Author: Jake Huolihan

A technique used by brewers to ensure the transfer of clean, clear beer to its target package is cold crashing, which generally involves reducing the temperature of the fermented beer prior to packaging. This works because rapidly decreasing the temperature of a colloidal solution encourages the coagulation of particulates such as proteins and yeast, and as these particulates coagulate, they become heavy enough to drop out of solution. There’s more that goes into it than that, but suffice to say, cold crashing beer tends to result in a densely packed trub layer and clearer beer.

The benefits of cold crashing aren’t limited to just clarity of the finished beer, it also allows for a much easier racking experience since particulates that could clog a siphon or diptube have dropped out of solution, even on highly dry hopped beers. The method also has its downsides such as the fact it requires a brewer to have the ability to control temperatures and it also extends the time the beer needs to stay in the chamber. Another potential drawback of cold crashing that seems to have caught some attention of late has to do with the vacuum created as the beer cools, which results in the beer being exposed to both airlock fluid and oxygen from the chamber environment.

I’ve cold crashed many times over the years and it always seemed to do as promised, my beers tend to clear up quickly even without the use of finings. I hadn’t really questioned this technique much, as it has become a ubiquitous practice among brewers and my own experience has been largely positive. That said, I won’t pretend the suck-back issue didn’t make me nervous, not so much about the airlock liquid since I use sanitizer, but it seemed an obvious vector for oxidation. This anxiety was amplified by the results of a recent xBmt showing not only that oxygen exposure on the cold-side led to a distinguishable aroma and flavor difference, but that it also caused the beer to darken quickly. I began to wonder if cold crashing was the culprit and decided test it out to see for myself!

| PURPOSE |

To evaluate the differences between a German Pilsner that was cold crashed in the fermentation vessel prior to being kegged and one that was kegged warm.

| METHODS |

I chose to make a delicate German Lager for this xBmt thinking it would allow any differences caused by a potentially subtle variable to shine through.

Autobahn

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 32.3 IBUs | 4.1 SRM | 1.050 | 1.010 | 5.2 % |

| Actuals | 1.05 | 1.01 | 5.2 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Weyermann Pilsner Malt | 9.625 lbs | 88.51 |

| Munich II (Weyermann) | 1 lbs | 9.2 |

| Carahell | 4 oz | 2.3 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 18 g | 60 min | Boil | Pellet | 11.5 |

| Hallertau | 21 g | 30 min | Boil | Pellet | 2.3 |

| Hallertau | 28 g | 10 min | Boil | Pellet | 2.3 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Global (L13) | Imperial Yeast | 75% | 46°F - 56°F |

Notes

| Water Profile: Ca 71 | Mg 0 | Na 8 | SO4 75 | Cl 75 |

Download

| Download this recipe's BeerXML file |

A few days prior to brewing, I whipped up a large starter of IOY L13 Global yeast, which is quickly becoming a go-to strain for me.

On the morning of brew day, after my future brewing assistant woke me up earlier than I would have liked, I collected my water, adjusted it to my desired profile, then milled my grains while it was warming up.

Once the water was at strike temperature, I added the bag of grains and realized this 10 gallon no sparge BIAB batch was pushing the limits of my 20 gallon kettle.

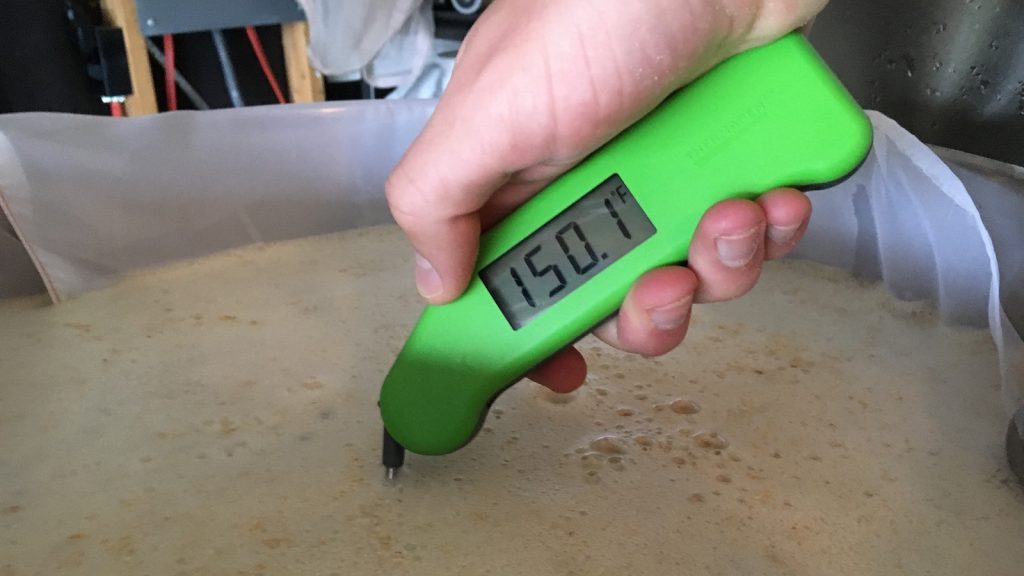

After given the grains a gentle stir, I checked to ensure I hit my target mash temperature.

