Author: Marshall Schott

A few months ago, Robb Burden, owner of Southern Hills Homebrew Supply, announced that he’d combined 59 packs of 25 different strains of almost expired yeast into a 5 gallon batch of starter wort, the slurry of which of he planned to split up and dole out to interested homebrewers. Boring purist that I am, I was hesitant to request any samples at first, happy to stick with the reliable single strains I’ve come to appreciate. Then as news of this so called Frankenyeast blend began to spread, Dan Paris from the In Bounds Brewing blog suggested this might be an ideal yeast to use for yet another fermentation temperature xBmt, explaining a warmer fermentation ought to encourage the expression of esters from the plethora of English strains in the mix while a cooler fermentation should favor the less expressive yeasts.

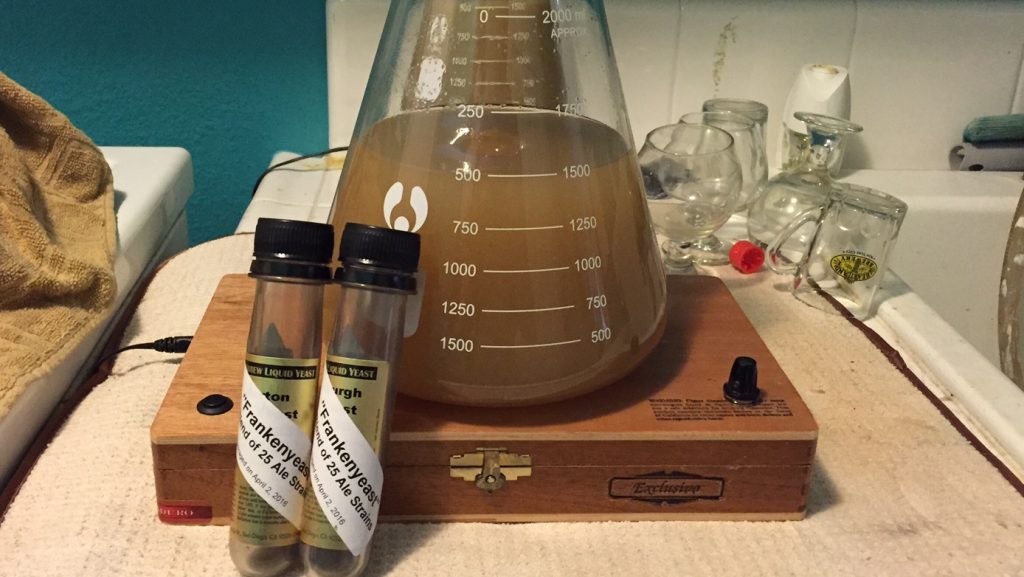

Given the unexpectedly interesting results from the prior xBmts on this variable, I agreed with Dan that the Frankenyeast blend provided a rare opportunity to test a unique facet of fermentation temperature and put in my request for a couple samples.

| PURPOSE |

To evaluate the differences between 2 beers of the same recipe split into separate fermentors and fermented with the same “Frankenyeast” yeast blend where was half fermented cool (60˚F/15.5˚C) and the other half fermented warm (73˚F/22.8˚C).

| METHODS |

For this xBmt, I went with a play on my Tiny Bottom Pale Ale recipe using different hops, mostly because I hadn’t had an easy drinking Pale Ale on tap for awhile.

Frankenyeast Pale Ale

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 11 gal | 60 min | 42.5 IBUs | 8.1 SRM | 1.050 | 1.008 | 5.6 % |

| Actuals | 1.05 | 1.004 | 6.0 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Malt, 2 row (Gambrinus) | 16.5 lbs | 73.13 |

| Vienna Malt | 2.812 lbs | 12.47 |

| Caramel/Crystal Malt - 15L | 1.5 lbs | 6.65 |

| Victory Malt | 1 lbs | 4.43 |

| Caramel/Crystal Malt - 60L | 12 oz | 3.32 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Columbus (Tomahawk) | 21 g | 60 min | First Wort | Pellet | 14.1 |

| Amarillo | 28 g | 25 min | Boil | Pellet | 8.9 |

| Amarillo | 28 g | 10 min | Boil | Pellet | 8.9 |

| Cascade Hops | 21 g | 10 min | Boil | Pellet | 6.1 |

| Cascade, New Zealand | 70 g | 2 min | Boil | Pellet | 6.1 |

| Amarillo | 28 g | 2 min | Boil | Pellet | 8.2 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Frankenyeast | Frank | 77% | 65°F - 70°F |

Download

| Download this recipe's BeerXML file |

Two days before brewing, I pitched both vials of Frankenyeast into a single yeast starter in order to ensure equality between both batches.

