Author: Marshall Schott

Even before publishing the first boil length xBmt comparing a Pale Ale boiled for 60 vs. 30 minutes, and then failing at a second attempt, I’d been anticipating repeating it with a mostly Pilsner malt wort. I imagine most homebrewers have heard that longer boils drive off more DMS, the precursor of which (SMM) is more abundant in lower °L Pilsner malts. I’ve even heard of some people who boil for a minimum of 90 minutes for every batch, regardless of the base malt used, influenced at least to some degree by the fear of creating a beer that tastes like cooked cabbage or creamed corn.

I’ve always thought the way us humans deal with time is interesting, how we’ve imbued certain chunks of time with immense meaning, and this couldn’t be more prominent than it is in homebrewing– mash for 1 hour, boil for 60-90 minutes, rehydrate dry yeast for 15 minutes, ferment for 2 weeks, bottle condition for 3 weeks. Obviously, shit happens over time, I’m not saying this stuff doesn’t matter, but taking a huge step back, I can’t help but notice the absurdity of it all, how arbitrary it feels.

I fully understand there are those brewers out there who engage in particular practices purely as a function of their interest in said practice, despite evidence suggesting it likely makes little difference in the finished product. I truly appreciate and almost envy this mentality, though as I’ve made rather clear, I’m far more motivated by simplification and efficiency– if I can make in 3 hours a beer that’s equally as delicious as one that takes longer by modifying a few parts of my process, count me in!

| PURPOSE |

To evaluate the differences between a 30 minute boil and 90 minute boil in beers produced from the same mostly Pilsner malt grain bill and otherwise treated exactly the same.

| METHODS |

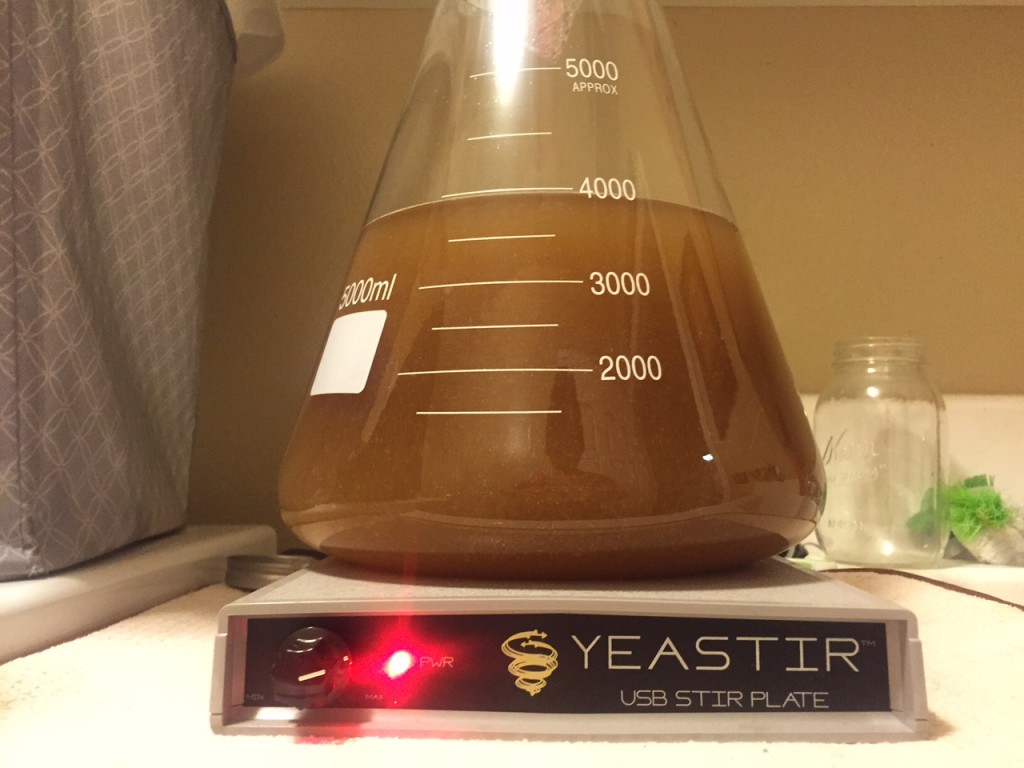

Hoping to avoiding the mess I ran into last time, I produced a large starter using a fresh vial of WLP029 German Ale/Kölsch yeast a couple days before brewing, it would be split between the 2 batches after I stole some for future use.

