Author: Jake Huolihan

Debated ad nauseam by professional and homebrewers alike, hot side aeration (HSA) occurs when wort is treated in a manner that introduces what many believe to be excessive amounts of oxygen in the period between mashing and knockout. It seems a growing number of brewers have accepted HSA as a non-issue, though some continue to view it as a brewing bogeyman that leads to rapid staling and, of primary concern on the commercial scale, poor shelf stability.

We’ve performed a couple xBmts on HSA, the first comparing beers when they were fresh and the second after a period of aging, with neither returning significant results, meaning participants could not reliably distinguish low HSA samples from high HSA versions of the same beer. While it’d be easy to rely on these findings and the anecdotal reports of others to bolster one’s perspective of HSA as myth, a passionate group of German beer loving homebrewers recently introduced an idea that calls this into question.

In a document released in April 2016 called Brewing Bavarian Helles: Adapting To Low Oxygen Brewing, members of the German Brewing Forum laid out a method for producing Helles and other traditional lagers that have “it,” the seemingly ineffable characteristics of genuine Bavarian beer that a few have described as “fresh malt flavor.” The authors of the paper assert this character can only be achieved on the homebrew scale by utilizing a very specific set of processes intended to significantly reduce oxidation not just from the mash onward, but throughout the entire process– conditioning grain, pre-boiling strike water, underletting, and spunding, to name a few. Perhaps most curious of these methods involves using a “modest dose” of sodium metabisulfite (SMB), a compound whose proven antioxidant properties have made it a popular preservative in the food and beverage industry. However, as Dr. Charlie Bamforth once pointed out in an interview, commercial brewers have generally refrained from using SMB likely due to laws requiring disclosure of content over thresholds as low as 10 parts per million (ppm). Moreover, the authors of the paper suggest certain large commercial breweries are capable of brewing in a low oxygen environment due purely to larger mash volumes, which is impossible at the homebrew scale without the use of SMB.

As someone with a strong adoration for German beer who feels I haven’t been able to replicate the quality of what I drank while visiting the region, I was very intrigued by these ideas, to say the least. With heaps of hope, a small dose of skepticism, and a bit of an investment in the gear required to properly brew a so-called LODO (LOw Dissolved Oxygen) batch, I designed an xBmt to help me better understand the impact oxidation throughout the brewing process has on beer.

Note: Given the common usage of the term LODO, we opted to use it throughout this article when referring to the low oxygen brewing method laid out by the German Brewing Forum and espoused by the Low Oxygen Brewing website.

| PURPOSE |

To evaluate the differences between a beer brewed using methods to significantly reduce oxygen throughout the brewing process (LODO) and the same beer brewed without such methods.

| METHODS |

I began messing around with LODO brewing immediately after reading the aforementioned paper, before I had all of the necessary gear. I soon learned that, according to some advocates of the method, even the slightest deviation from protocol, such as using a copper immersion chiller instead of a stainless one, would likely mitigate the desired “it” character. It wasn’t until my setup was completely LODO-fied that I performed this xBmt, as my goal was to test the method as precisely as possible and see how it compared to a batch treated in a less oxygen restricted manner. Munich Helles is the style most associated with LODO, but I went with a simple Kölsch for this xBmt after a strong advocate of the method confirmed low oxygen brewing can positively impact any style; I did use a charge of Carahell in the recipe due to claims it lends a noticeably unique flavor to the beer when mashed in a low oxygen environment.

SuffoKÖLSCHian

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 19.8 IBUs | 3.5 SRM | 1.044 | 1.009 | 4.6 % |

| Actuals | 1.044 | 1.014 | 3.9 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Weyermann Pilsner Malt | 9 lbs | 91.72 |

| Caramel/Crystal Malt - 10L | 6 oz | 3.82 |

| Weyermann Vienna | 4 oz | 2.55 |

| Acid Malt | 3 oz | 1.91 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 8 g | 60 min | Boil | Pellet | 12.5 |

| Hallertauer Mittelfrueh | 30 g | 30 min | Boil | Pellet | 2.4 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Kolsch Yeast (2565) | Wyeast Labs | 75% | 56°F - 64°F |

Notes

| Water Profiles: Standard: Ca 82 | Mg 0 | Na 21 | SO4 101 | Cl 95 | HCO3 16 LODO: Ca 76 | Mg 0 | Na 21 | SO4 102 | Cl 93 | HCO3 16 |

Download

| Download this recipe's BeerXML file |

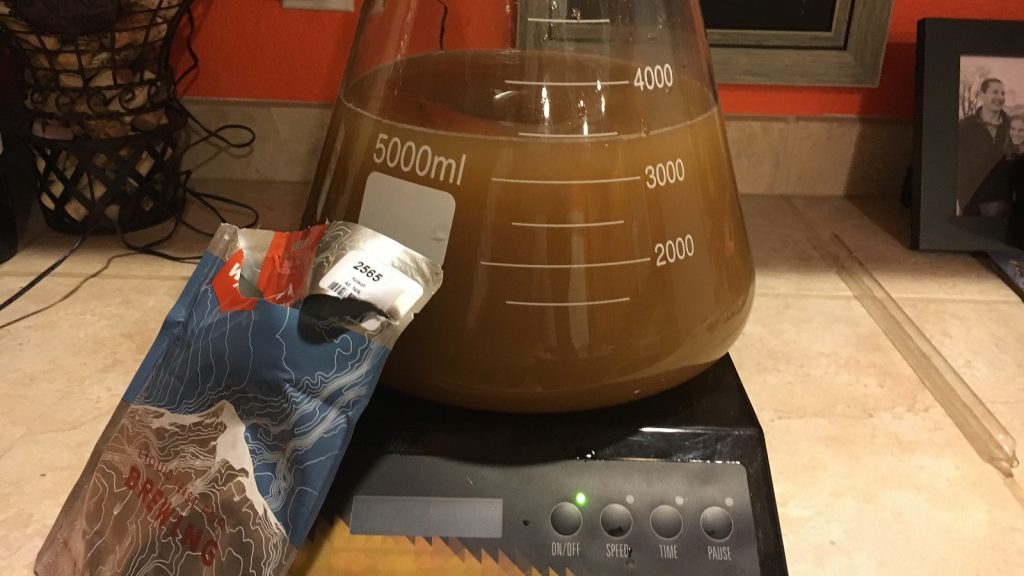

I prepared a large starter of Wyeast 2565 German Kölsch yeast a couple days prior to brewing to ensure an adequate pitch rate.

I began filtering my brewing water the night before brewing.

It was at this point I carefully measured out all of the brewing salts. As indicated in the original document, “a 100 mg/l dose of SMB will add 24 ppm sodium to your water, and 76 ppm of sulfur compounds (sulfur dioxide, sulfite, and bisulfite).” Since xBmt results have demonstrated minerals have a noticeable impact on beer, and the point of this xBmt was to isolate the effects of low oxygen, I used the Bru’n Water Spreadsheet to determine amounts of other minerals to use so that both batches would finish with a similar water profile; ultimately, the non-LODO batch received slightly more gypsum and calcium chloride than the LODO batch.

My first order of business the following morning was pre-boiling the strike water for the LODO batch in order to off-gas any dissolved oxygen. The standard batch was simply heated to the strike temperature recommended by BeerSmith.