Since this was a rare afternoon brew day, I weighed out and milled the grain while my strike water was coming to temp.

After transferring the slightly overheated strike water to my MLT for pre-heating, I mashed in to hit a slightly lower than planned mash temperature. Meh.

Since this batch would be split post-boil, I brewed a standard 10 gallon batch using the mash in a bag (MIAB) batch sparge method. After a 60 minute rest, I collected the first runnings then added the sparge water, which I ran off to collect the proper pre-boil volume of sweet wort.

With the flame on full blast under my full kettle, the was boiling vigorously within about 15 minutes.

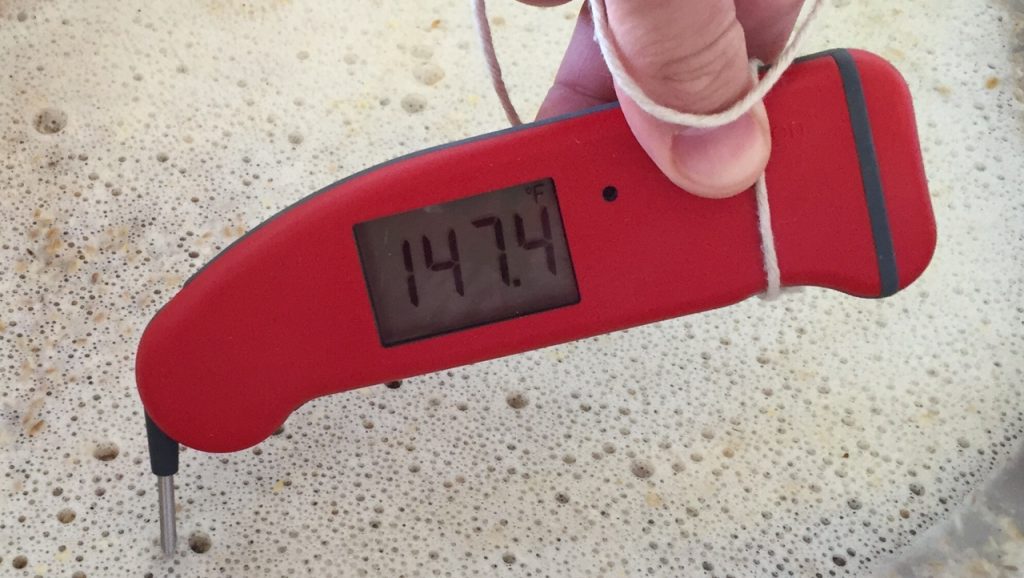

Hops were added over the hourlong boil, after which I quickly chilled the wort to a few degrees above my groundwater temperature, which is fairly warm this time of year.

