Author: Jake Huolihan

The most common method used by new brewers to carbonate their beer is bottle conditioning, a simple procedure that requires little in the way of additional gear. Generally, a specific amount of sugar water is incorporated into the beer in a bottling bucket then transferred to bottles and capped. The remnant yeast in the beer metabolizes the added sugar, creating carbon dioxide (CO2), which gets dissolved into solution leading to an effervescent beer. The process takes some time, but it works, and with modern calculators, carbonation levels can be precisely tailored to one’s liking.

One posited benefit of bottle conditioning is that it can reduce the risk of oxidation since yeast consume any dissolved oxygen during the refermentation process, thus improving shelf and flavor stability. However, the common recommendation to store beer relatively warm during the conditioning period, which can be anywhere from 1 to 3 weeks, is cause for some concern since temperature is positively correlated with chemical reaction rates– any changes bound to occur will do so faster in a warm beer than in a cool beer.

With growing evidence suggesting a particular susceptibility to the deleterious effects of oxygen, packaging methods have become a major focus for brewers of hazy New England IPA (NEIPA). The internet abounds with stories of NEIPA that started out great but quickly turned, often accompanied by pictures of murky beer in shades of grey, brown, and purple. One solution to this problem involves limiting the beer’s exposure to oxygen post-fermentation by racking into a CO2 purged keg, though such a process is unavailable to those who bottle condition.

Considering the results of our recent xBmt on cold-side oxidation of NEIPA along with numerous reports of bottle conditioned NEIPA quickly discoloring, I began to wonder if bottle conditioning actually leads to a qualitative difference as compared to force carbonation. Shelving my abhorrence for the bottling process, I hunkered down to test this one out!

| PURPOSE |

To evaluate the differences between force carbonation and bottle conditioning in a New England IPA.

| METHODS |

I designed a NEIPA recipe with a fairly common grist and solid hop charges of Centennial, Cascade, and my new favorite, Loral.

Purple Haze

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 23.9 IBUs | 4.7 SRM | 1.062 | 1.016 | 6.1 % |

| Actuals | 1.062 | 1.018 | 5.8 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Ale, Finest Maris Otter (Simpsons) | 6.75 lbs | 45.38 |

| Pale Malt (2 Row) US | 6.75 lbs | 45.38 |

| Oats, Flaked | 1.375 lbs | 9.24 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 14 g | 30 min | Boil | Pellet | 11.5 |

| Cascade | 21 g | 5 min | Boil | Pellet | 5.5 |

| Centennial | 21 g | 5 min | Boil | Pellet | 10 |

| Loral | 14 g | 5 min | Boil | Pellet | 10.3 |

| Cascade | 28 g | 3 days | Dry Hop | Pellet | 5.5 |

| Centennial | 28 g | 3 days | Dry Hop | Pellet | 10 |

| Loral | 28 g | 3 days | Dry Hop | Pellet | 10.3 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Juice (A38) | Imperial Yeast | 74% | 64°F - 74°F |

Notes

| Water Profile: Ca 174 | Mg 0 | Na 8 | SO4 150 | Cl 200 |

Download

| Download this recipe's BeerXML file |

The night before brewing, after adjusting the full volume of water to my desire profile, I weighed out and milled the grains for two identical 6 gallon batches.

When I woke up the next morning, I immediately turned on the element to heat the water to slightly warmer strike temperature, at which point I transferred equal volumes to separate mash tuns for a brief preheat before mashing in to hit my target temperature.

Each mash rested for 60 minutes.

Since the variable being tested would be introduced post-boil, I collected the sweet wort from both mashes into a single kettle. The wort was then boiled for 60 minutes with hops added per the recipe.

When the 60 minute boil was complete, the wort was quickly chilled to my desired fermentation temperature of 66°F/19°C.

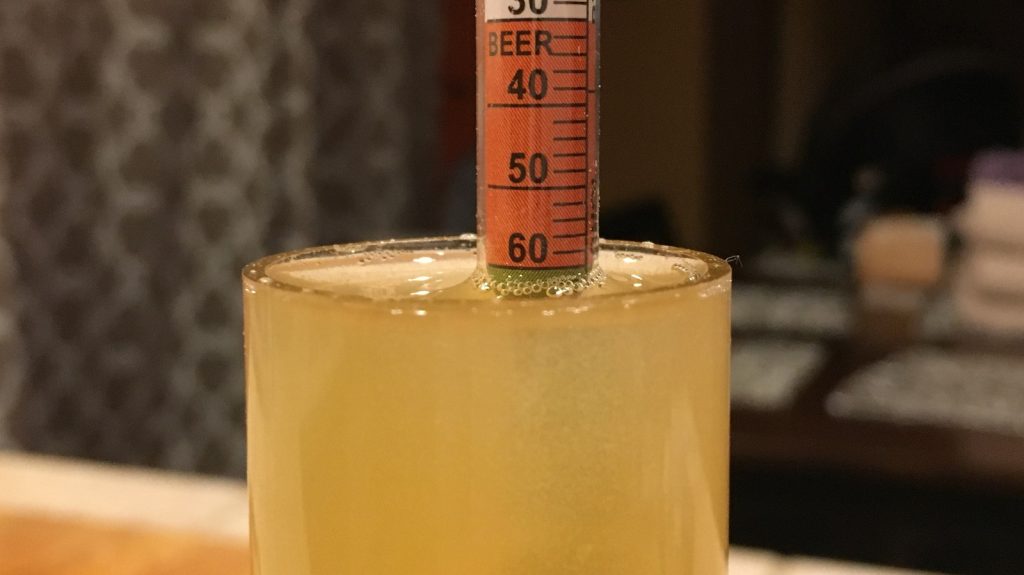

A hydrometer measurement showed the wort had hit my target OG.

