Author: Greg Foster

Belgian beers are known for a few things such as possessing unique esters and phenols compared to styles from other regions, as well as being higher in ABV while maintaining the quintessential dryness expected in styles like Golden Strong and Tripel. In order to accomplish this wonderful melding of drinkability and buzz-building strength, brewers of Belgian ale often employ the use of sugar, usually added to the boiling wort in amounts of up 10% to 20% of the fermentables.

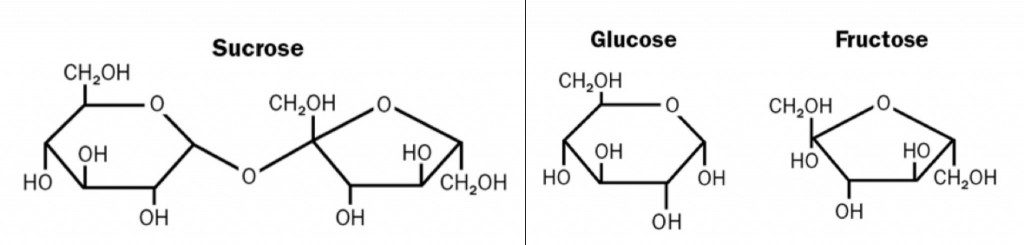

Briefly, I want to discuss some differences in the types of sugars commonly used in brewing. Pure sucrose sourced from sugar cane or beets, also known as table sugar, is made of a glucose molecule bonded with a fructose molecule and is the building block of many Belgian candi sugars and syrups. While completely capable of being used in beer, some smart people discovered yeast more readily digests sugar that has been inverted, a process that splits the fructose and glucose apart, producing a moderately viscous syrup that’s perceptibly sweeter than sucrose alone. Dextrose, on the other hand, which is commonly known as priming sugar to homebrewers, is a simple sugar derived from corn that consists of a single molecule of glucose, meaning it does not require any inversion. When it comes to Belgian candi, there are two main options, a crystalline rock or syrup. While researching the topic revealed some terminological confusion, it seems candi sugar is commonly reserved for the type that comes in non-inverted rock form, while candi syrup refers to the inverted liquid form. Regardless of the veracity of these claims, this xBmt concerns the latter.

Stan Hieronymous, in his fantastic literary tribute to Belgian beer, Brew Like A Monk, tells of how a friend who began making his own candi sugars recognized that given the Belgian spirit to “make a great beer with what we have,” spending upwards of $2 per pound was “anti-spirit.” A homebrewer’s mentality, indeed! Sharing this spirit, I hit the web in search of recipes for my preferred form of sugar, candi syrup, eventually settling on a simple method that produced beers I was largely pleased with. However, due to the veil under which makers of candi syrup tend to keep their processes, I began to wonder how close my hack was to popular commercial varieties. An xBmt born!

Stan Hieronymous, in his fantastic literary tribute to Belgian beer, Brew Like A Monk, tells of how a friend who began making his own candi sugars recognized that given the Belgian spirit to “make a great beer with what we have,” spending upwards of $2 per pound was “anti-spirit.” A homebrewer’s mentality, indeed! Sharing this spirit, I hit the web in search of recipes for my preferred form of sugar, candi syrup, eventually settling on a simple method that produced beers I was largely pleased with. However, due to the veil under which makers of candi syrup tend to keep their processes, I began to wonder how close my hack was to popular commercial varieties. An xBmt born!

| PURPOSE |

To evaluate whether a beer produced with commercial candi syrup is distinguishable from the same beer produced with homemade candi syrup.

| METHODS |

There is a lot of controversy in the brewing community on how to correctly make candi syrup. As far as I can tell, nobody has cracked the code for making a perfect commercial candi syrup clone, but I was confident I could make something reasonably close. After a good deal of research, I settled on modifying a recipe I found on the Sui Generis Brewing blog. My quest for candi perfection led me to brew up 7 different batches in total, with my two favorites happening to be made from dextrose rather than the usual sucrose, which made things a little easier since the inversion step isn’t required with dextrose due to the fact it is a single molecule of glucose.

As a sponsor for this xBmt, Home Brew Supply provided the Westvleteren 12 clone kit called The Pious, made popular by user Saq on HomeBrewTalk.com. Since the kit came with two different candi syrups, a lighter D-45 and a darker D-90, I set out to make similarly colored syrups of my own, the details of my process can be found at the bottom of this article.

About 48 hours prior to brewing, I pitched the provided vials of WLP530 Abbey Ale Yeast into separate jars of previously canned starter wort and spun them on two stir plates.