I turned my pump on at this point and let the mash recirculate for the duration of the 60 minute saccharification rest, after which I removed the grain bag and let it drip to reach pre-boil volume while the sweet wort was heating. The wort was then boiled for 60 minutes with hops added as stated in the recipe.

With the boil complete, I quickly chilled the wort to 70°F/21°C.

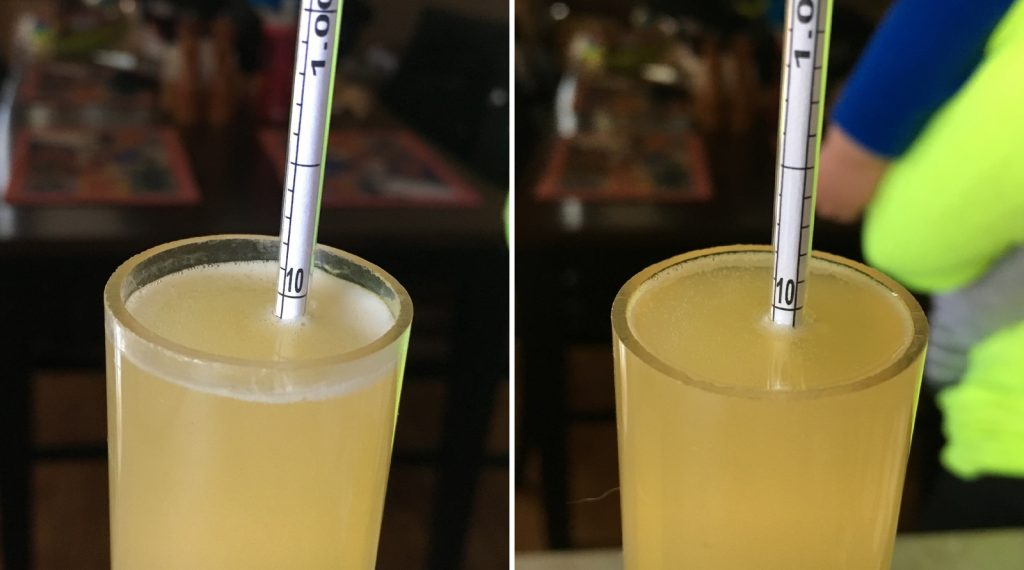

A hydrometer measurement confirmed I’d achieved my target OG.

The wort was evenly split between 2 Brew Bucket that I placed next to each other in my chamber where they were left overnight to finish chilling to my desired fermentation temperature of 50°F/10°C.

The following morning, I evenly split a decanted starter between the batches before hitting each with a 90 second dose of pure oxygen. I checked on them the next day and found both were actively fermenting. I left the beers alone for 2 weeks, at which point no observable signs of fermentation were present, so I took hydrometer measurements indicating both had reached FG.

I bumped the chamber up to 60°F/16°C for a day diacetyl rest. After 1 day at this warmer temperature, the time had come to introduce the variable. Since the purpose of this xBmt was to evaluate the impact cold crashing in a fermentation vessel has on beer, I opted to keg the non-crashed beer at the same time I reduced the chamber to a cold crash temperature of 32°F/0°C.

