Author: Andy Carter

The mineral composition of brewing water affects various facets of beer, from mash conversion and attenuation to flavor and mouthfeel, and it’s widely accepted that specific mineral profiles are necessary to achieve the expected characteristics of certain styles. One such style is New England IPA whose creamy mouthfeel and juicy flavor is widely believed to be a function of the mineral makeup of the water used to brew it.

There are a number of ways brewers can approach water chemistry, one of the simplest being to focus primarily on the ratio of sulfate to chloride (SO4:Cl), which are added in the forms of gypsum (calcium sulfate) and calcium chloride, respectively. Known to accentuate dryness and hop punchiness, sulfate has traditionally been the favored mineral of IPA brewers, with common ratios ranging from 3:1 up to as high as 7:1. Higher amounts of chloride is associated with perceived fullness, round malt flavor, and a softer hop character, hence the reason many brewers of NEIPA prefer an opposite sulfate to chloride ratio of somewhere around 1:3.

I’ve been a believer in the importance of water chemistry for much of the time I’ve been brewing and make adjustments to every batch depending on the style. For NEIPA, that has meant going with less sulfate and more chloride, though this has admittedly been based on what I’ve heard from others. With a past xBmt showing tasters could reliably distinguish an American IPA made with a high SO4:Cl from one made with a low SO4:Cl, I thought it’d be interesting to test this variable out again on NEIPA to taste any differences for myself.

| PURPOSE |

To evaluate the differences between a NEIPA brewed with a high sulfate to chloride ratio and one brewed with a high chloride to sulfate ratio.

| METHODS |

The recipe for this xBmt was inspired by one of Scott Janish’s articles as well as past batches I’ve brewed.

Add Hops To Taste

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 6 gal | 60 min | 93.4 IBUs | 3.6 SRM | 1.067 | 1.010 | 7.5 % |

| Actuals | 1.067 | 1.01 | 7.6 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner (2 Row) Ger | 6 lbs | 42.86 |

| Pale Malt (2 Row) US | 5 lbs | 35.71 |

| Oats, Flaked | 3 lbs | 21.43 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Cashmere | 6 g | 45 min | Boil | Pellet | 7.9 |

| Amarillo | 43 g | 15 min | Boil | Pellet | 8.3 |

| Idaho #7 | 43 g | 15 min | Boil | Pellet | 14 |

| Galaxy | 28 g | 15 min | Boil | Pellet | 16 |

| Amarillo | 43 g | 10 min | Boil | Pellet | 8.3 |

| Idaho #7 | 43 g | 10 min | Boil | Pellet | 14 |

| Amarillo | 43 g | 10 days | Dry Hop | Pellet | 8.3 |

| Galaxy | 43 g | 10 days | Dry Hop | Pellet | 16 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Juice (A38) | Imperial Yeast | 74% | 64°F - 74°F |

Notes

| Water Profile (high SO4:Cl): Ca 76 | Mg 0 | Na 0 | SO4 124 | Cl 42 Water Profile (low SO4:Cl): Ca 76 | Mg 0 | Na 0 | SO4 41 | Cl 123 |

Download

| Download this recipe's BeerXML file |

I started my brew day by weighing out and milling the grain.

Next, I collected two equal volumes of RO water and set the controllers to heat them up before weighing out two sets of minerals, one to achieve a sulfate to chloride ratio of 124:42 while the other was 41:123.

I then added the minerals to their respective waters.

Once the water for each batch was adequately heated, I incorporated the grains then checked to make sure both were at the same target mash temperature.

While the mashes were resting, I prepared the kettle hop additions.

Once each 60 minute mash was complete, I sparged to collect the same pre-boil volume then boiled the worts for 60 minutes before chilling them.

