Author: Ray Found

Brew In A Bag (BIAB) has become a staple of the modern homebrewing landscape, often touted as the easiest introduction to all grain brewing because it requires little more than an over-sized kettle and fabric filtration bag. Unlike other lautering setups that involve removing the wort from the grain, the fine mesh bag allows the brewer to remove the grain from the sweet wort, the key advantage being that it allows for mashing and boiling in the same kettle. A brilliantly simple solution.

BIAB was initially met with some skepticism and early admonitions were many, the most common being to refrain from squeezing the bag for fear it might lead to the extraction of tannins from the grain husks. Undoubtedly, this early guideline contributed to the broadly accepted notion that BIAB resulted in worse extract efficiency than other mash methods. However, BIAB brewers are now commonly implored not to heed the lore of antiquity, and our xBmt on squeezing the bag supports the idea that it may not be as detrimental as once believed.

With the exception of BIAB, all other mash methods demand the use of at least 2 vessels, one for mashing and one for boiling. I’ve been using a mash/lauter tun (MLT) batch and no sparge brewing since I made the switch to all grain years ago, and while I’ve used a fabric filter in my MLT, I’ve never actually brewed a true BIAB batch. My friend Wes, on the other hand, does often and we’ve found his beers tend to skew less bitter than mine, and not deliberately so. For some reason, they deliver less perceived bitterness than mine even when expected IBU is the same, hence our creation of the “WesIBU” unit of measurement.

I’ve long accepted that one’s choice of mash method was purely personal preference and had little if any impact on beer quality. But Wes, wanting to figure out the bitterness issue, has long pushed for a comparison of our approaches. Admittedly bored by the idea and a little annoyed with Wes’ yearlong insistence, I eventually relented.

| PURPOSE |

To evaluate the differences between beers of the same recipe brewed using either the BIAB method or no sparge method.

| METHODS |

I went with a simple Vienna Lager for this xBmt in hopes of emphasizing any differences caused by the variable.

Mashing Vienna

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.8 gal | 60 min | 31.6 IBUs | 8.8 SRM | 1.046 | 1.011 | 4.7 % |

| Actuals | 1.046 | 1.011 | 4.6 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Vienna Malt (Weyermann) | 11 lbs | 97.78 |

| Pale Chocolate Malt | 4 oz | 2.22 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 15 g | 60 min | Boil | Pellet | 12 |

| Saaz | 44.9 g | 15 min | Boil | Pellet | 3.2 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| German Lager (WLP830) | White Labs | 77% | 50°F - 55°F |

Notes

| Water Profile: Ca 55 | Na 0 | Mg 0 | SO4 67 | Cl 55 |

Download

| Download this recipe's BeerXML file |

After weighing out the same amount of grains for both batches, I ran each through a single pass of my 3-roller mill.

Accounting for the lower absorption rate of the BIAB batch due to squeezing, it required slightly less water than the no sparge batch. Starting with RO water, I adjusted each volume of water to the same profile then began heating them. Hitting precise mash temperatures when using unfamiliar methods is never straightforward, but I was pleased with how close they were to each other.

Despite being mashed in a kettle that was wrapped with an insulative blanket my grandmother made, the BIAB batch precipitously dropped 6°F/4°C over the course of an hour long mash, while the no sparge mash only lost 1.5°F/0.9°C. Since the comparison was between mash methods, this was determined to be a function of the variable.

When the 60 minute mash rest was complete for the BIAB batch, which I started a little before the no sparge batch, I removed the bag and gave it a good squeeze as is commonly recommended when using this method.

For the no sparge batch, I did a quick vorlauf before collecting the same same volume of sweet wort as was in the post-mash BIAB kettle.

Both worts underwent vigorous 60 minutes boils.