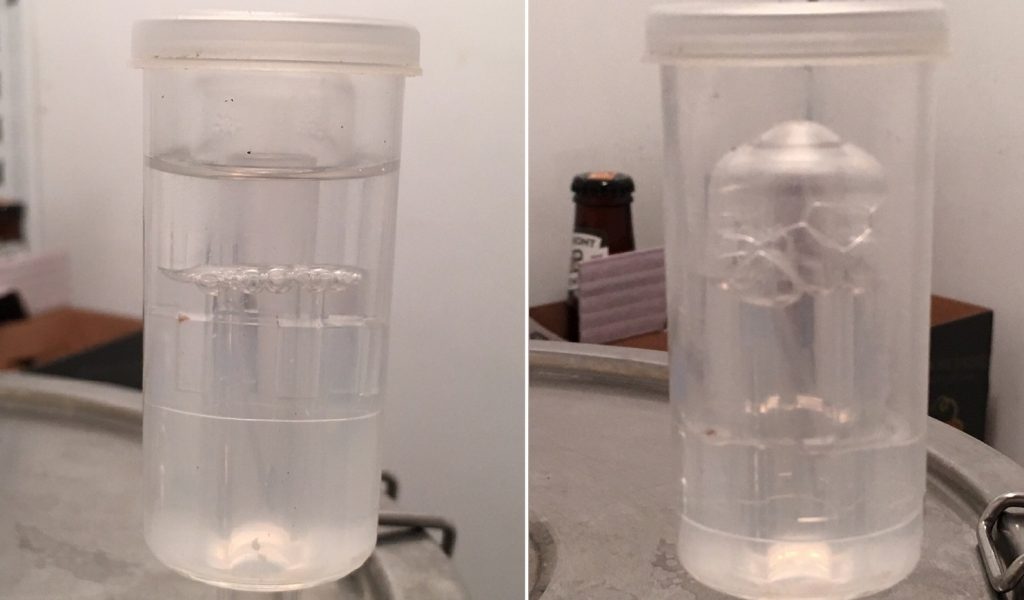

I noticed the next day that a noticeable amount of the sanitizer in my airlock had been sucked into the beer, undoubtedly accompanied by an unknown amount of oxygen.

After 2 days of cold crashing, I racked the beer to a keg that was placed next to the non-crashed beer in my keezer. Both were briefly burst carbonated before I reduced the gas to serving pressure and let them cold condition. I took samples at 3 weeks to see if there were any noticeable differences in color or clarity and found that, at least to my eyes, they looked the same.

While clarity is a purported benefit of cold crashing, we were curious if the introduction of oxygen that occurs when using the method would have an impact, hence the beers were allowed to age another week before I began collecting data. Again, they looked the same in every respect to me, but how would they taste?

| RESULTS |

A panel of 26 people with varying degrees of experience participated in this xBmt. Each taster, blind to the variable being investigated, was served 2 samples of the cold crashed beer and 1 sample of the beer that was packaged warm in different colored opaque cups then instructed to select the unique sample. At this sample size, a total of 14 (p<0.05) correct selections would have been required to achieve statistical significance, while only 9 tasters (p=0.52) chose the different beer, indicating tasters were not able to reliably distinguish a German Pilsner that was cold crashed prior to packaging from one that was not.

My Impressions: In multiple blind triangles, I was unable to identify the odd-beer-out and resorted to guessing every time. They tasted, smelled, and looked identical to me. And the beer was so good! Substituting my normal charge of Vienna for some Munich II gave it a deep golden color that I found very pleasant. I absolutely plan to make this recipe again.

| DISCUSSION |

While many brewers have adopted the practice of cold crashing to aid in the clarification of their beer, others have questioned whether it might be more detrimental than it’s worth given the fact it usually results in oxygen being sucked into the fermentation vessel. Admittedly, after reading the results of the cold-side oxidation xBmt, I was convinced cold crashing was the culprit and expected the Pilsners from the present xBmt to be noticeably different. However, not only were blind participants unable to reliably distinguish the cold crashed beer from the one packaged warm, but I couldn’t either, they were similar in every respect.

It might be easy to take these findings as some sort of proof cold crashing is a waste of time, and while it may not be totally necessary, it has its benefits in certain situations. For example, when making a heavily dry hopped IPA, especially when the hops are added loose, a good cold crash will encourage a lot of that hop matter to the bottom of the fermentor thereby making packaging less of a mess. I’ve also noticed the trub cake after cold crashing is more compact, meaning there’s a lower risk of transferring that unwanted gunk to the keg or bottling bucket.

I won’t be forgoing the step of cold crashing in my brewing, though considering these results in light of the aforementioned NEIPA xBmt, I’m left scratching my head as to what in the world could be causing the hasty degradation of those beers. I suppose the next step would be isolating the variable of oxygen exposure at packaging, though based on my personal experience, I’m not convinced that alone is the answer. And so the search continues…

If you have thoughts about this xBmt, please feel free to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

69 thoughts on “exBEERiment | Impact Cold Crashing With An Airlock Has On A German Pils”

If you cold conditioned them werent they both technically cold crashed?

That’s always the case, indeed, but the variable here was really cold crashing in primary vs. not.

The hydrometer reading… We’re both beers the same temperature because this can have an effect on the hydrometer reading.

I am wondering about your water profile. Why so high of a sulphate level? I have been experimenting with my profile and am hesitant to go higher than 100.

I’ve used 150 pppm sulfate in Pils, and it gives a very nice crisp, dry edge to the beeer.

Surely this will create a significant chill haze if polyphenol and or protein levels are high. If filtration is not used could give seriously cloudy beer.

Wouldn’t it have made more sense to perform this experiment on a NEIPA recipe, as that’s the style that seems to be the most sensitive to cold side oxidation and as cold-crashing seems to a lot of benefits in a heavily dry-hopped style as NEIPA? Also letting the beers age a bit longer in a hotter environment might still cause differences in both beers, as oxidation takes a bit of time.

