Author: Andy Carter

As the US craft beer industry expanded in the last two decades, the enthusiasm for bold flavors was matched only by the vitriol expressed at “macro” brewers and their flagship product– American Light Lager. Often characterized by self-proclaimed beer aficionados as insipid, watery, and tastes-like-piss, it seems some lovers of the craft have recently adopted a more mature perspective, recognizing the precision required to make a good American Light Lager and even admiring the result.

How did American Light Lager come about? The definition of “light” has varied over time, but it’s generally used to describe a beer with reduced caloric content. While Coors briefly produced a light lager in the 1940s, it wasn’t until the mid-70s that Miller Brewing introduced Miller Lite along with the “tastes great, less filling” slogan, which ultimately inspired other large commercial breweries to create their own beers targeted at health-conscious consumers. By the 1990s, American Light Lager from the likes of Budweiser, Miller, and Coors accounted for more sells than any other beer in the United States.

Reducing the caloric content of beer is primarily driven by reduced alcohol content, as ethanol has 7 calories per gram whereas non-alcoholic carbohydrates contribute just 4 calories/gram. However, given consumer expectations of alcohol content per serving, reducing the non-alcoholic carbohydrates is critical in the production of American Light Lager, and one way to achieve this is through the use of non-malt-derived enzymes. When paired with a low mash temperature and the use of highly fermentable adjuncts like corn and rice, it’s possible to make a beer that’s kinder on the belly without sacrificing flavor… at least in theory.

| Making BRÜ LITE |

My goal being to create a lower calorie lager in the vein of a Brülosophy favorite, I opted for a base of Pilsner malt with a bit of dextrose and a single CO2 hop extract addition, as Miller Lite lists corn syrup and hop extract as ingredients in their recipe.

BRÜ LITE

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.8 gal | 60 min | 7.7 IBUs | 2.2 SRM | 1.035 | 1.004 | 4.1 % |

| Actuals | 1.035 | 0.996 | 5.1 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner (2 Row) Ger | 6 lbs | 94.12 |

| Corn Sugar (Dextrose) | 6 oz | 5.88 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| YVH Hop Extract | 1.2 g | 60 min | Boil | CO2Extract | 60 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Saflager Lager (W-34/70) | DCL/Fermentis | 75% | 48°F - 59°F |

Notes

| Water Profile: Ca 77 | Mg 8 | Na 8 | SO4 18 | Cl 77 |

Download

| Download this recipe's BeerXML file |

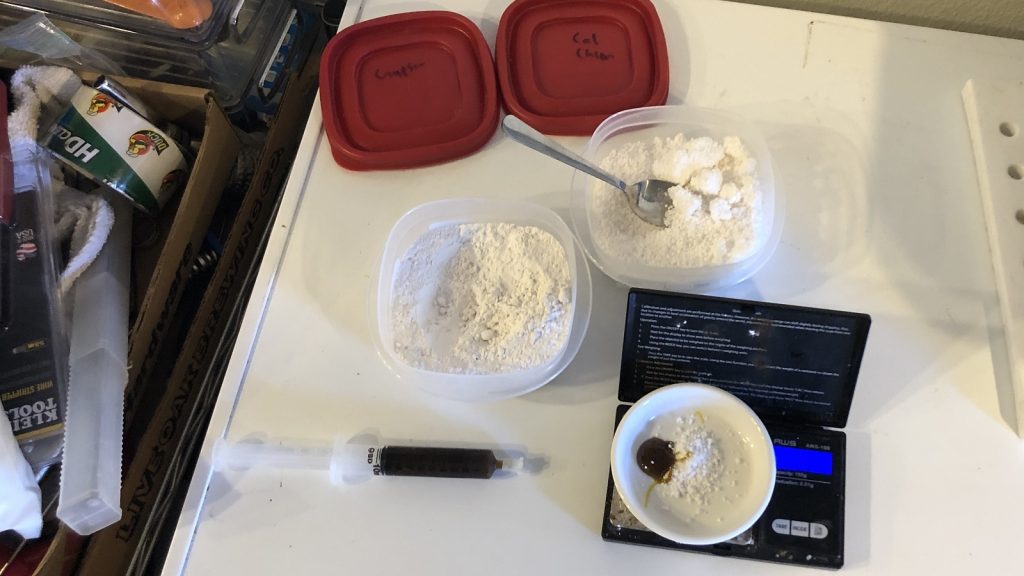

After collecting the water for this batch and setting my controller to heat it up, I weighed out and milled the grain.