I filled 2 identical fermentation vessels with equal amounts of wort then placed them in my temperature controlled chamber and pitched a pack of Imperial Yeast A38 Juice into each.

I checked on the beers about 10 hours later and noticed both were fermenting actively. The following day, 2 since pitching yeast, I added the biotransformation dry hop charge.

Signs of fermentation were absent 8 days post-pitch, so I took initial hydrometer measurements indicating FG had been hit; a second round of measurements 3 days later were unchanged, confirming fermentation was complete.

The time had come to begin the task of preparing to bottle 5 gallons of beer. Each beer was first transferred to a CO2 purged 5 gallon corny keg, only one of which had a pre-determined amount of sugar solution in it. The force carbonation beer was immediately placed in my keezer and hit with gas per my usual routine, while I used a Blichmann Beer Gun to fill each bottle from the other keg.

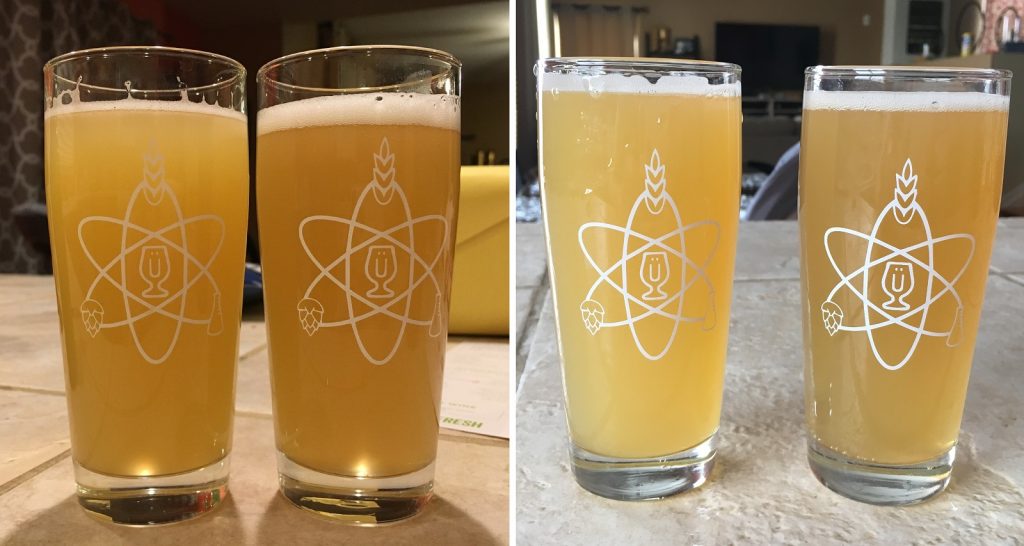

The filled and capped bottles were placed in a room that maintains a fairly consistent 66°F/19°C to carbonate. After 1 week, I impatiently chilled a bottle for an early comparison and decided to leave them be for another few days to ensure they were properly carbonated. Visual comparisons to the kegged version at both of these points were very interesting, the bottle conditioned beer appearing noticeably darker both times.

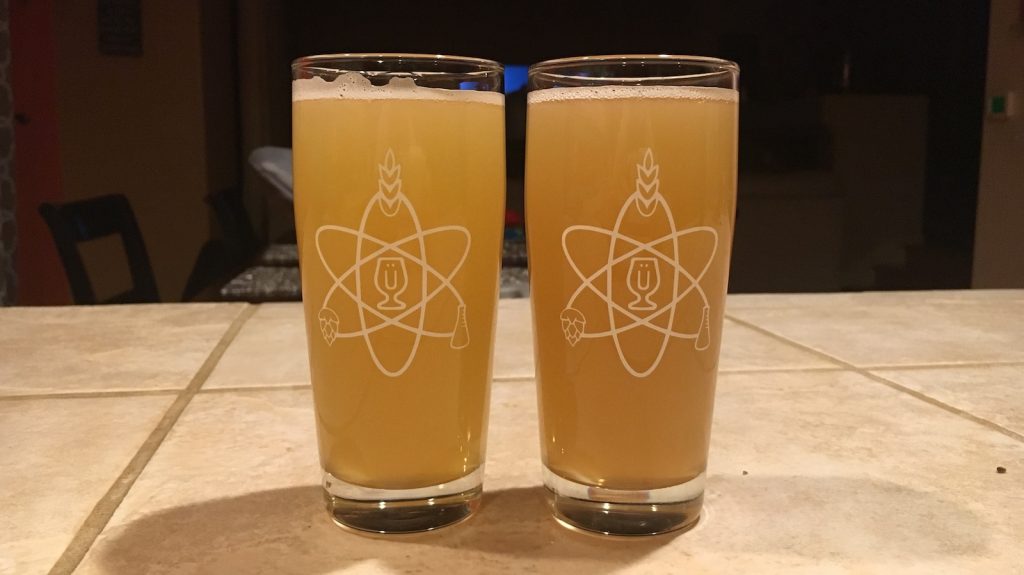

Wanting to give the bottle conditioned beers enough time in the fridge to allow things to drop out of solution, I began collecting data after another week, at which point the visual difference between the beers was even more stark.

| RESULTS |

A total of 20 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the force carbonated beer and 2 samples of the bottle conditioned beer in different colored opaque cups then asked to identify the sample that was unique. While 11 tasters (p<0.05) would have had to identify the unique sample to reach statistical significance, only 6 (p=0.70) made the correct selection, indicating participants were unable to reliably distinguish a New England IPA that was force carbonated in a keg from one that was carbonated via bottle conditioning.