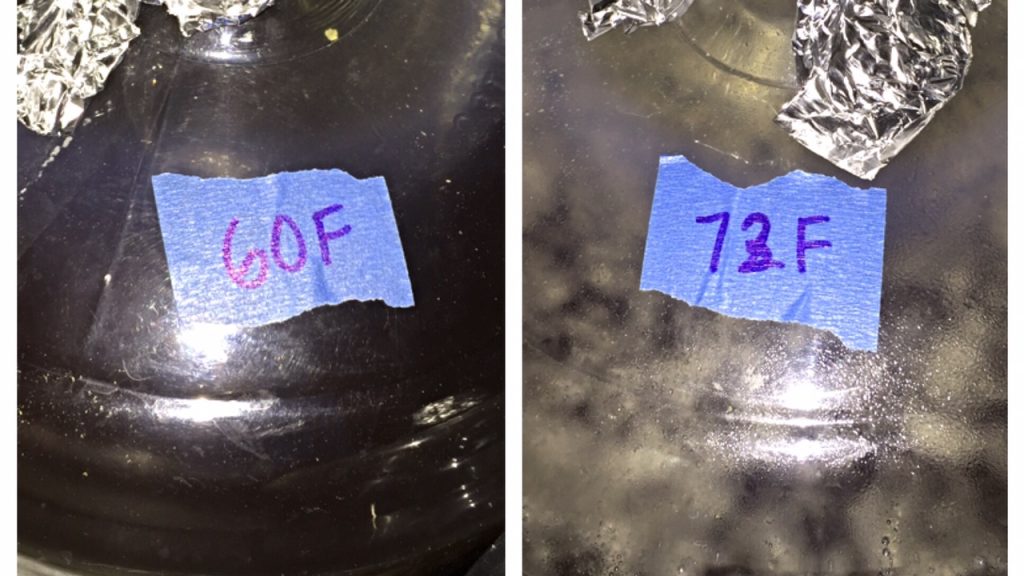

The chilled wort was equally split between two 6 gallon PET carboys then one was placed in a chamber controlled to 60˚F/15.5˚C and the other was placed in a chamber controlled to 73˚F/22.8˚C. While the warm ferment batch was ready to pitch after about an hour, I waited until the cool ferment wort had reached its target fermentation temperature before splitting the yeast starter between the carboys. Twelve hours later, differences were easily noticeable.

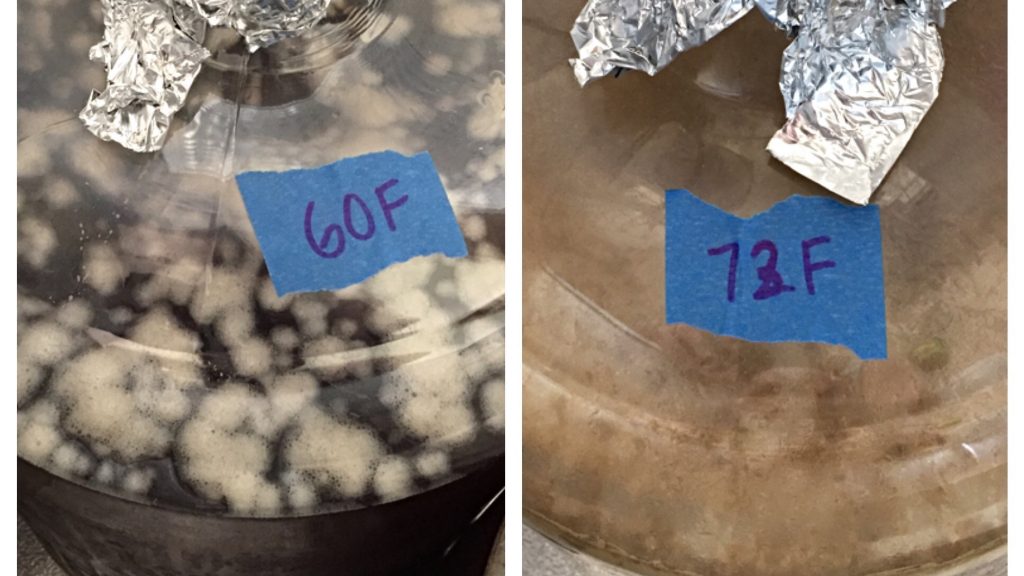

After another day, the cool ferment beer was finally starting to show signs of activity, its appearance quite a bit different than its warm ferment counterpart.

It took another 12 hours or so for a full kräusen to develop on the cool ferment batch, and as expected, it required more time to finish fermenting. After 6 days, the warm ferment beer looked to be done while the cool ferment beer was still chugging along.