The following day, with signs of active fermentation all but gone, I stuck both starters in the fridge for a 24 hour cold crash.

Brew day began with the crushing of grains, which took a little while given how big this beer was!

I proceeded to heat up my strike water and measure out my brewing water additions then I mashed in, double checking to ensure I hit my target temperature.

My RIMS rig recirculated the wort for a full hour, after which I transferred the sweet liquor to the kettle then performed a quick batch sparge. The wort was boiled for an hour with hops added per the recipe’s instructions. Upon completion, I quickly chilled the entire batch.

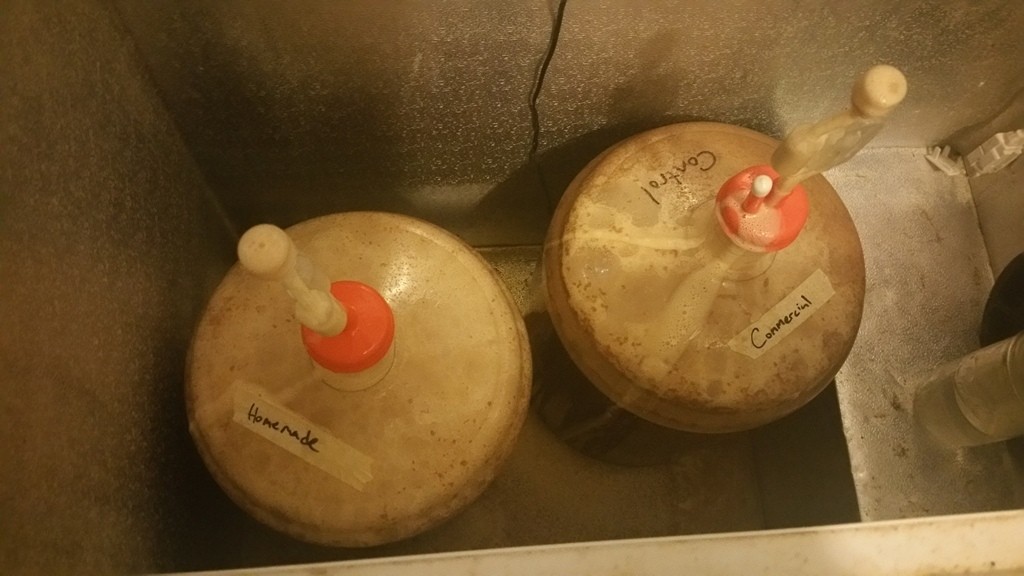

The wort was then split evenly between two 6 gallon PET carboys, dosed with oxygen, then pitched with equal amounts of yeast split from the starters.

In hopes of keeping the yeast from becoming stressed during fermentation, I split the candi syrup additions into two stages, immediately adding 1 lb of the commercial D-45 syrup to one carboy, slightly more than the recipe called for, while the other carboy received an equal amount of my homemade light candi syrup. Both fermentors were put into the same fermentation chamber controlled to 75˚F/24˚C. I checked on the beers a day later to find both were making a yeasty mess, so I swapped the airlocks for blowoff tubes.

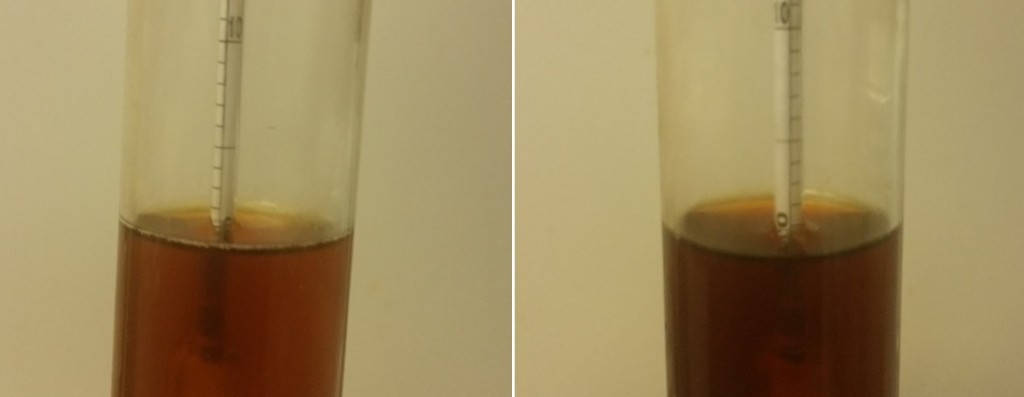

I began gently raising the temperature in the chamber 3 days into fermentation until it reached 82˚F/28˚C, this took another 3 days. Activity appeared to be winding down around a week in, so I added the remaining 2 lbs of D-90 and dark homemade candi syrup to their respective carboys. Fermentation took off quickly then appeared complete a week later, at which point hydrometer readings revealed the beers to be sitting at nearly identical SGs.