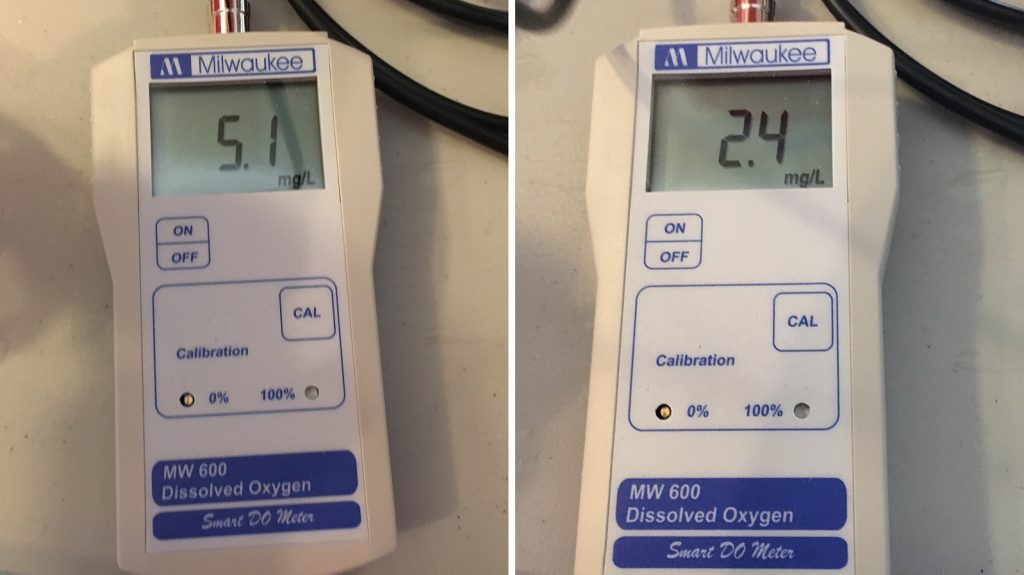

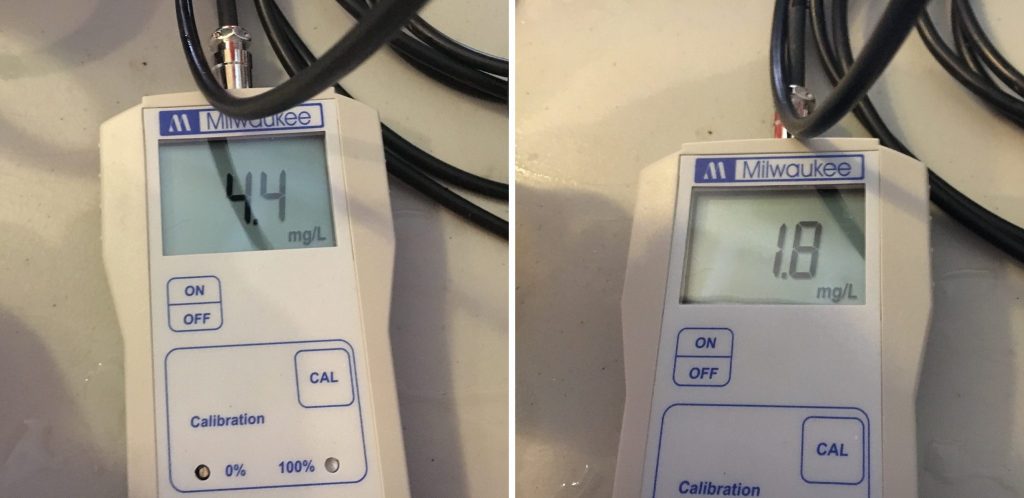

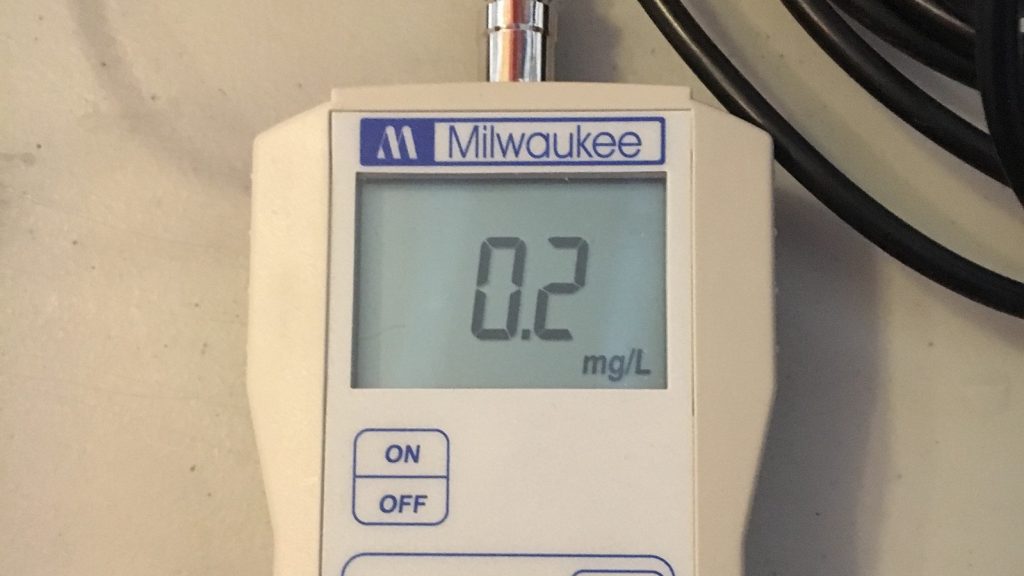

A measurement of the LODO strike water after only 10 minutes of boiling revealed a very low level of remaining dissolved oxygen (DO).

I let the LODO water continue to boil while I prepared the grains. With two sets of the same amount of grains already weighed out, I ran one through my mill as I normally do before proceeding with preparing the malt slated for the LODO mash. As recommended by Kunze, I used 1.5% water by weight to condition the grains before milling, a step the authors of the referenced document say “will keep the husk intact and reduce the number of lipoxygenase and peroxidase enzymes into the mash, which would otherwise accelerate the oxidation of malt lipids and phenols.”

I started the mash for the standard batch before the LODO batch by transferring the slightly overheated strike water to my MLT for a brief period of pre-heating before incorporating the grist. The LODO batch required a bit more work…

After chilling the boiled water with a stainless steel immersion chiller to the target strike temperature, I added 55 mg/l of SMB to the water and let it rest to scavenge any remaining oxygen. A DO measurement revealed 0.2 ppm, which when adjusted for altitude (Denver is high) meant there was basically no oxygen present; in contrast, the adjusted DO level of the standard strike water was 5.3 ppm. Next, I very gently transferred the water from the kettle through the valve on the bottom of my MLT that already held the milled conditioned grain in a process known as underletting.