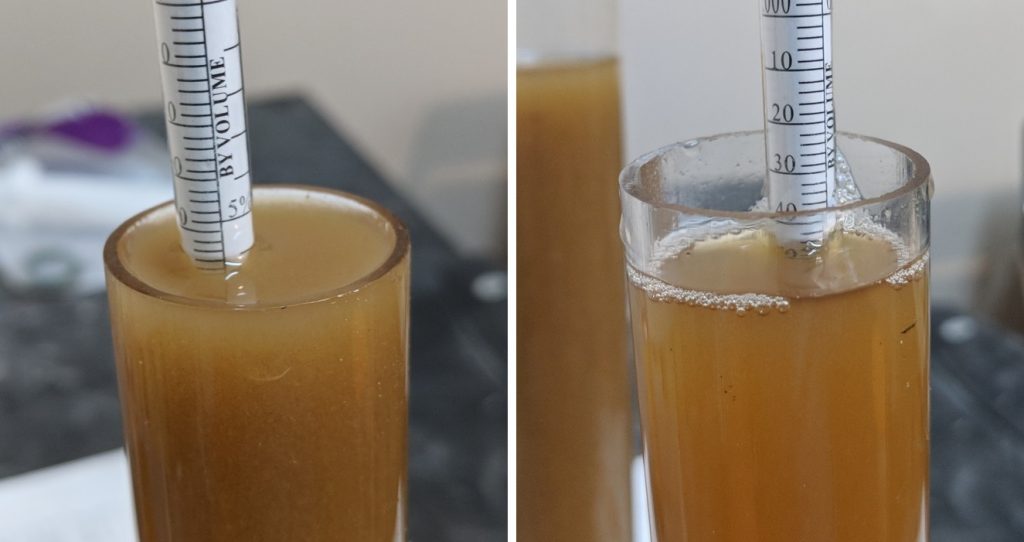

At the completion of each boil, the wort was very quickly chilled, at which point hydrometer measurements showed the BIAB OG was unsurprisingly a pinch higher than the no sparge wort.

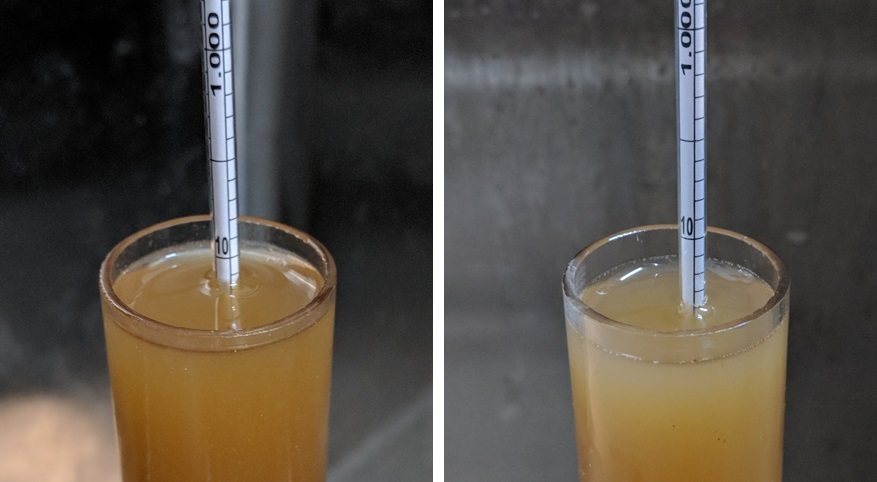

Both worts were allowed to settle for 20 minutes following chilling before being racked to sanitized 6 gallon PET carboys. Once the carboys were filled, differences in appearance were readily apparent.The BIAB wort was clearer with a large, chunky mass of trub at the bottom whereas the no sparge wort was had just a skim coat of a hard packed trub.

Fermentation took off and progressed similarly throughout for both beers, though I noticed the BIAB batch seemed to have a “dirtier” kräusen that left more trub stuck to the carboy shoulders.

At the end of fermentation, the beers still looked dissimilar with the BIAB batch having a much thicker trub cake, which may explain its clearer appearance.