Anyway, it is great to see that for less sensitive styles, that the little oxygen that is introduced during cold-crashing, doesn’t seem to affect the beer. when it’s consumed fresh

We chose German Pils for this xBmt specifically because of its delicate nature. It’s entirely possible something about NEIPA makes them more sensitive to cold crashing (oxidation?) than other beers, and while we’ll continue to explore that phenomenon, we’re also curious about the impact certain variables have on other styles as well. Cheers!

Thanks for the response. Looking forward to lots of new xBmts!

You state “… it [cold crashing] has its benefits in certain situations. For example, when making a heavily dry hopped IPA, especially when the hops are added loose, a good cold crash will encourage a lot of that hop matter to the bottom of the fermentor thereby making packaging less of a mess.” Was this a subject of a prior experiment, or is it supposition?

It’s physics– colder environments encourage the precipitation and dropping out of particulates. The comment had only to do with packaging ease as opposed to any impact on the perceptible aspects of beer.

I have to agree with Michael here, your statement is still only a hypothesis until it’s been tested in an exbeeriment. In order to back up the claim that it would make a bigger difference in a dry hopped IPA, it should be tested in that certain situation. In an exbeeriment such as that, measuring the trub layer or clarity of the beer might be more important than triangle test results.

It becomes immediately obvious that cold crashing makes racking heavily-dry-hopped beers much easier. You can literally see the layer of dry hops on top of the beer drop to the bottom over less than 12 hrs, and your keg out QD will never clog if you keep the autosiphon out of the muck at the bottom. That said, you can get around cold crashing if you buy a SS mesh autosiphon filter from Arbor Fabricating.

The autosiphon mesh filter will clogged on a heavily dry hopped beer that is not cold crashed.

Jake, you said you substituted Munich II for your usual Vienna. The recipe listed still has Vienna. I am assuming you meant to type in 9.2% Munich II and NO Vienna? I would have thought that would be a little too malty for a German Pils. Was the flavor noticeably more malty?

I did sorry the recipe wasn’t updated for Vienna. I don’t think it was too malty, in fact it tasted really good. I really want to try Vienna v Munich because I kind of doubt in this % the difference would be extremely noticeable. Without anything to compare this recipe to though I thought it had a little more munichy flavor which I always perceive as a slight spice

A way to avoid oxygenation during cold crashing is to pressurize the fermentation vessel prior to crashing. My fermentation vessel is a fermonster that I’ve converted to a pressure vessel. You can spund the beer to 20 psi or so during the end of fermentation, or pressurize with CO2 to 20 psi or so and then cold crash.

You could calculate the amount of pressure needed to dissolve during cold crashing by calculating the difference in CO2 volumes from the pre crash to the post crash temperature, and then figuring out how much CO2 you need to put into the head space.

Or, of you can’t pressurize your fermentation vessel, you can connect your fermenter to the CO2 Tank and set the regulator to the minimum pressure during crashing. The regulator will add CO2 as needed.

Another option that has worked pretty well for me is to put a solid stopper into my carboy when I begin chilling it down. Then, right before racking, I pull out the stopper and let the air suck in only at that moment. I doubt the small amount of oxygen coming in right before racking is going to hurt the beer much if at all. It’s a very short exposure, and maybe the very top layer of wort gets some oxidation, but I really don’t think it’s a big deal. It would be cool to compare though.

that would work except the low-pressure inside carboy can either break it (if glass) or deform it (if plastic).

Great idea Aaron

Doesn’t the built up pressure difference result in the same total amount of oxygen going in?

In my (non-verifiable) experience, the effects of oxidation in a lightly flavored beer like pilsner will take quite a long time (months) to show, as the oxidation reactions take a while to go to completion due to the cold temperatures. A heavy dry hop charge will show oxidation more readily as there are a lot of volatile and reactive compounds introduced to the beer from the hops. Most of these compounds are driven off when added to the kettle. A possible experiment would be to bottle samples of both beers in to CO2 purged bottles, cap them on foam, and force age the bottles. IIRC, 3 days at 100F is commonly used to simulate 3-4 months of aging. redoing the test at that point might show more differences.

Using an s-shape airlock can prevent sanitizer intake. I have also replaced my airlocks with a sanitized balloon when i add a dry-hop charge, as the expansion and contraction of the headspace gasses are (hopefully) taken up by the elasticity of the balloon. I just hope that the oxygen introduced when dry hopping gets consumed by the yeast… I’ll also “half-crash” an IPA and keg it at around 35-40F, using CO2 to push the beer through the racking cane. I only take these extreme measures with IPAs, as most other styles of beer are long-gone by the time any oxidative effects are noticeable.

You write that there’s an unknown amount of oxygen that moved into the fermenter, however, we can get a very good approximation.

There are 2 gallons (7.6 L) of head space in a brew bucket with 5 gallons of beer in it. Charles Law allows us to calculate the volume change with temperature decrease; I’ll save you the math: that’s 0.4L, which means about .08L of oxygen, which weights about .05 grams. That’s about 26 ppm, if all of it gets absorbed. I would guess that far, far less is absorbed by the beer.