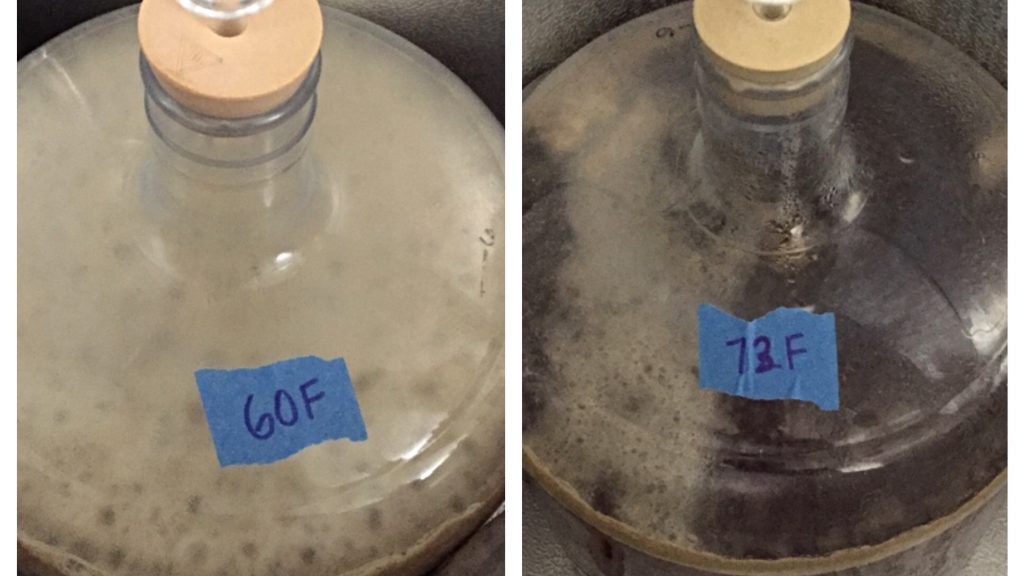

The kräusen on the cool ferment batch finally drop 11 days after the yeast was pitched, and indication fermentation was nearing completion, so I took preliminary hydrometer measurements that showed both beers were at the same SG.

I left the beers alone at their fermentation temperatures while I attended a family event away from home, taking second hydrometer measurements when I returned that confirmed both had indeed reached FG. It was at this point I cold crashed, fined with gelatin, and kegged the beers.

The full kegs were placed in my full chamber and hit with 40 psi of CO2 for about 24 hours before being dropped to serving pressure. When it came time to collect data the following weekend, the beers were carbonated, clear, and ready to present to tasters!

| RESULTS |

A total of 21 people participated in this xBmt, each blindly served 1 sample of the cool ferment beer and 2 samples of the warm ferment beer. While 12 tasters (p<0.05) would have had to accurately identified the unique sample in order to reach statistical significance, only 10 (p=0.12) were able to do so, suggesting the participants in this xBmt were not able to reliably distinguish a beer fermented with the Frankenyeast blend at 60˚F/15.5˚C from the same beer fermented at 73˚F/22.8˚C.

Given the variable of investigation, I thought it’d be interesting to share some of the blind comparative evaluation data, though it should be interpreted with caution since this xBmt failed to reach significance. Of the 10 people who correctly chose the cool fermented beer as being unique in the triangle test, 5 said they preferred it over the warm ferment sample, 3 reported preferring the warm ferment beer, 1 had no preference despite noticing a difference, and 1 person felt there was no difference between the beers. Furthermore, in conversations following completion of survey and revelation of the variable, many of the participants incorrectly believed the warm ferment beer to be the one that was fermented cool.

My Impressions: I made 6 triangle test attempts served to me by different people at different times with the unique beer being picked by the server. I was correct twice, which is exactly chance, and exactly opposite of what I thought would be the case. Similar to Jake’s experience with Frankenyeast, both of these beers were super clean with very little of the esters I expected given the plethora of English yeast strains included in the blend. Crisp and refreshing with an odd though not off-putting character I can’t really describe, neither of these beers were perfect, but both were definitely drinkable. I didn’t pull any yeast off for future use, which I’m not distraught about.

| DISCUSSION |

Two of the yeasts in the Frankenyeast blend were WLP036 Dusseldorf Alt and WLP080 Cream Ale Blend, the former a hybrid strain that works well at cooler temperatures and the latter a blend that includes an actual lager (s. pastorianus) strain. While 60˚F/15.5˚C is certainly warmer than traditional lager fermentation temperatures, I fully expected these yeasts to express themselves more in the cool ferment beer, while I was convinced the warm ferment beer would have been an ester bomb, especially since 73˚F/22.8˚C is quite a bit warmer than most would ferment with anything other than a Saison strain. The fact they were so similar has yet again shaken my conviction that fermentation temperature is one of the most important components of brewing good beer.