As expected, hydrometer measurements showed the BIAB batch finished with a lower FG than the no sparge beer, likely as a result of the drop in mash temperature.

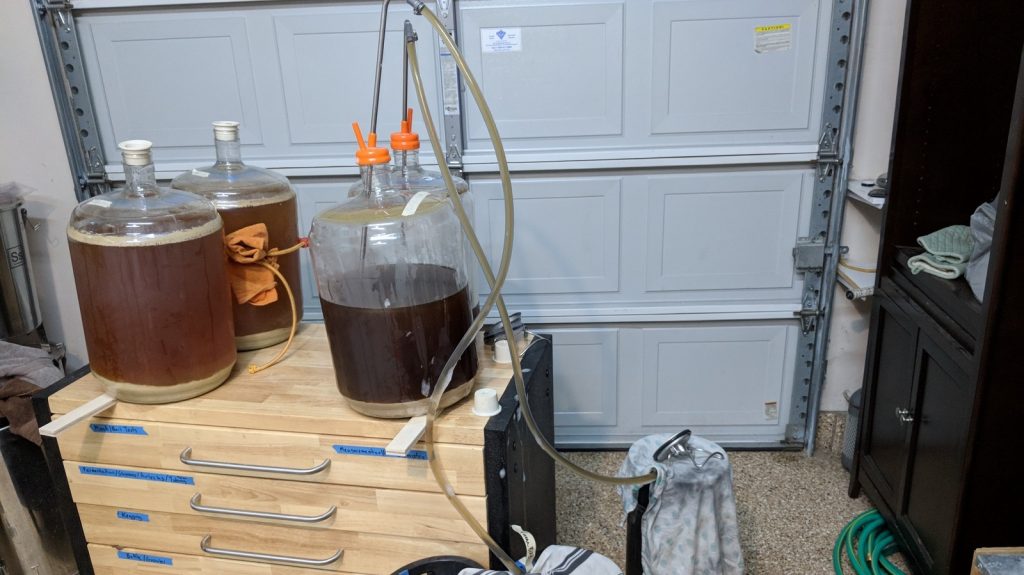

I proceeded with cold crashing and kegging, opting to skip my usual gelatin fining process.

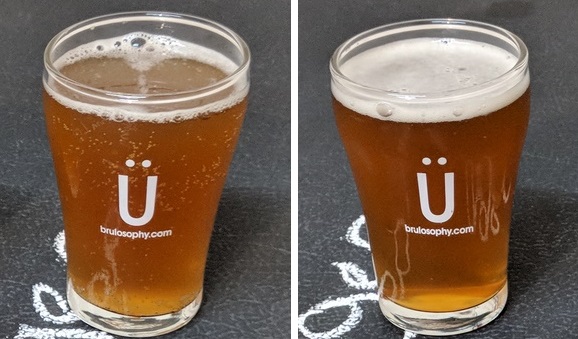

The filled kegs were placed in my cool keezer and briefly burst carbonated before I reduced the gas to serving pressure. The first pours showed the beers maintained a difference in clarity, only it seemed the roles reversed, as the no sparge beer seemed to be clearing up faster than the BIAB beer.

Even after 6 weeks of lagering, the BIAB batch remained hazier than its no sparge counterpart.

| RESULTS |

A total of 25 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the BIAB beer and 1 sample of the no sparge beer in different colored opaque cups then asked to identify the unique sample. At this sample size, 13 tasters (p<0.05) would have had to identify the unique sample in order to reach statistical significance, while 14 did (p=0.02), indicating participants in this xBmt were able to reliably distinguish a Vienna Lager made using the BIAB method from one produced using the no sparge method.

The 14 participants who made the accurate selection on the triangle test were instructed to complete a brief preference survey comparing only the beers that were different. A total of 5 reported preferring the BIAB beer, 7 liked the no sparge beer more, and 2 reported having no preference despite noticing a difference.

