Author: Marshall Schott

I’d brewed about 20 batches of extract with steeping grains beer before I finally decided to jump into the world of all grain brewing, enticed by the idea of having more control over the ultimate character of the beer I brewed. When a worker at the homebrew shop I purchased my first equipment kit from realized I was hooked, he began peer pressuring me into making the switch to all grain, and I was intrigued… until he explained what all in entails.

Back then, the primary all grain method for homebrewers was continuous/fly sparging, an approach modeled after professional breweries that called for the use of multiple vessels and gear in addition to what seemed to me at the time a rather fine-tuned process to avoid screwing things up. As easy as this dude tried to make it sound, I was in no way prepared to invest the time and money into something that I’d convinced myself wouldn’t have a noticeable impact on the quality of the beer I was making (ahem).

Cut to early 2011– I’d finished graduate school, got a job, and bought a house, the perfect scenario for any brewer looking to reignite an obsession! During my few years of brewing downtime (thanks grad school), I’d heard about a novel approach that people swore made getting into all grain brewing much easier. Originally published in early 2004, Denny Conn’s Cheap ‘n’ Easy Batch Sparge Brewing article introduced many homebrewers to the idea of using a standard insulated ice chest or water cooler as a mash/lauter tun (MLT) as well as replacing the traditional sparge with a much simpler “batch” sparge step. I was sold and immediately spent $86 acquiring all the parts necessary to build an adapted version I found online. Indeed, the method was easy and the beers were great.

A few years later, I published an article on how I clean my gear, within which I included a picture of my converted cooler MLT in all its well-used glory, a picture that someone in a particular forum, well, noticed. Despite my beers coming out fine, I began to wonder about the flavor impact my lack of scrubbing might be having on my beer. Then I published my review of the Ss Brewtech InfuSsion, an insulated stainless MLT, which yielded many questions regarding potential flavor differences between beers produced in either tun. Having admitted my belief the latter product was more of a luxury and didn’t have a noticeable impact on the quality of my beer, I thought the idea of a comparison was stupid. That is, until the fermentation vessel comparison xBmts started consistently yielding significant results, which suggested to me that perhaps material isn’t as benign a variable as I thought.

| PURPOSE |

To evaluate the differences between two beers of the same recipe brewed using the same process where one was mashed in a stainless MLT while the other was mashed in a converted cooler MLT.

| METHODS |

I hadn’t had a Vienna Lager on in awhile and thought it’d be ideal from this comparison, as it should allow any differences caused by the variable to shine.

Go-To Vienna Lager

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 26.9 IBUs | 8.8 SRM | 1.050 | 1.013 | 4.9 % |

| Actuals | 1.05 | 1.012 | 5.0 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Vienna Malt (Weyermann) | 10 lbs | 97.56 |

| Pale Chocolate Malt | 4 oz | 2.44 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 14 g | 60 min | First Wort | Pellet | 11.2 |

| Hallertauer Mittelfrueh | 28 g | 10 min | Boil | Pellet | 2.4 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| German Bock Lager (WLP833) | White Labs | 73% | 48°F - 55°F |

Notes

| Water Profile: Ca 81 | Mg 0 | Na 8 | SO4 116 | Cl 60 | pH 5.15 |

Download

| Download this recipe's BeerXML file |

Since I hadn’t noticed any efficiency differences when I switched from my cooler MLT to the InfuSsion, I used the same recipe for both. Since these would both be no sparge batches, I collected equal volumes of water in separate kettles, adjusted each to the same target water profile, then weighed out and milled two sets of equal amounts of grain the evening prior to brewing.