My Impressions: Sampling these beers next to each other just 10 days after they were packaged, I was pretty convinced they were different and confident tasters would be able to distinguish them. Of course, I not only knew the variable, but saw their difference in appearance, which undoubtedly biased my perception. In an attempt to reduce at least some of this bias, I attempted a total of 10 semi-blind triangle tests served to me in opaque cups, out of which I chose the unique sample a whopping 2 times. I actually did worse than chance. My first 5 trials were completed when the bottle conditioned beer had been conditioning for 10 days, while the last 5 trials were occurred when the beer had been conditioning for 21 days. The beer itself was great! I really enjoyed the aromatic punch that came from the hops used, it reminded me of grapefruit juice with a citrus bite.

| DISCUSSION |

Bottle conditioning certainly has it’s critics, not only those who loathe all that’s involved in getting 5 gallons of beer into a bunch of bottles, but some also claim it produces a different quality than force carbonation. Then again, the fact it necessarily involves a refermentation period has led many to believe bottle condition can reduce the risk of oxidation in the package, thereby improving overall shelf stability. With the results from this xBmt corroborating those from our last comparison of bottle conditioning and force carbonation, it seems a plausible assumption that both methods produce qualitatively similar characteristics.

However, accepting such a conclusion would require ignoring one glaring difference– the surprisingly disparate appearance of the beers. As far as I can tell, stories of beer turning purple and gray were all but absent until a few years ago when brewers began reporting observations of such in NEIPA, both commercial and homebrewed. Various hypotheses have been posited as to the cause of this issue, the most common culprit being post-fermentation oxidation, an issue bottle conditioning can presumably help to ameliorate. If this is true, why did the bottle conditioned beer change color?

Even more confounding is that, despite this very obvious color change, tasters blind to the appearance of the beers could not reliably tell them apart based on aroma, flavor, and mouthfeel. The murky, purple, disgusting looking bottle conditioned sample tasted the same as the creamy, orange, beautiful force carbonated sample to a majority of participants.

What?!

I’m not even going to attempt to provide a cohesive explanation as to what’s going on, so instead I’ll free associate…

Maybe there’s a point of no return with NEIPA… the one in the cold-side oxidation xBmt was pushed into a purged keg with CO2… I purged the keg for the force carbonated beer in this xBmt but transferred it via gravity… perhaps the presumably small amount of oxygen exposure from the exchange of air is enough to begin the staling process such that, even though they looked different, they had the same aroma and flavor because they were equally oxidized at the time of packaging.

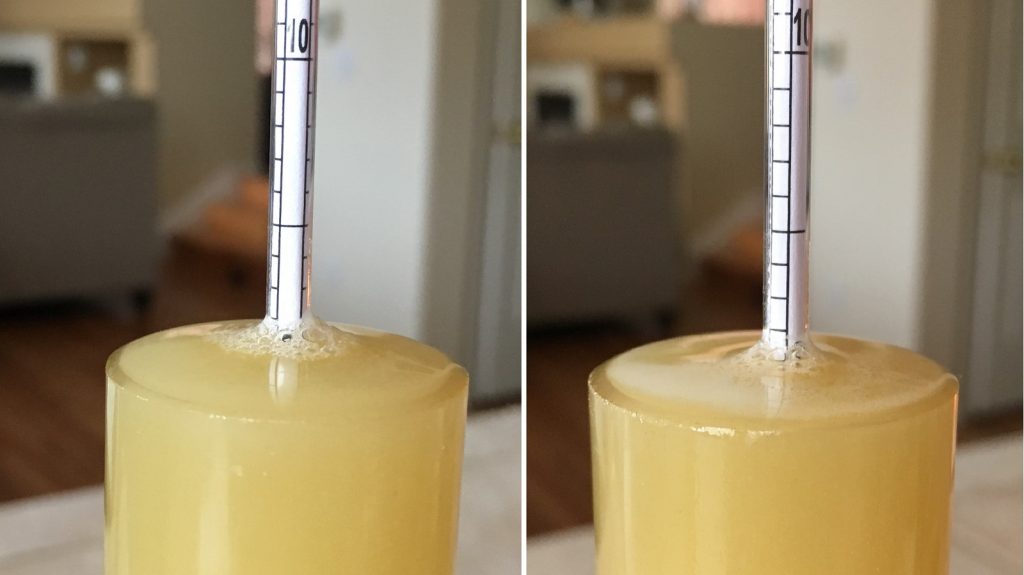

Out of curiosity, I did a little side experiment to test the impact oxygen exposure in a warm environment has on NEIPA, similar to what was done in the recent xBmt comparing flaked oats to wheat malt. I left uncovered samples of both the force carbonated and bottle conditioned beers on my counter for 3 days, taking a photo daily to document any changes in appearance.