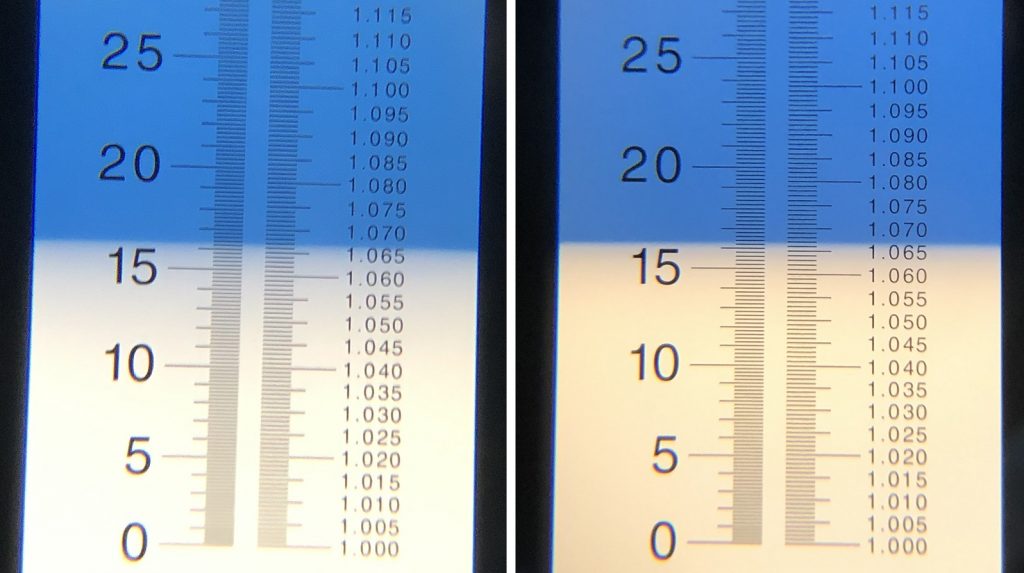

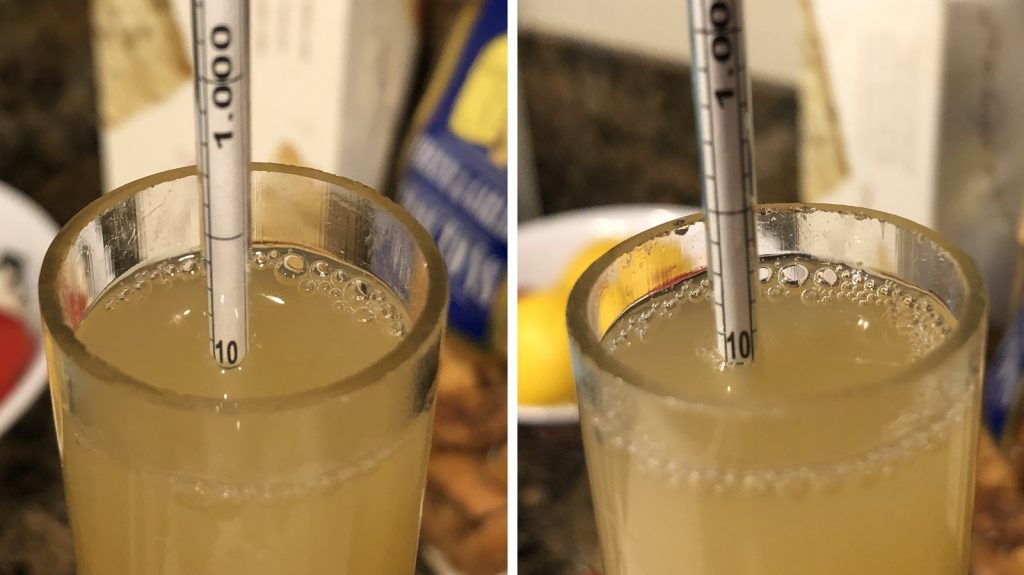

Refractometer measurements showed both worts were at the same OG.

Equal amounts of wort were racked to sanitized 6 gallon/23 liter PET carboys that were placed in my fermentation chamber and left to finish chilling to my desired fermentation temperature. Once stabilized at 66°F/19°C, I pitched a single pouch of Imperial Yeast A38 Juice into each batch.

Both beers were actively fermenting the following day.

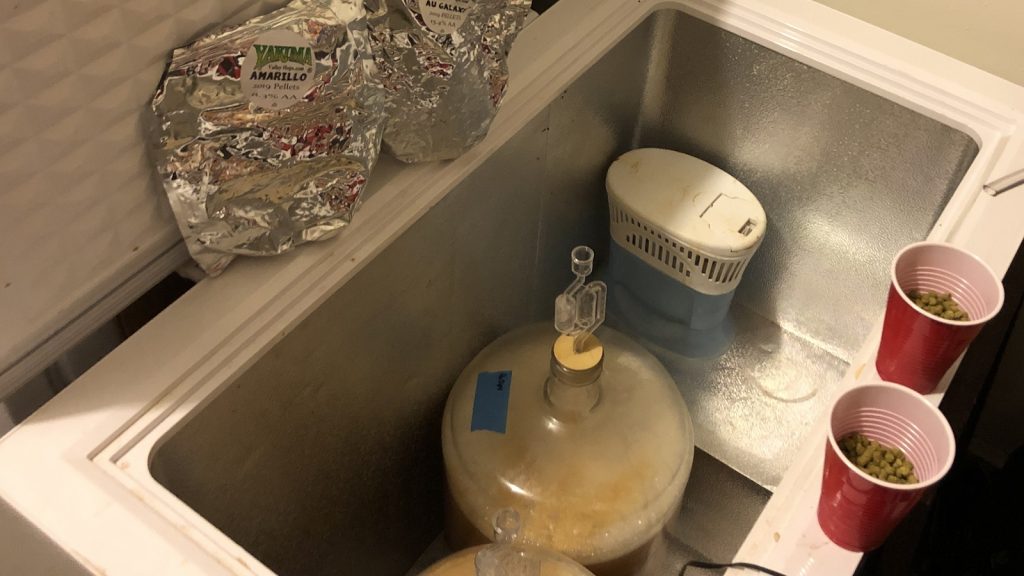

After 2 days of fermentation, when both beers were at high kräusen, I added the dry hops.