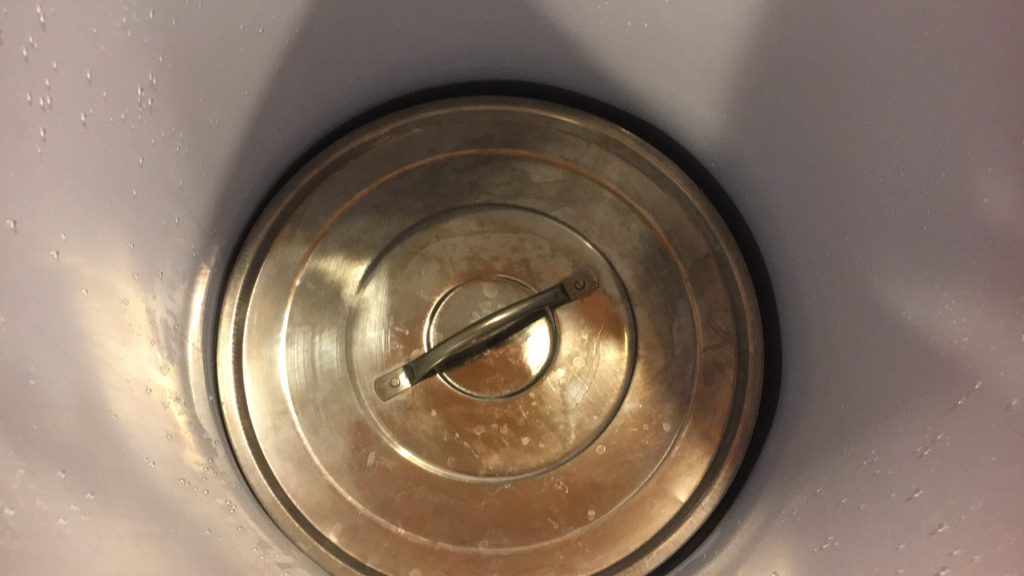

I utilized the no sparge method for both batches, meaning each was mashed with the full volume of brewing liquor, and I placed a mash cap (an old kettle lid that conveniently fit my MLT) on top of the LODO mash to further inhibit oxygen ingress.

Temperature measurements from both mashes showed a slight variation, which I chalked up to the different methods used for mashing in.

With claims that oxidation can quickly have a visible impact on wort, I stole small samples of wort throughout the mash rest to observe any differences in appearance, an initial sample just minutes into each mash confirming said claims.

I took more samples 30 minutes into each mash and, to my eyes, they still looked quite different.

Separate samples, the one from the LODO mash sealed to reduce contact with oxygen, were chilled before I took DO measurements.

At 60 minutes into each mash, before collecting the sweet wort, I pulled more samples for comparison, again sealing the LODO sample and chilling both before taking DO readings.

I lautered each batch similarly by allowing the wort to flow from the MLT valves to the valves on my kettles, as bottom-filling is another way to reduce oxygen ingress. I also made sure no bubbles were in the hose and no splashing occurred during the transfer.

Both worts were boiled very gently for 60 minutes, the standard batch only to avoid potentially large differences in evaporation due to boil vigor.

Once the boils were complete, I used my copper immersion chiller to quickly chill the standard batch to my groundwater temperature while I used a stainless steel IC to chill the LODO wort without any agitation, which required much more time.

The chilled worts were gently racked to sanitized corny kegs, the one receiving the LODO wort having first been purged with CO2 (sanitizer pushed out with gas), before being purged again and placed in a cool chamber to finish chilling to my desired 58°F/14°C fermentation temperature. Hydrometer measurements showed the normal batch achieved the expected 1.044 OG while the LODO wort clocked in at a much lower 1.035 OG (50% efficiency), which is exactly as I’d experienced in multiple prior brews using this method.

After sharing an image of both worts with the other contributors, we began to speculate that perhaps the color difference was a function of the standard wort simply having a higher concentration of sugar. To test this out, I diluted the standard wort sample with water until it reached the same 1.035 SG as the LODO wort then compared them again with validating results.

A couple hours later, both batches sitting at target fermentation temperature, I equally split the yeast starter, pitched, hit both with 90 seconds of pure oxygen, then attached blowoff tubes.

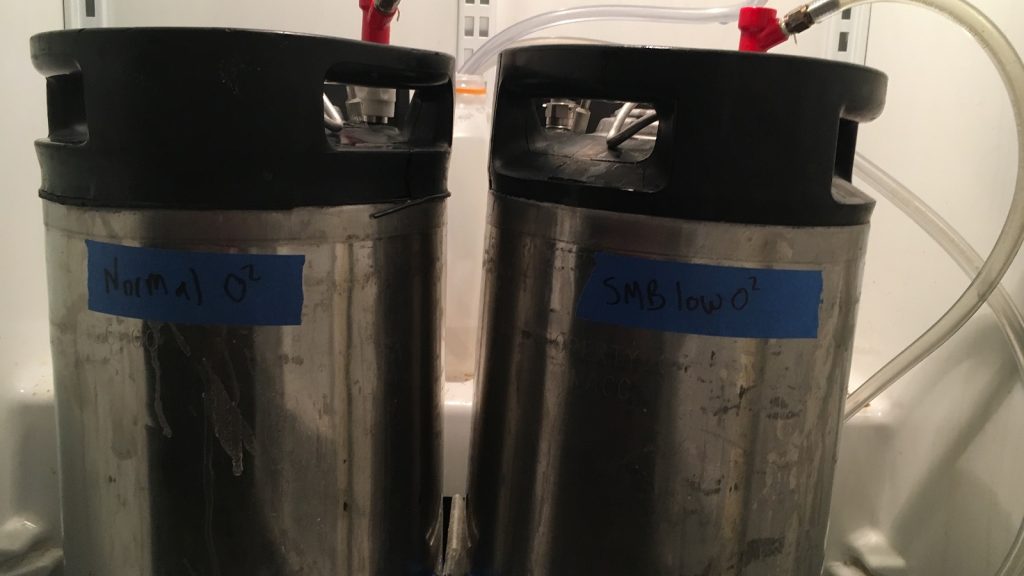

I noticed a bit of bubbling in the blowoff vessel a few hours later indicating fermentation had indeed begun. After 3 days of activity, I took hydrometer measurements indicating the LODO beer was within a few points of reaching FG, which meant it was time to rack to serving kegs. I sanitized two kegs, again filling the one intended for the LODO beer with sanitizer and pushing it out with CO2 to purge, then filled them using a pressure transfer process.

Spunding valves were placed on the gas-out posts of each keg, the one on the LODO beer set to the recommended 8 bar while the standard beer was left under no pressure. They sat for another 5 days at 62°F/17°C before I began to slowly reduce the temperature in my fridge to 32°F/0°C. I let the beers lager at this temperature for 4 weeks before I took final hydrometer measurements.