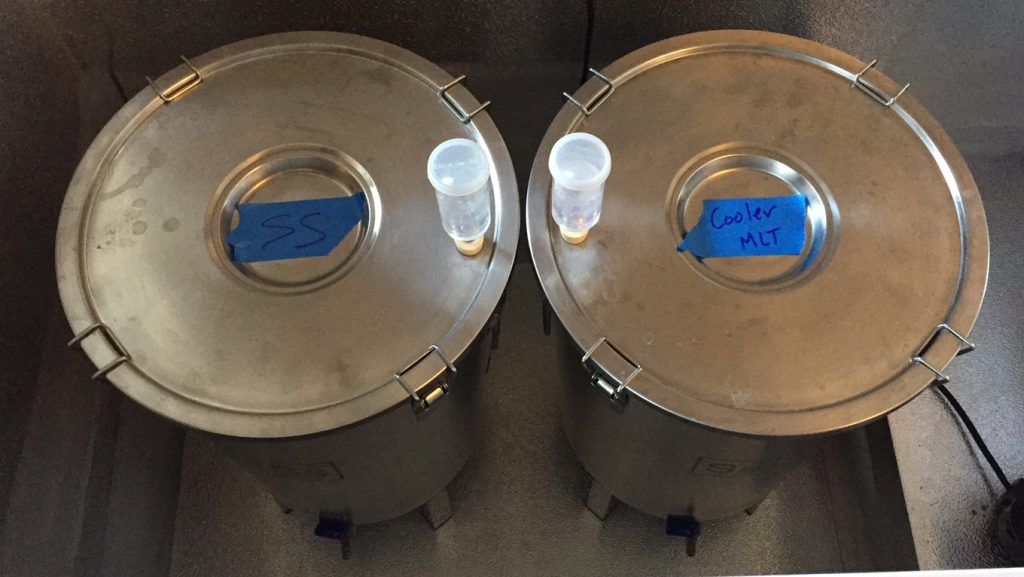

I began heating the full volume of strike water for the first batch, the one that would be mashed in the stainless MLT, about 20 minutes before hitting the flame under the second kettle.

I mashed in the stainless MLT batch about 20 minutes later.

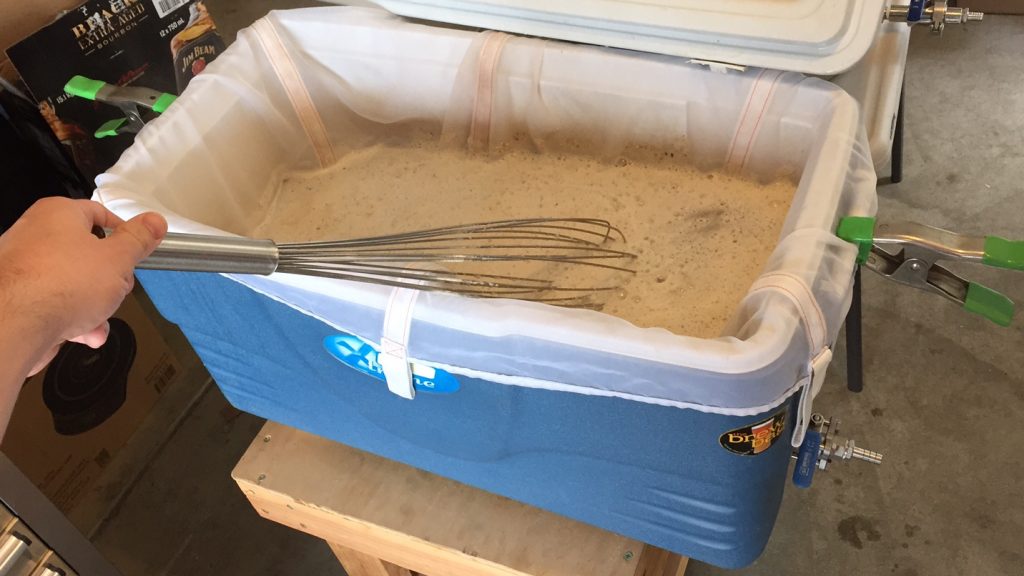

And approximately 25 minutes after that, I mashed in the plastic MLT batch.