Similar to the latest sloppy old slurry xBmt, the recipe for this Kölsch was a product of the odd yet fun limitations of the BrewUnited Challenge.

BrewUnited Challenge Kölsch

| Batch Size | Boil Time | IBU | SRM | OG | FG | ABV |

| 5.5 gal | 90/30 min | 22 | 4.1 | 1.043 SG | 1.010 SG | 4.3% |

Fermentables

| Name | Amount | % |

| German Pils Malt | 8 lbs 8 oz | 92.9 |

| Gambrinus Munich 10 | 5 oz | 3.4 |

| Flaked Wheat Malt | 4 oz | 2.7 |

| Crystal/Caramel 60 | 1.4 oz | 1.0 |

Hops

| Name | Amt/IBU | Time | Use | Form | Alpha % |

| Northern Brewer | 27 g/20 IBU | 30 Min | Boil | Pellet | 10.1% |

| Saaz | 20 g/1.8 IBU | 10 Min | Boil | Pellet | 3.0% |

Yeast

| Name | Lab | Attenuation | Ferm Temp |

| WLP029 German Ale/Kölsch | White Labs 029 | 83% | 66°F |

Water Profile

| Ca | Mg | Na | SO4 | Cl | HCO3 | pH |

| 64 ppm | 0 ppm | 10 ppm | 56 ppm | 71 ppm | 33 ppm | 5.3 |

For sanity’s sake, I usually stagger the start of each batch on dual-batch brew days by about 20 minutes, but because this xBmt had a 1 hour differential built-in, I hit the flame under both kettles of strike water simultaneously. The long-boil batch had 1 gallon more water and took about 6 minutes longer to heat, enough of a difference that I was able to begin collecting the sweet wort from each batch after both completed a 1 hour rest.

Both no sparge mashes ended up being just a hair north of my target rest temperature of 148°F, which was fine for me, so secured the lid and let them rest for an hour, briefly stirring every 15 minutes or so.

About 10 minutes in, I pulled a small sample to ensure a similar pH, as I’d used the Bru’n Water spreadsheet to adjust each batch based on their different liquor volumes. Not too shabby!

The timer for short-boil batch went off after an hour and I began collecting the sweet wort, which I finished just as the timer for the long-boil batch began to ding. The worts were collected in a bucket and transferred to separate kettles.

My boiloff rate currently hovers around 1 gallon per hous, thus the short-boil batch had approximately 1 gallon less sweet wort in the kettle than the long-boil batch. I added the first charge of Northern Brewer hops at 30 minutes and a later addition of Saaz was tossed in prior to chilling.

Once the boils were complete, I was pleased to find each wort shared a similar OG, with the short-boil batch clocking in at 1.044 while the long-boil batch ended up at a slightly higher 1.046. Separate 6 gallon PET carboys were filled, labeled, and placed in my chamber to finish chilling to my target fermentation temperature of 66°F. After about 4 hours, I returned and pitched equal amounts of starter slurry into each fermentor. It didn’t take long for signs of active fermentation to arrive.

Fermentation progressed similarly for both beers. My Black Box temp controller began ramping temps up after 3 days, eventually stopping at 72°F where it remained for a couple more days. It was at this point I took an initial hydrometer reading, which was followed by a confirmatory measurement 2 days later.

It wouldn’t have surprised me to discover the beers finished at different SGs, though I thought it was curious the lower OG short-boil beer had a slightly higher FG than the long-boil batch. Still, close enough. I proceeded to crash the beers, fine them with gelatin, and rack them to kegs.