Immediately after pouring

After 8 hours

After 16 hours

After 36 hours

After 48 hours

The results were astonishing. I’ve left half-full glasses of other styles of beer out in similar situations numerous times, usually unintentionally, and never have I witnessed such a rapid change in appearance. While bottle conditioning, for whatever reason, does seem to hasten the onset of the discoloration compared to kegging, the fact both samples so quickly turned suggests the issue has more to do with the style overall.

I have no plans to go back to bottle conditioning my beers, I far prefer the ease of kegging, and unsurprisingly, the dark NIEPA from the bottle was very unappetizing to me. In fact, prior to my 10 triangle test attempts, I’d convinced myself I’d not only be able to tell the beers apart, but that the force carbonated version was much better. How easily our perception can be influenced by the way something looks. All in all, I find it sort of comforting that tasters could not tell the beers apart when appearance was hidden, as it suggests decent tasting examples of NEIPA can be made by those who don’t keg, even if it ends up resembling something from another planet.

If you have any thoughts about this xBmt, please share them in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out our Support page for details on how you can very easily do so. Thanks!

74 thoughts on “exBEERiment | Impact Bottle Conditioning Has On A Hazy IPA”

A very topical and interesting exbeeriment! Although personally I think that there should have also been a test with older bottles than just two weeks. Given that the change in bottle is so rapid, I would assume that the taste is also deteriorating faster and if you bottle a batch, you probably won’t drink all of it two weeks after bottling. Same goes with the commercial examples where you probably won’t get a bottle of NEIPA so fresh if you don’t pick it up from the brewery. Again, thanks for the test!

Cheers! It’s on the list

It’s a long list, huh? Seems like every experiment exposes more questions than answers. There’s just so much we don’t understand yet. You guys are doing good work!

Great experiment! I think you were already very careful with bottling with a beergun from a keg. Did you flush the bottles with CO2 prior to filling? I’m guessing that already helps a lot in reducing oxidation.

I just know that for me, with the tradional racking of the beer to the bottling bucket and then filling non-purged bottles from that bottling bucket led to severe oxidation within a few days.

As a second note, does anyone know how much oxygen stays in the bottle after natural carbonation has finished. I always heard a number of 70% percent of the oxygen still being at the end of natural carbonation, but don’w know if that’s based on anything.

The bottle condition beers were not flushed with co2.

I don’t how much oxygen stays in the bottle v is consumed. Be interested to know that better for sure

Any dissolved oxygen will be consumed rapidly. At 20C (room temperature) you can dissolve a maximum of around 9mg/L (same as ppm, parts per million) oxygen. So if you really wisk around 1L of beer there will be 9 mg of oxygen in it. How much sugar is needed to consume that oxygen?

First, how many moles are 9mg oxygen? 0.009/32 (molar mass of 02) = 0.00028.. moles.

Then how many oxygen molecules are consumed per glucose molecule?

C6H12O6 + 6 O2 -> 6 CO2 + 6 H2O, so 6 molecules of oxygen to one molecule of glucose. So we require:

0.00028…/6 = 4.69e-5 …. moles of glucose to consume that oxygen.

How much sugar is that?

4.69e-5..*180.16 (molar mass of glucose) = 0.00844 g or 0.0003 ounces. Compared to the 5-8 g/L of glucose used in the bottle conditioning that is nothing.

So, should we be more worried about oxygen in any air in the headspace? In a typical bottle the headspace might be around 15 ml (on tablespoon), how much oxygen is in that space?

At standard conditions, 1 liter of air at 21% oxygen possesses 0.21 L of oxygen. Since at STP 1 mole of gas occupies 22.4 L, simply divide 0.21/22.4, to arrive at 0.0094 moles of oxygen in 1 L air. In 15 ml there is then 0.0094 * 0.015 = 0.000141 = 1.4e-4 moles of oxygen.

Compare that with the 0.00028 moles dissolved in one liter of beer. In a half litre bottle there is then 0.000141 /(0.00028*0.5) = 1.00

So almost exactly the same as the dissolved oxygen (assuming vigorous oxygenation).

@Anders

The reaction you used for your calculations is a combustion reaction. This is [fortunately] not what’s going on inside the bottle.

If you would have flushed the bottles before putting the beer in there and again flushed the headspace before capping there would be no such grate difference if at all. And consider also bottling straight from fermenter with sugars measured to the bottles if you don’t have keg systems. Works wery good and makes wery nice hippy and bright neipas.

I recently switched to kegging after bottle conditioning (bottling bucket with bottling wand) for several years.

The difference in shelf life and hop aroma is night and day ESPECIALLY for dry hopped beers!

Would be interested to see this experiment retried with samples after several weeks. This experiment is great but warrants additional testing

I haven’t yet tried bottle conditioning with my beergun, but would be curious to see how well purged and bottle conditioned beers perform compare to force carbonated.

I bottle all my beers for a number of reasons so this is a really interesting test for me, particularly the non-significance on tasting vs appearance.

I presume the reason you did two batches was you wanted to avoid deadspace in the keg? Otherwise I would have thought it would be simpler to brew a single batch and only split at packaging – this would also eliminate the risk of experimental error in the earlier steps.