My Impressions: I found these beers to be difficult to tell apart when excessively cold, though it became easier as it warmed, which I found both surprising and hard to explain. The no sparge beer was, well, normal, not my favorite Vienna Lager ever, but as expected based on my process. My experience with the BIAB beer was somewhat puzzling– at the start of each sip, I perceived it as being generally less characterful with notably less hop flavor, while it finished with a slightly sticky, almost cloying quality. While noticeable when looking, I found the differences largely faded after sampling 8 oz/0.24 L of each, at which point both just tasted like middling examples of Vienna Lager.

| DISCUSSION |

With upwards of 31% of homebrewers relying on the BIAB method to make their beer, many of whom have racked up competition medals, it’s safe to say it’s a legit approach to crafting quality beer. From the beginning, adherents have claimed BIAB produces a beer that’s no different than those made using more common mash methods requiring the use of a dedicated MLT. Having accepted such an assumption as truth, I was resistant to even testing it out, which is why I am, in a word, stunned that participants in this xBmt were capable of telling apart a Vienna Lager made using the BIAB method from the same beer made via no sparge.

Considering the similarities in observed differences in appearance between this xBmt and our recent one on squeezing the BIAB grain bag, it would seem something about the squeezing process is responsible for producing haze. While results from the former weren’t significant, it’s possible whatever caused the haze in the BIAB beer from this xBmt is what led to tasters being able to distinguish it from the no sparge beer.

However, some other factor could be the culprit. It’s possible the drop in temperature of the BIAB mash is responsible for the difference in character, though I’m skeptical, not only because of our prior mash temperature xBmts, but personal experience– I’ve tasted several similar beers that attenuated differently and in zero cases have I experienced anything like this. The BIAB and no sparge beers were different in a way my humble palate says has nothing to do with a few gravity points, but rather the actual character of each beer.

I won’t attempt to explain away or pretend to understand why some people make perfectly clear beer when squeezing the BIAB bag like it owes them money, but I’ll confess that it is still a mystery to me why some beers drop bright nearly instantly while others require weeks. Ultimately, I’m inclined to stick to my guns on my belief that a BIAB fabric filter is in no way appreciably different than any other lautering device, but that perhaps there’s some element of truth to the old wisdom that squeezing the bag extracts something normally left behind in the spent grain. There’s no way to know based on this xBmt what exactly “something” is, and since neither beer was noted as having an astringent quality, this seems the appropriate degree of ambiguity.

With my preference for the no sparge beer in this xBmt as well as the fact I’m comfortable with my current setup, I’ve no plans to make any changes to my brewing process. If I were a BIAB brewer, I’d simply skip the squeeze in hopes of creating a clearer finished beer, though for those looking to eek every last point of efficiency out of the mash, squeeze away.

But what about Wes?

Since it was ultimately my friend Wes’ experience brewing with BIAB that inspired this xBmt, I asked him to share his impressions on the beers and how these results have impact his approach, if at all.

I went into this xBmt with the expectation of discovering why the “WesIBU” was consistently lower than Ray’s. I enjoy brewing as an avid hobbyist and always value quality results, quick cleanup and continuing to find ways to simplify process. My typical brew day starts at 5:00 PM as the neighborhood gathers together for our brew nights and BBQ. With the simplicity of BIAB, I just carry my entire setup next door to my neighbor’s garage-turned-bar lovingly called “Spanky’s” in a couple quick trips. We’re always completely finished by 8:30 PM.

The BIAB process has kept me involved in brewing with its simplicity and low barrier to entry. We’ve also gotten many people hooked on the hobby when they realize that brewing does not have to be complicated or expensive. My normal equipment to produce 6-12 gallon batches clocks in quite modestly at $30 for The Brew Bag fabric filter plus an inexpensive aluminum pot with valve from the local Mexican market and a Bayou KAB6 burner that manages to heat water and singe anything near it with amazing speed. Several of my friends have the more traditional setups, so it’s always been entertaining to compare and contrast our setups.

