Author: Marshall Schott

BIAB is quickly becoming my go-to method for 5 gallon batches– start to finish in 3 hours, easy clean-up, and less equipment all make it very appealing to me. A few weeks back, while finishing up a BIAB brew day, I wondered, “Couldn’t I just pitch the yeast into the chilled wort in the kettle?” Given the results of the trub exBEERiment, I wasn’t at all concerned about all the hot break and hop sludge in the kettle. No shit, a day or 2 later I received an email from Wilser, maker of the the awesome WilserBrewer BIAB bags, asking if I’d considered fermenting a beer in the kettle. Synchro-fucking-nicity. Wilser mentioned he had done this a few times and had yet to experience any problems, he shared some of his techniques with me and I started planning for the brew day!

My good friend’s Padalinski Porter recipe is one I’d been wanting to try making for awhile, so I plugged it into BeerSmith and bastardized it a bit.

Padalinski Porter (5.5 gal)

8 lbs Maris Otter

1 lbs Brown Malt

12 oz Munich 10L

12 oz Pale Chocolate

6 oz C120

6 oz Special B

6 oz Acidulate Malt

Magnum @ 60 to 25 IBU

26 g Hallertauer Hersbrucker @ 10 min

WLP090 San Diego Super Yeast

Mash at 157˚F for 60 minutes

Boil for 60 minutes

Pitch at 64˚F and ferment at 66˚, ramp to 72˚F after 3-4 days

I hadn’t had Porter on tap in months, I was pretty excited to get this thing going. Per my normal procedure, I collected all of my water and milled my grains the evening before brewing.

I mashed in the WilserBrewer bag, which again kept all husk material separate from the wort.

In the past, I used the kettle thermometer to determine when I needed to turn the heat on due to drops in mash temp; because of the more rapid loss, I always mash in 1-2° warmer when using the BIAB method. For this batch, I had the genius idea to check temps in the middle of the mash using a probe thermometer– 20 minutes in, I’d lost 0.4°F when I was expecting closer to 2°F, meaning the mash was about 2°F warmer than the recipe called for. I prepped myself for a slightly less fermentable wort.

After an hour, the bag was removed, the pulley setup making this part of the process a cinch.

I nailed the pre-boil gravity and brought the sweet wort to a nice rolling boil in about 10 minutes, at which point the first charge of hops were added. What I imagine was the Brown Malt really came through during the boil, it smelled pretty damn nice.

Chilling commenced once the boil was complete, my King Cobra got me to about 78°F (4°F above groundwater) in just under 5 minutes– I went nuts sloshing the wort around vigorously to aerate.

This is where things took a turn toward the novel, for me at least. After sanitizing the ball valve and underside of my kettle’s lid, I moved the entire 6-ish gallons of wort, kettle trub and all, directly to the fermentation chamber in the kettle.

My 14 gallon kettle almost didn’t fit, I failed to check this beforehand. Ehh. Given the larger diameter, I was unable to heed Wilser’s advice to secure a plastic garbage bag around the lid of the kettle. I used a goddamn bungee cord. It was tight.

It took about 4 hours for the wort to reach my target pitching temp of 64°F, at which point I poured the starter of WLP090 directly into the kettle… and then the questioning began.

What if a tiny stupid little bug is able to squeeze between the lid and lip of the kettle?

Will all the headspace have an impact on the finished beer?

Do I have what it takes to lift a beer filled kettle out of the freezer without having a hernia?

Fuck it, what’s done is done. I wasn’t going to let my neuroses get the best of me and accepted this beer was going to be shit. I proceeded to check on it multiple times over the following 3 days, you know, just to make sure “everything looked okay.”

I use WLP090 often and know that it is a quick fermenter, but I was sort of surprised to discover the krausen on this beer had dropped almost completely in just 3 days.

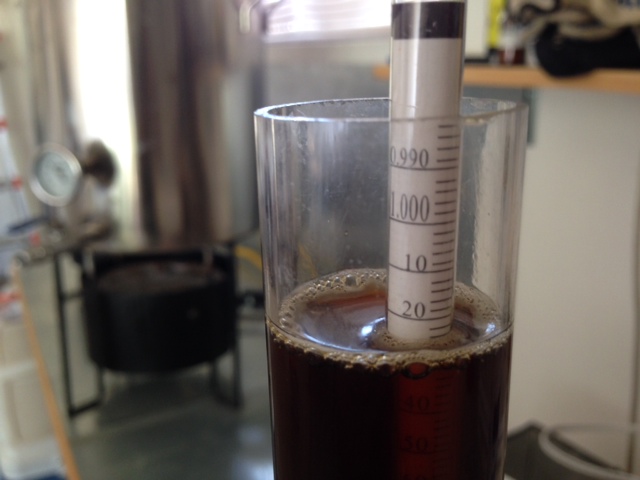

My curiosity got the better of me and I pulled a hydrometer sample.