I proceeded to cold crash overnight then transfer them via a closed pressurized system from the carboys to my serving kegs.

Given the higher OG of these beers, I decided to let them age for a couple of months in my keezer on CO2, after which they were both nicely carbonated and crystal clear, though a visual difference was quite apparent.

| RESULTS |

A total of 27 avid homebrewers, craft beer drinkers, and BJCP judges participated in this xBmt. With this many tasters, 14 (p<0.05) would be required to correctly identify the different beer to achieve statistical significance; however, only 11 (p=0.27) were able to do so, suggesting a general inability for participants in this xBmt to reliably distinguish a beer made with commercial candi syrup from one made with homemade candi syrup.

After data collection had concluded, a few brew club members approached me insisting they could indeed tell a difference between the samples. For fun, we decided to run a quick and certainly less-than-scientific test of their claims. Four members were repeatedly given “blind” side-by-side samples of the only the two beers that were different, fully aware of the nature of the xBmt at this point and blind only to which sample was in which cup, then asked to select the one they thought was made with commercial candi syrup. Collectively, this group selected the correct sample 9 out of 10 times. Huh! I inquired on what differences they thought they were perceiving and they reported the homemade candi batch tasted more complex, though not necessarily in a good way. One taster who never chose wrong was adamant the beer made with my homemade candi syrup had the unmistakable aroma of shiitake mushrooms.

My Impressions: Since I’d already noticed a stark flavor and aroma difference between the commercial and my homemade candi syrup when tasted on their own, I was pretty confident I wouldn’t have too much trouble with the triangle test. I was wrong. I completed multiple blind triangle tests as well as a few side-by-sides and I couldn’t differentiate between the two beers using taste or smell, they were far more similar than I had expected. One thing that did not surprise me was the beer being absolutely delicious. The homebrewsupply.com kit is actually based off of a very highly regarded homebrewtalk recipe by user Saq. This is the second time I’ve made a Westy 12 clone, both times based on Saq’s advice, and there’s a pretty good chance I’ll brew it again in the future because it always gets rave reviews.

| DISCUSSION |

To me, this is one of those xBmts where a non-significant result should feel like a personal victory– participants were unable to reliably distinguish a batch of beer made with my homemade candi syrup from one made with much more expensive (though less time consuming) commercial syrup, an obvious indication mine was a good enough approximation of the commercial variety. Perhaps, but I’m left with lingering doubts due my candi syrup tasting, in my opinion, clearly inferior to the store bought variety. Bias? Of course, but I still feel like I have much more work to do before I can claim to have discovered the holy grail of candi syrup production. I already have a few ideas I plan to experiment with, definitely count on a detailed future article following up on my sugary progress.

I would be remiss if I didn’t conclude with a strong safety warning. If you choose to make your own candi syrup using the recipe here, I implore you to please take extreme caution with sodium hydroxide. Caustic chemicals are no joke, so do your research and take all precautions before you even consider utilizing hazardous materials.

If you have any experience with using and/or making your own candi sugars and syrups, please share your thoughts in the comments section below!

How I Made My Candi Syrup

Both the light and dark batches of candi syrup started with 1.5 lbs of dextrose, 1/2 tsp of light DME, and 200 mL of distilled water that I combined in a large pot. This mixture was heated very slowly, stirring gently from time to time until everything dissolved into a thick syrup. While it continued to heat, I prepared my pH adjuster of choice, food grade sodium hydroxide, also known as lye, which is very scary and dangerous stuff! I donned my safety goggles and gloves before adding 1 tsp of lye to 40 mL of water, which I set aside to fully dissolve. Once the molten sugar reached my desired 290˚F/143˚C, I slowly added portions of the dissolved lye solution to the pot, a step that not only induces instant maillard reactions and sugar browning, but also a violent eruption of molten sugar bubbles. Seriously, if attempting this on your own, please be very, very, very fucking careful!

For both batches, I let the sugar cook until the color roughly matched that of the commercial varieties, which obviously took longer for the darker syrup than the lighter, then I very slowly added 1/2 cup of boiling distilled water so the final product would remain in liquid form. In the end, I was pleased with how similar my homemade syrups appeared next to their commercial counterparts.

