobic (puke, rotting garbage, baby diapers)

-Acetobacter is aerobic

-Less than 112 allows Clostridium butyricum to populate and grow

-Between 120-130 and the L. delbruckii goes dormant

-Above 130 and the L. delbruckii dies

Based on this I chose to incubate a glass jar of sour mash inside my preheated MLT round cooler in a water bath of 120°F, which was wrapped in an electric blanket and kept on high as much as possible for 48 hours. One quart of old water was swapped out every 8 hours for boiling water.

The glass jar was filled with sour mash and purged with co2. I then laid a layer of plastic wrap across the surface avoiding trapping many bubbles and purged again. I added another layer of plastic wrap over the opening of the jar, and put the lid on.

This went into my “incubation vessel” and the headspace in the vessel was purged. Each time I swapped out the quart of water I re-purged the headspace.

Two days later I had a fantastically tart and clean smelling sour mash. I tasted it straight and it was tart, sweet, malty wort. This was added to my main mash (the other 80%) just before lautering and sparging. The rest of the boil went forward as normal and efficiencies were within a couple percent of expected. I sampled the entire wort several times during the boil and after chilling; the tart aspect was definitely present without being overwhelming.

As I said, I recently transferred this to a secondary for bulk aging and during the transfer I pulled a sample for tasting. While the sour is still very present across the top and sides of the tongue, I feel as though it has slipped into the background more than I expected. I wonder if I might have been happier with 30%; then again, I have brett brux in there that should drive down some of the residual sugars and I’m hoping that will have the effect of bringing forward the sourness a little more. Only time will tell.

I failed to mention:

-Innoculant was ~1/2 cup of crushed german pale ale malt

-Oxygen incorporation was kept to a minimum during mash and stirring of innoculant

-Temperature drops at the end of 8 hours varied from about 5-9 degrees (overnight was worst)

-Electric blanket has to be turned back on every 3 hours which is why overnight was biggest drop

Lacto work better in an anaerobic environment. This also suppresses the other bugs found on grain. You took no steps to stop O2 interaction. You’d definitely want to do this in a carboy or growler. Carefully transfer, fill it to the very brim, and cover it in foil.

The method I’ve used a couple of times now with reasonable success has been to save 2L of wort post boil which I put into a 3L erlenmeyer flask and add a handful of uncrushed grain. The best result came when I left this in a fermentation chamber at 18˚C for 2 weeks. It had developed a wonderful pellicle across the top and was super tart. I boiled this for 10min, chilled, then added to a keg to which I topped up with the clean fermented batch of beer. That ratio of 2L soured beer to 17L clean beer gives a great sourness though possibly not as harmonious as doing a sour mash. An easy way to sour a beer as it works alongside your regular fermentation. Perhaps taking more care such as flushing with CO2 and acidifying the wort would produce better results. Has anyone else soured like this?