Most curious to me has always been the consistently low perception of bitterness when compared with Ray’s batches. We’ve even gone as far as to use the same amount of hops from the same batch with similar observations, though we’ve done a comparison as direct as this xBmt.

I helped Ray brew these beers, so I did not complete the official survey, but I did evaluate the beers at 2 points– once soon after they were kegged and a second time after all data had been collected. I perceived the first samples as being immediately obvious and taking no guesswork. As Ray noted, cold samples were tougher, but as they warmed, the difference was quite plain. My perception was the usual lack of bitterness, or stated differently, a maltier backbone in the BIAB batch.

On the second evaluation done more recently, I brought along my trusty wife whose prowess in baking and cooking is rivaled only by her strong dislike for beer. Her reaction was quite interesting. We performed 3 semi-blind triangle tests with the beers at keezer temperature and in each case, she was able to identify the odd-beer-out on smell alone, something I simply could not reproduce. In her words, the BIAB beer “did not have as much smell.” She also noted there was “another smell” present in the no sparge beer, which I presume might be a stronger hop character.

I already have thoughts on follow up experiments to further explain the variables at play, notably using my normal kettle insulation during the mash and also using a yeast that is known to flocculate extremely well. With the great results I have using the BIAB method, I have no plans to change my current setup. Rather, I’ve found that adjusting my recipes to be about 20% higher in IBU consistently leads to great results that our neighborhood goes through as quickly as I can turn them out.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

40 thoughts on “exBEERiment | Mash Methods: Brew In A Bag (BIAB) vs. No Sparge In A Vienna Lager”

Sometimes you need to redo experiments, just to find out what you have missed.

One thing that probably should be added is to measure the pH for:

* the wort from the no sparge batch

* the wort from the BIAB batch just after lifting and letting drip out the bag

* the wort from the BIAB after squeezing the bag

The observations would seem to indicate that there is less solubility of alpha-acids, which can be explained by a lower pH after squeezing the bag.

I’m surprised by the results, though I haven’t done BIAB yet. I’m not however surprised by the impact of temp on taste. This is why all my darker beers I will drink in a room temp mug. Besides on hot days I even enjoy when an IPA warms a bit from it’s frosty mug!

Might be helpful in your taste tests to allow time for some warming for full evaluation?

I wonder if maybe the trub is stripping some of the hop matter out or affecting it in some way.

Obviously a late reply here, but I was reading this and thinking the same thing. I was just reading Brewing Lager Beer (Noonan) and came across this passage:

“When the wort is the product of an infusion mash, it should be boiled vigorously for 15 to 30 minutes before more of the hops are added (referring to a small percentage added before the boil) to allow the boiling action to decompose and precipitate some of the proteins. If this is not accomplished before the hops are added, then hop polyphenols will combine with the coarse protein flocks and be precipitated out of the solution, carrying hop resin with them.”

These are both infusion mashes, but I’m wondering if the biab batch has more coarse protein flocks than the other. Possibly a longer boil period before adding the bittering hops would resolve this?

That BIAB version has the weirdest kräusen I’ve ever seen. Have you ever gotten a kräusen like that befor?

Every time I use London III. That’s a real go getter of a yeast, and it makes for some serious sludge on top.