1.025, obviously the yeast was still doing its thing. Even at just 3 days and with a high SG, the beer was pretty tasty with noticeable roast, chocolate, and hints of toasted nuts and maple (?). I figured I’d give it another couple days before testing again. Damn… the yeast wasn’t doing its thing, the beer had only dropped to 1.024. In complete annoyance and following a brief consultation with Chris, I sprinkled in a sachet of Danstar BRY-97, a yeast I understand takes a few days to take off then finishes in about a day.

Well that didn’t do shit, 4 days later and the beer was still at 1.024, argh.

Hey, it tasted alright, it was only 5 gallons, I know some people who would probably enjoy it… no, I was fucking annoyed and my stupid mash temp idea was the likely culprit. I was done trying to dry this beer out, so I started cold crashing. It looked like beer before kegging.

Moving the kettle/fermentor out of the freezer was definitely a pain in the ass and I ended up stirring up a fair amount of yeast. I let it sit for about 15 minutes before attaching a sanitized tube to the sanitized ball valve and transferring to the sanitized keg (this part was really convenient). I tossed it in the keezer and hit it with 30 psi for 36 hours then lowered it to 12 psi for another 4 days before a faucet opened up. It was carbonated and, as far as I could tell, rather clear.

While the flavor and aroma are actually pretty decent, the sweetness definitely takes away from the quaffability of this beer. I’ve had Chris’ Porter and it is far easier to swill than my version. Still, it’s not a dumper, I try to have a 1/2 pint or so per day and am definitely willing to share (if you’re in Fresno, even if I don’t know you, hit me up… please).

It seems pretty obvious to me the problems with this beer have nothing to do with the fact I fermented it in a brew kettle, but rather seem to stem more from process issues. In fact, I was pleased with the fact I didn’t pick up any flavors or aromas indicative of some sort of infection, which I reckon is partially a function of the fact it fermented in a sealed freezer. Would I ever ferment in a kettle again? Hmm. Truthfully, not on my normal setup, but only because the cumbersomeness of my kettle outweighs the convenience of kettle fermenting. Now, for my smaller 1-2 gallon batch sizes where I use a 4 gallon kettle, I definitely plan to try this again!

A huge thanks to Wilser for all the tips and Chris for the recipe (sorry I fucked it up). If you have any questions or comments, please don’t hesitate to ask or leave ’em. Cheers!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

| Read More |

18 Ideas to Help Simplify Your Brew Day

7 Considerations for Making Better Homebrew

List of completed exBEERiments

How-to: Harvest yeast from starters

How-to: Make a lager in less than a month

| Good Deals |

Brand New 5 gallon ball lock kegs discounted to $75 at Adventures in Homebrewing

ThermoWorks Super-Fast Pocket Thermometer On Sale for $19 – $10 discount

Sale and Clearance Items at MoreBeer.com

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

32 thoughts on “Ultimate Single Vessel Brewing | Ditching The Carboy”

High mash (150-160) temps. will leave a lot of dextrins in the finished beer. Lots of residual body and sweetness. So, if you want a brew to finish drier, lower your mash temp to the 140s….

________________________________

I would be surprised if your high mash temp was entirely to blame for this, especially if you were only off by 2F. While the higher mash temp will give you more dextrins, the vast majority of these long-chain carbs are not sensed by your tongue as being sweet. They would add body, but not sweetness. Sweetness is usually a recipe issue or your yeast crapping out too soon.

– Dennis, Life Fermented Blog

Good points. I should point out, I had a pint of the Porter last night and I wouldn’t necessarily say it’s sweet like candy, but “sweet” in that dextrinous sort of way. Cheers!

Cool stuff, man. Sorry it didn’t turn out perfect, but thanks for sharing the process!

Interesting idea. What are your thoughts on pitching into a kettle with possibly high levels of trub and hop matter? Some trub levels are beneficial for fermentation, but excessive levels could cause off-flavors depending on pitch rate, aeration, etc. It would be interesting to do a side by side tasting between kettle vs fermenter. Thanks for posting. Cheers!

I agree, a side by side would be very interesting. My thoughts on fermenting with a shit ton of kettle trub stem from this prior exBEERiment, I’m barely concerned these days and the beer certainly doesn’t have any off-flavors, it’s just sweeter than I’d prefer, which I think is from the high mash temp.