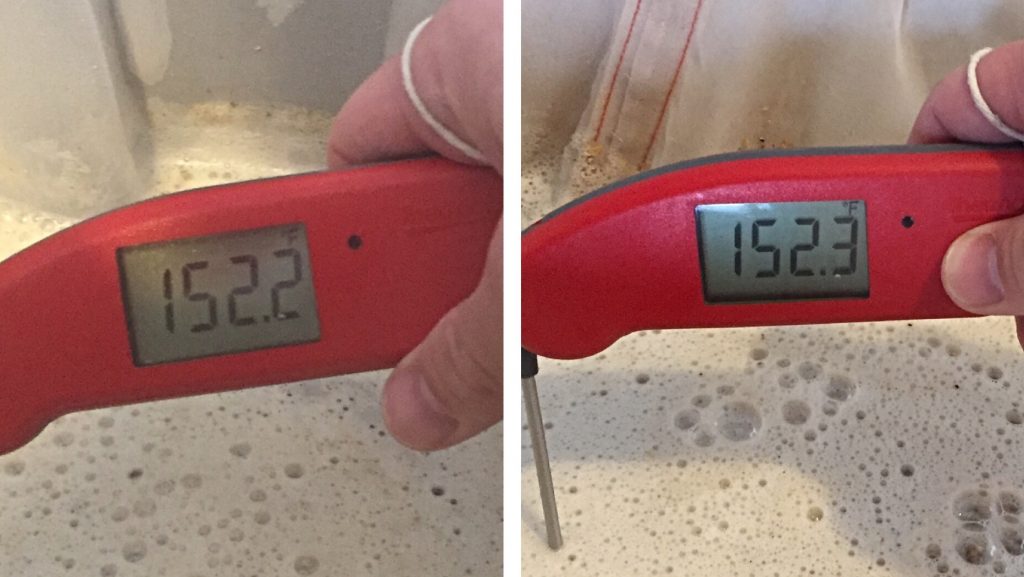

Temperature readings a couple minutes after mashing in were consistent between the batches.

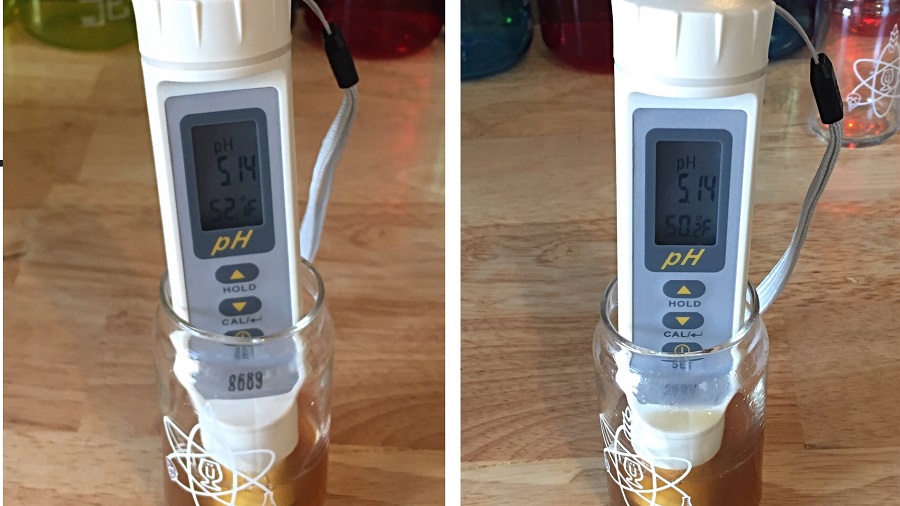

I took pH measurements 15 minutes into each mash that were identical as well.

While the mashes were resting, I measured out the small amount of hops that would be used in each batch then tossed the first wort hop charge into either kettle.

