Author: Matt Del Fiacco

Historical relevance aside, wood-aged beers have surged in popularity in the craft beer market, particularly for big, boozy styles. These beers are commonly aged in liquor barrels to impart characteristics from both the wood and alcohol, which while romantic, can be a cumbersome process. In addition to being pretty expensive, a good barrel can be difficult to maintain and takes up quite a bit of space. For the brewer seeking wood character without all the trouble, there are wood alternatives such as cubes, chips, and spirals, which get added directly to the beer.

Brülosophy Patron Brandon Lepley proposed an xBmt idea that was right up my alley. In his research, Brandon found a lot of conflicting timelines for alternative wood additions, with suggested contact times ranging from just a couple weeks up to a few months. On one end of the spectrum were critics claiming reduced contact time leads to unpleasant wood flavors, while others felt extended contact time was essentially useless, as any wood character would dissipate.

I’ve talked quite a bit about wood aging in the past, and while I have my own assumptive rule of thumb about wood-aging timelines, I was excited to collaborate with Brandon on this xBmt in hopes of learning something new!

| PURPOSE |

To evaluate the differences between beers aged on oak for either 2 weeks or 2 months.

| METHODS |

Brandon and I agreed on my house Porter recipe for this xBmt, as I’ve aged it on wood in the past and knew what to expect.

The Last March

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5 gal | 60 min | 33.0 IBUs | 27.2 SRM | 1.060 | 1.013 | 6.2 % |

| Actuals | 1.06 | 1.01 | 6.6 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Ale Malt (Muntons) | 10 lbs | 89.89 |

| Crystal, Medium (Simpsons) | 8 oz | 4.49 |

| Black (Patent) Malt | 5 oz | 2.81 |

| Pale Chocolate Malt | 5 oz | 2.81 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 14 g | 60 min | First Wort | Pellet | 12 |

| Cascade | 27 g | 15 min | Boil | Pellet | 5.5 |

Miscs

| Name | Amount | Time | Use | Type |

|---|---|---|---|---|

| American Oak Cubes - Medium Toast | 2.00 oz | 60 days | Secondary | Flavor |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| House (A01) | Imperial Yeast | 74% | 62°F - 70°F |

Notes

| Water Profile: Ca 50 | Mg 5 | Na 8 | SO4 36 | Cl 80 |

Download

| Download this recipe's BeerXML file |

Having collected my brewing water and adjusting it to my desire profile the night before brewing, I started my day by powering the controllers on.

While the water was heating up, I weighed out and milled two identical sets of grain.

With strike temperature reached, I added the grist to the water and checked to make sure both achieved the same target mash temperature.

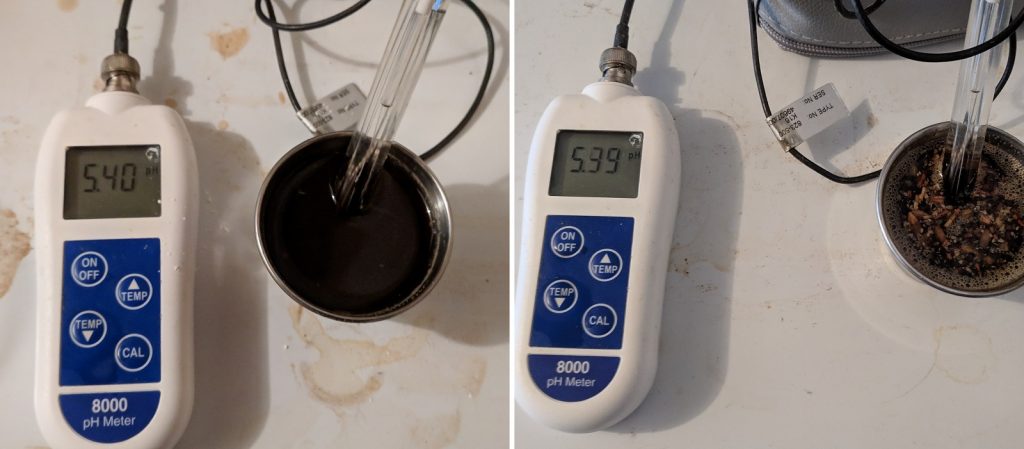

I took pH readings about 15 minutes into each mash rest that showed now real difference.

As the mashes rested, I prepared the kettle hop additions.

At the end of each mash rest, the grains were removed and the worts were brought to a boil, during which hops were added at the times listed in the recipe.

Following the 60 minute boils, I ran the wort through my counterflow chiller during transfer to fermentation vessels.

