Author: Jake Huolihan

Hot side Aeration (HSA) is often cited as detrimental to long term stability of beer. It has been extensively studied at a professional level with results demonstrating that when wort is between 120°F-212°F/49°C-100°C, oxygen pickup can increase the concentration of oxidized fatty acids that are carried forward into the finished beer and cause off-flavors. HSA has been a focus of discussion and experimentation among homebrewers, with many ultimately choosing to view it as a myth, a brewing bogeyman that’s perhaps more an issue for larger scale commercial operations.

However, some brewers maintain their position that HSA does indeed have an impact, arguing that previous experiments designed to test the effects HSA has on beer were in some way flawed. Following publication of the first xBmt on HSA where participants were unable to reliably distinguish a high HSA beer from a low HSA beer, some people contended the non-significant results were due to the fact data was collected when the beer was fresh, that the off-flavors associated with HSA require time to develop.

I’ve personally stuck with trying to keep HSA to a minimum in my brewing because, well, better safe than sorry. Having never noticed much of a qualitative difference between my low HSA beers and those of other brewers I know who pay it no mind, I thought it would be useful to revisit the variable of HSA, this time focusing on how it effects beer over time.

| PURPOSE |

To evaluate the the differences between two beers of the same recipe aged for a period of 8 weeks where one was intentionally aerated at numerous points in the brewing process prior to the wort being chilled while the other was not.

| METHODS |

I was in the mood for a simple dark lager and thought it’d work well for this xBmt given the aging component.

Dark Lager Recipe

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 28.5 IBUs | 18.9 SRM | 1.054 | 1.014 | 5.2 % |

| Actuals | 1.054 | 1.012 | 5.5 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner (2 Row) Bel | 9.75 lbs | 86.67 |

| Honey Malt | 9 oz | 5 |

| Melanoiden Malt | 9 oz | 5 |

| BlackPrinz | 6 oz | 3.33 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Nugget | 11 g | 60 min | Boil | Pellet | 13 |

| Saaz | 29 g | 30 min | Boil | Pellet | 3.8 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Saflager S-189 (S-189) | Fermentis | 74% | 48.2°F - 71.6°F |

Notes

| Water Profile: Ca 7 | Mg 2 | Na 2 | SO4 5 | Cl 5 | HCO3 15 | pH 5.4 |

Download

| Download this recipe's BeerXML file |

A day before brewing, I prepared a traditional viability starter of Saflager S-189 dry lager yeast to reach the cell count recommended by my preferred calculator.

Later that evening, I collected the proper volume of brewing water and adjusted it to my preferred profile in preparation for the following day’s brew. I awoke the following morning and immediately began heating my strike water.

As the liquor was coming to strike temperature, I measured out and milled my grains.

With the strike water slightly overheated, I transferred it to my converted cooler MLT, let it sit for a brief period to preheat, then mashed in once the water had dropped to the recommended strike temperature.

Rather than performing separate mashes, which could introduce extraneous variables, we decided it would be best to evenly split the sweet wort from a single mash prior to boiling then beat the shit out of one while treating the other like a frail kitten. During the 60 minute rest, I gently stirred the mash 3 times in 15 minute intervals, per my normal routine. Underletting the sparge water to reduce aeration as much as possible, I performed an otherwise standard batch sparge to collect the proper volume of sweet wort when the mash was complete.

With the entire volume of wort in a single kettle, I gently stirred to ensure homogenization, making sure not to splash it around, then transferred half to a second kettle.

As the wort was transferring, I began vigorously whipping the HSA half with a comically large wire whisk.

I did this throughout the duration of the transfer, which left my arm feeling like it was going to fall off. The temperature of the wort at this point was approximately 150°F/65°C. I staggered the start of each boil by 10 minutes, letting each roll for 60 minutes with hops added at the times stated in the recipe. I regularly beat the HSA batch throughout the boil at a rate of 1 minute every 20 minutes or so. Each wort was quickly chilled at the completion of their respective boil.