A comparison of the syrups side-by-side left me with a definite preference for the commercial varieties. Not that my homemade candi syrup was bad, but I perceived a slight burnt flavor and aroma that lingered on the palate while the commercial stuff was smooth, sweet, complex, clean, and had no off-putting characteristics. I plan to continue tweaking this process until I get it right, but based on the results of this xBmt, it would seem the homemade syrup worked quite well. Your mileage may vary.

Support for this xBmt comes from Home Brew Supply, a full service walk-in and e-commerce store selling quality home brewing recipe kits, ingredients, equipment, and much more! The next time you’re in the market, give Home Brew Supply a look!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

| Read More |

18 Ideas to Help Simplify Your Brew Day

7 Considerations for Making Better Homebrew

List of completed exBEERiments

How-to: Harvest yeast from starters

How-to: Make a lager in less than a month

| Good Deals |

Brand New 5 gallon ball lock kegs discounted to $75 at Adventures in Homebrewing

ThermoWorks Super-Fast Pocket Thermometer On Sale for $19 – $10 discount

Sale and Clearance Items at MoreBeer.com

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

52 thoughts on “exBEERiment | Belgian Candi Syrup: Homemade vs. Commercial In A Belgian Quad”

Bryan (of the sui generis blog) here. That burnt flavour/aroma is something I have noticed in about 1/3rd of my batches as well, and is something I notice primarily when making darker sugars. I’ve not yet conclusively tracked down its source, but I think it may be due to adding too much of the protein/amine source (i.e. DME) to the mix. My last couple of dark batches used 1/4th the amount of DME as my post mentions; despite the lower level it “candi’d” fine, and didn’t have that burnt character. But I cannot say for certain that is the only difference as I also take greater care in my temperature control and try to stir the mixture much less than I used to. Regardless, the combination of the three seems to have addressed that issue. I’ve also noticed that this flavour fades as the beer ages.

I’ve done a few side-by-side comparisons with commercial candi and there are some notable differences, although they seem to be less once the candi is in the beer. I find that my homemade versions have a higher degree of both stone-fruit and caramel notes than an equivalently-coloured commercial sugar. The differences likely come from differences in the production processes, as they are not at all similar between home-brewed and commercial candi’s. Although the European candi makers are somewhat secretive about their processes, it appears that they use beet sugar (presumably one with a low degree of impurities) alone, a repeat rounds of heating and cooling, to make their product. I’ve tried a similar process with raw sugar, and was very unsatisfied with the product (it was mostly burnt/caramelized, with none of the complex fruit notes). ‘My’ version (which was based on the work of many other homebrewers) was developed more with an eye towards the underlying chemistry rather than a home-scaled replication of the commercial equivalent.

Thanks for the info Bryan! Looks like we are on the same page on a lot things. After my repeated batches I also think that using less DME is the way to go. I also quickly learned that vigorously stirring was counterproductive so I only stir very gently. I’ve read that commercial candi sugar is made with not only multiple heating and cooling cycles, but also at different pressures. I might have to do a little experimentation with my pressure cooker to see if that helps at all. I’m also planning on making a few batches with other amino acids (lysine, glycine, tyrosine) to see how the flavor is impacted.

Another thing I read in one account of commercial production was limiting oxygen – hard to do at home, but perhaps accounting for some of the more burnt character in some home batches (and yet another reason to limit stirring).

When it comes to stirring I now only do it when blending in the lye. Better temperature control means I no longer stir in water to cool things down, and that seems to help a lot – but like I said, I also dropped the amount of DME substantially at the same time.

I’d be interested in the amino acid tests – I tried DAP in the past and ended up with an unpleasant ammonia aroma and unpleasant mineral flavour.

Your reference to pressure and a couple of things Bryan mentioned, triggered a memory. In the winter, my grandmother used to make candied syrups using an old pressure cooker. If memory serves me correctly, she would repeatedly take the cooker off the stove and put it in an old milk pass-through by the back door – I’m guessing to chill it. Not sure if there were any additions to it afterwards or not. Long story short, we used to eat the stuff with Cream of Wheat, etc. Rumor had it that a grand-uncle used to use the syrups to make whiskey back in the 1920’s. She was born in the late 1890’s first generation off the boat from Bavaria. Wish she would have written some of those recipes down.

I am enjoying a Belgian Triple that I brewed in December and yes, I bought some Belgian Candi Syrup. Not anymore. I’m trying “Sui Generis” method on my next batch.

Thank you guys.