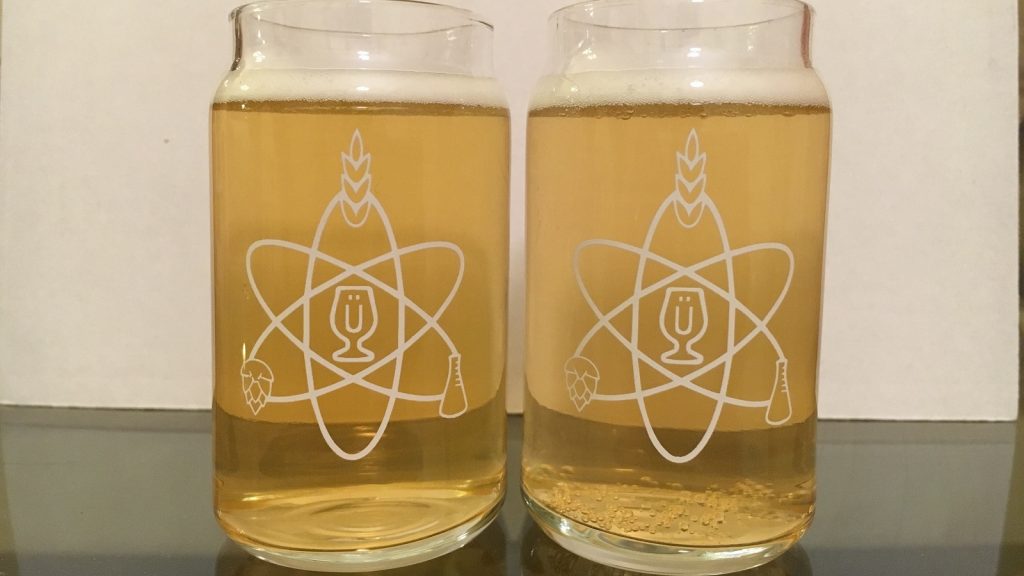

The kegs of naturally carbonated beer were moved into my keezer and put on just enough gas to allow for serving. After letting the beers settle for a few days, I pulled initial samples that looked great!

| RESULTS |

A huge thanks to Colorado Grist Busters Homebrew Club and CO-Brew Homebrew Supply in Denver, CO for allowing me to collect data during a meeting!

A panel of 38 people with varying levels of experience participated in this xBmt. Each taster, blind to the variable being investigated, was served 1 sample of the beer brewed with standard oxygen levels and 2 samples of the beer made using LODO methods in different colored opaque cups then instructed to select the unique sample. While 19 participants would have had to identify the unique sample in order to achieve statistical significance, a total of 25 (p<0.05; p=0.00004) made the accurate selection, indicating tasters in this xBmt were indeed capable of reliably distinguishing a LODO Kölsch from the same beer made with higher amounts of oxygen.

The 25 participants who made the correct selection in the triangle test were instructed to compare only the 2 different beers, still blind to the variable in question, and asked about their preference. In all, 15 tasters reported preferring the beer under normal conditions, 5 said they liked the LODO beer more, 3 people had no preference despite noticing a difference, and 2 tasters felt there was no difference between the beers.

My Impressions: In samples tasted prior to the lagering phase, I perceived a rather strong sulfur component in the LODO beer that I figured would dissipate over time. Given my excitement about this variable, I attempted more triangle tests with these beers than I have on any other xBmt, and sure enough, I was consistently able distinguish the LODO beer from the one made using standard practices. To me, the LODO beer maintained a slight aroma of hydrogen sulfide (H2S) that made it fairly easy to identify, even after an additional few weeks in my cold keezer. The beer from the standard batch had what I perceived as a honey note, perhaps from the Carahell, that I found immensely pleasing and more preferable than the LODO version.

Side exBEERiment: Proponents of the LODO method have expressed concerns about the perilous nature of both packaging and shipping, namely that it can rapidly erase the benefits brewers work so hard to create. To test this out, I sent 3 inconspicuously marked bottles to Marshall, 2 the same and 1 different. He and 2 friends who were unaware of the variable all failed their triangle test attempts. Marshall attempted 4 more times with the remaining beers and was correct just once, though he admitted he resorted to guessing.

| DISCUSSION |

On an objective level, the results of this xBmt provide evidence that the use of SMB is effective at reducing oxygen levels throughout the brewing process, which isn’t nearly as exciting to read as it is to observe, as it can be easily explained by chemistry. And, as the authors of the referenced document often point out, the information they’re sharing isn’t necessarily new at all, in fact they extensively credit German brewing scientists Ludwig Narziss and Wolfgang Kunze as advocating the merits of brewing in low oxygen environments long ago. Of course, their focus was on large-scale commercial beer production, and given their stature in the brewing world, I’m compelled to take them at their word. However, as scientists, I also trust they’d understand the interest in testing things out for oneself, particularly given the smaller homebrew scale we operate on that requires the use of interesting techniques, namely the use of SMB for oxygen scavenging.

Prior to collecting data for this xBmt, I contacted Dr. Charlie Bamforth, the Anheuser-Busch Endowed Professor of Malting and Brewing Sciences in the Food Science and Technology department at UC Davis, to seek his thoughts on using SMB in the production of beer. His response was straightforward, “Sulfites in the mash are to be avoided, yeast will reduce it to sulfide and you will end up with an egg-y aroma in your beer.” Perhaps this explains the H2S I’ve perceived in the various LODO beers I’ve brewed.

Indeed, the beer brewed using LODO methods was different enough from the batch made with standard oxygen levels that a significant portion of tasters could tell them apart. Curiously, a whopping 60% of those who could distinguish the beers endorsed the standard one as their preferred, whereas only 20% liked the LODO beer more, drastically contrasting the 90% preference rate for the LODO beer in another experiment. Why so disparate? And what about the growing number of reports that LODO has helped brewers achieve the Bavarian “it” character they so long for and couldn’t produce prior to employing techniques to reduce oxygen throughout the brewing process?

It’s possible the results of this xBmt are a function of the OG and subsequent ABV differences between the standard and LODO beers, though if that were the case, I would have expected Marshall and his friends, at least one of them, to be able to confidently identify the odd-beer-out in the samples I sent. But that’s not what happened, none of them could tell the beers apart and they all described them as tasting very similar, supporting the idea shipping may remove whatever it is the LODO method imparts. This makes me wonder how German breweries who ship beers to the US that I believe have “it” do it, as well as how homebrewers who say LODO helps them do well in competitions keep the character present.

I’ve thought about this a lot lately and came up with a few other potential explanations for the findings from this xBmt:

Bad Methodology

LODO brewing is an involved process, far more so than most homebrewing approaches, requiring myriad steps that if missed can ruin the whole shebang. Take a look at any forum or blog post from someone whose attempt at LODO brewing resulted in less than stellar results and you’ll almost certainly find someone pointing out how the methodology is to blame. As confident as I am in my methods due to following the paper as closely as I could, consulting with LODO adherents throughout the process, and brewing multiple batches using LODO methods prior to this xBmt, sure, it’s possible I screwed something up and that the LODO beer would have been more preferred if I hadn’t. I’m also a process nut, so if this is the case, I have to wonder about the success rate of most other homebrewers.

“It” Doesn’t Exist

Frankly, I’m a believer in “it” and feel there is a unique character to many Bavarian lagers that I’d love to be able to reproduce at home but haven’t been able to. Still, it’s one possibility, extreme as it may be.

“It” Exists But Isn’t Preferred

The only problem I have with this is that I adore all of the German beers LODO advocates claim have “it,” yet between the beers in this xBmt I preferred the one brewed using standard methods. Maybe my LODO Kölsch had too much “it” and there’s a level at which it becomes overbearing, sort of like the way many view Crystal malts?