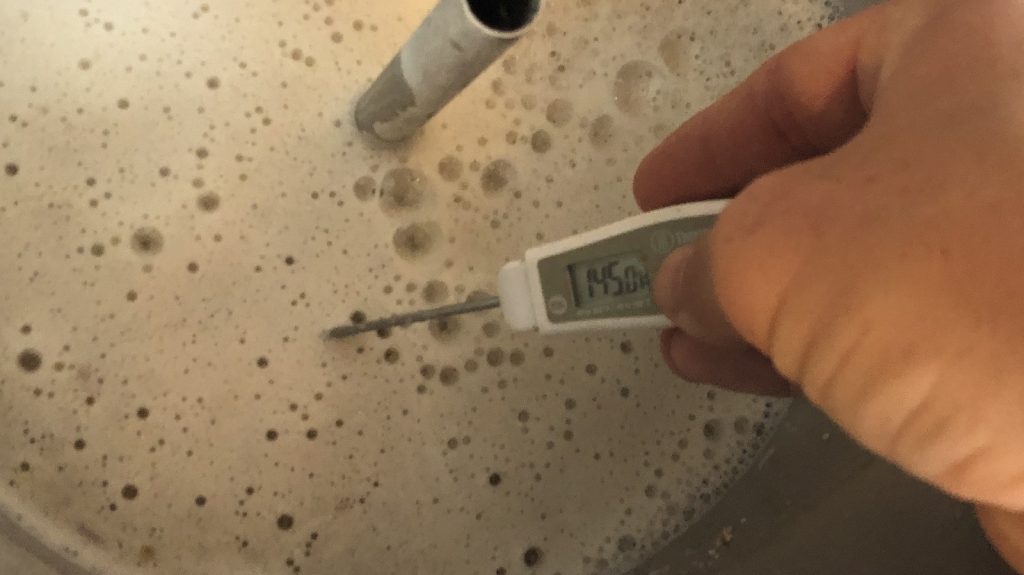

Once the water was properly heated, I incorporated the grist then set the controller to maintain a relatively low mash temperature of 145°F/63°C, which was intended to encourage maximum dryness.

During the mash rest, I weighed out the minerals and hop extract that would be added to the sweet wort pre-boil.

After the 90 minute mash rest, I removed the basket of grains and fly sparged until my pre-boil volume was reached.

With the sweet wort collected, I set my controller to full power, added the minerals and hop extract as soon as a boil was reached, then proceeded to boil the wort for 60 minutes before chilling it on its way to a sanitized Delta FermTank.