One variable I’ve seen mentioned as an issue for commercial bottling runs is the cap. Some caps are apparently better than others at keeping oxygen out, with all sorts of cap liners being tried to reduce oxygen pickup. Possibly worth trying an A/B/C with flip-top type bottles (like a Grolsch bottle) vs crown caps vs screw caps to see if the type of bottle has an impact?

Another variable that might be worth testing is the fermentation type itself rather than the container. It might be interesting to compare “normal” bottle carbonated vs force carbed beer bottled using a counter pressure filler (like a Beer Gun). This would hone in on whether yeast activity creates any differences. If that test didn’t present a difference, then to hone in on whether it’s the container type that produces the difference, you could naturally carbonate in a keg and bottle from that, compared to bottle carbonated.

>I presume the reason you did two batches was you wanted to avoid deadspace in the keg?

Actually i wanted 10 gallons of beer instead of 5 🙂

It would be interesting to compare these two beers after they’ve aged a bit more, so you can see whether bottle conditioned beers have longer shelf life, as many bottlers believe.

The colour change is, I think, more related to the style of beer than the packaging method. I’ve been bottling beers for 30 years and never seen this darkening, but I’ve never tried making a NEIPA yet.

I haven’t noticed (maybe not looking closely enough) this problem with batches I’ve brewed/bottled before, but I didn’t really ramp up the Cl levels like a true NEIPA. Do you think that has any impact on it?

I’ve been waiting for this exbeeriment for awhile. I’m glad to see you guys did it. I’ve had commercial NEIPAs from bottles that when I poured were a greyish puprle color, but they still tasted fine.

Great exbeeriment!

Oats seem to be one commonality in most all NEIPAs. Maybe they are the culprit for fast discoloration? Maybe it’s just flaked oats and if you had used oat malt it would be different? Perhaps a NEIPA that uses oats and another that uses wheat for proteins, left out side by side for 48 hours, would be a good way to check this? Maybe I’ll even do this as it’s has my curiosity majorly peaked.

That’s exactly what I’m wondering. I had also wondered if the change in appearance might be caused by sediment dropping out & the beer clearing, but the dark brown colour looks far too strong for that, so oxidation seems much more likely.

There’s an older exbeeriment where Brian Hall compared NEIPAs made with oats and wheat and found the two looked identical and tasted the same (no sig difference). Brian left a glass of the oat beer out for a few days and it turned a horrible dark colour (but he didn’t do the same test with the what beer).

So my suspicion is that the oats are causing colour problems after oxidation but contributing nothing to flavour. The solution might be to make bottled NEIPA with wheat instead of oats.

https://brulosophy.com/2017/10/30/flaked-oats-vs-wheat-malt-in-a-new-england-ipa-exbeeriment-results/

[IMG]http://i68.tinypic.com/2hi8289.png[/IMG]

That’s a shame he didn’t leave the wheat version out as well. Thanks for the link!

I have made two batches of NEIPAs, which partially would cover that experiment. First batch I used pale, wheat and meladonin, second batch was pale, wheat, flaked oats.

Had discolouration on both batches – overall discolouration seems to be higher on the first batch though.

My line of thinking as another factor for greying was trub density. The first batch had a lot more hop trub in the bottles, the second one I slightly filtered. Which in my setup actually leads to an increase in oxidation.

Quite a few factors – it’s a rabbithole

I have bottled 3 NEIPA now and have not seen any color change. It was botteld directly from Fermentaourus and was very keen on not intrrducing air, hence, I very carefully poured and strewed the sugar-solution into Fermentaourus, or lastly used sugar-packs (not sure of the english word of those small packs of sugar weighting 2.1gram each for a 330ml bottles), where the later worked very fine.

When botleding make sure the siphon do not allow the beer-solution to run to fast in the beginning of filling the bottle hence make sure it do not makes boobles, eg. lift the bottle up near the same level as the outlet and carefully fill the bottle firstly for then lower it a bit for faster filling.

Good one! I accidentally did this expariment last year with similar results, but I also had an interesting additional data point. I bottle primed 6 bottles of NEIPA for a competition at the same time i kegged therest of the beer thinking the bottle conditioning would decrease oxidation.

After receiving score sheets that noted oxidation I did a side by side taste between the bottled & kegged beer. The color & taste difference was stark. The bottled beer was Brown, muted & grassy, but the keg was still pale & tasty.

Where it gets interesting is this was actually a split batch. Before adding the flameout hops I ran off part of the wort and diluted it to make an “oat kolsch”. I did the same thing with it and bottled a 6er while kegging. This 1/2 of the batch did not have any of the color and flavor differences the NEIPA half did. The bottled and kegged versions were very similar.

My thought is that the dry hop either introduced oxygen or catalyzed the reaction. I have pics of both side by sides of you want them?

Very interesting! I too wonder about hops being the main catalyst for the color change, especially ones containing certain compounds potentially from fertilizers used in the growing process.

I’m pretty sure I’ve read on Scott Janish’s blog that hops contain some of the same colour compounds as fruit that also goes brown when exposed to oxygen – for example, apples.

Chefs stop this colour change by adding acid or sugar… I wonder if dry hopped sours go brown when oxidised?

Would be very curious to see an exbeeriment done with pellet dry hops vs. cryo hops. If hops are a contributor to the darkening due to oxidation (which I believe to be the case), it would make sense that eliminating half the vegital matter in the beer would make a significant difference. Cryo hops would accomplish that.