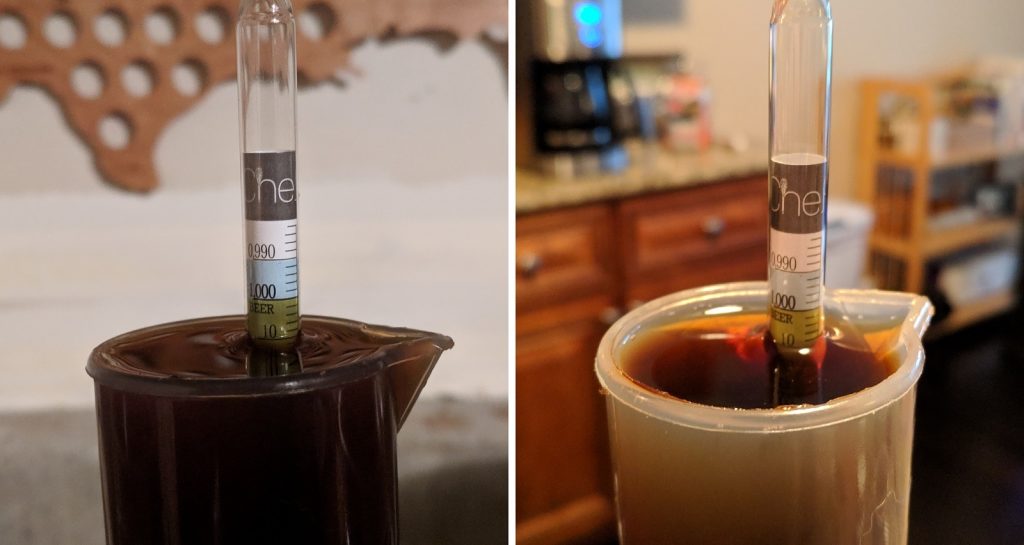

Hydrometer measurements confirmed both worts had reached the same OG, as expected.

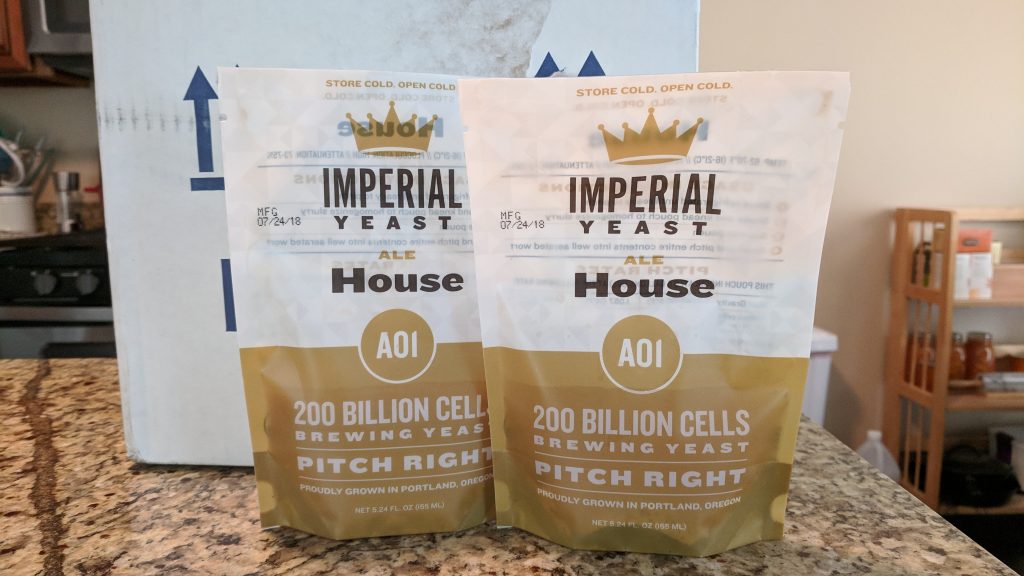

I placed the fermentors in chambers controlled to 66°F/19°C and proceeded to pitch a single pouch of Imperial Yeast A01 House into each batch.

With diminished signs of activity 2 weeks later, I took hydrometer measurements showing both beers were finished fermenting.