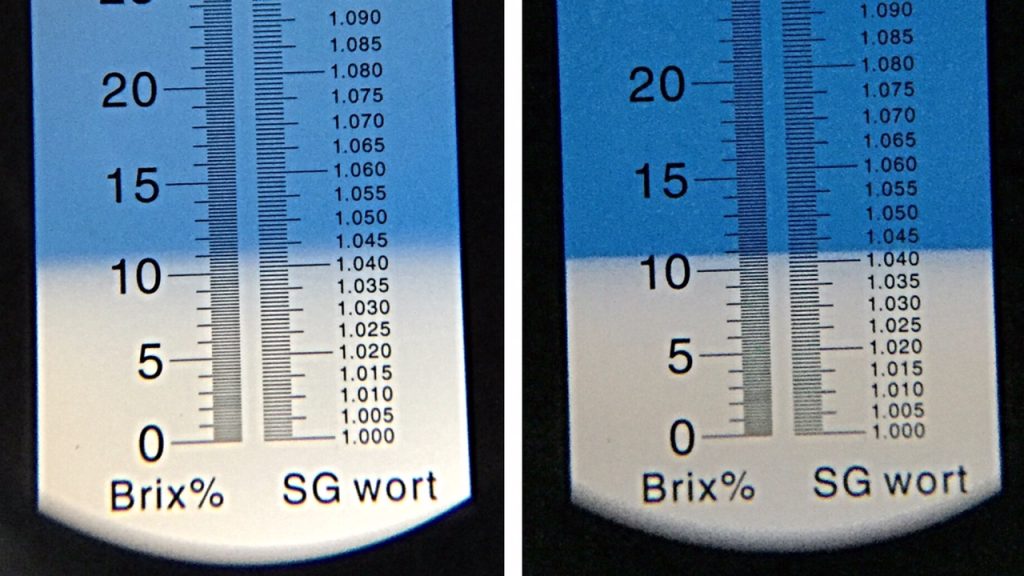

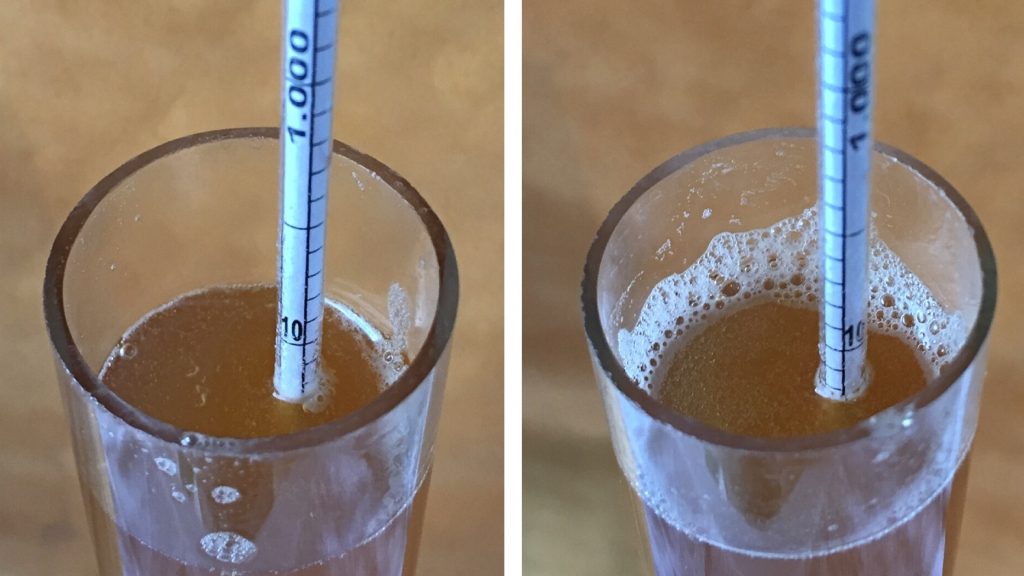

I took pre-boil OG measurements at the completion of each 60 minute mash just to confirm things were equal, which they appeared to be at this point.

The same amount of sweet wort was collected from each mash, transferred to kettles, then boiled for 60 minutes.

Each wort was quickly chilled to 74°F/23°C at the end of the boil, about 6°F/3°C warmer than my groundwater temperature at the time.

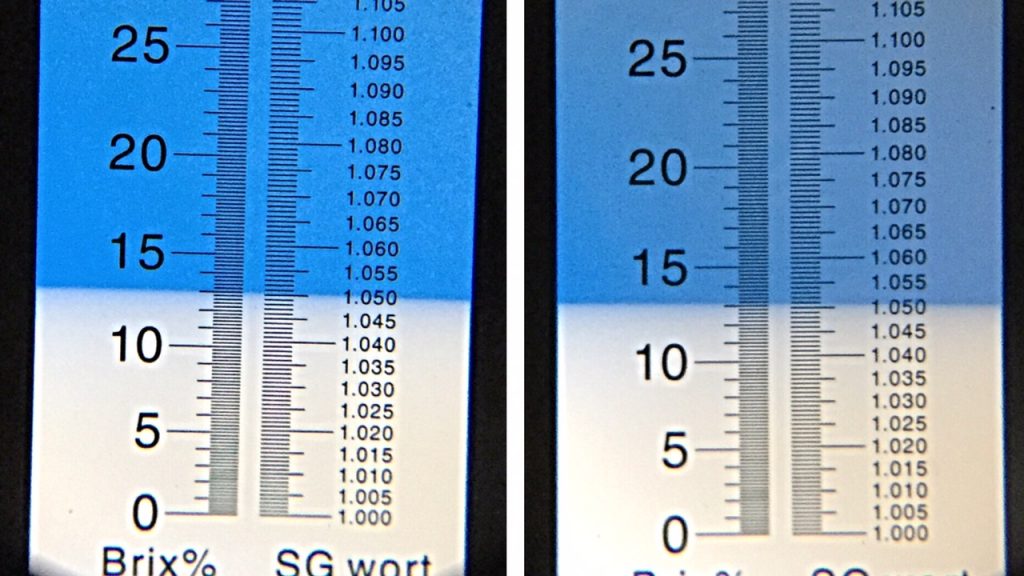

Post-boil refractometer measurements were again consistent between the batches.