The beers were left alone for another 6 days before I took hydrometer measurements showing both hit the same FG.

At this point, I racked the beers to sanitized kegs that were placed next to each other in my keezer and left on gas for a week before I began my evaluations.

| RESULTS |

Due to social distancing practices as a result of the COVID-19 pandemic, data for this xBmt was unable to be collected in our typical manner. As such, temporary adaptations were made involving the author completing multiple semi-blind triangle tests in as unbiased a way as possible.

Utilizing 4 opaque cups of the same color where 2 were inconspicuously marked, one set was filled with the higher sulfate to chloride ratio beer while the other set was filled with the higher chloride to sulfate ratio beer. For each triangle test, 3 of the 4 cups were indiscriminately selected, thus randomizing which beer was the unique sample for each trial. Following each attempt, I noted whether I was correct in identifying the unique sample. Out of the 10 semi-blind triangle tests I completed, I needed to identify the unique sample 7 times (p<0.05) in order to reach statistical significance. However, I correctly chose the unique sample just 4 times (p=0.44), indicating my inability to reliably distinguish a NEIPA made with a sulfate to chloride ratio of 124:42 from with a sulfate to chloride ratio of 41:123.

With so many past water chemistry that were significant, I went into this one expecting to be able to tell the beers apart and was surprised to discover they tasted identical to me. Thankfully, these beers did not disappoint! I perceived a pleasantly complex hop combo including mango and pineapple with a touch of dankness in the finish, though I also picked up a slight hop burn that was a bit distracting. Still, I’ll definitely brew this recipe again, likely upping the whirlpool addition to increase the hop punch.

| DISCUSSION |

Water chemistry is unquestionably an important factor in determine the ultimate way a beer presents to the drinker, which numerous past xBmts have supported. One method of adjusting brewing water involves focusing on the ratio of sulfate to chloride, where a higher ratio accentuates crispness and hops while a lower ratio lends a softer mouthfeel and rounder malt profile. Contradicting prior results, I was unable to reliably distinguish a NEIPA made with a high sulfate to chloride ratio from one made with a high chloride to sulfate ratio.

It’s well known that perception is largely subjective, and that some people are more sensitive to certain things than others, and hence it’s entirely possible my inability to tell these beers apart is due to my inept palate. Perhaps all the years I’ve spent drinking hoppy IPA has burned those receptors off my tongue. However, it’s also possible something else is at play, like any subtle differences caused by the minerals being covered up by the stronger characteristics of this particular NEIPA.

Even though this xBmt failed to achieve significance, I’ll continue to adjust the minerals in my water when brewing beer, including NEIPA. I’m strongly of the belief that good beer can be produced without minding water chemistry, but that doing so is the key to dialing in excellent recipes. Given how confident I was that I’d be able to tell these beers apart, I do stand humbled and corrected, though unchanged in my conviction that water chemistry matters.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

23 thoughts on “exBEERiment | Water Chemistry: Impact Sulfate To Chloride Ratio Has On New England IPA”

Do you add SMB at kegging? As I know some at Brulosophy do and it will increase the SO level which would screw your water profile.

It is quite interesting. I mean obviously we’d all love a larger n but this is what we’ve got at the moment. Wondering about finishing pH effect on a NEIPA.

Mouthfeel in a Neipa is the sum of multiple variables – dextrins, beta-glucans, glycerol, polyphenols. In my point of view for a stile as complex as Neipa removing only one variable can lead to a non significant result. Could be your tongue but can be easily a low synergy effect…

Would a longer lagering time solve the hop-burn effect ?

Yep, mhm. Or the use of a fining agent like Biofine.

Again another interesting exbeeriment. I think the mineral quantities could have been increased to maybe gain a more pronounced distinction between the to beers. You mention in the text that rations of 3:1 up to 7:1 are normal. Here the lower end of this range was tested (3:1). Also I would have like to see a minimum of 50ppm for either Cl or SO4, low 40s is a little too low. So low ppm and low ratios were tested. What was your reasoning behind this?

Just a foot note, why were no Mg additions made to help fermentation? Was a yeast nutrient used?

Despite my criticism I think this was a great exbeeriment! Keep up the good work, thank you all so much for all the amazing tips I’ve picked up over the years!