“It” Exists But It’s Not The Same “It” LODO Produces

This notion stems from my love of German beers that I think have an elusive desirable character coupled with my preference for the non-LODO beer in this xBmt. It’s plausible there is something special to German beers and even that it’s due to low oxygen brewing, but that as a function of scale, we’re simply unable to replicate it. Moreover, it’s reasonable to assume that relying on SMB for oxygen scavenging impacts beer character beyond what one might expect in an oxygen and sulfite free environment.

Whatever it is, I really don’t know, and honestly, I really don’t care. A growing number of homebrewers who have adopted the LODO method swear it allows them to make better beer, which is fantastic! There’s no reason they should stop doing what works for them, in the same way people who are happy with the beer they make using standard homebrewing approaches need not change.

Cheers to those who have invested the time to explore these methods in such depth and share their findings with the homebrewing community, their passion for producing delicious beer is admirable. In no way am I willing to accept oxygen doesn’t have some deleterious impact on beer, though neither will I accept it does to the extent believed by some. Combining the results of this xBmt with my prior experiences using this method, the reports from others who have tried it out, and what I’ve gleaned from brewing professionals, I’ll be hanging up my LODO gloves for the time being. Not because it doesn’t work, just that it’s not for me.

If you have experience using low oxygen methods or have thoughts about this xBmt, please don’t hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

91 thoughts on “exBEERiment | The LODO Effect: Impact Low Oxygen Brewing Has On A Munich Helles”

Awesome. One of the most informative Exbeeriments in a while.

All very interesting & good write-up, thanks. I wonder if the different OG (& FG) is caused by crushing conditioned (i.e. damp) grain, resulting in a less fine crush? If so, you might be able to compensate for that with a longer mash.

To my eyes the LODO beer looks cloudier – perhaps because it was chilled more slowly?

Obviously there are a few confounding variables (sulphites, OG, slower chill), so it’s hard to know whether LODO makes a significant difference. I’m inclined to think it’s not the secret to brewing beers with “it”.

I believe the haze is related to sulfites damaging yeast and making them less flocculent

Jake, that’s something I’ve never heard of. Can you fill me in on that process?

Oh it’s purely speculation on my part. Sulfites are used to stop yeast reproduction -> must do something to yeast health -> unhealthy yeast could lead to less flocculation.

I mean 2565 is a freaking super hazy yeast so it could be as simple as that, though the hido beer cleared much faster.

I’m not sure about that. Sodium & potassium metabisulphite are standard ingredients in home-brewed wine and don’t cause any yeast haze. Something as big as a yeast should inevitably drop out once a wine or beer has degassed and settled (unlike haze-forming protein-tannin).

I had the same thought re: the crush. If the grain crush results in lower extract, that will cause cascading changes throughout the rest of the brewing process, invalidating this experiment where LODO is concerned. Even a longer mash to compensate would cause changes not specific to the LODO techniques.

I brewed a couple of LODO batches as Im also a believer that oxygen is always the bad guy and I wanted to see if I could make some “marginal gains” to the quality of my beer. I’m more of a pale ale / IPA brewer and brewed a batch of NE pale ale with the expectation of being able to limit oxidation of hop aromatics even more than my existing corny keg fermentation, spund after 3/4 days and closed CO2 transfers setup.

This is anecdotal as I had no control (and dont have a DO meter), but I also got a big H2S character in the beer when using metabisulfite that I had never gotten before (I brew the same pale ale recipe 4-5 times a year). It faded over a little over time. But that also led me to at least pause my exploration of LODO for the time being.

Thanks for doing the expt and I look forward to more LODO results in future.

I’m sure you will be bashed by the LODO brigade for your wort oxygenation and not getting the yeast in straight after transfer. Looking forward to reading the rest of the comments.

🙂 luckily it’s only beer!

Keep in mind that there’s a list of ingredients that won’t work with this process. Perhaps you used some.

Jake, it’s sorbates that are used to kill yeast, isn’t it? I was under the impression that sulfites won’t do it.

I believe sorbate just interrupts the reproduction of yeast (budding) so it prevents fermentation wit out actually killing the yeast. Vintners supposedly use Kmeta (or sulfite) to kill surface wild yeast on grapes.

I was under the impression that sulfites along with sorbate are used to make a hostile environment for yeast. There goes that theory haha, no idea on the slightly more haze in the lodo beer then. It’s a very hazy yeast though.

combination of sorbate and kmeta is what we wine nerds use to stop and kill yeast respectively

I use sorbate and SMB to kill off yeast in cider making too.

I think if someone were to brew using the method outlined here it’s pretty important to ensure you carry over no SMB into fermentation

“It’s possible the results of this xBmt are a function of the OG and subsequent ABV differences between the standard and LODO beers, though if that were the case,”

But the ABVs between the beers ended up being nearly identical! I find that to be surprising.

Before hanging up your gloves, I’d recommend dropping you SMB dosage to 30-40 ppm. I don’t think you missed any steps in the process, therefore the concentration of SMB needed to mitigate oxygen ingress can be lowered. No doubt the H2S you were picking up is because there was residual.

Jake has work stuff today and will be intermittently available, but we talked about this and he has messed around with SMB levels, still seems to get a fairly strong sulfur smell regardless. By hanging up the gloves, I’m pretty sure he means for personal (non-xBmt) brewing 🙂

I’ve done batches in the 20-30 range since, less eggy aroma but still present

This is what has me scratching my head. I’ve used the low oxygen process on about 20 beers now with ale yeasts including 1318, 001, 007, 2565 and 1450 with SMB levels ranging from 40-75 ppm and I’ve never once had sulfur issues. My process really isn’t much different from what you’ve outlined here except for the oddly low mash efficiency you’re seeing which I think is due to inadequate initial mixing of the underlet mash water. Either way, cheers on y’all for taking this on and writing up as fair an assessment as possible on what some want to make a hot-button topic.

I agree. The trick with SMB is it use just enough to get your DO a bit lower than your process allows. You need to de aireate your water before using SMB. It helps to have sulphite test strips to see haw much residual is going to your kettle.

I thought the point was to get as close to 0 ppm DO as possible, not a bit lower than one’s normal process allows. Am I missing something?

I am not a LODO brewer but my impressions are that this process is most impactful for lagers and that certain ale strains do not provided beneficial results. Any chance of a similar trial with a lager?

We consulted with a major proponent of LODO while designing this xBmt, he assured us the benefits would be seen in Kölsch or pretty much any other beer style. That said, when we revisit it, it will likely be with a light lager.

Cool. Just curious. I have seen forum posts where some were putting a yeast strain list together that didn’t benefit from LODO methods. I guess all German beer styles are supposed to benefit from LODO so Kolsch should not be an exception…

We specifically asked about Kölsch.

Curious to see the results using the yeast method as opposed to pre-boil/SMB. As well as the effects on the hop character.

I believe LoDO ppl are mixed on the yeast method for fear of autolysis

Keep working that DO meter! Armed with that thing, you can slay all remaining homebrew boogeymen around oxidation, and find the ones that actually matter. More DO meter experiments please!

It’s on the list!

On the AHA forum, someone mentioned that both Bamforth and Kunze say that DO can’t be directly measured in the mash. Thoughts?

I took my method from Matt Chrispen. Essentially take a small vial, submerge it, seal, chill measure. I’m sure my (and Malcolm’s) measurements arent 100% accurate but I think it at least shows trends.