I transferred 5.5 gallons/21 liters of wort from each batch into separate fermentors that I placed in my cool chamber to finish chilling to my desired fermentation temperature.

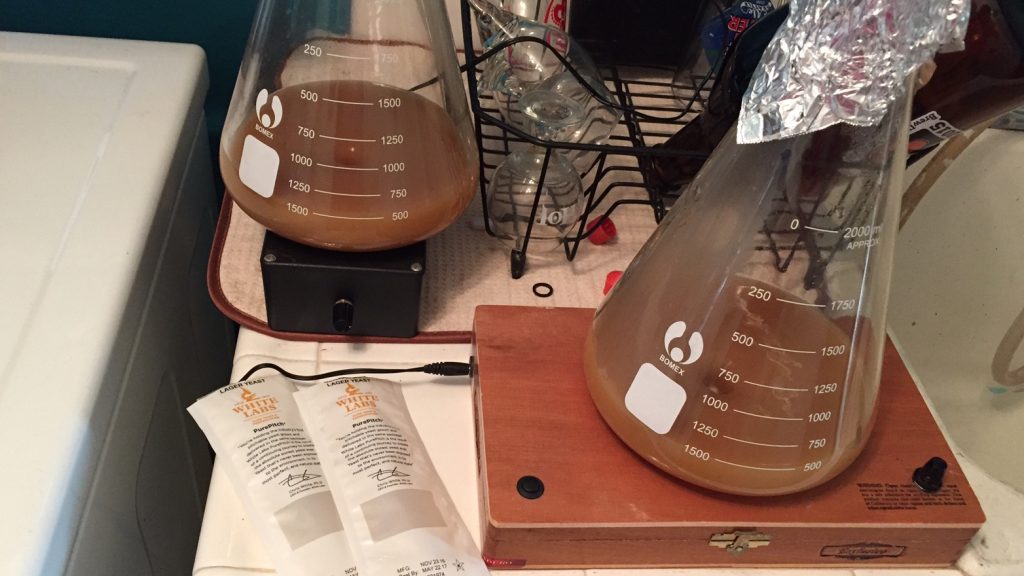

I then returned to my kettles to prepare vitality starters by collecting two 500 mL volumes of leftover wort in sanitized flasks, pitching a pack of WLP833 German Bock yeast into each, then placing both on stir plates.

With both worts sitting at my intended fermentation temperature of 52°F/11°C 4 hours later, I pitched a starter into each batch. Returning 12 hours later, I noticed similar bubbling from each airlock that confirmed fermentation had taken off.

The beers were left alone for 8 days before I raised the temperature to 68°F/20°C for off-flavor clean-up and to encourage complete attenuation. At 15 days post-pitch, neither beer was showing signs of activity so I took preliminary hydrometer measurements showing they had both dropped to the expected FG.

With no detectable signs of diacetyl, the beers were cold crashed, fined with gelatin, and kegged.

The filled kegs were placed in my cool keezer where they were burst carbonated overnight then I reduced the gas to serving pressure. I let the beers lager for 2 weeks while I was in New Zealand before I began serving them to participants, a point at which they looked exactly the same to my eyes.

| RESULTS |

A total of 20 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer mashed in the stainless InfuSsion and 2 samples of the beer mashed in a converted cooler MLT then asked to identify the sample that was unique. While 11 tasters would have had to correctly identify the unique sample in order to reach statistical significance, only 6 picked the odd-beer-out (p<0.05; p=0.70), indicating participants in this xBmt were unable to reliably distinguish a Vienna lager mashed in a stainless MLT from one mashed in a plastic MLT.

My Impressions: It’s common when I’m sampling xBmt beers throughout the process that I think I notice a difference, only to be proven wrong when attempting blind triangle tests. That was not at all the case with these beers, not even my bias was strong enough to convince me I could tell them apart, which was upheld by my consistent-with-chance performance multiple triangle attempts. For all intents and purposes, these beers were the same, and they were damn tasty!

| DISCUSSION |

It’s true that plastic ice chests and water coolers weren’t necessarily designed to hold hot liquids that would later be consumed, hence the presumed validity of concerns about chemicals leeching into the beer that might not only influence flavor but be unsafe. Anecdotal as it is, the fact thousands of people regularly make beer using converted cooler MLTs and haven’t grown appendages out of their foreheads, in addition to professional opinions I’ve read and heard, leads to believe it is a relatively safe practice. And while my confidence that plastic cooler MLTs could produce a beer no different in character than one made in a stainless tun had waned due to prior fermentation vessel xBmts, I was admittedly reassured by the results of this xBmt showing tasters could not reliably distinguish between beers made in either.