That’s a lot of acid malt! I don’t even use that much for an all-pilsner grist. Is that because you’re doing a whole-volume mash, and need to ensure the ph is low enough when the mash is so diluted?

You got it, BIAB is “no sparge” so I typically use a touch more acid (malt or liquid) in the liquor when using that method, calculated using Bru’n Water.

Also, what was your OG and expected FG, out of curiosity? It’s hard to know how you under-attenuated. I’m guessing in the 1.060’s for OG?

Don’t have BS on this computer, but I’m pretty certain OG was 1.059 and expected FG was 1.017, so it finished at 4.5%.

Did you do any water treatments in addition to adding the acid malt?

Yep, per Bru’n Water, as I always do.

Sounds really similar to my recent experience trying to brew a stout!

Was trying to brew https://www.brewtoad.com/recipes/smooth-oatmeal-stout-4. Recipe called for a mash at 156, but I definitely overshot that for most of the time. OG ended up being 1.062, but FG only 1.028.

I really need to learn how to control the mash temp better.

Good to be in similar company! Haha. I have a mash temp exBEERiment planned (148 vs 155) and now I’m even more excited for the results. If you want to email me (brulosopher@gmail.com), I’m happy to help you troubleshoot your mash temp issues, I’ve come up with a few tricks over the last few years that have really helped (disregard the fact I fucked up the temp on this batch). Cheers!

On the no Sparge BIAB mashes or full volume mashing (whatever you want to call it), would that high of a mash temp denature quite a bit more of the beta amylase enzymes? Could that be the problem with the low attenuation?

Also what were Wilser’s exact techniques on his single vessel brewing?

I believe the higher mash temp is to blame for the low attenuation, for sure. The only thing I did differently than Wilser, as far as I can tell by our conversations at least, is not put an unused garbage bag over the lid, which he said is convenient because it starts to fill up with CO2 as fermentation takes off.

So just tie off a bag around the whole kettle? Sweet. I’m gonna try this out with a small batch some time.

Great read! I loved that you hung in there and finished the brew! I love home brewing. It’s like something crazy will happen even if everything is planned.

Hangin’ tough, baby! Thanks for the support, man, I appreciate it. Cheers!

So it looks like you’ve got something to give in exchange for my cider and pale ale!

Of course!

157 might have been too high with those darker grains, also I what did you do about letting CO2 out? Did the lid have an airlock thingy or what? Did I miss that part, I do skim, I confess

Hey Scott! Way too warm. No airlock, the lid just kept flies from getting in, not co2 from getting out.

In theory I would say that is a kind of airlock =) With all that CO2 forming inside the kettle, trying to get out, chances are oxygen and bacteria will have a very hard time getting in, and excessive CO2 will be let out once the pressure is high enough to lift the lid, like a pressure vent… should work just fine…

I was scared you might have an exploding kettle chief, glad you’re safe

Couple of things to think about if you ever do this again. You didn’t mention the use of O2 in the post… You’re not new so I’d guess you used it but if you didn’t that may have had an impact on your attenuation. Also rather than putting the lid on the kettle consider an “open fermentation”. Use a large hairband or other strap to hold a piece of voile fabric (the material your BIAB bag is made of) over the top of the fermentor/kettle.

I’ve been brewing for a long time and do so often, I’ve never once used pure O2. I’ve also never had a stalled fermentation, perhaps that was part of the issue here.

Open fermentation would be fun.

I probably said that wrong. I’m not convinced one needs to use pure O2 but my understanding is that some form of aeration for the liquid strains is essential for a heathy fermentation. I didn’t see that in your process.

No, you’re right. I did slosh it up real good while chilling, but that’s it. I usually use a $4 wort spray aerator, it’s worked fine so far.

I’d like to see a new test on this

I am considering this method, with the hope to reduce my required storage space for equipment. I am planning on using a stainless fermentation bucket with a flat bottom. That could double as a brew pot, although I’m a little concerned about it holding up to an open flame. When paired with the biab method I could potentially reduce gear and time needed for brew days. Hopefully without sacrificing significant changes in quality.

I have experienced with using brown malt is that it may take a lot longer to ferment particularly if used in high percentages in the grist.

I am from Aus and our brown malt from years ago used to produce astringency as well as being slow to ferment.

As such I stopped using it with porters.

Maybe your wort could have benefitted by a bit of aeration or axygen.

I like the look of the recipe minus the brown malt so I might borrow it and have a crack at it.

I will probably use a combination of the Caramunich darks to substitute for the brown although in fairness I do note there are a couple of different brown malts now available in Aus now.