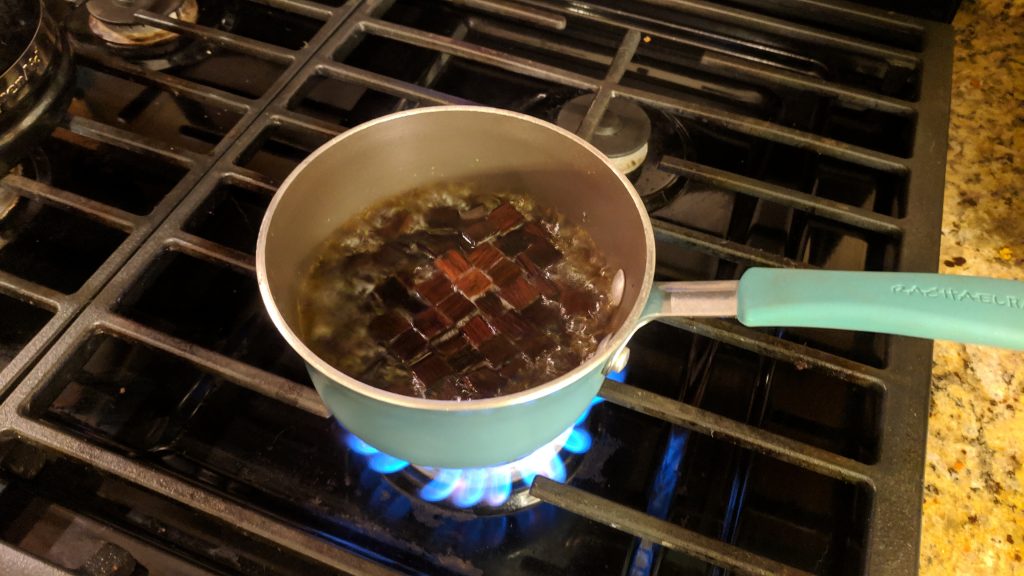

At this point, I prepared the oak for the beer that would be aged on it for 2 months by boiling it for 10 minutes.

The boiled oak was gently placed in the bottom of a sanitized keg, which was then purged with CO2 before being filled with beer. To keep things as similar as possible between the batches, the other beer was racked to a CO2 purged keg at the same time.

Six weeks later, I prepared the same amount of oak in the same manner as before then gently added it to the other keg, removing the lid from the batch that already had oak in it to ensure similar exposure to oxygen. After another 2 weeks, both beers were pressure transferred into CO2 purged serving kegs.

The beers were given a bit more time to condition than usual, a little over a month, as I was in the process of moving into a new home. Once settled in, the beers were nicely carbonated and ready to serve to participants.

| RESULTS |

A special thanks to the C.H.A.O.S. Homebrew Club for allowing me to crash their annual Stout & Chili Night to collect data for this xBmt! A total of 36 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the beer aged on oak for 2 weeks and 1 sample of the beer aged on oak for 2 months in different colored opaque cups then asked to identify the unique sample. While 16 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 13 (p=0.42) did, indicating participants in this xBmt were unable to reliably distinguish a Porter aged on oak cubes for 2 weeks from the same beer aged on oak cubes for 2 months.

My Impressions: Out of the 4 semi-blind triangle tests, I identified the odd-beer-out 3 times, which while not perfect, is pretty consistent. In my admittedly biased opinion, I felt the beer that was aged on oak for 2 months had a slightly richer mouthfeel and stronger wood characteristic with more chocolate flavor compared to the one aged on oak for 2 weeks. That said, both beers were delicious, perfect for the unreasonably cold Illinois winter.

| DISCUSSION |

There is more to barrel aging than the contributions of wood characteristics, and arguments of scale certainly come into play when we consider its impact on the homebrewing scale. Contrary to a barrel, alternative wood additions don’t play a meaningful role in determining the oxygen exchange rate of the vessel the beer is stored in. Furthermore, surface area-to-volume ratio becomes increasingly difficult to calculate based on the penetration of beer in a smaller alternative wood addition relative to the staves of a barrel. The effect of the toasting process changes too, as does the typical lack of a char on homebrew wood additions.

It is perhaps due to carry-over practices and disjointed logistics such as these that homebrewers have typically recommended longer aging periods for beers in contact with wood, regardless of the volume, type, or toast of the wood itself. The fact tasters in this xBmt were unable to distinguish a Porter aged on oak for 2 weeks from one aged for 2 months suggests cubes possibly contribute maximum effect within a 2 week period, or perhaps the more granular contributions simply aren’t large enough to be detected.

These results have me thinking less about what wood contributes to beer, and more about the overall situation surrounding the use of wood in beer. Do aging recommendations come from a need for the beer to age, regardless of the fact it is in contact with wood? Is a fresh barrel more harsh than boiled wood cubes, and as such, the longer aging period alleviates some of that harshness? There’s a lot of room to explore the variable of wood aging further, and I look forward to doing so.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

19 thoughts on “exBEERiment | Wood Aging: Impact Contact Time With Oak Cubes Has On An American Porter”

Great xbmt and very timely… I’ve got a KBS clone aging on about 2 oz of bourbon soaked cubes as I type this… it’s been about 2 weeks and I was planning to leave it in for at least a month, tasting every week to see if I can tell a difference. It’s my first time using a wood addition.