Bryan, we’ve been discussing your method on reddit quite a bit, and while you are the second closest of any public posting we have seen, we are not sure you have it right as of your last post on the subject. The Maillard reactions need reducing sugars, and sucrose is not a reducing sugar. The inversion reaction (to get fructose and sucrose) at the pH of cooking sugar (including its self-acidification) has a half-life of something like 3.5 hours — and it’s an equilibrium reaction when you get to something like 3/4 of the way to inverted. At pH 4.0, the half-life is 30 minutes. So do you need to consider acidifying the sugar solution before alkalinizing? Reddit user Uberg33k and I have been experimenting this way, and getting fairly close to the real product.

As far as the Belgian makers’ vague implications that they are using local beet sugar and that is what makes the difference, that is poppycock IMO. There is nothing to suggest that they are using anything as their substrate other than pure refined sucrose from beets. Heck, the largest source of domestically-produced sucrose in the U.S. is beet sugar from the Red River Valley of MN/ND. I can get beet sugar in my back yard. I have tried turbinado as my substrate, and I feel like that makes less difference than the nitrogen source. For that I have tried yeast nutrient, DME, powdered milk, and others. I’m not a blogger, but hope to get my results tabulated and posted somewhere some day.

Anyway, that’s some food for thought. I feel like your blog post (along with the Dukes of Ale’s method) gave us food for thought and something to build on, so thanks!

Chino,

You do not need complete conversion of sucrose to invert sugar (which is not possible with heat +/- acid anyways) to get Maillard reactions. Keep in mind that the total amount of Maillard products are less than 1% of the total weight of the candi, and therefore you only need an equivalent (but preferably a modest excess) of inverted sugar. 30 min inversion, without acid, gives you about 10% conversion, thus giving you an ~10X excess of reducing sugar. I’ve experimented a little bit with longer inversion processes and even adding modest amounts of acid to accelerate the process, and noted no significant differences in flavour in the end-product. Like you, I’ve noticed some big differences depending on the protein source (I’ve tried DME, DAP and protein powder), but more recently I’ve decreased the amount of protein I am adding significantly and those ‘characteristic’ flavours no longer appear in the completed product.

I’m not sure that the beet sugar story is BS – Belgium has a pretty large sugar industry, and as such low-grade sugar (i.e. manufacturing leftovers) would be pretty easy to come by and pretty cheap.

So what were the cost savings in making your own candi sugar? I just paid around $7/lb for the commercial stuff making my Tripel (using 4 lbs) an expensive beer to make!

In my case the savings are substantial – a kilo (2.2lbs) of table sugar costs about a buck, the amount of lye and DME required is minute (my $4 packet of lye appears to be enough for ~200 kg of candi, the amount of DME required is about 1/4 tsp/lb). Greg used dextrose in place of sucrose (which allows you to skip the inversion step of the process), but it costs more. But even at the higher price, around here it would still be only a few bucks per pound.

Sounds like a winner. I’ll be referring to your blog for instructions when next I make a Belgian beer!

Hi nice test! Some comments: I would recommend adding the lye prior to heating rather than after already having produced the heated syrup. This would avoid “violent eruption of molten sugar bubbles” and as a plus would give the reaction longer time to happen at lower temperatures which should lessen the harshness which is probably due to caramelization.

I would also suggest that you boil the syrup under a lid to avoid water loss and temperature increase over the course of the process. If the temperature gets too high (due to too little water) caramelization will happen which may give more harsh tones.

Cheers

Anders

Thanks for the ideas Anders! I did in fact use a lid and it helped tremendously with maintaining temperature.

I was also thinking the same thing about adding lye prior to heating. The only reason you would not want to do so is to keep the solution acidic for sugar inversion, but since I was using dextrose anyway it wouldn’t be a problem.

Next up- using cane or table sugar instead of candi sugar. Many people say you can do it without a noticable difference in taste!

I would love to tackle that – candi syrup vs cane or beet. I would all but guarantee it’s a non issue. Especially given that supposedly the Belgians and Brits use granulated

Have you tried to make your own Candi Syrup, yet?

Yes I have. I enjoyed the process and the learning that occurred but I also won’t be doing again anytime soon. Too much for too little. I rarely brew beers that make use of it so I’ll just buy it in the forseable future.

On the list!

This is one of the few experiments with results that do not surprise me in any way. I started out making my own syrup and never had any problems. A co-worker accidentally bought a 5-gallon clone kit instead of the one-gallon he wanted and gave it to me to brew. It had the commercial stuff. I could detect no difference between the expensive stuff and the stuff that I made (well, my wife made) for very cheap. There was nothing scientific about my opinion, I just couldn’t justify spending $4+ dollars per pound on a product that I could make for 1/10 the price that didn’t seem to be any different.