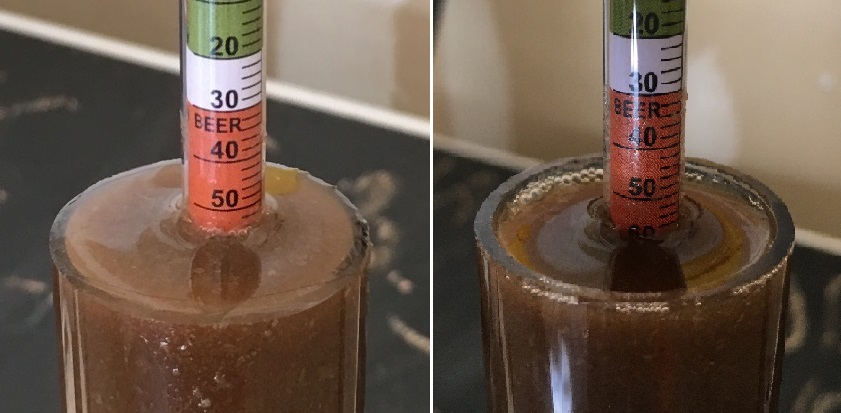

Hydrometer measurements at this point showed the HSA batch to be a couple SG points higher than the low HSA batch, which may very well be a function of something other than the variable of investigation, though I wondered if maybe the constant agitation of the HSA wort somehow led to increased evaporation.

I transferred equal amounts of wort from either kettle were transferred into fermentors that were then placed in my fermentation chamber to finish chilling. Both batches of wort had stabilized at my preferred fermentation temperature of 58°F/14°C by the following morning, so I decanted the starter then evenly split the yeast between each batch, hitting each with a 60 second dose of pure oxygen afterwards. I observed activity in the low HSA beer 12 hours after pitching yeast, while the HSA beer appeared to be lagging a bit.

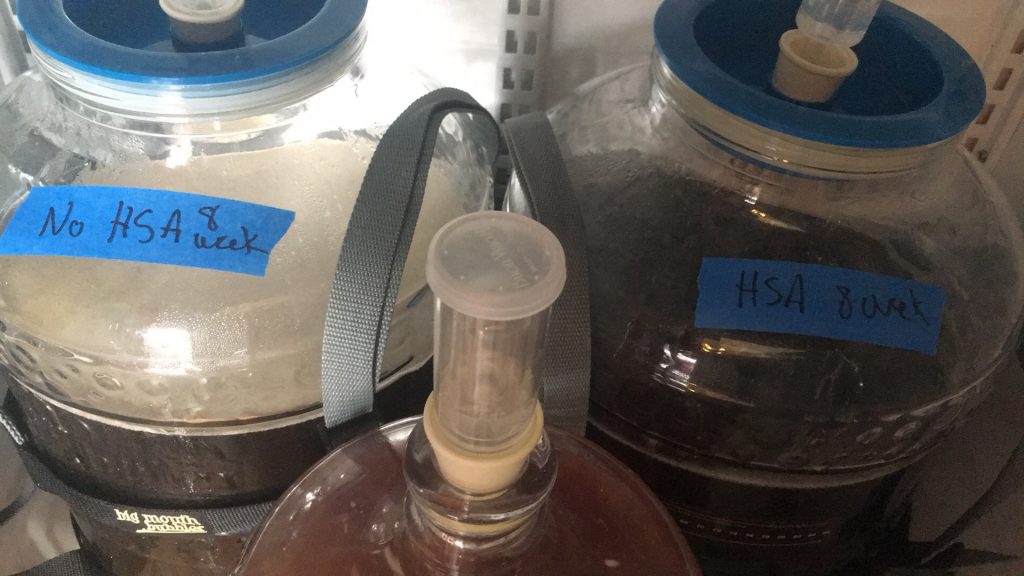

Just over 24 hours later, both beers appeared to be fermenting along nicely.

I began gently raising the fermentation temperature at this point in hopes of encouraging complete attenuation, ultimately reaching a peak of 70°F/22°C a week or so later. Initial hydrometer readings at 2 weeks in revealed both beers had likely finished fermenting. I gave them another few days before confirming FG had indeed been reached.