Thats awesome dude! I think wood additions are a fantastic alternative to barrels for home brewers, especially soaked in bourbon. Since it has been two weeks, you could even try this xbmt for yourself! Make another tincture, then try the 2 week and 1 month samples side by side.

Great xbmt! How you handle the oak cubes, the water to oak cubes ratio and you drain the water before adding to the keg?

Thanks!

I actually do not include the water before adding the cubes to the keg, the point of that boil is two fold: Remove initial tannic character, and sanitation. Adding the water back would contribute some of that tannic character as well, so I use just enough water to cover the cubes. If using liquor soaked cubes, I do the same thing. Boil in water, add just the cubes to the liquor, and then ultimately add BOTH the liquor and the cubes.

Cool xbmt! There are certainly a lot of avenues you can further explore when it comes to wood aging beer. I have often wondered but never tried for myself, the effects of wood aging on lighter styles like pale lager and pale saison. I really only see wood aging on lighter styles when it involves some sort of mixed culture or the use of wine barrels to impart the character of say chardonnay to the beer. I imagine the lagers of Germany which were stored in barrels in cool caves for long periods of time must have had some sort of wood character, good or bad.

Maybe a pale style for the next xbmt? Or maybe pale styles aren’t done with wood anymore because the results are not good? I’b be curious though. Thanks for the work!

Love it! I’ve actually had a wood aged imperial pilsner before that was really pleasent, as well as an IPA aged on cherry wood. It can definitely be done well, I’m honestly not sure why we don’t see too much of it in the market. But I’ll be putting this on the list!

Well, isn’t Budweiser supposed to be aged with beechwood?

I don’t know what the wood does for Bud, and I don’t ever remember tasting it in Bud. Someone here has to know!

Ha the beechwood used in Budweiser is actually treated so that it doesn’t contribute flavor to the beer! It is primarily used to increase the amount of surface area the yeast has to be in contact with the beer.

What temp. were they aged at with the oak? Cold or warm?

Depends on perspective, a little bit of both? My basement sits at around 58F – 60F, give or take.

For cubes, it’s more of a 2 month minimum contact time. The cubes are toasted, and since they are thicker they have a gradient of flavor impact, so you want them in there longer to get all that wood goodness. 2 months is too short. In my experience.

Nice work! I have used two methods of adding wood. I have toasted oak chips dry in a skillet then added to Bourbon, then added both oak and Bourbon to beer. And I have used a blow torch to toast the oak chips then added to Bourbon, then added both Bourbon and oak chips to beer.

I have not yet tried not toasting or not bourboning. I enjoy the char flavor. Both these methods worked great. I didn’t notice too much difference in the skillet vs the blowtorch, but the blow torch is wayyy more fun.

Great experiment! It would be cool to see the difference contributed by different types of oak alternatives. E.g., I’ve heard that people use chips for shorter periods of time (given greater surface area:mass ratio) vs. cubes for longer aging. There’s a component of how quickly each contributes flavor to the beer as well as the actual quality of that character.

I think I’d have bet on this coming back insignificant – it’s not a particularly high abv beer, with a relatively short maturation time on the wood and it wasn’t too warm where they were stored – 58F, did you say? There’s not a lot of potential in those conditions for the lignin etc in the wood to break down and for those vanillins and low molecular weight phenolics to begin to express themselves. Another vector for faster wood maturation is lower pH, so sours tend to get more from the wood faster than beers of a regular pH. But the experiment usefully shows that if you’re looking for some nice toasted oak character, you can get away with a few weeks without too much f.o.m.o. Nice one.

Would be interesting to see this done with two 18 month old barley wines – 1 on oak the whole time, the other on oak for a month or two. I’d bet on that coming back significant!

There’s some good stuff on wood aging here:

https://www.ibd.org.uk/resources/document-library/wooden-casks/wood.pdf

Do you have any plans to Exbeeriment with the difference in toast levels of the wood cubes? I’ve seen these for sale with different toast levels, but I’m not sure how that affects the beer. My understanding was that the charred inside of a barrel acted as a filter. Does the char also impact the flavor?

Thanks for all the fun.

I was wondering if wood-ageing provides some stability for long term storage.

Tannins acting as anti-oxidants. I know not all are created equal.

Great job

Mike

Is it me, or does boiling the cubes for 10 minutes seem excessive? I only boiled water in the boundary waters to sanitize for 5 minutes.

How much wood flavor is lost with the tannins in the boil?

Brandon’s beer is amazing. I love his full flavors. I’m not a critic so may not be describing this according according to standards but love the beer.

Hi there,

Nice xbmt!

how many grams of wood cubes did you use for each 5 gallon batch?

Thanks