After sitting on 40 psi of CO2 for 24 hours, I reduced the pressure to 14 psi and left them alone another 4 days before presenting the beers to participants. Both were nicely carbonated and clear by this point, and as I’d noticed during both hydrometer measurements, the short-boil beer was ever-so-slightly lighter than the long-boil beer.

| RESULTS |

Data for this xBmt was collected over 6 days and included a panel of 18 participants from various backgrounds ranging from BJCP judges, experienced homebrewers, and dedicated craft beer junkies. Each participant was served 3 samples in separate colored opaque cups, 1 from the long-boil batch and 2 from the short-boil batch. In order to achieve statistical significance with the given sample size, 10 tasters (p<0.05) would be required to accurately identify the long-boil beer as being unique. Of the 18 participants, only 6 (p=0.50) made the accurate selection in the triangle test, a response rate consistent with chance, indicating a demonstrable inability to reliably distinguish a mostly Pilsner malt based beer boiled for 90 minutes from one boiled for only 30 minutes.

While the comparative evaluations of those participants who did accurately identify the odd-beer-out are inconsistent and generally meaningless, I think it’s prudent to note not a single person reported perceiving anything close to DMS in either beer and, in fact, both were equally well received.

My Impressions: From the first hydrometer readings to my final comparison, there was one difference between these beers that was very obvious to me– color. The long-boil batch was noticeably, though not all too obviously, darker than its short-boil counterpart, which I expected and assumed would produce a perceptible difference. Nope. In no way was I capable of telling these beers apart in a reliable manner, regardless of my sampling method. Both have a nice bread crust character from the Best Malz Pilsner malt balanced by a soft spicy Saaz note and, interestingly, a slight murmur of cotton candy, which I believe is a result of the 1% C60 I was forced to use. All in all, I think this beer may fare well in the BrewUnited competition, into which I plan to enter the short-boil version, though I’ve no plans to brew it again.

| DISCUSSION |

It’s been awhile since the negative results of an xBmt have really surprised me, shaken the core of what I’ve accepted as brewing truth. This one sort of did. It’s weird because a part of me expected these results, though a larger part hoped for significance, mostly for self-validating reasons– I’ve a history of advocating for 90 minute boils in mostly Pilsner malt based worts. While I’ve neither the equipment nor the intelligence to be able to objectively measure differences in beer composition, I can’t help but wonder if the long-boil batch actually contained less DMS than the short-boil, perhaps just below the threshold of perception. I’m compelled to believe this is likely true, though my belief is admittedly motivated by my own appeal to authority. Moreover, I wonder the extent to which boil volume plays a role. Since evaporation rates are generally fairly constant and not linearly related to volume, it stands to reason less DMS would be driven off during the boil thereby increasing the risk of DMS in the finished beer. Given our propensity as homebrewers to accept professional brewing practices as the gold standard, it seems wholly possible the conventional wisdom regarding boil lengths stems from experiences and research that don’t necessarily apply on our smaller scale.

In most of these discussions, we try to comment on how the results will impact our brewing, and nearly every time we’ve said it likely won’t. Even with the scarcity of good evidence, my obsession with efficiency combined with my experience with these (and a couple other) short-boiled beers is winning out, I absolutely plan reduce my typical boil times. However, this isn’t something I’m ready to recommend for anyone else, I rather enjoy the risks involved with process tweaks like this. For those who are interested, keep in mind you will need to use more and/or higher AA% hops to achieve your target IBU, and your paler short-boiled beers will likely be a touch lighter than expected.

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

61 thoughts on “exBEERiment | Boil Length: 30 Minutes vs. 90 Minutes In A Kölsch”

Wow, this one IS surprising. I definitely made a beer with DMS so strong I had to throw it out one time. It was the first time I had used a 60 min. boil in a Pils-wort beer, a saison. Maybe something else was at play, such as a lower than necessary boil-off rate or a problem with the yeast somehow? It could also be that my wort production process at the time resulted in maximal DMS into the wort (e.g. mashing, sparging and heating that somehow maximized DMS.)

I’m wholly convinced our biases hugely sway our perception– since you knew you used mostly pils malt and boiled for less than the conventionally prescribed time, your mind may have been hyper-focused on picking up DMS characteristics. Not saying this is true, just something I think we all ought to consider when it comes to beer evaluation.

Maybe there was a significant difference in the amount of DMS in the two beers, but people are not very good at detecting it and Aaron is.

I wish you would have had the two beers analyzed by a lab. Then we would know if your results were process or perception.