Maybe it really is a combination of german malt (there’s still breweries who do the malting process themselves and choose specific barley varieties), water, fresh yeast, spunging and kräusening along with equipment. Most of the german beers don’t even have that character though. Maybe it’s the equipment and old brewing traditions.

THANKS to the Brulosophy team for being open to try the method for themselves.

It is extremely important to mention that scientists have never used a DO meter in low-oxygen experiments. Both Bamforth and Narziss clearly state that oxygen in the mash cannot be measured directly. Narziss recommends the simple method of measuring sulfite consumption (which of course will invalidate this experiment). Chemoluminiscence has also been common but clearly out of reach for almost all of us (if not all). I will comment a bit more on this later when I have time.

THANKS AGAIN !!

Any sources on the inability of measuring oxygen in the mash? I’ve always found LODO interesting, although I’m not convinced that it’s worth the effort. I love reading about it, I always seem to learn something new whenever it comes up.

It seems like the final ABV of the beer should be similar (~3.8% from my calculations), but it seems like in past experiments, variations in ABV or final gravity aren’t always distinguishable. I wonder if it’s more critical with poor fermentation and production of fusel alcohols, or beer pH.

Great work Jake!

Ref sources –

Narziss et al – Abriss .. 2017 ed pp.145

Bamforth – J Inst Brew v104(4) 1999

I am boggled by the huge discrepancy in the gravities of the two beers, which I am sure had some effect of the outcome. I have been experimenting with LoDO recently and routinely (in my whopping two batches) get 75% brewhouse efficiency. But, I step mash and I stir each step (gently and briefly). Maybe an undisturbed underlet infusion allows to much temperature stratification. And who knows, maybe you had dough balls in there.

Great xBMt! I was particularly intrigued by the explanation of the color difference between standard and low-O2 batches could possibly just be a matter of decreased extract.

I appreciate your attention to detail. Interestingly, I had the exact opposite experience in my first LODO helles I brewed. Similarly, I brewed two 5-gallon batches using the same recipe and incorporated LODO techniques in one (water deoxygenation, SMB, Brewtan B, mash cap) and my usual method in the other. I ended up dumping the non-LODO beer as the taste just didn’t compare. I haven’t had the sulfur issue either, but have only brewed several helles batches using S-23 and a couple of weissbiers using 3068 since making the switch. Keep on experimenting!

Pure, scientific, inspiring, brunography! Count me as another lover of German beer who had high hopes you had led me to the “it” factor. Not to be, but not for lack of admirable effort.

Keep in mind that many brewers, not just the GBF guys, find the method very effective. While I’m not interested in doing it, I do find it interesting. Keep in mind that a single experiment is a data point, not a conclusion. The key to science is repeatability. Much more work needs to be done before a conclusion can be drawn one way or the other.

Would love to see you do some experiments denny

There have been some sulfur issues using Ale yeasts, I believe Lager yeast deal with the sulphites better. I have 50+ lodo lager batches under my belt, none have had any sulfur issues. I’d like to see this experiment again but a Helles recipe with similar OG’s and a good lager strain like 2124 or 2206.

Excellent write up and the extra steps detailed in the brew day make for a very involving article. Thank you! At the risk of being a pedant, you mention that at packaging “the one on the LODO beer [was] set to the recommended 8 bar”. Just checking you meant 0.8 bar as per the original forum article?

Cheers!

Question…there has been speculation that the LODO beer was lower OG because the mash was underlet and not mixed (to prevent O2 pickup) while the conventional mash was mixed as is…well, conventional. Was this the case?

After reading the New Belgium paper I’ve been using an olive oil product in place of oxygen for fermentation in my last 20 or so brews. Seemed the most logical way to reduce O2 in my beers. I’ve done very well at local beer tastings with every style of beer made using this technique and i store several of my beers for months without perceived oxidation.

Please don’t think that it’s actually doing anything. As we detail in the book Experimental Homebrewing, we talked to Grady Hull. He wrote the original paper on OO. He said he wast astounded that homebrewers thought they could use it as a sub for oxygenation. It was never intended that way and actually does nothing. He said it was developed for yeast storage and does not help in wort. The most that can be said of it is that it probably doesn’t hurt. Remember, this is coming from the guy who invented it!

Thanks Denny, I’ll look into that further. I’m surprised that it does nothing, I took the reading of the paper as quite clear noting that the only change was likely to be an increase in esters (I use fruity yeast so cool with that). I take great care to ensure no oxygen uptake in wort between kettle and fermentation vessel and have relied entirely on the OO product (not pure btw) to provide what I thought was needed. Never had a slow ferment or any issues with under attenuation in a wort which should be near 0 oxygen. xbmt on oxygenated wort vs non?

Brulosophy team: Hope you do take this criticism as constructive. My comment is neither for nor against LODO. We all make mistakes during experiments/ brewing and there will be times we make mistakes and when that happen, we just need to do things all over again. This experiment fail to meet the condition that the only difference was the LODO treatment. You did equalize for OG, but the FG was so different that it is almost impossible to discard it as a factor in picking up the difference.

The most logical explanation for the difference is in my view gelatinization temperature; rinsing differences can also be possible.

Gelatinization: LODO was 2F lower and this difference can make the carbohydrates less available to the enzymes. Eventually, carbs will gelatinize but it will take more time. The amylolytic enzymes were evidently working as shown by the very high attenuation.

Rinsing: LODO process uses either gentle stirrers below the mash cap or water recirculation below the mash cap, given no description above, I assume you did not do either (did you?). Lack of a mixing process via either stirring or recirculating the water may also explain the differences in OG.

The difference in FG is even more puzzling. Given you diluted the Standard with water, the recipe and the mash regime, I do not think anyone would have predicted an FG of 1.014 independent of the LODO experiment, so something happened in the mash, the fermentation or in both.

A minor comment: 8 bar is 116 psi – something is wrong… You meant 0.8 bar, right? At what temperature- 17C?

Kind regards,

2F is not gonna make an appreciable difference. It’s not like you’re turning a light on and off. It’s a range, not a specific temp.

Indeed is not on/off but 1044 vs 1035. Nonetheless, it is a valid hypothesis. Your underletting hypothesis above actually does support and can work together my hypothesis, as inadequate mixing would likely result in temperature pockets. Cheers 🙂

Very confusing exbeerament. Seems more then one variable was changed. Wet crush/Dry crush, copper/SS, slow chill/fast chill…… Also when something so important and very measurable, OG, is seen almost before the exbeerament started raises a flag with me. Was the exberament: does wet crushing grain lead to a lower OG? Or: Does a SS chiller add or take away tast from the beer Or: Does a fast chill improve beer compared to a long slower chill. Etc.

I think another exbeerament: Everything the same, crush, chiller, bottom fill, ect. What ever it takes to do the LODO. BUT take away the loLODO advantage by adding, by bubbling or injecting, o2 or air during the mash, transfer, boil, transfer, stages to the non LODO (showing I have a firm grasp on the obvious :).

I love these exbeeraments. Please keep up the great work. It is so nice to see people with so much dedication to a great hobby they love.