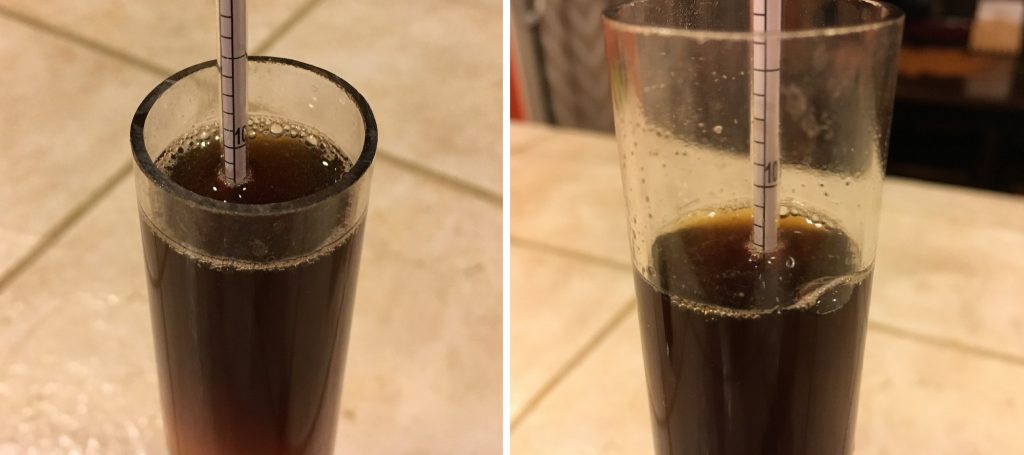

The beers were cold crashed and fined with gelatin before being kegged in separate 2.5 gallon corny kegs that were placed in my keezer on gas and left alone for 8 weeks, which we reasoned was more than enough time for any negative effects of HSA to manifest. After the tedious wait, when the time came to present these beers to participants, both were gorgeously clear and carbonated.

| RESULTS |

A panel of 27 people with varying degrees of experience participated in this xBmt. Each taster, blind to the variable being investigated, was served 2 samples of the high HSA beer and 1 sample of the low HSA beer in different colored opaque cups then instructed to select the unique sample. Given the sample size, a total of 14 correct selections (p<0.05) would have been required to achieve statistical significance, while only 9 tasters (p=0.57) chose the different beer. These results indicate participants were unable to reliably distinguish a beer produced with intentionally high HSA from one made using low HSA methods after both were aged for 8 weeks.

My Impressions: I pulled my first samples of these beers during a brew day video chat with the other contributors and immediately remarked how different the high HSA sample was from the low HSA sample. In a non-blind side by side comparison, I boasted about how easy this was going to be for me, a longtime HSA fearing brewer, to distinguish. Then, during another video chat later that day, I confidently did my first “blind” triangle test. First whiff… crap, those are similar, no biggie though… second whiff… nope, hmm… first taste… what the hell… second taste following a palate cleansing sip of water… shit! I got it wrong, I simply couldn’t tell them apart, my desire to have my beliefs confirm apparently influencing my perception. Over 4 additional attempts, I was right only once, leaving me resigned to the likelihood that a perceptible difference didn’t exist.

Out of curiosity, I entered the high HSA beer into a great competition hosted by the Fermentologists homebrew club, it was 6 weeks old at the time. I didn’t really have a specific style in mind when I brewed the beer but figured it most resembled a a Baltic Porter, so I entered it as that. Lo and behold, it took gold in the category and came up just a tad short in the BOS round.

| DISCUSSION |

The results of this xBmt corroborates previous findings demonstrating the inability for tasters to distinguish a high HSA beer from a low HSA beer, even after a couple months of aging. While the growing mound of evidence really does seem to support the idea that HSA may not be as big of an issue as many of us thought, particularly on the homebrew scale, there are other possible explanations some have posited as to why we’re not experiencing the expected negative effects. For example, since cold storage tends to slow down reaction rates, there’s a chance the off-flavors associated with HSA are more quickly expressed when beer is stored at warmer temperatures. Another curious hypothesis, is that the ingress of oxygen at all points during the brewing process, from milling through packaging, is enough to essentially mitigate the effects of HSA alone.