Are you certain that the bottle conditioned beer really is darker than the kegged beer, and not only clearer?

When viewing the beers (and especially taking a photo using a flash) the cloudier beer will appear lighter in color as it reflects more light back at the observer, in contrast in a clearer beer the light will penetrate more easily and then have a greater chance of being absorbed – making the beer darker.

Why would the bottle conditioned beer be clearer, after all there will be yeast in the bottle?

Two reasons:

1. The bottle is much lower than the keg meaning by the time all the matter in the bottle has sedimented that process is only partly underway in the keg, and the bottom of the keg will actually be more cloudy than it was when filled. (A particle will sediment at a given rate = distance / time)

2. The storage temperature of the bottles was higher which means sedimentation will be quicker as the molecular and particulate speeds are greater at higher temperatures.

It’s funny, i actually struggled to capture the color difference in photo, it’s much more stark in person. I looked at these long and hard to determine if turbidity was causing the color difference and came to the conclusion that i couldn’t tell if one was “more clear” than the other. Both are quite turbid.

Did you try shaking/stirring to redistribute any settled sediment? That would resolve the issue pretty quickly.

For a few of the personal glasses of the bottles version I swirled the sediment and dumped it into my glass. Honestly looked way more disgusting than it already looked so I didn’t do that for any of the pics you see.

Agree that clarity (suspended material) will impact the perception of color and thus darkness vs lightness of a beer, especially with a flash. We see it all the time on various social media platforms when someone uses harsh front flash.

As to the floc rate – you accounted for some portions of Stokes Law, as it applies to sedimentation, but omitted others.

{Fd =6*pi*η*R*v}

Fd is the frictional force – known as Stokes’ drag – acting on the interface between the fluid and the particle

η is the dynamic viscosity (some authors use the symbol μ)

R is the radius of the spherical object

v is the flow velocity relative to the object.

But that doesn’t tell the whole story, instead of rehashing, readers to can go here (easy to read) or to a more reputable Science based site.(https://en.wikipedia.org/wiki/Stokes%27s_law). We need to consider the flow around a sphere (the objects in suspension), their mass – and whether that masss will overcome the resistance to said object falling due to relative molecular mass as comp’d to forces holding it in place.

Yes, distance is less in the bottle, and the viscosity of the the due to the thickness of the fluid is lower in the bottle due to temp; however, there is potential for the increased mass due to flocculation – of not only yeast but also proteins and fats – which may impact the rate at which the objects fall.

Another aspect if yeast metabolism. Some studies have suggested that when yeast are active and/ or at standard activity temps (60-70F9 they are less apt to attach to each other as compared to colder temps. And the micro fermentation in the bottle may create enough friction to hinder floc – potentially due to CO2 production. (http://onlinelibrary.wiley.com/doi/10.1111/j.1365-2672.2010.04897.x/full#f3)

Kegged homebrewed beer is consistently clearer (and less cloudy) than bottled beer (look at the saison example linked in the post). My personal experience with my and friend’s homebrew has also demonstrated this finding

I bet there’s going to be a lot of disappointed people sending bottles of NEIPA to NHC, forced carbed or not.

Could you do another one comparing bottle conditioned vs force carbd and bottled off the keg? For people looking to do comps, one might be more viable than the other.

I wonder if the kegged beer was left at the same temperature as the bottled beers while they were carbonating if the colors would be more similar… Great article

Next time send samples to a lab to have disolved oxygen levels tested objectively.

That’s really not how testing packaging DO works. You need to measure it immediately or else it’s consumed by reactions. Also would be difficult to measure packaging DO of a corny keg.

Interesting and surprising results here, especially the stark change in color without change in flavor/mouthfeel etc. However, your bottling technique here really is a “best case scenario” which still may not be available to those without kegging setups. I wonder if bottle conditioned beer packaged using the standard/basic method of transferring into a bottling bucket on priming sugar and filling bottles through a bottling wand would give you different results.

This was my only quibble!(not really a quibble, but i’ve seen a much more stark difference when using a bottling bucket/stirring in sugar, which is both the ‘worst case’ and the ‘most common beginner’s following instructions’ method.

Otherwise, awesome test! So glad you finally bit the bullet and bottled an entire batch. I feel for you. Kinda shocked nobody could taste the difference, but I guess with that quantity of hops, everyone probably just tasted hops.

I had a minor brew day accident the first time I made a NEIPA, where I ended up with about 4 gallons of wort… I fermented and it looked incredible; bright orange, hazy and beautiful. I kegged the beer in a 5 gallon corny, so there was a little over 1 gallon worth of headspace, and tossed it in my kegerator to carbonate… at which point I discovered I was out of CO2. Took me about 4 or 5 days to get my CO2 canister refilled and get the beer on gas.

All this context to share that my kegged NEIPA tasted great but turned a very puzzling grayish color by the time I started pouring pints. It was the keg version of the bottle scenario (sort of)… I theorized it was due to oxidation but it’s cool to see a similar scenario deliver similar results.

A brewer on the Brewtube facebook group https://www.facebook.com/groups/BrewTubeMk2 also conducted an experiment, trying to find out the cause of the colour change. He bottled 2 beers from the keg, and kept them both in the dark – One in the fridge and the other at room temp. The room temp version experienced the colour change much faster than the cool bottle…

Maybe it’s temperature that’s the culprit rather than oxidisation, or a combination of the two?