We did:

https://brulosophy.com/2015/10/08/update-lab-data-on-pils-malt-boil-length-exbeeriment/

DMS isn’t near as common as people think. The corn that most people think is DMS is often the actual taste of pilsner malt. American two row malting varieties taste much different than a nice German pilsner malt. I have made numerous beers with substantial amounts of pilsner malt and from time to time people tell me it tastes “corny.” That’s not DMS. That’s the flavor of pilsner malt. DMS isn’t corny. It’s vegetal. Some varities of pils malt are stronger flavor, like the Best Malz pils, and some are more neutral and grassy like Weyermann. But they are markedly different than american two row.

Amen!!!

One thing for the DMS. I believe you should have experienced different results had you used different boil kettles. Your kettle shape and fill during the experiment has a ton of surface area and less depth. This encourages DMS to come out of solution easier.

I believe that the vigor of the boil is an important factor, but also that most people probably go well over what is necessary.

From a thermodynamic perspective, you are adding heat to the bottom of the kettle, which transfers to the bottom of the wort, which then rises naturally and sets up convection flow and mixing throughout the kettle. You probably want a little bit of actual “boil” to provide more bubble surface area for DMS to diffuse into the water vapor and give it a better chance of getting to the surface of the wort before it is reabsorbed, but I suspect that you get most of what you need with a little over a simmer.

Also, as Dan noted, the geometry of the kettle is an important factor, and directly related to boil evaporation rate (and boil vigor, and energy usage). With a relatively small surface area, it takes less heat per volume of wort to create the desired disruption at the surface. For the same boil vigor, you are therefore adding proportionately less heat, but the bubbles are rising through a longer height in the wort and allowing more time for any interaction.

I would like to see an experiment on boil evaporation rate, starting as low as a simmer and comparing this to moderate rolling boil. You could quantify this with actual measurements of evaporation rate, relate it to wort surface area per total volume, and perhaps even fuel consumption (e.g., change in weight of your propane cylinder through the duration of the boil).

Science.

Over the summer, I kept one keg pretty much dedicated to a lighter beer for my friends/family that weren’t into heavily hopped brew. It was usually a Belgian Wit. I always kind of groaned when the keg was getting low, because the grist of the wit I make is largely pils malt. As such, I boiled for 90 minutes, per common convention. I know it is only 30 minutes more, but during an already long brew day, it feels longer than that.

Each time I made it, I told myself that I was only going to boil for 60 minutes, but I would chicken out every time, fearing the dreaded DMS. Maybe now I’ll actually go through with the shorter boil 🙂

Question though…when you are doing a shorter boil, do you make an effort to drive the boil harder than you normally would?

I boil with the same vigor, which I’d say falls in the moderate range.

Love these boil experiments. Very happy to hear you are changing your brewing practices based on these boil experiments. Count me in too! Will you be doing 30 minutes boils, you think? — or like 45 min as insurance? High gravity beers as well (is that relevant?)?

Probably 30 unless a recipe/kit explicitly calls for longer (i.e., kit sent with specific amount of bittering hops).

Your quick chilling may helps here. People with slower chilling methods should be more cautious. Another test with longer whirlpool or even with no chill method?

Good ideas!

I’m just coming here after the recent post summarizing the quantitative measurement of DMS in the samples. Based on those results, it would seem that all of the DMS was probably formed and driven off long before the end of the boil, in which case a long rest before chilling wouldn’t have any remaining SMM to convert.

But I would still like to see the test.

So glad you did this. I went down to 18m for an all pils malt boil a few months ago with similar results, no DMS. At this point i do a 20m mash (getting efficiency in the 80s with BIAB, a tighter crush, and some stirring ) and 20m boils (sometimes shorter), for every beer, and occasionally no chill, with no issues. There are very few of the homebrewing “rules” that are true in my experience. Sanitation and controlled fermentation temp may be the only ones.

goddamn that’s brave!

Nice experiment. Yet another instance of something being more pertinent on a full size brewery scale, yet not necessarily on a homebrew scale.

By the way, I was reading an experiment dealing with SMM/DMS here: http://onlinelibrary.wiley.com/doi/10.1002/j.2050-0416.1979.tb06845.x/epdf It is an interesting study of how boil length, evaporation rate, and yeast strain choice affect DMS in beer. However, this study was done at a full scale brewery, with no taste-testing.

Also, I have heard strong DMS can result from infection, so that is something to keep in mind as well.