I use a bag, but otherwise my method is like standard mash and sparge. I mash in the boil kettle, in a bag, with a ratio of quarts of water to pounds of grain about 1.3. (Typically 4 gallons of water in an 8 gallon pot). I insulate the kettle with a blanket wrapped tightly and held in place with bungie cords and with a pillow on top. The temperature is monitored with a wire probe, and I stir a couple of times during the mash to maintain uniform temperature throughout the mash. Typically the temperature drops by about 2 degrees F during the hour. If it falls below my target, I add a little near-boiling water. After the one hour, I pull the bag of grains out and let it drain back into the kettle for about 2 minutes. (Standing there holding it, feeling like I must look like an idiot.) I do not squeeze. Then I do a batch sparge. I place the bag in a second pot with about 2 gallons of hot (160-170) water, fold the bag over the edges, and gently stir until the mixture is uniform. Let it sit for a few minutes (usually 10). Then gently stir again and pull out the bag of grain and again let it drain for a couple of minutes, until the water (“2nd runnings”) is dripping rather than streaming (no squeeze). Pour the liquid into the boil kettle. That’s it. I get extraction efficiency of almost 90% according to brewersfriend software, and kettle efficiency of about 80%. I’m surprised I don’t read about more people using this technique. I avoid having to set up a mash tun, never have to worry about a stuck sparge, get high efficiencies and good beer. Admittedly, I do have to have a second kettle, which is my old 5 gallon one that I bought before realizing I wouldn’t be happy brewing with it (made smaller batches or did partial boils). The spent grain holds about 1 gallon of water, by the way, something that’s easy to remember when planning how much water will be needed. I would like to see an exbeeriment comparing this method as well as the ones described here, and the more standard mash-and-sparge method using a tun.

Thanks for writing this, I like you’re method. I’m going to try it. I would squeeze my bag & didn’t think of using a 2nd pot like that instead of just pouring hot water over the bag.

you can also use cold water. Then the spent grain is easier to handle

I use the same method with the addition of squeezing both times the bag is pulled. I haven’t had any issues with clarity but i also bottle (which is when my batches drop clear). I wonder if kegging plays a factor in the haze in the biab?

I also use a one pot approach with a false bottom and a bag. I just run off the mash wort into food grade buckets (initial and one cold sparge) pull out the bag and false bottom, then pour the wort back into the kettle for the boil. I usually hit 90 – 95 % conversion efficiency.

Tim, are you milling your grains once or twice?

This is my go to as well, I love it and my eff is always high 70’s to low 80’s.

Thanks for the experiment.

Technically, the only core difference between the methods is that in BIAB grains are moved out, wort stays; in no-sparge wort is moved out, grains stay. The rest are process differences within BIAB / no-sparge.

For example, in BIAB you can heat the kettle to keep the mash a constant T (or step mash) as long as you separate the bag from the heat (see Brewhardware BIAB false bottom); you can also constantly recirculate during BIAB; you can double-bag (quite a bit of “dirt” gets in between the bags); you can skip the squeeze.

All brewing textbooks recommend vorlauf until the wort going out becomes reasonably clear; I do not have a reference for what is different in “dirty” wort but I seem to recall that there are more long chain fatty acids, tannoids, and beta glucans in dirty wort.

I therefore think that your results can be explained in terms of dirty vs clean wort after mash out, although the mash temp differences explanation cannot be discarded.

Jurgen, above, makes an argument for pH differences. I do not think there will be, but cannot be discarded. pH can explain the differences in hop utilization between your neighbor and you.

Thanks again for taking the time and for sharing.

I’d like to hear more about the grandma and the blanket.

Tangentially related question: for no sparge 5.5 gallon batch sizes, would you recommend going bigger than 10 gallon MLT? I’m moving from extract to grain, and have an option to get either a 10 or a 20 gallon MLT. The 20 seems big; the 10 small. I wonder if for the 20, my pre-heating approach (Hot Rod, in well-insulated SS tun) would preheat the vessel enough that its thermal mass offsets temp losses due to the extra head space.

I really love my 15galllon thermobarrels. 6g nosparge or 12g batch sparge. Smaller and lighter, easier to manage than 20g, but way more room than 10g.

That’s what I tend to see recommended … somewhere in the 13-15g range. The “problem” is that I have an option to get either a 10 or 20 (SS mash tun, which I like quality-wise, too) with some discount locally, so I’m trying to figure out if either of those would/would absolutely not work.

I am a long time BIAB, partial mash, partial boil brewer. I never squeeze, and if the grain bag is small (mostly LME), I don’t even rinse the grains.