Or, maybe it really isn’t that big of a deal. As difficult as this is for me to swallow, these results, combined with the fact I’ve had many delicious beers made by brewers who don’t concern themselves with limiting HSA, have left me feeling inclined to release my grip on the conventional wisdom. I won’t be whipping my wort on the hot-side or anything silly like that, but I’ll admit to feeling more relaxed knowing a little splashing during transfers won’t ruin my beer.

Finally, an interesting anecdote– I administered the triangle test to a professional brewer from a fairly well known local brewery and he happened to accurately select the unique sample. In discussing the xBmt with him after he finished the survey, I learned he had a strong preference for the high HSA beer, which surprised both of us seeing as he takes effort to reduce HSA in his own brewing. This reminded me of something I once heard Dr. Charlie Bamforth say during an interview:

When you talk about flavor stability, you quickly, if you’re not careful, go into the realm of philosophy about what is right and what is wrong.

Such a poignant observation!

Feel free to share your thoughts on hot-side aeration and how it is potentially impacted by age in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

56 thoughts on “exBEERiment | Hot-Side Aeration: Evaluating The Impact Of Age On A Czech Dark Lager”

Interested to see what difference there would be if you bottled a few beers of each batch and stored them warm (like most beer is )

Otherwise thanks !

Agree. This is the method consumers have most likely experienced oxidation. I would think most homebrewers started and continue to and would be pertinent.

Most commercial beer? I honestly can’t remember the last time I stored beer I made warm, or in a bottle for that matter, haha. We have some warm storage xBmts on the list 🙂

not all of us have the luxury of kegs my friend …when i buy a third fridge it’ll be for extra ferment not serving .

Even the brewers i know who also keg often have some kegs stored warm until there’s space and a tap available

About half of my brew is bottled, and stored at room temperature until consumed. That can be a month or so in warm storage. Have heard some say bottled beer is best aged at room temp as it facilitates on going yeast action.

Thoughts ?

This is what I would like as well. Also, let’s be real, 8 weeks is not “aged” or old. Needs more time. 90 days would be the minimum but I would like to see the bottles stored like they would if you were a commercial brewery and shipped your beer to the store or a warehouse and it sat.

Great read and interesting stuff though. I personally have always tried to avoid has when possible cause, but ether safe than sorry and really it just takes a piece of tubing. Appreciate the efforts and look forward to more! Cheers

one other possible confounded is that dark malts hav a strong anti-oxidant effect. Just a thought. Great XBMT!

I was wondering this as well though I have had dark beers that were definitely oxidized.

I have never worried about HSA and I won’t worry about it in the future.

To my little understanding, the worst time for HSA is between the boil and the chilling. Lots of homebrewers do not even chill their beer (looking at you, Australia!), and this is where the averse effects of HSA are said to be by some. How realistic is it to make an exBeeriment with no-chill, and constant aeration of the wort during the cooling phase? Cheers!

Don’t most people stir the hell out of the wort during chilling? I do.

Yup. I basically use my IC as a whisk.

I generally lightly stir with the IC (no splashing) as I’m chilling my wort. The HSA was definitely splashed a lot during chilling as well.

I did not know that! I do not use an immersion chiller myself 🙂 @Jake: Ah! So the HSA wort *was* splashed during chilling; I believe this is worth mentioning in the article 🙂 Cheers!

Oi ! it’s pretty hot down here , water is scarce and if i spend the time chilling my beer properly a dingo might steal my baby , have to saddle a handy kangaroo and chase the bugger ! any other cliches i should add here ?

i do actually actively chill my beer , ice bath is simple but it does work .

interesting idea though re; aerating during the no chill , i could throw a cube in back of my work ute and drive around .

I found it interesting that the high HSA wort was a couple of SG points higher than the low HSA wort. Causation through correlation says the whisking, which was the only different process between the two kettles during that time, was THE culprit for this variable. In the end, it looks like it had little difference in the final xBmt result.