By the way, you should double check my math on that before you go quoting it as accurate.

I actually fill my brewbuckets to the 6 gal level and leave about a gallon of beer/trub behind when kegging. So headspace is about 1.1 gallons

Then we have just half that much!

0.05 g in 5 Gallons (20L or 20kg of beer) is 2.5 ppm, so even less. My headspace is a lot less than 2 gallons for most beers (using plastic carboys). But beer has thermal contraction too – water density at 70F is about 0.998. So 5 Gallons (about 20L) of water will contract by 0.2% or another 40 mL, which will be replaced by air, which is 20% oxygen, so about 8 mL of O2, or .36 mMole, or 32g*3.6*10^-4 about 0.01 g. Or 0.5 ppm from beer contraction by itself. Having said all that, there are people (mostly LODO types) who claim even 10ppb can be important in degrading flavors over time.

As far as the “vacuum effect”: 1. at colder temperatures more co2 is absorbed into liquid than released into headspace. 2. assuming there are significant amounts of o2 in headspace, 02 could be absorbed after “blanket of co2” (because co2 is heavier than o2) on top of beer is already absorbed at colder temperatures.

So to effectively cold crash without too much o2:

could you just purge headspace with co2 prior to cold crashing?

Thus leaving a bigger “blanket of co2” ontop of beer in carboy…

Is it just as easy as sanitizing beer gun and filling headspace full of co2 before cold crashing???

Thanks for taking the time to do the experiment, Jake 🙂

A few comments:

1. +1 on Kyle’s comment above. Both beers are cold crashed. Although Marshall agreed, the title and the initial description of the experiment are still at odds with Marshall’s response. Timing of cold crashing seems to be a better title.

2. The introduction leads the reader to believe that the experiment is a comparison of cold crashing vs. no cold crashing. Additionally, there is no hypothesis on why cold crashing before transferring would be different to cold crashing after transferring. Eg, when transferring warm, you are transferring more yeast, which can be beneficial if extract remains, to create a lagering effect. Finally, one of the not-discussed hypothetical problems of cold crashing is the effect of crashing on heat shock proteins in the yeast and yeast release of unwanted substances.

3. The article would benefit from a brief description of the differences between rapid and slow cooling; cold crashing = rapid cooling and slow cooling = “cold ramping”. The appropriate comparison to cold crashing would be “cold ramping” (cooling to lager temp over 4-5 days).

4. The pressure differential created with cold crashing does not necessarily lead to oxygen introduction unless there is a process error (apologies for the directness). For example, I ferment in plastic and when I crash, I cap the fermenter (Speidel); the plastic absorbs the pressure difference until you open it. In your case, stainless should be able to absorb the small pressure difference if sealed. Also, if you were to crash from 10C instead of 16C, the pressure differential would be much smaller.

Cheers!!

Ok, clarity is clarity.

However if we are talking about oxygenation, generally that is something that shows itself over time.

If the beer is served fresh, yes we get results like we saw in the xbeeriment.

However, what would be the results if there the same tasting say 6 and 12 months after this first experiment with the same exact batches?

Big breweries worry about shelf life than do homebrewers. That is why they have such a big concern over oxygen. I am not surprised by the results of this experiment and I think homebrewers worry too much about stuff they should not be worrying about…and brulosophy does a good job of debunking much of these theories uncritically translated from the world of commercial brewing to the homebrew scale.

In the presentation “Beer Oxidation: Chemistry, Sensory Evaluation, and Prevention” NHC 2017, Robert Hall stated that 40% of the NH competition 2nd round beers were oxidized (survey of a sample of judges). This is the best homebrew in the country!

But were they oxidized? Or is oxidation a common refrain?

@Malcolm – It is admittedly anecdotal evidence unless published. My observations when judging are similar, ie, I notice that many beers are oxidized. The catch is that oxidation flavors are not necessarily bad to many tasters. BJCP guidelines described oxidation flavors in English beers as the appropriate flavors until recently. Bamforth published a study in which the preference for stale (oxidized) beer was similar to that of fresh beer.

Oxidation after fermentation has been well studied/ demonstrated and, as I mentioned more than once –not here :-)–, research is done in pilot systems (almost homebrew systems), not in 100 barrel tanks, so the data is more applicable to us homebrewers than to pros.

So, short answer, my best guess is that it was not a common refrain, that is many beers were oxidized. You judged at this year’s NHC, what’s your take?

Cheers,

I tend to agree the most common flaw I run into when judging home brew is the perception of oxidation or stale beer. I would say the same is probably true in many professional packaged beers as well, unfortunately.

I often play Devil’s Advocate because it’s the perception of, or what I assume is oxidation, I certainly don’t truly know. Seems a common refrain to brand any “bad, or dull, or muddled” beer, that has no other glaring and more readily identifiable faults, the tag of “oxidation”.