Why do you add the NaOH after boiling? Also, could you use a less volatile weak base like calcium hydroxide?

Normally you would keep the solution acidic and maintain a boil to facilitate sugar inversion, after which you would add the NaOH. For this experiment I was using Dextrose which does not require inversion, so there’s no reason why I couldn’t have added the NaOH in the beginning. It was kind of nice to monitor the color while adding the NaOH to insure I didn’t over-darken the syrup.

Slaked lime is also commonly recommended for Candi Sugar making, but I didn’t have any on hand.

I have messed around with Candi syrup in the past. I noticed the same thing Greg. An almost burnt flavor. I also wondered about reducing the amount of proteins going into the pot. I also think a larger batch would help as a buffer against some of this. But with 4-6 kiddos in the house I wont be making any candi syrrup again any time soon. Maybe Bryan could give us his thoughts on making larger batches, and if that buffers the burnt taste at all?

Dave, I’ve not noticed a trend one way or the other – but I’ve also not looked. Like I said in my first post here, I’ve changed my approach slightly since posting my blog posts/video on the topic so its hard to point to a single factor from my own tests. My largest batch was ~2kg, and did not have that flavour, but my last batch was ~0.1kg and also did not have the flavour.

I think the burnt flavour was largely due to too high a protein (DME) content, and poor temperature control, as after I changed those two factors I’ve not had any issues (in four batches).

shiitake mushrooms, was that the last thing you cooked in that pot used for the homemade syrup, and what were the og comparisons?

I’m pretty sure I did not make shiitake mushrooms in my candi sugar pot because I absolutely hate mushrooms, lol!

I don’t have accurate OG comparisons because the sugars were added in two phases throughout fermentation.

I didn’t come up with this idea but you can also replace the distilled water with beer for a ton of unique flavor options. I’ve done this with a stout and one with New Glarus Belgian Red which resulted in the best belgian dubbel I’ve ever made.

It is difficult to evaluate the xbmts when you guys use a Home Brew Supply recipe without posting the recipe. Home Brew Supply keeps their recipes proprietary. In this case, there are TWO recipes by user saq on Home Brew Talk, one that uses 1.5 lbs. of 80°L candi and 0.75 lbs. of 40°L candi, and the other recipe has 3 lbs. of 180° candi. The ingredients shown in the box don’t seem to match up with either recipe. The amount of homemade candi you used (1.5 lbs. of one color, also does not match up with either recipe published on Home Brew Talk.

Can you elaborate on the two recipes used, Greg?

The kit from homebrewsupply was “The Pious New World” version of Westvleteren 12 http://www.homebrewtalk.com/showthread.php?t=147815

I have made sugar number five from this lengthy forum post several times, and I’ve also done blind tasting’s compared to D2 and brewed a Westy 12 clone with homemade and D2 syrup and the people in our homebrew group could not tell the difference.

http://www.homebrewtalk.com/showthread.php?t=114837

The method that I use is completely different than what you are doing. I use DI ammonium phosphate, which when heated forms phosphoric acid which Cleaves the sucrose into fructose and glucose and also provides a nitrogen base for the Maillard reactions. Technically speaking nitrogen is required for the reaction, which I believe is different from your method, but also much safer because there is no boiling/spitting lye involved.

Don’t stir if you’re going to try this method. I would highly recommend it. I heat up to 290F, then add the water than heat back up to 290 and then add another cup of water. It’s delicious.

I make dark candi syrup in a pressure cooker. Sucrose, wyeast nutrient, pinch of slaked lime. I heat the ingredients in a pan so that I can use as little water as possible (~1:0.7 by weight sugar:water). I pour the hot sugar water into a jar, seal it up and pressure cook it for 15 to 45 minutes depending on how dark I want it. I know it’s not inverted but it produces a dark sugar syrup with the characteristics I am looking for (no burnt flavors, lots of raisin-plum, super fermentable). I haven’t done side-by-side tests with commercial candi syrup, but this method gives me the flavor I want in my beers.

If I want invert syrup I use my slow cooker. Sugar, water (~1:1) a splash of 2N H2SO4 to get the pH to <3.5 and I set it on the 10h (low) setting and in the morning I have a sugary syrup that has a lovely caramel flavor and a strong butterscotch aroma. I haven't had someone complain about diacetyl in the english beers that I brew with this syrup. That buttery character goes away after fermentation and leaves what I perceive as a hint of low lovibond caramel and the dryness I want in a session beer.