Keep the experiments coming,

I wonder if your hydra chiller plays a big part in this.

NOW I read the comments… Peter beat me to the thought.

Quick chilling could play a role, though I know of no-chillers who have no DMS issues…

I’m one of those. Every batch over the last 3 years has been no-chilled and no DMS issues. However, I haven’t done a boil less than 60 minutes either 😛

@Kelsey Stubbin: “Every batch over the last 3 years has been no-chilled…”

And I assume no botulism poisoning either. Now what kind of experiment do we have to do to get that issue put in its proper place?

Another great exBEERmint. Thank you!

Awesome Experiment. I make a lot of IPAs and Pale Ales and have been basically adding an extra half hour onto my brew day letting my wort cool to 185 and then doing a 15-20 minute hop stand. With your experiment in mind I might shorten my boil time to 30-45 minutes when doing a hop stand.

If my experience is any indication, you have nothing to worry about.

Great article! I’ve been doing 30m boils as standard for a little while now with no noticeable issues, no chill also. I do at times struggle with a 30min hop addition potentially giving a flavour profile that differs from a 60min addition, for example in a porter/stout where I am really only wanting bittering. Do you have any suggestions for this scenario? Or am a buying into more unverified dogma? Cheers

Yeah, use less hops if you want less hop flavor. Higher alpha varities. Something neutral like Newport, Bravo, Warrior. You don’t need much of a >14% AA hop for bittering.

I’ve never made a dark beer with a 30 min boil, though I plan to! I’d imagine a high AA hop would do the trick, something like Magnum or Warrior.

Experiments are better seen as informing your process, not your recipe. Try a recipe, see if you like it. Karl Popper tells us that scientists must take risks as well as use their rational mind, right? Seems like if you want to pioneer new processes, you must also pioneer new recipes!

Yeah, there’s no DMS in wort at the end of the boil unless you leave a lid on; all of it (unless from infection) comes from SMM still in the wort that evolves to DMS after boiling. That evolution stops at about 140 degrees F. Hence, rapid chilling should, in theory, prevent that evolution so that DMS is below the flavor threshold of 60ppm. I’ve looked at George Fix’s model and it definitely predicts the results of the previous xBMT, but I’m not sure about this one. My take away here is that you should settle for shorter boils, but those with other chilling processes millage may vary.

Is there any data available on the decay rate of SMM at different temperatures? You start with a fixed amount depending on the malt variety and quantity, and if that gets converted to DMS and boiled off within the length of your boil then there should be no issue with how quickly you chill.

I’ve never seen it mentioned on this blog that in theory you can remove DMS by carbonating, allowing the beer to de-gas and repeating, as necessary. So DMS is actually a problem you can solve, if you have it and you keg.

Thanks alot for yet again moving my brewing cheese Marshall lol – good shit man!

Have you ever done a exbeeriment where you don’t bother chilling and just pitch the yeast the next day? Chilling is a pain especially when the groundwater is warmer. Curious…

Not yet, but it is planned. My buddy Aaron wrote an article on his experience with no-chill, pretty good stuff!

Love the experiment! I really think the variation on who judged the beers may be the biggest source of error in this experiment. I have friends who love craft beer but have a hard time breaking apart many of the flavors present. Many people, even BJCP judges, have different levels of perception of DMS. I’ve personally been yelled at by another judge for not dinging a beer for the high level of DMS. To me it was at a very good level. This may be due to some people being much more sensitive to DMS (super-tasters).

My point being that the variation in your testers DMS detection, really hinders the ability of you rejecting the null hypothesis that there isn’t a difference in the two boil times. If you could actually see the ppm of DMS there must be a difference. You found that it is not perceivable to a significant number of tasters.

A couple of variables not accounted for: temperature of the beer. DMS is volatile and if it was warmed up it would be more perceivable. Just like crappy beer the colder the beer the less you taste. Keg vs bottles:again DMS is a volatile and can be blown off with CO2 in a keg more easily than a bottled beer.

I’m sticking with a 60 minute boil at least. I have the time and propane, and that boil time has produced some awesome beers, so why take a chance in saving 30 minutes?