Great xBmt! Left me asking one question, though. Was there a preference of either beer by the participants?

@Jake Both HSA and Oxidation are packaging concerns. When the beer leaves the brewery who knows what’s happening to it in the real world. Unrefrigerated trucks, poor storage at retailers, etc. There’s a beersmith podcast with Charlie Bamforth that is a good intro to these concerns. It’s all about how the bottle or can is handled. If you’re kegging and keeping in a state of 1-2c the whole time you’re not going to notice any difference. If you have one sit Infront of a store window in direct sunlight at 25c for a week it’s going to impact flavor. At UC Davis they test for HSA/oxidation/stayling by heating a sample to 150+f for several hours to mimic storage at room temperature for several months. According to Charlie, however, HSA is the last thing a brewer should be concerned with as the storage temp and handling are the primary concerns for the reactions that come from HSA.

You write “I wondered if maybe the constant agitation of the HSA wort somehow led to increased evaporation.”; isn’t that something you can simply check with the final volume? Cheers!

The resolution on my kettles is .5 gallons. Both batches finished boiling/cooling within the resolution of that specific interval. It’s tough for me to know if one was at say 5.85 versus 5.6 with much accuracy.

Ah, shoot. But let’s keep in mind that whatever caused that, it did not even have an impact on the final beer. Man, the science behind RDWHAHB is amazing 🙂 Thanks for your answers!

I’ve been sticking a paint stir on the end of a drill in combination with my IC for years. I’m pretty well convinced that HSA isn’t a practical concern at the homebrew level. I’ve never actually done a controlled experiment, but I’ve made many different styles that have aged in different conditions for different periods of time and never experienced any noticeable oxidation, HSA or otherwise. I’ve had of flavors for various reasons, but not oxidation specifically.

Oxidation at mash temps happens in minutes. By just raising you strike water to temp and doughing in, you’re oxidizing the mash with the dissolved oxygen already in the water. Both beers may have ultimately been just as oxidized after sitting at high temps for the length of the mash

Every brewing site I go to, there you are, Brian, with your bad spelling, faulty logic, and mini-mash mantra.

Thanks for sharing your work, Jake!

I hope you read the comments below as constructive.

When a scientist wants to do an experiment, first performs a literature search to find out how previous experiments were designed and what results were obtained in these experiments. The comparison made by those finding HSO is not control vs super-oxidation but control vs no-oxidation (the point being that they believe the control is oxidized unless it is protected from oxygen). The comparisons in the literature are also made in light-colored, flavorful lagers (ie, Munich Helles, or German Pils). It is theoretically possible that oxidation can taste better than non-oxidized beers in certain styles. We all know that until recently, BJCP guidelines for some styles were based on the oxidized characters of the listed beers (some British styles); we also know that some beers get better with time (oxidation).

Another important comment is that there has to be consistency in one’s method. A scientist should be able to make a consistent control beer over and over. Brewing an international dark lager and coming up with a good Baltic porter is a nice, but as scientist one needs to realize that one did not meet the experiment goal, which was to make a very good International Dark Lager as the control beer.

May be your findings can be interpreted as oxidation of the dark malts that you used can lead to interesting porter-like flavors. Dalgliesh describes increases in caramelly and currant (ribes) flavors over time and many tasters may like these flavors in a Baltic porter but not in a dark lager.

Merry Christmas and thanks for sharing 🙂

I would posit that the fruity characters in this beer are a result of the honey malt after my experience in the honey v melanoidin xbmt. I also did not really set out to brew an international dark lager in this xbmt, simply a lager, which was dark based on ingredients I had left over from said xbmt.

Everyone has a different idea of “aging” i suppose. For me personally, 6 weeks with a dark beer is barely any time at all…

Somehow I knew the choice of a dark lager would “invalidate” your results in the eyes of some

That’s fine by me, all results should be looked at for reasonability in application to other beers. Honestly the result raises a few more questions in my mind than it answers. More testing required as always!