I wish you had done a pils + candi. The biscuit, aromatic, and special b would definitely mask the flavors of the syrup. I’m not surprised you couldn’t tell the difference.

How many people are making 100% Pils malt beers with candi syrup? Even if a difference was noticeable, would it be relevant or applicable?

ME! For BGS or Triple! haha. Ok, sometimes I add a few flicks of something or other (Aromatic, Belg or German crystal-type).

The Trappists! I think you’d be hard pressed to find a traditional Belgian brewer that uses special b in a dubbel or quad. Plus, it would give you a more definitive result. For the result above all you prove is that commercial and homemade candi syrup are indistinguishable when mixed with three other specialty grains.

“For the result above all you prove is that commercial and homemade candi syrup are indistinguishable when mixed with three other specialty grains.”

That’s how many people brew with similar products. I may not use Spec B in Belgian Dark Strongs or Dubbels now, but I think I did years ago. People play around with a few specialty character grains, noble-like (Saazer, Euro Continental or UK hops), add sugar, and a Belgian yeast.

Maybe one of us can make a light invert sugar for a BGS or Tripel xBmt, but I just use beet sugar or cane, so we’ll see.

I’m not sure we “proved” that, though I’d say there’s some value in the results– people who make Belgain styles with 3 specialty grains likely have nothing to worry about if they make their own candi syrup!

Really interesting xbmt, I have been hoping homemade candi sugar vs commercial was going to be done and doesn’t disappoint. I have been making candi sugar of various colors to use in all sorts of fermented beverages (cider with gold candi syrup is awesome).

One question I have though is related to the lye. Why is this step necessary? The way I learned to make sugar all I use is table sugar, acid, and water (used to add yeast nutrient but stopped). In 30 minutes or so the sugar begins caramelizing on its own as the temperature rises and begins changing color. Given time and heat the sugars will caramelize without manipulating the pH. (I’m not the candi-master or anything I’m just curious if the pH adjustment is supposed to just be a time saver or meant to create a superior product)

You answered the question yourself: “Given time and heat the sugars will caramelize”. Ceramelization is a different reaction compared to the Maillard reaction they are aiming to induce by introducing amines and increasing the pH. Caramelization requires higher temperatures and gives a burnt sugar taste (which may be very nice, if in moderate amounts) while the browning reaction of the Maillard reaction happens at lower temperatures and gives a toffee flavor.

Just to expand on Anders’ response. Mallard reactions take place under basic pH conditions. Liquified sugars will be near-neutral to slightly acidic in pH and thus Mallard reactions will occur slowly (or not at all). By adding a strong base (lye or picking lime) you drive the pH to a range which is compatable with Mallard reactions.

With lye/lime you get flavours of stone fruit, toffee, chocolate and toast. Without it you get caramel/burnt flavours.

Interesting, I guess I’ve never gotten the caramel/burnt character in my sugars. I don’t mean to suggest I am the rule, but I have had beers with dark homemade sugars and almost entirely Pilsner as the base malt entered into competition and come back with comments on the plum/stone fruit character(I definitely can smell the dark stone fruit when I am making it).

I do try and keep the temper lower once the sugars start changing color so that may be why I never get burnt caramel tones, controlling the temp to under 270F may be part of it. Would be an interesting variable to attempt. Obviously something in my process makes me an exception to the rule, or I’ve just been super lucky.

Reading more comments and poor temperature control seems to be part of the culprit for burnt character showing up so potentially that’s a major reason I don’t get that in my sugars. Low and slow, temp starts to rise I’ll squirt it with a little water from a syringe to drop the temp in my sugar.

Potentially combine that with my city water having rather high alkalinity (110). Maybe I have been unintentionally increasing the pH during the end phases of my process and that’s why I haven’t experienced the burnt caramel sugar character.

Great read – thanks!

How do Belgian candi syrups compare to British invert syrups? I’ve been looking at the recipes on Ron Pattinson’s Shut Up About Barclay Perkins blog, many of which call for invert – #1 through #4.

From a little digging it seems like using unrefined sugar (Turbinado, Sucanat, etc.) is considered important as the molasses content is important to the overall flavor development.