You should try to isolate the “O2 suckback” variable in two hoppy beers that are both cold crashed. One beer you allow to suck oxygen through the airlock, the other, you use a device that replaces the headspace with CO2 as the vacuum is created.

I can’t see a lot of air getting into the fermenter when cold crashed. The volume of air and beer reduced cannot be more than 2-3 cups. Even if a considerable amount did get in, CO2 is heavier than air, so the contact with oxygen would be minimized unless you shook the fermenter. I know your results confirm this, but logically I don’t see the beer being in contact with a significant amount of oxygen. Heck homebrewers filling bottles without a gun get more air in their beer probably.

CO2 being heavier than air will not actually stratify the gases. On the whole, the concept of a CO2 “blanket” is false. The only reason it could possibly be true is when an active fermentation is constantly outgassing

If you are not micro filtering your beer you will still have some yeast hanging around in solution, regardless of cold crash, which could mop up a bit of your oxygen.

Although if you keep at low temperatures, I guess it might be hibernating.

I suspect that what little oxygen gets sucked back and absorbed by the beer gets metabolized by yeast as there will still be a small amount of fermentable matter keeping yeast working even after two weeks, though attenuation will have fallen to a rate too low to see with regular hydrometer readings. As another poster has noted, this residual extract is what’s fermented very slowly during traditional lagering, reducing gravity another point or so over weeks or months.

So I’d expect no difference between the beers resulting from oxidation.

The mechanism by which cold crashing drops sediment is largely physics. Cold water can hold more dissolved gas, so chilling suppresses effervescence. When CO2 bubbles stop rising, fine particulate matter can no longer resist gravity. Yeast flocculation and protein-polyphenol coagulation are also factors.

Good catch on also pointing out the potential for efflorescence to hinder the ability for solids to more readily start “dropping” vs rising due to either convention or hitching a ride on a bubble. Stokes’ Law applies.

Not only can it be metabolized, but not very much of the O2 will even dissolve into the beer. To get 8ppm of O2 into wort, you need vigorous shaking with a 80/20 Nitrogen/Oxgen mixture (i.e., atmospheric air) and if extending the amount of time on contact were able to greatly increase that, then our atmosphere would have a lot less oxygen and the ocean would be a lot more than 4-6ppm.

One other aspect of cold crashing to consider if bottling instead of kegging, CO2 in the space above the beer will go into solution as the beer cools. Not an issue with carboys but can be with conical fermenters where a fair amount of space may remain above the beer. You just need to calculate the additional volume this represents and adjust the priming addition to compensate. Cold crashing ales will absorb up to an additional 0.6 volumes assuming a starting point of 20 C (68 F).

“I’ve cold crashed many times over the years and it always seemed to do as promised, my beers tend to clear up quickly even without the use of finings. I hadn’t really questioned this technique much, as it has become a ubiquitous practice among brewers and my own experience has been largely positive. That said, I won’t pretend the suck-back issue didn’t make me nervous, not so much about the airlock liquid since I use sanitizer, but it seemed an obvious vector for oxidation.”

This is exactly what I had been doing and I always thought my beers came out good. But with all the focus on reducing O2 during packaging I’ve grown increasingly concerned I was letting in O2. I came up with a method where I would connect the blowoff hoses to a tank of CO2 to add a little bit of CO2 while cold crashing.

But after listening to a beer oxidation lecture at homebrewcon this last June I have stopped cold crashing. The idea is you will most likely always get in a little bit of O2 in your keg during racking and if you rack warm into the keg you’re going to get some active yeast that will scrub out any O2 that might have gotten in. I also make sure to leave the serving keg warm for a couple days before I drop it into my conditioning fridge. You do end up with more material in your keg but if you don’t have to transport the kegs it’s not much of an issue.

The lecture is really interesting if you have not heard it yet. The guy from New Belgium describes how they inject a few yeast cells into each bottle not for conditioning but to scrub any O2 that gets in during bottling. They also discuss an experiment that they were able to reduce the off flavors of oxidation in an old beer by adding fresh yeast to the beer.

https://s3-us-west-2.amazonaws.com/homebrewassoc/wp-content/uploads/Beer-Oxidation-Sensory-Evaluation-And-Prevention-1.m4v

Great presentation from the conference!

Andrew, how did you convert your Fermonster into a pressure vessel? I’ve contemplated the same solution to this quandary but have haven’t read about a successful application. Please advise. Thanks

I bought a 4” tri clover stainless steel ferrule (aka flange), 4” steel cap, silicone gasket, and clamp from brewershardware.com. I sanded the flange and inner portion of the fermonster lip. I cut a folded over a piece of fiberglass mat to the circumference of the flange, wrapped it, and covered it in epoxy. Then I drilled 3/8” holes in the stainless cap, and soldered in pieces of 3/8 stainless tubing as the dip tube and gas port. I attached valves to both of these tubes. If you could do the same with corny keg style quick connects it would be better but I couldn’t figure out way to do that.