You learn in research that if you want to validate a previous experiment, you match the experimental conditions of the previous experiment as closely as possible. If you change the beer type, you do not know whether you got different results because the other experiment was performed incorrectly, because your experiment was performed incorrectly, or because you changed the beer type.

In regards to a “lighter” beer style, for several months now, I’ve been using my boil kettle for step mashes – hefe mostly. At mash out, since it has a false bottom, I dump the whole thing into my 10 gallon Igloo cooler and let it set for ~20 minutes. The amount of air introduced is huge. I typically will have 4 to 5 inches or more of foam sitting on top of the wort which does not diminish until I vorlauf and sparge. I’ll generally keg 3 gallons and bottle 2. Only difference I’ve seen/tasted: Keg is a bit clearer and dryer, bottle is a bit more malty and fuller.

After talking Colin Kaminski a while back I care very little about HSA. He explained that a good fermentation will clean up any of the off flavors associated with it. His process proved it to me with his mash tun re-circulation drain continuously falling into a open grant. Plenty of foam but no HSA..

It is an open debate. Bamforth thinks the effect exist but is too small compared with cold-side oxidation and keeping the beer cold. Narziss and Künze both think it is important. The late George Fix agreed with the Germans. The published data show a minor effect, that is why it is important to reproduce the experiment in delicate beers very well brewed and with little room to hide differences. Also, the published data does not have splashing vs normal, but they think normal is HSO and the experimental treatment is low oxygen.

I’m inclined to think that such effects do matter, especially on the commercial scale where shipping temperature and time can potentially greatly increase staling. Will definitely be interested to explore low O-2 on the hot side compared to “normal” and see if that indeed does matter on our scale where beer is basically set to serving temperature upon FG and never warmed again. Cheers

Thanks Jake 🙂

Happy Brew Year !!

“it is important to reproduce the experiment in delicate beers very well brewed and with little room to hide differences.”

Nope. Not important for me at least (and probably 98% readers of this site). They brew the exact same beer and change one variable. It’s a real experiment, it’s simple, it speaks for itself, and it’s incredible useful to readers of this site – homebrewers.

Please brulosophy don’t brew pale lagers just for the sake of it. Brew a variety of styles because that’s what people do. thanks!

What about the claims of the LODO crowd that HSA already occurred in the mash for both beers and thus the “damage” was already done for both beers?

We haven’t done an xBmt on this yet and they have not provided blind data to support this point yet. I’m personally pretty interested in this process and fascinated to explore it.

you could try googling “lodo mini mash” and do that test, perhaps first with yourself and then a larger batch with participants. although it isn’t quite beer, I think it would be interesting to report on

You should try again on a light beer or pale ale To figure out The real Impact . On a porter is dificult and The results are not reliable

Will definitely try it again with a different beer. I’m not sure the results are not reliable, they at least speak to this type of beer

Hi Jake,

What are the references for “It has been extensively studied at a professional level with results demonstrating that when wort is between 120°F-212°F/49°C-100°C, oxygen pickup can increase the concentration of oxidized fatty acids that are carried forward into the finished beer and cause off-flavors.”

I’m surprised the argument for HSA is time for the off flavors to develop.

I don’t mean to discredit your efforts because I love your experiments but in my opinion this experiment is flawed because you had high levels of oxygen in your mash water (~4-8 ppm) as soon as you started, oxidising your wort throughout your mash with hot side temperatures.

So of course both beers in your experiment are going to taste identical, as they’re both oxidised already from the get go.

To do this experiment properly you need to eliminate O2 during the entire process, hot and cold throughout.

As soon as your crushed grain is exposed to oxygen you’re going to end up with less flavor and an oxidised wort than you would have had otherwise. Hence why the Germans wet crush their grain with oxygen purged water under a nitrogen blanket and dough in with oxygen free water.

Definitely on the list but those are a lot of presumptions.

In fairness to the Brülosophy team, there are two issues that need to be discussed separately.

For an experiment to be valid (not flawed) one just needs to brew two beers that are identical except for the experimental variable, and the beers in both style and quality have to minimize statistical noise (strong/ off flavors and aromas) so if there is a difference between the beers, it can be picked up.