Brad

But isn’t the experiment to test the LODO method vs the regular method? If you change the regular method then it’s not really comparing the two is it?

I see what you are saying by wanting as many things the same as possible, but am experiment like that wouldn’t be useful to me in trying to decide what method to use.

Jake, I’ve been hunting the same “it” you are for several years now. My best guess is, regardless of the information given out on their brewery tours, I feel the brewmasters have their own trade secrets that homebrewers will never know or, if they did, just can’t replicate.

In reference to packaging, I will say, I’ve noticed on several occasions now that the flavor consistency of some of the Bavarian beers I drink, produced by the same brewery, seem to be lacking the “it”. If allowed by my SO, I’m going to bring a couple of hefe’s with me when I go to Germany this summer and do my own taste test to see if I’m off target or not.

Best article yet.

This test should really be considered “Invalid”. I’m not on either side, but the goal isn’t to compare a LODO sulfur bomb to a traditional way of home brewing. This information provides people with nothing other than maybe you need to dial down your amount of SMB used. Seems like your system and technique are very tight.

This reeks of just trying to get as many left mouse clicks as possible on a hot topic.

Dammit, you figured us out…

Sorry Marshall, I enjoy your exbeeriments, but maybe next time hold this stuff back and redo this before posting something that you know is of no use to anyone. What did this exbeeriment actually tell us? That SMB can create sulfur? Yeah, we already knew that. Everyone’s system is different. Maybe try to dial it in before just throwing these up here?

It’s all good you didn’t like it. Based on the comments it got, I’d say quite a few people appreciated it, I certainly did.

doesnt oxygenating the wort prior to yeast pitch completely invalidate any efforts of your LODO process before hand? I cant understand why that was done…..the paper referenced specifically says not to…..otherwise awesome writeup!

I second what Zach said. I would like to see this revisited without aerating at all considering the results of the yeast exbeeriments. Also I believe there is a typo. You say you fermented at 8 bar which is 116psig. The paper says 0.8 bar which is about 12psig.

Lodo folks all oxygenate their wort once yeast is pitched AFAIK. Idk why I wouldn’t do this?

As always a very interesting exbeeriment, Jake. The Brulosophy site has greatly influenced my brewing methods and I’m very appreciative of your efforts.

Please indulge this stupid question: while you say that adjustment of the dilution of the standard wort sample resulted in “validating results” its not clearly stated that you did that to the rest of the wort. Did you make that adjustment?

Also the discussion of olive oil additions to the yeast starter instead of oxigenating are also intriguing. Any possibility of a exbeeriment in the future?

I did not dilute the entire volume of hido wort.

While I agree the olive oil is interesting as a yeast supercharger, I’m not sure it’s one we want to tackle given the redactions regarding the method.

Where there any DO readings taken after the boil?

Another simple, practical, easy to understand experiment. If you asked these commentators how to design these experiments before you did them, you would get 50 different answers I gather.

You made a LODO beer, you made a regular beer, you shared the results. Well done. That’s one LODO experiment in the books.

Perhaps a good experiment to do is the mini mash:

http://forum.germanbrewing.net/viewtopic.php?t=301

It’s fairly straightforward and a triangle test with multiple participants would be something new! It’s not beer, but it would be a good start to really getting a handle on this whole LODO thing

Thanks guys. I think this LODO stuff requires joint effort of brulosophy AND Denny’s crew. Awesome experiment, and more are required. One suggestion would be slight lowering of the SMB, and maybe do a No sparge HERMs, put the LODO whirlpool underneath the surface, the HIDO above the surface. Maybe slow chill both, or at least don’t mix your Jaded chiller, just let them sit covered. And why not use your Helles kit, it was my first ever Lager, and Im loving it. Did I mine HIDO BIAB.

Other option is LODO vs HIDO BIAB, where the underletting is just dropping the bag of grains in.

By the way, definitely glad you posted, it’s quite valid.

Love the podcasts by the way. (Yours and Dennys)

I have brewed LODO twice now (finished my second one this morning). I have a set-up similar to Jake’s in that I simply dough in and mash without any type of re-circulation. I haven’t experienced the gravity problems that he has here. I can’t imagine what I am doing differently. I just dough in, stir the grains gently via gravity, and then mash. Plugging my numbers into Beersmith, my mash efficiency today was 89.6%.

89% is quite high, who knows what causes my efficiency drop, I suspect the wet milling

Great work Jake. I gather that LODO is overall not the silver bullet it has been made out to be – or it is just too troublesome for an average brewer to execute properly. I still find this fascinating and look forward to more LODO experiments in the future. Thanks.

Pretty late to the party on this one, but if you guys decide to try a similar xBmt again I would love to see the process done exactly the same way for both batches (both LODO) with oxygen added back to one batch at various points in the process. It won’t test the LODO process against the traditional process like this xBmt did, but rather will specifically test oxygen itself in the brewing process. This should eliminate variables such as the original gravities differing, which likely has to be compensated for when brewing LODO vs traditional.

Hi guys, interesting result. I’ll add my name to the list of people who’ve done a few LODO batches will good results – anecdotal as they may be.

In the paper, they suggest 100mg/L dosing of SMBS. Although 1 mole of SMBS will react with 1 mole of O2, on a weight basis the requirement is about 6:1 hence their suggestion that up to 15ppm can be covered by 100mg/L dosing, or up to 15mg can be covered in 1L.

Excuse the boring chemistry, but some quick balances below:

Na2-S2-O5 (SMBS) + H2O -> 2Na-H-SO3 [sodium met to sodium bisulphite]

The sodium bisulphite (SBS) can then readily react with O2 – or chlorine, or choramine incidentally – as per the following:

2Na-H-SO3 + O2 -> H2-SO4 + Na2-SO4 [sulphuric acid plus sodium sulphate – a source of sodium and sulphate ions, which need to be balanced with chloride ions with CaCl2 addition]

That’s ok, but what about if there’s an excess? We potentially have H2SO4, Na2SO4 and NaHSO3 floating around (from unreacted SMBS):

2Na-H-SO3 + H2SO4 -> Na2SO4 + 2H2O + 2SO2 [same sodium sulphate as before, plus also sulphur dioxide]

I’d be surprised if you smelled H2S. I guess it’s something than can form anaerobically, but I think it would be more likely that it’s from SO2. While 100mg/L SMBS may remove 15mg/L O2, unfortunately it only needs 2-3mg/L of SO2 to pop up and you’ve got an issue.

When I originally read 100mg/L I was pretty surprised – seems very high, and there is indeed a lot of uncertainty with actual dissolved oxygen – so I decided to go with CO2 purging (on transfer lines, and on the top of my mash tun), yeast/LME in the strike water, and a combination of SMBS and ascorbic acid, another oxygen scavenger, in the mash tun and sparge containers – so I’m able to sparge as well with everything completely sealed.

Anyway, the moral of the story is that I believe the best approach to LODO is a combination of a few methods. Putting all of your eggs in the SMBS basket has some side-effects which you appear to have felt the brunt of – yet that was the advice in the original paper.

Being German I wonder which breweries you meant when you talk about a good Helles having the “it”? Which Helles is the best is quite a debated question 😀

Wow! Just wow!

Would using ascorbic acid instead of SMB as an anti-oxidant work to keep the DO low enough?