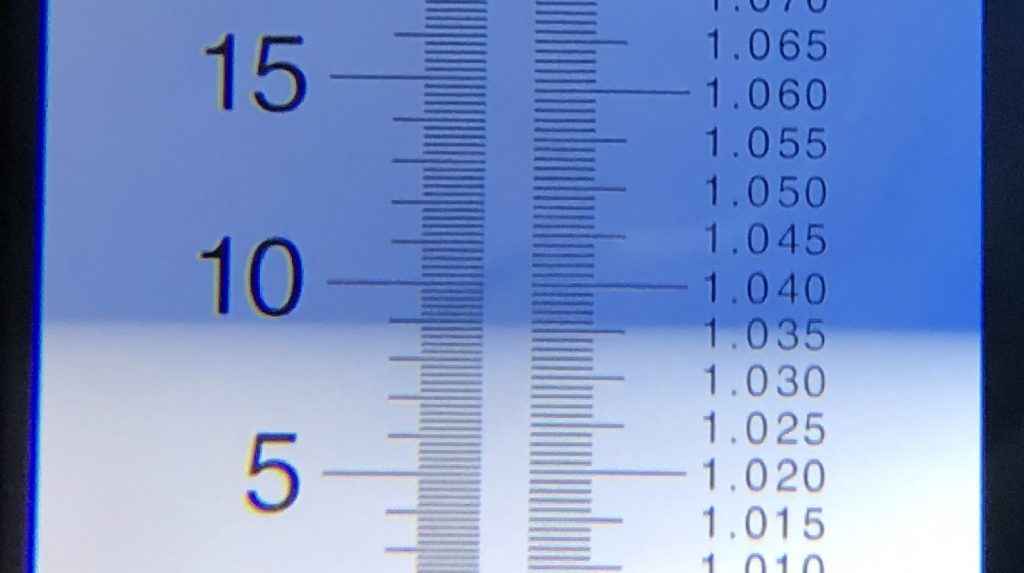

A refractometer reading showed I was right at my target 1.035 OG.

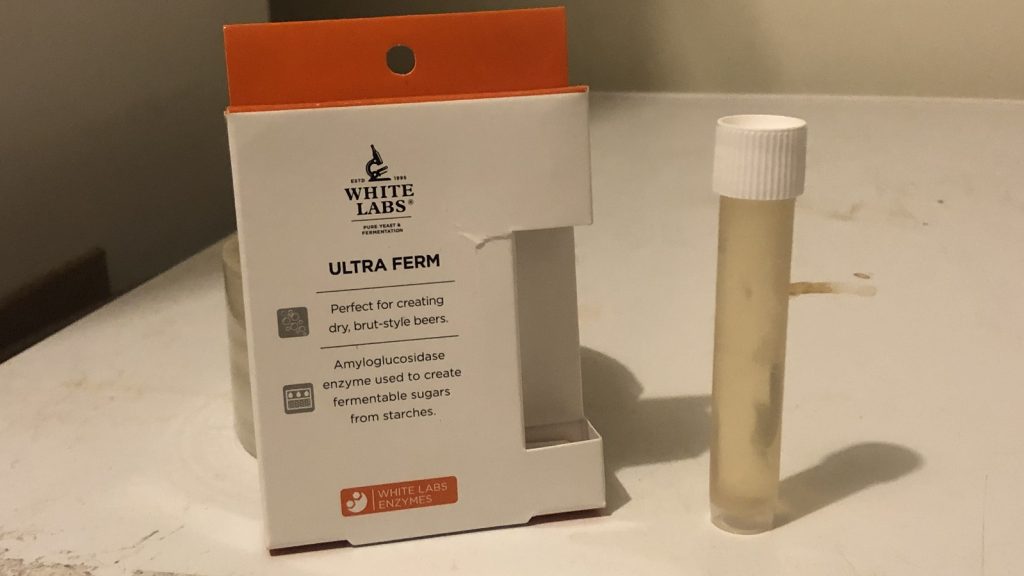

At this point, I placed the filled fermenter in my chamber and left it alone for a few hours to finish chilling. Once it had dropped to my desired fermentation temperature of 50°F/10°C, I pitched a rehydrated pack of Saflager W-34/70 along with White Labs Ultraferm enzyme.

Following 5 days of active fermentation, I raised the temperature in the chamber to 60°F/16°C to promote complete attenuation. The beer was left alone for another 9 days before I began to gradually reduce the temperature by 5°F/3°C every 12 hours until it reached 40°F/4°C. A hydrometer measurement taken a week later showed the beer reached a rather dry 0.997 FG

I let the beer sit one more night before pressure transferring to a CO2 purged keg.