It makes in my opinion the best pressure fermentation vessel. It holds 7 gals, I’ve tested it to 25 psi, and it’s clear so you can see what’s going on inside.

I’ll post some photos to one of the homebrew forums one day and put a link here if there’s interest.

Wow! Would love to see photos!

Not Andrew, but you can use Carbacap (use stainless steel with barb) and a regular 10 stopper, plus spunding valve. The trick is making sure the red plastic cap makes a perfect seal, which may not be easy.

https://www.amazon.com/Stainless-Steel-Carbonation-Weekend-Brewer/dp/B01FG5G1MO/ref=pd_lpo_vtph_79_lp_tr_t_2?_encoding=UTF8&psc=1&refRID=6BA1DNEH7M8XDQGZVFMZ

https://www.austinhomebrew.com/Adjustable-Pressure-Relief-Valve-w-Gauge_p_4808.html?utm_source=google&utm_medium=shopping&gclid=Cj0KCQiAl8rQBRDrARIsAEW_To9gGgmb_2ox43nsCwwxcZZl9n0xMZgYcSeU5B2R5qA0SoSoHgM-d4IaAi-NEALw_wcB

I tried this at first but the red cap would break under pressure when it was tightened enough to form a good seal. Probably couldn’t pressurize the vessel beyond 6 psi.

Hey Jake,

Just performed same type of experiment – however the grain bill contained 15% flaked fermentables so the initial haze was a significant variable. The cold crashed version was definitely less opaque. No detectable variation in flavor, smell, nor mouthfeel.

Moreover, finally pulled the trigger on corny kegs. One of the pictures above shows you transferring from a Ss BrewBucket to a closed corny via gravity. Do you have to release pressure as keg fills? I am hoping to adapt the same system but want to confirm how that process is done before first attempt with a fermented beer.

Much kudos to your writing and this website in general.

There is a gas QD on the in ball lock

John Palmer says quickly cold crashing might interfere head retention and readily oxidization in his “How To Brew”, 4th edition.

Do you think it’s a good topic for xBmt?

page 95

”

Cold conditioning is a process of slowly cooling the beer down by 2F(1C) per day to about 9-15F(5-8) below the fermentation temperature to promote the flocculation of the yeast and the coalescence of the protein-polyphenol complexes that cause haze.

….(deleted)

The point of slow of slow cooling is to prevent thermal shock of the yeast cells and subsequent excretion of fatty acids and other lipids. These lipids can interfere with head retention and will readily oxidize, creating stale flavors. Thermal shock at any time can cause the yeast cells to release protein signals that cause other yeast cells to shut down to protect against the cold, potentially leading to premature flocculation and under-attenuation.

”

Thanks for your great work.

Thanks for the reference, I would say the head on this beer was pretty exceptional but definitely plan to test quick crash v slow and steady

Looking forward to it. In fact, looking forward to everything from you.

Thanks.

I too would like to see such experiment.

..and enjoy all that you have done. Thanks!

I know this is old, but (like Vito) I’m VERY interested in seeing this done, too. I came to this post hoping for insight on slow chill down to lager temp vs quick crash, as there appears to still be some divisiveness on the subject. I, for one, am inclined to believe Kai Troester and traditional German techniques when they state a quick crash leaves the yeast susceptible to shock and thus less able to clean up the lager after primary fermentation is complete (post d-rest). Obviously would love to see a side-by-side.

One thing I have found is that you don’t really have to “crash” your beer down to the 30s or 40s to get a benefit. I just drop my ales from 66 to ~56 and almost everything settles out in a few days including the yeast and dry hops.

Assuming that there is a higher dissolved oxygen level in the cold crashed beer compared to the non cold crashed beer, I’d be interested to see if maybe there are any effects that could be attributed to that increased oxygen concentration in that beer when it perhaps has been stored for a period of time. 1-3 months perhaps. Maybe longer. I assume a lower D.O. level would probably increase shelf stability. Perhaps there is definitely a noticeable difference in the two beers, they just can’t be noticed yet cause the beer is young.

So, I’ve adopted a lot of the processes for cold crashing, kegging and fining that I’ve read about on these pages. But, I’m stuck in a bit of quandary. It seems that different Brulosophy contributors follow somewhat different approaches.

Option 1. Cold crash in the fermentor; fine with gelatin in the fermentor; then rack to purged keg. (Note: this is what I’ve been doing but I now fear the adverse effect of oxygen exposure).

Advantages: By cold crashing and fining in the fermentor, we transfer clean beer into the keg that simply needs to be force carbonated.

Disadvantage: Risk of oxygen exposure from suckback through the airlock when cold crashing.