Yes could well be temp – it’s a shame the two batches weren’t treated the same way in this respect as temp has become an alternative dependent variable.

Intersting yet shocking results!!!

A few years back, ascorbic acid (vitamin C) was used as a antioxydizing agent. A small amount (1ml/gal) could be added to your beer just before packaging to prevent oxydizing and prolong shelf life (apparently).

We don’t seem to hear very much about this method anymore….

Any updates or comments regarding this addition ? Could this be a solution to oxydizing beer… ?

It may be interesting to repeat this experiment to see if you get the same results with Brewtan B or will Brewtan B hinder the color change. Nice work, though.

This beer had BtB, been standard practice for me for a while now.

Do you think that could explain why there wasn’t a difference in taste?

Definitely possible though I can’t say for certain. I’m not aware of BtB being used to combat post fermentation oxidation but do believe it’s used to remove some of the proteins which may oxidize in the package. Either way if it helped in this instance it does not appear that it prevented the color change. We’re definitely testing BtB and will be interested to see what comes of it

Loved the exbeeriment, as I have certainly noticed this discoloration in my NEIPA before I moved to kegging.

One question though: If you’re testing out bottle conditioning vs kegging, why wouldn’t you chose to use equipment that most bottlers will be using? Most bottlers will be using a bottling bucket and will not have access to a CO2 purged keg + Blichmann beer gun. While the results are interesting, it’s real life applications would be limited to only those who CAN keg but CHOSE to bottle?

Then there’s the people who complain that he didnt use the best case scenario for bottling. Just extrapolate the information into your own circumstance 🙂

Hum. Looking at the recipe I can’t help to wonder… have you guys ever had a NEIPA? The recipe is quite strange. No whirpool? A bittering addition? Only 3oz dryhop? Maris otter? (try Golden promise next time) … This is quite strange. You guys need to come out east and get a tour of treehouse/trillium/alchemist and suchy…

Also… Centennial? Cascade? What is this?!?! Try galaxy and mosaic next time ;o) …

Hate to say it, but I agree with this guy

Excellent experiment!

Once did an experiment dividing the wort of a single mash into 3 kettles. In each one I’ve made a single hop NEIPA. One using Citra, and the others Azacca and Mosaic. After 20 days of bottle conditioning, the Azaca and Citra NEIPA became disgusting dark, but the Mosaic one remained beautiful orage until the last bottle 6 weeks later. All the bottles were stored in the fridge after 10 days of carbonatation and I took the same care during botteling to avoid oxigenation. After that, I’m thinking if some hop varieties can make the NEIPA more susceptible to oxidation…

Not sure if I missed it in the write-up (or the comments), but did you take great care to make sure each version had the same volume of CO2? I’m wondering if it is not an O2 thing, but rather a CO2 (& pH) thing… This is just a hunch, but if the bottle conditioned version had less CO2 (and/or different pH) to start with, that may account for the slightly darker color. At acidic pH, the CO2-HCO3-CO3 equilibria will be shifted to the left, dominated by dissolved CO2 & HCO3 (doesn’t matter that you didn’t add NaHCO3 – the CO2 will spontaneously react w/water to form HCO3). As CO2 vents to atmosphere (as the beer gets flat), the amount of CO2/HCO3 will change (according to the equilibrium between the two) and pH will change too…

Both beers were calculated to the same co2 volumes. Since I’m not measuring co2 there’s no way to know for certain if they were exactly the same but I trust the calculators used got it to within plus or minus a negligible amount. Additionally, I would assume different carbonation levels would be fairly detectable by tasters, but that could be wrong.

It may interest you as we proceed to a bottle conditionned NEIPA experimentation.

Some bottles where fully filled to the top of the cap and some others where leaving a quite large headspace. After 2 weeks and 4 weeks, the color differenciation is HUGE.

The post is in french but I am sure you might have a great translator somewhere.

https://www.happybeertime.com/blog/2018/03/06/limiter-risque-doxydation-dune-neipa-remplissant-bouteilles-a-ras-bord/

Great article, another reason I’m glad I keg!

Random question, but where do you buy your grain from? I’m in northern Colorado, and unfortunately we don’t have a huge LHBS in the state, to my knowledge.

Thanks!

Hey Darrell, I buy from Brew Hut in Aurora.

I’m a little late to the party here, but one suggestion if you re-run this experiment; use flush the bottles with CO2, as mentioned by someone else, and in addition use carbonation tablets instead of sugar water. Assuming that you didn’t make any effort to remove oxygen from your water used in the priming solution, it’s going to have dissolved oxygen in it. That alone might be the cause of the difference you saw.

Hi Jake I was a bit disappointed your comparison did not discuss the air in the headspace in the bottle which other research has shown to be the cause of the oxidation of the raw dry-hop particles causing the browning and also a harsh bitterness. Besides filling glass bottles to the top there is another nifty workaround involving filling plastic bottles and lightly tightening the cap and then squeezing the air out and then tightening. Then then CO2 generated re-fills the headspace and the bottle regains its shape.

Hi Jake I’m a little disappointed your article didn’t mention the air in the headspace in the bottle which other research has found to be the cause of the oxidation of the excessive raw dry-hop particles. A workaround is to fill plastic bottles and squeeze out the air before tightening, then the CO2 from conditioning fills the headspace and the bottle regains its shape.