The filled keg was placed in my keezer, burst carbonated, and left to lager for 7 weeks before it was ready to drink.

| IMPRESSIONS |

People hold strong opinions when it comes to mass-market American Light Lager—whereas some enjoy the cloyingly sweet apple flavor of Bud Light or the refreshing wateriness of Coors Light, others prefer the delicate nutty malt character of Miller Lite. As a fan of Fine Pilsner myself, that was the loose inspiration for this batch of BRÜ LITE, and I was quite pleased with the outcome. I got a blend of fresh baked bread, crackers, and hay on the nose with no noticeable fermentation or hop character. The flavor was similarly lacking in anything from yeast or hops, presenting rather a slight doughy malt note that was otherwise very clean.

Despite its low FG, I perceived a reasonable body in BRÜ LITE, it wasn’t thin or watery at all, though curiously, it was a bit sweeter than I desired. Curious to know some objective details about this beer, I sent a sample into Oregon Brew Lab for analysis.

Despite its low FG, I perceived a reasonable body in BRÜ LITE, it wasn’t thin or watery at all, though curiously, it was a bit sweeter than I desired. Curious to know some objective details about this beer, I sent a sample into Oregon Brew Lab for analysis.

BRÜ LITE ANALYSIS RESULTS

| FG | ABV | Calories | Color (SRM) | IBU |

| 0.996 | 5.24% | 120 per 12 oz | 2 | 5.3 |

After reviewing these results, it occurred to me that perhaps the sweetness I detected was a function of the higher than expected alcohol in the beer. Even at the OG and FG I measured of 1.035 and 0.997, respectively, this beer was right around 5% ABV, and the lab measured ABV of 5.24% puts it a whole 1% higher than Miller Lite. For my next batch of BRÜ LITE, I’ll likely remove a portion of the Pilsner malt and dextrose to reduce the alcohol and calories, while also slightly increasing the amount of hop extract to counter the sweetness I perceived.

If you have thoughts about this recipe or experience making something similar, please feel free to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

11 thoughts on “Brü It Yourself | BRÜ LITE”

Interesting approach using dextrose instead of corn flakes or rice. You could water it down to lower the alcohol. Wouldn’t help much with the sweetness, you’ll have to increase bitterness to counter that. I make a similar beer, but instead of dextrose, I add ~25% of the grist as Instant Rice. Works really well to lighten the color and flavor. I also quite often will split one batch into two kegs – racking on top of de-aerated water in one keg to have a lite version and keeping the other as a standard American lager.

I’ve never had a desire to brew a light beer, yet here I am desiring one now. Cool write-up. Have you calculated how much pilsner/dextrose you’d remove? What IBU will you look for in the next batch? Is there ever any room for aroma/flavor hops in light beers?

I would start by cutting 0.5 lb pilsner malt, but keep the sugar the same. I would just double the hop extract to hopefully just double IBUs. In a ~5 gallon batch, I think a 10 minute addition of a 0.5 oz of a punchy hop would be nice, but definitely drifting away from Am Light Lager.

How much of the Ultraferm enzyme was added? The entire vial or a portion?

Full vial, that is the recommended dose for 5 gallons.

Never used the stuff so I don’t know, but is the ultraferm responsible for the higher than expected alcohol? It does say “Ethanol production is faster and yield is higher. “

Since I had not brewed this before, the recipe was an estimate. I attribute the higher alcohol to the high kettle OG than software predicted, and to the lower FG. I suspect Ultraferm drove the FG so low. “Faster” and “higher yield” are, in my opinion, marketing-speak for “higher fermentability.”

Care to speculate how you would recreate the cloyingly sweet apple flavor of Bud Light or the refreshing wateriness of Coors Light or the delicate nutty malt character of Miller Lite.

Apple: Yeast strain choice or intentional yeast pressure

Wateriness: I don’t get that from Coors but it could be filteration stripping flavor, or a pH thing; sometimes my wild ales go through a phase of flavor dropoff then come back.

Nutty malt: Grain bill or yeast choice

Did you like the overall taste? It looks really refereshing.

Not really a question about the recipe, but you’re able to get your wort cold enough to transfer to the fermenter directly after going through the chiller from the boil? Is it because you have a good chiller ?(my setup is similar to yours, and chilling is my biggest pain)