These beers should have been different!

I honestly don’t get how a 13˚F/7˚C spread using a yeast blend with strains known for their ester production didn’t produce beers so vastly disparate in character that every participant could distinguish them. I couldn’t even tell them apart and I brewed the damn beers! One plausible explanation that I’ve discussed with others following every other xBmt focused on this variable is that temperature alone may not be the important factor, but rather precise control of fermentation temperature, with some speculating temperature variance is what causes problems. This is definitely something we’ll be getting to at some point soon. Until then, I’ll remain stumped and confused.

If you have thoughts about this xBmt, or if you happened to be one of the few people who got some Frankenyeast, please share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

30 thoughts on “exBEERiment | Fermentation Temperature: Frankenyeast Blend In An American Pale Ale”

So yeast strains collected into a mixture will go through competition for nutrients and result in certain strains taking hold in the population. Now considering the vials added to this mixture (varying levels of viable cells per tube and varying tubes per strain) it is entirely plausible there are actually only a few representative strains with many of the initial ones probably dying out. I’m still surprised this experiment resulted in what was essentially the same beer, but if some super clean strain ended up the victor in the population, this would help to explain the result.

Exactly what i was going to say something i learned trying to do my own yeast blends with usually disappointing results

Not a yeast physiologist but is it possible that esters produced by one strain are consumed by another

Temperature variance. Now that sounds about right! How about a temp controlled beer vs a room temp/let it ride xbmnt? Maybe with Conan?

Amazing! As a related token of dubious knowledge, the brewer at Fourpure told me about a rule to get clove/banana in Hefeweizen without the hassle: the 30 rule. It states that the pitch temperature and the fermentation temperature should add up to 30°C, a common choice being 9°C and 21°C. In any case, they argue that the yeast produced at 9°C does weird things at 21°C, or something like that. Also, with some people arguing that lots of the aroma compounds being created at the reproduction phase, it may be interesting to underpitch in these exbeeriments. Happy brewing!

Too much hops to evaluate ester production?

Perhaps single bittering addition and 15-25 IBU would fit better to evaluate this parameter?

I’m highly doubtful that’s the case… but perhaps.

I was thinking the same thing. Fruity hop aromas can be confused with esters and phenols, so maybe the “clean” beer still tasted similar to the estery one?

I doubt it, but if that’s the case, it still shocks me that a beer moderately hopped with US fruity hops can be fermented at 73F and still be indistinguishable from one fermented at 60F.

I have the same feeling as Jacob Hornick.

More and more you are showing that the key is temp stability, not the temp itself, except in extreme situations.

These exbeeriments totally stump me. I swear my beers started tasting cleaner/better/consistent when I began to control my temps. Maybe it’s just my perception changing because I “feel” like I’m doing everything right.

I think the biggest turning point for me beer was when I started controlling my water profiles by adding mineral’s and lactic acid, even more than fermentation temp. This is finally what gave my IPA’s that flavorful hoppy crispness I was missing.

If you go on the forums, you’ll read temp control is the most fundamental thing to get nailed down first and everything else is icing on the cake, maybe this isn’t the case…

I share your experience.

What about doing an experiment where one beer is temperature controlled and another is not? Ferment them both at vaguely the same temperature, but let one free float and one be temp controlled. Maybe more of the “better beer” with temperature control comes from actually keeping the wort/beer/yeast at a fairly even temperature and not allowing temperature swings as fermentation heats it up a bunch and then cools off, or day/night/daily temperature swings changing things around.

Just a thought. I also feel like my beers improved some with temperature control, but I also ferment in my basement on a concrete slab that stays a steady 72F on the slab in the summer and 67F on the slab in the winter. Fermentation will of course allow it to rise higher than that, but generally not a huge amount with the heatsink of the concrete slab.

I don’t notice much difference in temperature, other than with a couple of strains, having impacts on beer results, but I DO notice some difference with just plain temperature control. Maybe the next experibeer test?

For the first ferm temp xBmt, that’s sort of what I did– controlled vs. uncontrolled, though the former was kept a bit cooler. Still, no difference.