Glad you like the xBmt, thanks! This is one of the most common critiques we get with every xBmt, that the participants simply couldn’t detect it because they don’t have very good palates. While it’s possible this is true, my biggest response is that, given the apparently tiny proportion of super tasters in the population of beer drinkers, perhaps it still doesn’t matter. I serve my beer at about 45°F but usually take samples with me to a local taproom where they sit out for 10-15 minutes at a time, warming up a bit. I do keg, which involves some purging, though I’m not convinced that’s the issue.

I’ve plans to provide samples of both beers to a really kind dude who does this type of testing, when the results come back I’ll be sure to share it with everyone 🙂

I’d like to see the lab data too, if you do the testing, so we would have numbers to argue about!

But, the important part to me is: does it make a difference in the bottom line (taste). I always appreciate that your experiments are always tied back to the practical sense.

Definitely more focused on the pragmatic than theoretical here, though the lab data ought to provide some interesting grist for the mill.

I know I am dreaming here, but it would be great if there was some kind of test that everyone could do to establish their individual perception limits for various flavors/aromas, even if it were only qualitative. That would be interesting information for further interpretation of your triangle tests.

This was a VERY interesting xBmt! I for one am not all that surprised at the outcome, but now we KNOW. It’s not that I don’t ‘believe’ in DMS (and SMM), it’s just that it really shouldn’t be an issue. It is cool to know, that there really isn’t a need for a longer boil than the hop schedule dictates.

Now Marshall, would you please, please, with some sugar on top, make a similar xBmt, comparing a boil with lid on, versus one with lid off?

I’m thinking that boiling with lid on, still lets steam escape, but but you could make a ‘rolling’ boil with less power. That would be really good (especially here in Europe, where we almost exclusively use electric and are often limited to 2kW, which is really on the low side for achieving good boil for ~6 gallon).

You always hear you need to boil with lid off, just citing DMS (possily from dripback from condensation) as reason, but with no data to back that claim up. I would think that the condensate would quickly be depleted of DMS due to the low boiling point.

Anyway, I’d like to see this myth/old brewing truth debunked (or confirmed for that matter), as boiling with lid on would have benefits (conserve power, no dead bugs if brewing outside).

Cheers!

I don’t think the small amount of steam that would escape through the space around the lid would be able to carry away enough of the volatiles, and the DMS would fall back into the wort after condensing on the lid. That would probably keep the desirable hop aromatics around too.

You can probably reduce energy use and keep the same boil vigor, but still allow the volatiles to escape, by using some kind of “flue” on top of your kettle to mimic what you see in a commercial brewery. Try fabricating a funnel out of aluminum sheet with the large part overlapping the top of the kettle and a smaller hole at the top. This should keep much of the heat in the surface, allow enough vapor to escape through the top, and drain the condensate (which would have dissolved DMS) to the outside of the kettle. If you want to get really cheap, you could do this with a meter or two of aluminum foil.

That is right, you *think* that there won’t be enough steam escaping.

I *think* that there will.

Same laws of physics apply in both cases. The same amount of steam will be produced, wheter there is some small crack in the lid or if you have a flue on top. The same amount of steam will *need* to be vented for pressure to equalize, so reasonably there will be no more, no less, steam escaping in either case.

If anything, a flue will provide a larger area for condensation to form, that will drip back if not handled.

The reason commercial breweries uses flues, is probably to efficiently vent the steam, but I don’t really know. But a lot of the equipment and procedures of a commercial brewery need not apply to home brewing. We are not bound by a lot of the reasoning behind those decisions (be it financial or code or what ever).

Again, I’m willing to bet that boiling with the lid on will not affect the final beer (at least not negatively) and alsoyou could insulate the the lid as well, which should minimize the drip back (and conserve more energy).

The point is, we need not agree, but unless empirically (and in a scientific manner) *tested*, neither of us have any claim to what the truth really is.

Cheers!

I’m not trying to be snarky when I say try it yourself; honestly, the validation process used on this blog is tricky, but you can triangle test an experiment yourself with friends who also drink your beer. If those people can’t tell, what difference does it make? If I were in your shoes I would run the boil lid-on for the time required by your hop schedule until ten minutes before the end, then go lid off. This would be a safe side practice that let’s you try it out with a reduced “dumper” risk.