In every hobby, there are items necessary in order to accomplish the intended goal and then there are those desired items that can make accomplishing said goal perhaps a bit more enjoyable. When it comes to mash tuns, the results of this xBmt certainly suggest that cheap ‘n’ easy won’t have a negative impact on beer, supporting the “use what works” credo of many. However, neither does it prove there’s anything wrong with those who desire something different, a little bling in their brewery that perhaps improves their overall experience.

If you have thoughts about mash tun material or this xBmt in general, please don’t hesitate to share them in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

23 thoughts on “exBEERiment | Stainless Steel vs. Converted Plastic Cooler Mash Tun In A Vienna Lager”

Good to see RDWHAHB still holds

Since I use a converted cooler, biab and no sparge I read this with some anxiety. Very relieved when I got to the results. My method was developed reading Brulosophy articles and it works great for me. So easy and consistently good results. Thanks for the exbeeriment.

Hey Marshall, I see you used a brew bag in the Brewtech. How well does that work? I imaine the thermowell being an issue?? I like the idea though!!

Hey Todd, it works fantastic! There are times the weight of the bag pushes down just enough on the thermowell that it creates a tiny drip, but that’s easy enough to fix by readjusting the bag. That’s seriously the only issue I’ve had, and I don’t even consider it a real issue. Wouldn’t brew without my brew bags, love those things.

Great read! What is that PH tester you are using ?

Click the pic! It’s the Thermoworks 8689, super cool.

Another great xBmt! Love the podcasts too!

I’ve never used a ph Meter before but would like to start. Which solutions should I purchase with the Thermoworks 8689 to calibrate and maintain?

Thanks!

In a similar vein, I’d be curious to see the results of a test comparing the same beer in two different tasting vessels, for example glass vs solo cups. However, I guess it would be pretty hard to blind the participants to which one they are tasting.

Great experiment, and well played on getting two identical batches of a tasty VL!

Cheers,

Tim

PS- That is definitely a sexy ass pH meter.

I suspect organic compounds are more likely to leech out of plastic containers when alcohol is present as it can dissolve hydrophobic compounds that water can’t. So plastic fine for mashing, maybe less suitable for fermenting.

bigger contact time in fermentation vs mashing may play a role too

You need to explain the steps in this part of the recipe “finished graduate school, got a job, and bought a house”.

Did you take a temperature reading at the end of the mash? Wondering how they performed insulation wise.

Hey Marshall…

Is that straight gravity feed from SSBT bucket to keg? Did you open up gas side to allow for pressure release?

Thx Rob

Yeah, gas depressor on that post, gravity fed.

I’d be interested to know if there was any difference in heat loss over the course of the mash with the different mash tuns?

I’ve measured temp loss over an hour in both MLTs many times in the past, it’s never been more than 2˚F over an hour even on the coolest days for either MLT.

Were the final mash temps the same?

Gah! Nevermind, just saw the post ahead of me.

What did you think of your recipe? I’ve been debating between all Vienna with a little bit of black malt compared to a mix of Vienna, Pilsner Munich CaraMunich, etc.

I like your post…Water coolers come in two styles, bottled water coolers and bottle less water coolers. Water coolers are a great investment either at home or in the office.

Freestanding water cooler

Just a thought.

It has been found that plastics release compounds such as methane, ethylene and propylene over time and I’d expect that the latter two of these could react with beer components. I’d expect that with a mash tun and probably a fermenter the residence time is too short for these to be significant. The light levels would also be low and temperature low for a fermenter but I wonder if these effects might become more important for longer term beer storage in plastic containers? Probably not a good idea to store your plastic containers in direct sunlight either.

Here is the link to the research paper that has recently been in the news: http://journals.plos.org/plosone/article?id=10.1371/journal.pone.0200574

I’ve been fly sparging into a plastic cooler mash tun with false bottom. After every batch it takes a lot of force the pull the bottom out and sides of the cooler are scraped up from many batches done with same equipment. Brew water smells like plastic to me. Is the answer a new plastic cooler every so often or will stainless steel offer a better long term solution?