Why is a different p-value threshold being used? Pre-covid experiments were using p-value of 0.05, now p-vale of 0.02.

Typo. Fixed.

I think a different style would be a better test. NEIPA is noted for its absence of both maltiness and bitterness.

If he changed styles he’d have to change the hypothesis and experiment. The test was concerning NEIPAs, the dependent variable was mouth feel. In other words the goal is to eliminate confounding variables (maltiness and bitterness) to test ONLY mouth feel of NEIPAs. You’re right in that variations in maltiness and bitterness could change the mouth feel. More tests = more beer!!!

Did you also adjust the sparge water?

Thanks for this one guys. I’ve been playing with water chemistry a little on my last few batches, and this is good information to consider. From the conclusion, It would seem that it takes more than a 3:1 vs 1:3 difference to change the perception of mouthfeel, BUT even without the difference it still produces a tasty NEIPA. Love it.

Side note, I’m currently taking a doctoral level statistics class, and this website has been a godsend for loosing my mind a little when I get down in the dumps about chi-square, p values and inferential statistics. I read a new chapter, I think, “How can I apply this to the brulosophy tests to help it stick in my memory?”

So thanks for that!

This doesn’t surprise me at all given that the overall amounts used are so low. I really feel that the SO4:Cl ratio is an outdated statistic and that the overall concentration of each ion is much more valuable. If you were in the 200PPM range of sulfate and chloride, then I think you’d be more likely to notice a difference.

To be perfectly blunt, no crap. The ratio concept always left me flabbergasted. 1:2 is equivalent whether I’m counting 1 and 2 nanograms or 1:2 kilograms. It’s incredibly frustrating

Ratios aside (and just considering the absolute mineral content) I too have found in my NEIPAs they actually matter little, if anything, compared to everything else. I only came to that conclusion when I made a NEIPA with 150ppm sulphate and near zero chloride. There was a subtle difference but nothing any other variable couldn’t compensate/mask if the recipe was tinkered. There was an added bitterness to begin with but as the beer aged the difference disappeared completely.

The biggest masking factor with NEIPAs, the thing that makes or breaks it, is balance. So many hops and an increasing trend for higher gravity beers that finish a touch sweeter make dialing in the right recipe harder. I’ve found that dry hops can ruin the balance depending on what perceived sweetness they add…e.g Citra sweeter than most NZ/Australian hops for instance. I guarantee you a heavily dry hopped galaxy beer with high Chloride will taste more bitter (and give false perception of thinner body) than a high sulphate beer heavily dry hopped with Citra

The only two minerals that I find makes a difference is total calcium (increases chalkiness) and closely related calcium carbonate levels. Both of these transform a stout into something much more drinkable but make an IPA flat and lacking hop punch if too high.

Could be a good idea to get yeh final mineral content of the beer tested. What are the mineral contents of the other ingredients you are adding (grains, hops, etc)? Are they background or do they blow out your additions?

Before you re-experiment you might consider starting with a finished beer and dosing samples with different amounts and ratios of sulphate/chloride solutions. If you can’t tell the difference this way, then a full blown experiment seems unwarranted. Differences from dosing in the mash would likely be for things like mash or yeast health.

Can’t wait to see the results of a post-pandemic do-over with a tasting panel, though I came out of this read with a totally different question, as I’m diving into a mid winter NEIPA with no hops in the boil – everything (12oz) is going into the whirlpool and DH (4oz) additions.

I see you mentioned that you’d brew this again “likely upping the whirlpool addition” though I don’t see a whirlpool addition in your recipe or processes, unless I’m overlooking something. Are the 10 and 15 min additions actually in the boil or afterwards? It’s my understanding that moving everything out of the boil and into the 180-190 F range will smooth out all that hop burn you’re getting… thoughts? boil vs no boil = next xBmt?

I’m repeating this experiment with the same grain bill at the moment, but upping the SO4:Cl difference 1:6.

Just a quick totally unrelated to experiment question. I brew on a grainfather too, and just got a PB OG of 1040. Noooo way I’m going to hit the same 1067 OG unless I boil for 4 hours, haha. Could it be my crush is much more coarse than yours?

Thanks, mate!

1.040 for a 14 lb grain bill seems low on any system. Here is my 2 cents on mill gap:

https://nobodyaskedme655546114.wordpress.com/2020/12/03/grain-mill-gap-vs-efficiency/

I know this is an old thread but look into grain conditioning – wetting your grain – before milling. You can then tighten your grind and, in my experience, get much higher efficiencies.

I just read an article that quoted Eric Thomas, brewmaster at Trillium Brewing in 2015, and now at Sixpoint, as saying he goes as high as 300ppm Chloride and utilizes a chloride/sulfate ratio of 3-3.5:1. While your ratios were spot on maybe the issue was total Cl/SO4 numbers?