I really do hooe to do that in a not to distant future. It is on my todo list, but so is unfortunately a lot of other stuff and life has gotten in the way of brewing for a while, but I hope to get back soon.

If I find it works well for me or if it doesn’t, it won’t be a triangle blind test and with enough ppl to be statistically valid in any way. And even if I did do all that, I don’t have a following, so who’d care?

Maybe it doesn’t matter as long as I got a process that I’m content with, but I’m just saying this would be something that I’d like to see put to the test and have some ‘real’ evidence on, if it is ok or not.

This is awesome.

When using a 30 minute boil, have you had to increase the amount of bittering hops from amounts used in a 60 minute boil?

This is a great time and energy saver (esp when combined with the 30 minute mash …)

Yes, exactly.

Yeah, I should have known that – I was in a rush so I did a pilsner with a 30 minute boil and 30 min mash, but forgot to up the anty for the bittering addition. Oh well!

do you think boil off rate is a factor. I made your helles with a one hour boil. the beer has a noticeable off flavors a slightly rancid vegetable taste. its had to describe. but I’m guessing its DMS. I don’t think it is an infection. I brew on a stove top with the pot lid half off. boil off rate is 2.8 ltr / hour. used Weyermans pils.

I’ve never boiled with a lid even halfway off, but it’s usually not accepted as good practice. The rancid part leads me to assume contamination.

I chime in on alphaomega above, it would be very interesting to test this good practice 🙂

It is much more convenient to boil with the lid on and lower heat, less steam to vent, less boil off to account for, less energy required –> can boil larger batches on a normal 2kW plate etc. The question is: what’s the impact on the beer?

I would love to find out!

Cheers

Anders

Just thought I’d chime in on this. We use induction heaters in a 55L setup for a brewpub. Due to the large size of the pot and relatively small size of heater (3200kw) we have to keep the lid on but cracked in order to achieve a boil. I’d say it’s three quarters of the way on, but elevated so the moisture rolls off the lid and (mostly) not back into the pot.

Our boil off rate is a meager 4% / hour, but not once have we had issues with off flavors. We produce 220L per week (four pots per ‘batch’) using the same method and are very pleased with the results.

Definitely goes to your point of timing and such.

I love these experiments. This means that we can (confidently) brew pilsners at A: ale temps, B: shorter boils than traditional would have it and C; not bother lagering them for months on end (as well as fermenting them with all trub included)

This sounds one heck of a wreck on paper when they’re all put together. Would love to see this experiment

Sorry if I missed this, but why were you forced to use 1% crystal 60? Was your intention Carapils but that’s all you had on hand? Tangentially, have you done a comparison how carapils and mash temp changes are quanitatively/qualitatively related? For instance, could you have achieved same FG in two beers, one with some carapils/lower mash temp vs no carapils/higher mash temp, and how if same FG, how the beers differ? (different types/lengths of dextrins and unfermentable sugar chains.)

The C60 was a condition of the BrewUnited Challenge. We’ve done a CaraPils xBmt, but not necessarily in the vain you asked about.

I seem to remember from a brewing course I did (or maybe I read it somewhere), that DMS is both created and removed in the boil. I think the early boil removes any DMS formed during mashing etc. but then a lower level is attained as DMS is removed at the same rate it is formed. Your results are consistent with this.

I think I remember reading that hoegaarden and Allagash White were only 30 minute boils, (mostly Pilsner malt)

I finally grew a pair and tried doing a 60 min boil with Pils malt. I did it on a Pils and then on a Belgian Golden Strong. In both cases, the flavor is as expected. I use an all-electric HERMS, and am able to boil very strongly. I keep it at 80-85% for a 6-16 gal. batch, and it gives me like a 1.7-1.9 gal/hr boil off rate. I then recirc through my chilling system for 5 mins hot, chill down to like 110F over maybe 10 mins after that and then rack to carboy through my counterflow chiller. Thanks! Now, i can save an extra 30 mins on brew day!

Great study! Next question: how low can you go? I’m encouraging a just-boil ex-BEERiment, that is, flame out as soon as boil is reached. (I encourage you because you have that awesome two-brew experimental set-up that I don’t). This and even lighter temperature regimens are found in pasteurization tables. As to the other “benefits” of boiling, let’s see. After all, it’s when we reach the failure point that we really understand our system.