Hey man, great exBEERriment and very helpful too!

I’m in the verge of kegging half batch and bottling the other half of a NEIPA in couple of days. The one thing I changed on this particular recipe was adding near 1g of vitamin C (ascorbic acid) to my water (7 gals total). Hopefully it will prevent or at the very least, delay the oxidation process for my bottles. Will have to wait and see. Cheers!

Is there any value in making two identical 6 gallon batches here? If the experiment is all about the impact of bottle conditioning vs force carbing, why not just make a single 10 gallon batch with 5 going to bottles and 5 to a keg? Seems like you’re introducing an opportunity for variation by making two batches.

It was a single batch split post boil. If I had a ten gallon fermentor it would have been split at packaging

I’d also like to know if the kegged beer was refrigerated immediately while carbonating while the bottle had to sit at warmer temperatures to force carb for a week or so. What would the result be if the kegged beer sat at the same temp for the same duration as the bottled beer then quick carbed?

I feel like this experiment would be beneficial to try on another style of beer for comparison instead of simply a NEIPA to see if it’s an issue with bottle conditioning vs force carbing in bottles overall or if this simply is more impactful on the NEIPA style only.

https://brulosophy.com/2016/09/26/carbonation-methods-pt-2-force-carbonation-vs-bottle-conditioning-exbeeriment-results/

We’ve done that.

i havent read all the comments so maybe theres the same question somewhere in there- so my question is were those bottles kept in a dark place or were theye exposed to light? I saw in the background of the bottling pic a green bottle, and from my knowledge, green ones are far worse at keeping the light out

They were kept in dark boxes in a dark spot of house

Flat-footed question: beer can darken as certain things drop out of it. I find that particulate matter tends to fall more quickly and dramatically in bottles than from kegged beer. I wonder if what’s happening is that the dry hopping is contributing to oxidation in both kegged and bottled beers (because hop oils interact with oxygen and maybe some other stuff), and that it’s less noticeable in kegged beers because there’s more starch, beta glucans, proteins, or what have you normally produced by NEIPA adjuncts floating around after a normal pour?

Maybe this oxidation was happening with old west coast IPAs, too, and we just didn’t notice it because a lot of recipes shoot for a desired SRM of 8-10. Plus kegged and bottled beers of that sort strive to be similarly clear.

There might be a way, at the limit, to get no oxidation from your NEIPA, if you have a lot of equipment to minimize dissolved oxygen. But I wonder if the apparent differences we’re seeing just have to do with certain particulates dropping out in the bottles?

I have just made similar exbeeriment. I have entered a local beer brewing competition in the category of NEIPA. I am kind of new with using the beergun so I have bottles 2 liter of beer the normal way that I do and later bottled from the keg using the beergun. The bottled condition was a bit darker, and had a sweet aroma and taste, the keg bottle was lighter in color, had more fresh hops aroma, less sweet in taste and was my favorite of the two.

Several months ago, I had a friend come over and instead of the normal 5 gal batch, we brewed a 10 gal batch so he could have half of it. Fermentation occured in my SpikeCF10, therefore everything was identical up through the point of packaging (the beer was pushed with CO2 in to kegs purged of oxygen). Prior to packaging, the fermentor was cold crashed to 36 for 2 days. The differential was that mine was imediately placed into my keggerator at 36 degrees, and since he was going to be out of the country for two weeks, his keg was placed in my walk in cooler (equipment and supplies storage room) and placed on CO2 to carb, with the temp set at 59 which is as low as it goes sitting in my Florida garage. When he picked it up 2 weeks later and put it in his keggerator, he sent me a pic that clearly showed it had changed color. He said it tasted great, but we were trying to figure out the drastic color change from mine. Our conclusion is that NEIPA is highly susceptible to temperature from a visual standpoint.

I’ve heard that in an attempt to avoid oxidation, people tried adding ascorbic acid at bottling and I was under the influence that this may have been the factor that caused the purple beer. So you’re saying that it wasnt from the acid addition at all?

I’ve done several bottle conditioned NEIPAs, and I’ve found that when using Wyeast 1318 bottles tend to oxidize quite fast. OTOH, when using Coastal Haze Ale Yeast Blend WPL067 from White Labs I had no oxidation, even after 2 months of bottling. Not sure whether this is just luck, but that’s my experience so far.

Any advice idea or future experiment to test the effects of transferring the same beer via closed transfer and keg conditioning?

Very interesting. I definitely would have expected the bottle conditioned samples to oxidize more slowly. Clearly, the idea that yeast will quickly scrub oxygen and prevent oxidation is either erroneous or the effects oxygen exposure occur faster than the yeast can consume the damaging gas.

One last possibility that occurs to me is that the oxygen is concentrated in the small headspace off the bottle and that it isn’t fully dissolved in the beer while the yeast is still consuming oxygen. I wonder if shaking the bottle vigorously to force the oxygen to go into solution so that it could be consumed would help or hurt. Of course, this same question would apply to keg conditioning as well. I would think that minimizing oxygen in the package from the start is the best practice, shaken or not.

I have a lot of issues with beers turning darker in the bottle. Really interesting stuff.

If I make blonde, it’s fine. If I add jalapeno (soaked in vodka), it turns dark. Same beer with coffee, very bright. My saison always turns dark in the bottle. So does my tripel. IPA? Nope.