If an experiment wants to add to the body of literature on a topic, HSA in this case, then the researchers have to do a thorough literature review of previous experiments and decide whether their experiment will challenge the conclusions of the original experiments (in this case one must replicate the original experimental conditions as closely as possible), and/or will attempt to extend the validity of the original experiments to other beer styles or experimental conditions.

This experiment is designed to explore a completely new topic, HS Overaeration, and compare it to a control. It does not add anything to the HSA literature as described by Narziss, Künze, Krotenhaller, Wurzbacher, George Fix and others.

BTW – as a side comment to those stating that this experiment is just checking the validity of pro-brewers data at the homebrew level, please be aware ALL published experiments are conducted at the homebrew level. Nobody uses a 10 or 50 hectoliter system to do research. Research is done in pilot breweries with systems ranging from 20 to 200 liters (5-50 gallons) so, it is more logical to extrapolate their data to the homebrew level than it is to extrapolate it to a big brewery.

well, let’s start by a simple observation. This is not an academic paper, it’s just an exbeeriment on topics hb are interested in. So you cant argue that experiment are conducted differently. Yes it’s true because experiment are done by scientists and researchers with tons of lab instruments, not with homebrewing equip. That said, scientists are often wrong because in the last 3 year we saw major changes in the way brewing industry moved changing production process, so even if you demonstrate a phenomenon it’s just a little part of the picture because the year later someone demonstates something different. What is important is the taste, no matter if it’s right, wrong, if there is literature or studies and i come here because that’s the way brulosophy act.

To me this xbt’s really helpful.

ty from Italy.

P.s. Sorry for my bad english.

Cheers!

Any experiments involving oxidation require the product to be subject to room temperatures for a period of time. Otherwise it’s just a waste of time doing the exp.

While I’m not sure this specific test was a waste of time, i definitely agreed warm stored beer is an interesting variable.

HSA is a concern for commercial brewers, whose beers might be sat on a shelf for a year or two, before being consumed. How long were your beers stored before being consumed? LOL! You guys are experts, right? WTF!?

This paper is in huge contrast to the HSA exbeeriment results. What to do ??

http://www.germanbrewing.net/docs/Brewing-Bavarian-Helles.pdf

The paper does not provide original research, but refers the reader to the research and experience of most large pale lager brewers in Germany who mash in low oxygen environments.

This is a very complex topic with a lot of rabbit holes.

As to the experiment, not achieving a statistically significant difference does not mean that beers are similar, so there is no contradiction.

Thanks for your reply. Luke’s post on Jan 10, 2017 seems to make a good point about the exbeeriment not addressing the oxygen taken in during the mash, copied below –

I don’t mean to discredit your efforts because I love your experiments but in my opinion this experiment is flawed because you had high levels of oxygen in your mash water (~4-8 ppm) as soon as you started, oxidising your wort throughout your mash with hot side temperatures.

So of course both beers in your experiment are going to taste identical, as they’re both oxidised already from the get go.

To do this experiment properly you need to eliminate O2 during the entire process, hot and cold throughout.

As soon as your crushed grain is exposed to oxygen you’re going to end up with less flavor and an oxidised wort than you would have had otherwise. Hence why the Germans wet crush their grain with oxygen purged water under a nitrogen blanket and dough in with oxygen free water.

I am not affiliated with the Brü team, so no effort discredited.

Couple weeks ago I brewed Double IPA with little knowledge of HSA. This weekend I’m going to bottle it. It’s interesting to see how it comes out. At 80C/176F just poured the beer through 400 micron filter to fermenting vessel from about 3 feet high. Well let’s see how it tastes.

Lol, I’d never do that dave an xbmt but who knows!

I have been having some oxidation issues. I think the main culprit is HSA. It’s happening I think because I have been not chilling the wort enough before transferring to the fermenter. I have been transferring at 120-130f splashing into the fermenter. Then I put it in the garage and wait overnight for it to cool. It tastes okay after it’s done fermenting. But when I add dry hops (even after I purge the space with co2) , I think that is when the HSA shows it’s face.