I believe some ppl have used that. No experience here tough using it

You guys do great work! Keep it up. My initial reaction to the low OG was that the LODO mash simply hadn’t finished converting and could’ve benefited from an extra 15 minutes or so. I didn’t see anything that showed you tested for conversion. If would be interesting to see how significant the results would be if they were both mashed for 90 minutes.

Hi!

I am currently doing a project on DO at a brewery, and we are investigating the amount of oxygen throughout the process.

Would it be possible to know the actual method you use for sampling? The main problem seems to be the uptake of oxygen by the sample, that gives a very high number even on an end fermented beer, before transferring, even though it should be 0 ppm straight.

I am assuming the error comes from the sampling method itself, so it would be great to know how other people sample.

Hope I will find some help, and maybe a solution!

Silvia

Not sure if you have thought about doing a hochkurz mash setup along with the LODO and it could potentially change the outcome. The guy who has been talking to me about LODO from his pictures, he is doing something right as he is able to get that amazing German head that I have not been able to replicate in any form so far just do a normal type brew. I mean I get a good head, but it dissipates instead of like a german beer that just sits there and is incredible. Also, I would think a HERMS/RIMS system along with LODO would help out with your loss of abv. I have barely tried any other way except for HERMS so hard for me to say.

This was an awesome xbrmt. I have been reading up on this process and so far I am not convinced. Sodium Metabisulfite is not something I would ever want to add to my water. (egg bomb and possible problems with yeast reproduction.) I think there is another possibility that you only briefly touched upon. The “it” factor doesn’t exist and certainly isn’t created by the addition of SMB or extreme procedures if it does exist. It is created by careful brewing process. German brews taste German because they are brewed carefully by German brewers. I suspect that the freshness of ingredients is the key to the “it” factor. Im not saying Ill try to create HSA but Marshall did an xbrmt once on HSA where he whipped the mash with a whisk… Im sure we all remember that one…No meaningful outcome. The fact is that these well meaning lodo brewers are promoting something that just doesn’t seem to matter. Much like the drop of olive oil craze…of years gone by. B but they have unwittingly identified somethings that really do matter careful attention to process, and low oxygen packaging. Spunding beers for natural carbonation in a low oxygen environment has certainly been a benefit to all brewers. And attention to process is with out a doubt the single most beneficial outcome of the lodo craze.

So… for me… Ill take away from this the idea that careful process is a good thing. But worrying about oxygen ingress before the boil is not necessary. Worrying about oxygen after fermentation is absolutely a good idea.

Bring on the next fad…

The first edition of Kunze’s book was released in 1961, and has been updated regularly and translated to many languages. Since then, it has helped educate most pro-brewers in the world. Hard to believe that Kunze and the pro brewers and brewing scientists that helped compile the information in the book included fads in it.

Sorry for the late response but i had to collect some information from the father land. No doubt Kunze’s book is foundational. No doubt it has been important to the education of many brewers and brewing scientists. I have reached out to several friends in Germany who are involved in brewing professionally. I asked for their input on this issue. So far One has responded.

He has assured me that… At his brewery, which i will not be naming at his request,

they do take steps to limit oxygen at all points in the brewing process. But that they do not add any additional chemicals. They use city water and acid malt. Basically Its all just process. They begin by degassing the water with a column degasser that forces water down and nitrogen gas up. He also recommended that we use local fresher malts and hops. Indicating that they will not use aged malts. His feeling on head retention for home brewing was protein rest and spunding. Create medium length proteins and glycerine. As more respond I will share more. Sounds like there’s some truth to the idea of lodo. Rather than attempting to get 0 oxygen he suggests know Howe much your yeast needs and never give it more than it needs. So that it will all be scrubbed out. To this end they use filtered air.

@David, thanks for researching the topic. Indeed, no German brewer would use SMB/ KMB as it would be against the RGB. SMB/ KMB at very small doses is a way to mimic the effects of a pro LO brewhouse; so YES, no chemicals would be ideal. The paper by the German Brewing group has been superseded; the dose there is too high. Homebrewers that have used the process for a while are using around 0.3-1.0g of SMB for ~30L strike water (btw KMB has about 20% less MB by weight), some combine it with ascorbic acid. Bryan from the LO website has been brewing with no chemicals as of recently.

@ Jake. Please be aware that no LO brewer that I know has taken a gravity hit when using SMB or KMB. I have had no gravity hit in more than 50 batches.

Happy New Year everyone!

Thanks for reading!

I think if someone were to use SMB it’s pretty important to ensure none is there when you begin fermentation.

I do plan to test this again using a recirculating mash however I’ve still noticed a significant gravity hit using SMB in mashes as well as in a mini mash test I did recently.

This method seems to have pretty much fallen off for most Brewers but I’ll likely give it another go because I’m fairly interested in it.

Cheers!

Have you done other experiments to reduce oxygen without going full LODO?

For instance…. Preboil, be careful, switch to stainless for the chiller, leave out the sodium metabisulfite, etc…

Do half of the steps and see if there is any noticeable change for better or worse?

Incorrect. HSA exists, it would be impossible for it not to. It is a fact that when grains oxidize they release polyphenols which causes unwanted flavors in beer.

Hi, guys! I just want to know, have you heard about cannabis butter/oil? Its a thing now. I read that Medical marijuana is a very old medicinal herb that has been used for thousands of years to treat a great variety of ailments. Cannabinoids, have been shown to have anti-bacterial, anti-cancer, anti-inflammatory and anxiety reducing properties that have helped a great deal in several illnesses. Like this article http://www.ilovegrowingmarijuana.com/agent-orange/. I wonder if someone can teach me how to create an infused cannabis beer. I highly appreciated all your help. Thanks!

Great experiment! Cold side oxidation is definitely the bigger enemy, and can take a beer from being great to terrible. Not discounting the impact of LODO on hotside, just saying its not as important to focus on for most brewers.

Seems to me you can still make great beers with some hot side oxidation, but maybe just not as great (or just different) than the ones with LODO measures taken. Perhaps its more important for some styles and ingredients than others.

Currently, it would be difficult for me to RDWHAHB and implement strict LODO methods on the hot side. I’ll continue my focus to prevent cold side pickup for now, but curious to see more experiments like this. Maybe I’ll pick it up down the line.

Think it would make sense to collaborate with seasoned LODO brewer on the next one of these experiments. The LODO process seems like it would take practice and dialing the equipment to nail down. If this is your first attempt its probably not a great data point. But it is an amazing conversation starter and made people aware of the process!

Keep on brewin’ in the free world!

The first LODO homebrew bach I’ve made had thi disctinctive sulfur notes, even it was an IPA, I could feel the tangy funny feeling of the sulfur in my throat. Than I asked Rabe from Lowoxygenbrewing.com about this and he said “you probably didn’t oxygenate the wort enough before pitching the yeast”.

A little late to this thread, but could not help but notice one variable that may have led to the DMS sulphur smell in the LODO. Covering the kettle. The other kettle was uncovered.

I appreciated this xBMT because with these delicate beer styles, one variable can make a big difference. I will start small, beginning with boiling my water in advance of brewing. Never considered this.

Probably the best Brulosophy artiqle I’ve ever read.👍