Option 2. Rack the beer to a purged keg; cold crash and fine in the serving keg. (Note: I’ve never tried this approach).

Advantage: No oxygen exposure from suckback. The keg can be pressurized while cold crashing to ensure a tight seal.

Disadvantages: By cold crashing and fining in the serving keg, I fear there will be trub-like layer at the bottom that will clog the dip tube and/or poppit valve. Please advise if this is, in fact, and issue.

Does option 2 work for y’all? Do you experience clogs from all the stuff that drops out of solution during cold crashing and finish?

Thanks

Bruce

So in my opinion both options will work fine and this xbmt would suggest they are fairly similar when it comes to a non fined approach.

Fining in the keg definitely works though you can run the risk of having cloudier beer longer.

Love your site and experiments, always a pleasure reading…

Another topic for you regarding cold crashing. As a lot of matter coagulates and falls to the bottom during cold crashing, including yeast, what impacts does it have on the bottles carbonation. I mainly keg my beer and always fill a few bottles on the side for aging purpose. I would tend to believe that cold crashing impacts negatively the bottle carbonation. Experiment idea: days of cold crashing vs bottle carbonation vs qty priming sugar… Any suggested extra priming sugar addition to overcome the drop in yeast cells quantity in solution?

I did cold crash a Russian Imperial Stout 10% ABV, carbonated with recommended sugar. I got no bottle carbonation. It makes me think cold crashing that beer was a mistake as I dropped out of solution all necessary and already stressed yeast to provide sufficient carbonation…

I don’t really bottle, and when I did I wasn’t really cold crashing. Given enough time I would think cold crashed beer should carbonate up just fine assuming proper dosage of sugar was used based on temp reached during fermentation and volume

Regis. I performed a cold crash in my Blonde Ale (based on the “BEST BLONDE ALE” from Brulosophy. I have no way to force carbonate my production yet, therefore I need to prime with sugar. I read a lot and it seems no problem to cold crash and have still enough yeast to provide the right carbonation level. My experience confirmed that, I cold crashed to 4ºC (39.2F) over 2 days, after the fermentation was completed of course. Then I bottled with Coopers Carbonation Drops. I have European bottles (330 ml) and american 355 ml. No problem to get a nice carbonation on both with a single drop of this sugar. That said, I have brewed the same batch again. The first I didn’t enjoy as I expected, I am still a beginner and learning. Now I can control the fermentation temperature into +/- 0.2ºC with a modified refrigerator. But this time I decided to skip the cold crash, following the same principle with sugar and bottling.

After almost 2 weeks, I have tried one beer and it was almost complete flat… Now after almost 4 weeks is not much CO2 still. If I have done the cold crash in this batch it would be the culprit. Now I will just leave for a longer period and in the worst case I will reopen the beers and have a tiny amount of dry yeast to try to get the CO2 correctly. The beer is tasting much better now, but the lack of bubbles is annoying me.

If you don’t want sanitizer (or vodka) sucked into your fermenter, then why are you cold crashing using those 3 part airlocks? If you use those cheaper S-shaped two compartment bubblers, they go both ways. So yes, you will always suck a little bit of air into the carboy when you cold crash, but there is no need to always suck in the bubbler liquid also. And if I had a choice of getting a shot of Star San or shot of vodka in my batch of beer, I’ll pick vodka any day. That’s why I only use vodka in my airlocks.

Great xBmt Jake! Thanks!

For the oxygen problem couldn’t you retain 12oz of your wort (or Vodka:) in a growler that you top off with C02 and cover lightly and run a blow off tube? Then what is sucked in is desirable, or at least not as undesirable as sanitizer and/or oxygen.

Wouldn’t using a S-double bubble type air lock eliminate sanitizer being sucked back into the fermenter ? Watching this airlock in action, it appears to pass the air through the sanitizer in the air lock chambers, rather than sucking the sanitizer in ahead if the air.

Since CO2 is heavier than oxygen, wouldn’t any oxygen sucked back through the air lock during cold crashing stay at the top of the fermenter, above the CO2 blanket ?

A fellow, highly experienced homebrewer thinks that cold crashing has a negative impact on the yeast, which doesn’t like such a fast temperature change. This impact would result in the yeast giving off flavors. The exberiment tasting results do not support that though.

So a layer of co2 is kind of a misnomer. Gases mix. Cold crashing absent pressure by a gas will always result in oxidation. The results of this suggest it didn’t have a noticeable impact however.

In terms of yeast flavor the specific variable you describe is definitely on the list. Slowly crashed versus all at once

Thanks for the insights, Jake.

I’ve had success fitting a 1 gallon ziplock freezer bag to some tubing with a quick disconnect, fill it with co2 and attach it to my blow off connection prior to cold crashing. More than enough co2 in the bag to handle any suck back for a 5 gallon batch.