Emglish-style invert is quite different from candi; invert is prepared by mixing sugars of varying degree of purity (ranging from highly pure to fairly unrefined) which are then treated enzymatically to invert the sugar. There is minimal heating/acid/etc involved, and thus there is no caramelization or Malliard products/

I am curious why you’re using a basic substance instead of an acidic substance when inverting sugar. Also, what is the purpose of the DME? According to the following websites recipe for inverted sugar, which I have used, neither are indicated. Furthermore, and I am no chemist, so I am open to correction. Either way, the product I produced must not have risen quite to ‘hard-crack’ temperature because mine stayed in a semi-hard state, otherwise there were no burned, bitter, or off flavors from the sugar which was used in several different beers.

https://joshthebrewmaster.wordpress.com/2010/11/27/how-to-make-belgian-candi-sugar/

Hi Greg,

Very nice exbeeriment. I have a question isn’t about candy syrup. How do you exactly transefer the beer to the kegs? I think you put pressure in the carboy with C02.

Are in the same height the carboys and the kegs. Do you know any web or video when explain it?

Thanks

I’ve made a few sugars. Initially, inverted sucrose with heat, acid, and a lengthy cook to impart some color. Then I came across your same reference that includes nitrogen to induce Maillard reactions. I added base as calcium hydroxide, but the color rapidly and drastically changed when I added diammonium phosphate. The foam was difficult to manage. I liked this better than the longer cooked caramelized syrup without the dap. Less burnt flavor. I’ve also only made the dark versions for dark Belgians. For a lighter syrup, I may need less dap (or use DME like you did). Also, your thoughts on not having fructose in your base since you just used glucose? I just assume use the sucrose and invert it since it’s cheaper. Fructose is reducing, so it will brown as well.

I’ve tried making candi syrup before (with dap) and the problem I had with it was I never got an FG below 1.020. In your case your FG was 1.019. This is way too high for a Westy 12 clone which should be around 1.010-12. To me, the reason to buy the commercial product is this higher fermentability.

I have made my own syrup IAW procedures laid out on the BBR episodes from years back, and fermentated down quite dry. 1.012 range for a “Quad”.

Hello, I’m an Italian homebrewer, I apologize for the bad English. I wanted to bring my experience .. I read that the ‘smell of burned derived from use the’ invert sugar acid, but if we heat only table sugar (sugar + water without acid) we get a partial reversal but more Maillard reaction because we can cook longer without darkening too much sugar. maybe you can help this link http://ryanbrews.blogspot.it/2012/02/candy-syrup-right-way-hint-weve-been.html?m=1

I hope it is useful and congratulations for this wonderful blog

What was the recipe you used for this? I have made my own candi rocks following the process you also used (using a Base and due rather than acid) to invert the sugar. By far the most usual way to invert sugar is using acid although it takes.much longer. I wonder if more people use acid because maybe it gives better results? Lately what I have done is heat golden syrup (which Is already Inverted, in a sauce pan which browns very quickly. Not sure which method is best still but golden syrup seems easier and safer!

I’m sure the vast majority of the people who posted here no longer monitor it but…. Had any of you doing these sugar experiments used an induction burner when doing the sugar work? I see a lot of mention of burnt flavors and aromas…

I spent the majority of my life as a pastry chef and if you make caramel on a gas or electric stove, wet method or dry, and you pay very close attention to it (which you have to when making 20 gallon batches of caramel sauce) …. The color change from light to dark is not an even process…. Especially with the dry method..

Certain areas will color before the rest and “infect” the batch of sugar.

Good control with an induction burner will greatly reduce or eliminate the burnt aspects of the sugar.

And out of curiosity ….. Why the lye, dme, etc…

Has anyone tried just sugar and water?

I have a suggestion coming from my background as a chef…

Use a double boiler. If this doesn’t solve the Burt flavour issues, it’s definitely to do with the ingredients. Try backing off or omitting the DME, or try going back to sucrose, but use a better version, like sugar in the raw, or fine berry, or beet sugar. Beet sugar is used most commonly for candy making, and imagine it’s properties might lend better to the process. For an acid, try just citric acid, instead of the commonly used cream of tartar.

i’ve tried a few times to make my own syrup. i’ve used both pickling lime and lye and i always end up with that disgusting medicinal aftertaste. i’ve tried using less but it’s never enough to get reactions going. i just now used 5 grams of lye to 1kg of dextrose, about half a tsp of LME and a few hundred mls of water. i added it all to the pot and started stirring. it was quite dark straight away but that flavour comes in after the initial candi sugar taste. i wouldn’t want to add that to a beer

I’ve had a few failures making Candi syrup. The first crystallised, the second foamed up into a crazy mess becuase of the DME. So I left out the DME and took care not to stir during the inversion process. I find that adding the lime does produce a dark syrup but the burnt smell/taste is still there. Not something I want to add to my beer. I’m going to try just sugar and water next