I also have less hop utilization, and my carboy looks exactly like your BIAB carboy. There’s a thick trub layer, the wort is clear, and there’s a heavy krausen ring. Every time. I always assumed that it was related to the high gravity boil.

My wort is “dirty”. There’s usually a lot of barley flour and bits of husk left in during the boil and even the ferment. That could account for a pH difference that a previous poster was looking for.

I’ve been doing exclusively BIAB for 6 years (though I did just buy a 300 micron basket to replace the bag) with great results. I have in the last year completely eliminated the “washing” or rinsing of the grain because, once I went electric and started recirculating my mash my efficiency went over 80%.

Fun method to brew, especially with an electric hoist in the garage for the brew basket.

Where’d you get your basket from? I’m thinking about adding one.

Very interesting. I’m a BIAB-er too and would really like to believe that there is no downside to it, but I’ve got to say that this article has me a little worried …

Any chance you post a little more info on your fermentation & lagering timeframe for this beer? I’m curious if you’re using the shortened method for lagers, as is typical with you Brulosophy guys, and if that could have any impact on the results of this test.

I’d also be curious to see this experiment repeated with an ale, especially a more hoppy variety.

I would challenge your statement about there being a downside to it. Is there a downside to American sour brewers vs Belgian sour brewers because the flora and fauna are different and produce different sour flavors? Is there a downside to brewery A’s water composition versus brewery B’s? Is there a downside to brewers who age in oak vessels vs those who age in stainless with oak staves? (Okay, enough, but obviously the examples are nearly endless) As with most of the xBmts, it’s not that one is better than the other, just that the one is different than the other. I’d say brew your own beer and choose the inputs and outputs (equipment, processes, recipes, etc.) that you like.

This is such an interesting article. I almost always use a no sparge method with a cooler/Brewbag filter. The only difference I notice when I batch sparge is a slight increase in efficiency(2-3%). That being said, I have just built a small batch system much like the Braü Supply system one of the contributors uses. I’ll be interested to see if there is any difference between my two set ups. I should have mentioned I always squeeze the bag and haven’t seen difficulty getting brilliantly clear beers or great hop flavor. I do confess to using fining agent though and I am not comparing side by side samples.

It seems like both you and your friend have a similar assessment of the resultant beers flavor, more malt forward in the BIAB. If I remember correctly the team has already somewhat debunked the old adage of BIAB produced a more malt forward beer. Either way, this was another xbrmt that just causes more questions than answers. Great read!

I assume the grain was milled the same in both batches?

I know many BIAB brewers mill the grain much finer to improve efficiency, which could cause more fine particles to make it into the kettle. These fine particles could attract and latch onto the hop oils and acids, effectively binding them, and then they settle out fairly quickly in the fermenter.

Possibly there is an added variable related to mash temp in your experiment. I wrap a fluffy sleeping bag around my kettle and hold it together with a pair of bungee cords, then I place two old down pillows on top and ensure there are no gaps between the bag and pillows. Using this method I have noticed very little heat loss (2-3 degrees F) over a 90 minute mash.

Maybe another experiment might be testing for temp change during BIAB mash, I think many would be interested but unlikely to change their methods that have produced consistent results.

As an extract brewer who has been looking to go all grain for a while, perhaps I’ll give the BIAB a shot. Thanks for the comparison.

You should absolutely try BIAB with either method talked about in this article. It’s a great way to get into all grain. I personally don’t see a reason to stop using this method. The Brewbag is a great bag btw. Cheers

I’ve done BIAB a few times but usually mash in a cooler box and vorlauf, but skip the sparge. I get clear wort this way, but BIAB produces cloudy wort as there’s no way of draining wort without disturbing the grain.

Some brewers say cloudy wort doesn’t lead to cloudy beer. I suspect it does though. I reckon it causes problems with chill haze that can take months to later out.

Hop utilization is a function of protein levels in the wort during the boil. Brewing software uses sugar level as a convenient proxy to adjust expected utilization as high gravity beers have high protein. When comparing BIAB to a similar beer made after conventional mash, the two worts will have very different protein levels and potentially different bitterness.