Probably just because it is relevant to my brewing environment, but I would be curious if stable temp around 72F would be very different from uncontrolled at ambient 70F-72F. I’m an apartment dweller and based on my neighbors’ temperature preferences that’s where my apartment settles out without using my own AC / heat, pretty much year round. While your first ferm temperature experiment did test the stability factor, it didn’t test it getting significantly out of the manufacturer’s recommended temperature range, and an ambient temp around 70F, (and possibly a higher OG beer) would be a version of this experiment that I would find very interesting. Love the site, thanks for doing these.

You still are “controlling” temp by keeping it steady, but the choice of temp is the variable this is looking at. Meaning if you keep temp steady, there is prob a range of temps that will produce almost identical beer

My basement is 65-75 year round so I’m holding off on the ferm chamber until one of these experiments produces a dramatic difference. Unless I missed one, most of them have no or a small difference, with no horrible beers produced so far.

I’ve read most of your exbeeriments with many of variables I expected to matter failing to reach significance. I agree with the idea Michaël mentioned above. In all of these exbeeriments you are typically making a large starter using a stir plate. I completely agree with this practice when brewing but I’m wondering if pitching the proper amount of yeast is allowing many of these other variables to have less of an impact than expected.

Perhaps underpitching by a set amount would bring out more of the flavor differences you were expecting at the different fermentation temp.

Potentially!

I agree, but under-pitching is not something that is all too common. You may do it when you are new to the hobby but most likely because you just don’t know yet.

Ultimately finding out that a few key things done right mask all the other ‘bad’ practices would be kind of awesome.

Great, another WTF moment!

I too am surprised on this discovery of yours Marshall. Please get to the ferm chamber v no ferm chamber clash soon! Hopefully the non will include a strong swing in temps so happy hourly monitoring there! And maybe a SMASH or DMASH? American ale yeast too??

Go ahead mess with me and make me question ferm temps, I dare ya!

Now if you tip the water additions apple cart…. my brew world will be shattered!

Thanks for your exbeeriments!!

Jacob Hornick has it. As a microbial ecologist strain competition is the first thing I thought of.

Props man. Really like reading your articles. You have a fun and sarcastic way of writing which is enjoyable to read. And after all, were brewing beer. It shouldn’t read like a textbook. Keep up the good work. If u ever find yourself in Maui, gotta shitload of homebrew for ya.

I suspect that “steady temperature = better beer” is another myth waiting to be busted.

Fermenting cold is more about excluding wild yeasts than suppressing esters. Lagers were traditionally cold fermented to make sure only the lager yeast strain flourished, which ensured a particular taste. Wild yeasts can’t hack it at under 55 F.

It’s not all about taste though. Warm-fermented drinks like red wine and real ale have higher levels of congeners such as fusel alcohols. You might not taste the difference, but the after effects of drinking too much are another matter.

Somewhere along the way, homebrewers have confused the benefits of cold fermentation with flavour control and we now see endless posts and blogs extolling the virtues of brew fridges – “took my beer to the next level”; “impossible to make good beer without temperature control”; “ferment cold for a clean taste”; yada yada. All bullshit, but that’s not to say there aren’t good reasons to ferment on the cold side.

As always thank you to brulosophy and marshall For doing these experiments, teaching me so much, and pushing the boundaries of Brewing thinking.

The overriding point I would like to make about fermentation temperature control is this. All of these experiments most of which are inconclusive and when it has not been the difference has been perceived as small. Now consider this extremely small difference how it relates to a Brewer. Most of us don’t make two batches with different variables and compare them. So without a batch to compare against how is this small small difference going to matter. And that being said matter so much that you would post defensive and passionate argumentation online.

Sorry one last thought. Consider that 10 out of 21 people could tell the difference in this experiment. How many could tell the difference if a quarter teaspoon of cinnamon was stirred in. These tasters have good palettes especially if they have done these tests before. How many could tell one cup of coffee. When you consider All the Small amounts of things you can put in and notice a difference so heavily. It really puts into perspective how close these results are.

Not a yeast physiologist, but could it also be that esters produced by one strain are catabolized by another.

My guess would be that if you pitch enough yeast, the temperature effects are minimized.