“it finished with a slightly sticky, almost cloying quality” – my BIAB brews exhibit this same character, almost without regard to style (only exception is high% of roasted malt which presumably overpowers the sweet finish). I would love to hear any views on what causes this effect.

Interesting! The difference between the two batches is significant. The preference of the tasters not so much. So I guess it all boils down [no pun intended] to taste again?

After the trub xbmt I stopped worrying about unclear wort going into my fermentor. With some help of a gelatin fining and cold crash I indeed brewed some of the clearest beers around. But if there is a taste component to it then I certainly want to learn more about this!

What do we want?

– MORE BIAB XBMTS!

When do we want it?

– YESTERDAY! Or whenever you guys find the time in your schedules…

I do BIAB in the winter because the cleanup is so much easier. “Dirty” krausen – FWIW, I notice it with mine when the fermentation is particularly vigorous. It’s like the trub has been caught in suspension by the foam and can’t settle back. FWIW part 2, when I encounter a stuck sparge, I just dump everything into another kettle with my BIAB bag and go from there. However, when I dump the grains in my plant beds, the bag feels very slick and has a sheen to it. I’m not sure what that means at a molecular level.

Thought: Brew as you normally would but then the whole shebang through a BIAB bag and see what you get.

“I won’t attempt to explain away or pretend to understand why some people make perfectly clear beer when squeezing the BIAB bag like it owes them money, but I’ll confess that it is still a mystery to me why some beers drop bright nearly instantly while others require weeks. ”

I am wondering about this comment. I BIAB and have had issues where some batches ferment and are nice and clean in 7-10 days and taste great. Others appear really murky, brownish green and taste horribly for 2-3 weeks or more and never seem to be drinkable as hops/yeast dont seem to drop out of the beer. Is this what you are referring to? Have you only seen this in BIAB brewed beers? Its been very frustrating to try and figure out why this is happening.

When i transfer from boil kettle to fermenter i pass the wort through a muslin bag before it hits the fermenter – it seems to make the end product clearer and most of the trub coming through gets caught in the muslin bag – i get the muslin bag and wrap it around the transfer hose and have a bag tie holding it tight – i have tried without doing this and have gotten cloudier and product

Have you tested your water profiles which can account for bitterness factors (ex. Soft vs hard water) Also, when i do BIAB i also secondary and it lowers the FG a little as well as making beer almost crystal clear. Also adjust water profile according to style.

I use RO water and adjust as needed. I usually make NE IPAs so I dont need it to be clear, but I have issues getting hop matter and or yeast to drop out a lot of times. I finally have a glycol chiller but this last batch had to sit in the high 30s for 6 days to drop enough to keg.

I wonder about the oils in your hands as you squeeze/wring out that bag… I do a BIAB(basket), and I do rinse after fermenting.. My hands don’t touch the wort… Just some small variables that should be looked at… Thank you for all your Xbeerments!

I somehow missed this Xbmt when it was published.

I just wanted to chime in to say that about 1 out of 5 of my BIAB beers come out persistently hazy. I did read some random literature that suggested that squeezing the bag may be the culprit.

Also of note: Hops evidently have a clarifying effect. All of my IPAs and PAs come out clear as a bell. It’s my lesser-hopped beers that seem to have persistent haze no mater how long I cold crash/add gelatin.

So I’m going to add your observation to my suspicions and try very hard to not squeeze the bag on my non-hoppy beers.

But I do not know how I can NOT squeeze the bag. It must be squeezed. It begs the be squeezed. But I shall try. For science.

Maybe I missed something but aren’t these both “no sparge methods” ? I didn’t see any documentation about sparge water for the BIAB batch.

Hey,I was thinking the same,biab is basically no spare and other way around,the only difference is plastic container vs stainless steel,there shouldn’t be any difference at all,in theory anyway.